The global printing machinery market, including manufacturers of specialized equipment like Taylor press products, is experiencing steady expansion propelled by rising demand for high-efficiency industrial printing solutions. According to Grand View Research, the global printing machinery market size was valued at USD 16.4 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 3.8% from 2023 to 2030. This growth is driven by technological advancements, increasing automation in manufacturing, and sustained demand across packaging, textiles, and label industries—sectors where precision flatbed and transfer printing presses, such as those produced under the Taylor brand, play a critical role. As industry players seek reliable, high-performance machinery, a select group of manufacturers has emerged as leaders in engineering, durability, and innovation in Taylor press technology. Based on production volume, market presence, and technical enhancements over the past decade, the following three manufacturers stand out in delivering top-tier Taylor press solutions worldwide.

Top 3 Taylor Press Products Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

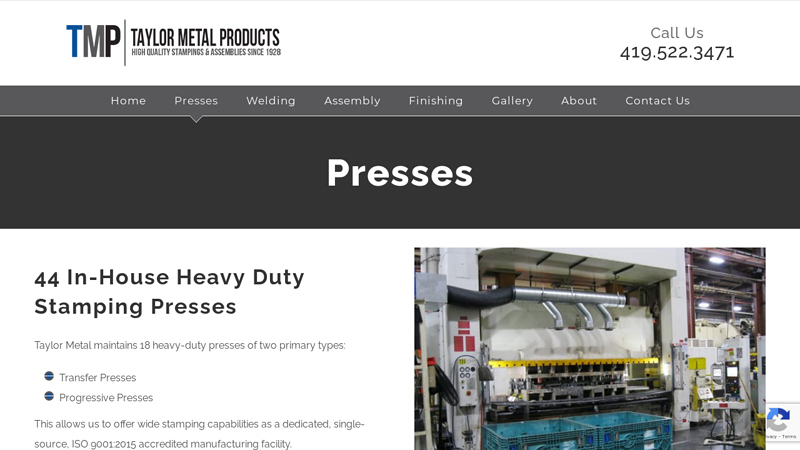

#1 Heavy Duty Stamping Press

Domain Est. 2001

Website: tmpind.com

Key Highlights: Taylor Metal maintains 44 heavy duty stamping presses to deliver complete metal stamping services. Call 419.522.3471 for a free consultation ……

#2 Taylor Press Products

Domain Est. 2002

Website: taylor-products.com

Key Highlights: We specialize in metal stampings and also offer fabrication, welded assemblies and metal coating. . Whether utilizing a 2D or 3D drawing, or even a sketch – we ……

#3 Applied Materials deal falters

Domain Est. 2013

Website: taylorpress.net

Key Highlights: The company has a manufacturing plant in Northeast Austin that employs an estimated 2,500 workers. The city would not confirm the news to the ……

Expert Sourcing Insights for Taylor Press Products

H2: 2026 Market Trends Outlook for Taylor Press Products

Based on current industry trajectories, macroeconomic forecasts, and technological advancements, the market landscape for Taylor Press Products in 2026 points toward significant transformation driven by sustainability, digitalization, and evolving customer demands. Here’s an analysis of key trends likely to shape the company’s environment:

1. Accelerated Demand for Sustainable Manufacturing

By 2026, sustainability will no longer be a differentiator but a baseline expectation. Customers across automotive, aerospace, and consumer goods sectors will prioritize suppliers with verifiable environmental credentials. Taylor Press Products will face increased pressure to:

– Decarbonize Operations: Transition to renewable energy sources and invest in energy-efficient hydraulic and servo-driven presses.

– Circular Material Use: Expand capabilities to process recycled metals and support closed-loop manufacturing partnerships.

– Transparent Reporting: Implement rigorous ESG reporting aligned with global standards (e.g., GHG Protocol), enhancing brand trust and compliance with regulations like the EU Green Deal.

2. Rise of Smart Presses and Industry 4.0 Integration

The adoption of smart manufacturing technologies will be widespread by 2026. Taylor Press Products must evolve from selling machinery to offering integrated digital solutions:

– IoT-Enabled Equipment: Machines with real-time monitoring, predictive maintenance, and remote diagnostics will dominate demand.

– Data-Driven Optimization: Customers will expect press systems that integrate with MES/ERP platforms to improve OEE (Overall Equipment Effectiveness) and reduce downtime.

– Cybersecurity Focus: As connectivity increases, secure industrial networks will be a critical selling point and compliance requirement.

3. Customization and Agile Production

Mass customization and shorter product life cycles will drive demand for flexible pressing solutions:

– Modular Press Designs: Systems that can be reconfigured quickly for different part geometries or materials will gain market share.

– On-Demand Manufacturing: Growth in nearshoring and micro-factories will favor compact, high-precision presses suitable for low-volume, high-mix production.

– Software-Defined Workflows: AI-powered process optimization will allow adaptive control, reducing setup times and material waste.

4. Supply Chain Resilience and Regionalization

Geopolitical instability and past disruptions have prompted a shift toward regionalized supply chains:

– Localized Production Hubs: Taylor Press may see increased demand in North America and Europe as manufacturers reshore metal stamping operations.

– Strategic Partnerships: Closer collaboration with material suppliers and automation integrators will be essential to deliver turnkey solutions.

– Inventory Digitization: Use of digital twins and blockchain for tracking component provenance and managing spare parts logistics.

5. Workforce Transformation and Skills Gap

As automation advances, the workforce will require new competencies:

– Upskilling Initiatives: Taylor Press may need to offer training programs for operators on digital interfaces, data analytics, and preventive maintenance.

– Human-Machine Collaboration: Designing presses with intuitive UIs and safety systems that support collaborative environments will enhance adoption.

Strategic Implications for Taylor Press Products

To thrive in 2026, Taylor Press should:

– Invest in R&D for energy-efficient, modular, and data-connected presses.

– Develop Sustainability Certifications and lifecycle assessments for all product lines.

– Expand Service Offerings beyond hardware to include predictive maintenance, performance analytics, and digital twin integration.

– Forge Alliances with automation and software firms to deliver comprehensive Industry 4.0 solutions.

In conclusion, 2026 will reward manufacturers who combine engineering excellence with digital agility and environmental stewardship. Taylor Press Products has a strategic window to position itself as a forward-thinking leader by aligning its innovation roadmap with these converging market forces.

Common Pitfalls Sourcing Taylor Press Products (Quality, IP)

Sourcing Taylor Press products—whether through direct manufacturing, private labeling, or distribution—can offer strong market potential due to brand recognition and perceived quality. However, businesses often encounter significant challenges related to product quality and intellectual property (IP). Being aware of these pitfalls is crucial for protecting your investment and ensuring long-term success.

Quality Inconsistencies and Control Issues

One of the most frequent challenges when sourcing Taylor Press products is maintaining consistent product quality. Variations can occur due to multiple factors:

- Manufacturing Variability: If Taylor Press uses third-party manufacturers or multiple production facilities, slight differences in materials, assembly, or finish can lead to inconsistent quality across batches.

- Material Substitutions: Suppliers may substitute lower-grade materials without notice to cut costs, especially during periods of supply chain stress or rising raw material prices.

- Lack of Oversight: Without rigorous quality control checks—both pre-shipment and post-delivery—defective or substandard units may reach the end customer, damaging your brand reputation.

- Misalignment on Specifications: Ambiguities in product specifications or tolerance levels can result in deliverables that don’t meet expectations, even if technically within stated parameters.

To mitigate these risks, implement third-party inspections, define detailed quality benchmarks in contracts, and establish long-term relationships with trusted suppliers.

Intellectual Property Risks and Brand Misuse

Taylor Press products often carry strong brand equity and proprietary designs, making them attractive but legally sensitive to source:

- Unauthorized Replicas or Counterfeits: Many suppliers, especially in global marketplaces, sell products that mimic Taylor Press designs without proper licensing. Sourcing such items exposes your business to IP infringement claims, product seizures, and legal penalties.

- Licensing Gaps: Even if a supplier claims to be authorized, failing to verify licensing agreements or distribution rights can result in unintentional trademark or patent violations.

- Private Label Confusion: If you’re rebranding Taylor Press-like products, there’s a risk of creating designs too similar to protected intellectual property, leading to cease-and-desist letters or litigation.

- Gray Market Goods: Importing authentic Taylor Press products from unauthorized international distributors may breach territorial distribution agreements, resulting in warranty issues and potential legal action from the brand owner.

To avoid IP pitfalls, conduct due diligence on suppliers, request proof of authorization, consult legal counsel before launching similar products, and ensure all branding and design elements are original or properly licensed.

Proactive Measures for Risk Mitigation

To successfully navigate these pitfalls:

- Audit Suppliers: Perform on-site factory audits or hire third-party firms to assess manufacturing standards and IP compliance.

- Secure Contracts: Include clear clauses on quality standards, IP indemnification, and audit rights.

- Verify Authenticity: Use batch tracking, holograms, or digital authentication tools when dealing with branded goods.

- Engage Legal Counsel: Ensure agreements with suppliers comply with international trade laws and IP regulations.

By addressing quality and IP concerns proactively, businesses can source Taylor Press products—or similar items—safely and sustainably, minimizing legal exposure and maintaining customer trust.

Logistics & Compliance Guide for Taylor Press Products

This guide outlines the logistics and compliance procedures essential for the safe, efficient, and legally compliant handling, transportation, and distribution of Taylor Press products. Adherence ensures product integrity, regulatory compliance, and customer satisfaction.

Product Handling and Storage

All Taylor Press products must be handled and stored under controlled conditions to maintain quality and performance. Store products in a clean, dry, temperature-controlled environment (15–25°C / 59–77°F) away from direct sunlight and moisture. Avoid stacking beyond recommended limits to prevent deformation or damage. Use appropriate protective equipment (e.g., gloves, safety glasses) when handling bulk materials or operating machinery.

Packaging and Labeling Requirements

Products must be packaged according to Taylor Press specifications using approved materials that ensure protection during transit. Each package must include a compliant label displaying: product name, model number, batch/lot number, manufacturing and expiration dates, net weight, handling instructions (e.g., “Fragile,” “Do Not Stack”), and regulatory symbols as required. Labels must be legible, securely affixed, and resistant to smudging or removal.

Transportation and Shipping

Shipments must comply with all applicable domestic and international transportation regulations, including IATA, IMDG (if applicable), and FMCSA standards. Use carriers certified for industrial goods transport and ensure vehicles are clean, dry, and secured against contamination. Complete shipping documentation, including commercial invoices, packing lists, and certificates of compliance, must accompany each shipment. Temperature-sensitive products require monitored transport solutions.

Regulatory Compliance

Taylor Press products are subject to federal, state, and international regulations, including OSHA, EPA, REACH, and RoHS, where applicable. Ensure all products meet material safety data sheet (MSDS/SDS) requirements and are registered with relevant authorities. Export shipments must comply with U.S. Department of Commerce (BIS) regulations and obtain necessary export licenses when required. Maintain up-to-date compliance certifications and conduct regular internal audits.

Import/Export Documentation

For international shipments, prepare accurate and complete export documentation, including export declarations, certificates of origin, and customs forms. Verify tariff classifications (HTS codes) to ensure proper duty assessment. Importers must confirm compliance with destination country regulations, including product registration, labeling, and safety standards. Retain all documentation for a minimum of seven years.

Quality Assurance and Traceability

Implement a traceability system that allows full tracking of raw materials, production batches, and finished goods. Conduct routine quality inspections at key stages: incoming materials, in-process production, and final packaging. Maintain detailed records of inspections, non-conformance reports, and corrective actions. All products must pass final quality check before release to logistics.

Environmental and Safety Compliance

Adhere to environmental guidelines for waste management, emissions, and energy use within logistics operations. Properly dispose of packaging waste per local regulations. Ensure all personnel are trained in hazardous material handling (if applicable) and emergency response procedures. Report any incidents involving spills, contamination, or safety violations immediately to the Compliance Officer.

Vendor and Carrier Compliance

All third-party logistics (3PL) providers, carriers, and suppliers must comply with Taylor Press’s Logistics & Compliance standards. Conduct periodic audits and require documented proof of certifications (e.g., ISO 9001, ISO 14001). Contracts must include compliance clauses and data protection provisions. Non-compliant partners will be subject to review and possible termination.

Training and Accountability

All personnel involved in logistics and compliance must complete mandatory training upon onboarding and annually thereafter. Training covers handling procedures, regulatory updates, documentation, and incident reporting. Managers are accountable for ensuring team compliance and must report any deviations to the Compliance Department promptly.

Record Retention and Audits

Maintain comprehensive records of all logistics and compliance activities, including shipping logs, inspection reports, SDS documents, and training records. Digital records must be backed up securely. Internal audits will be conducted quarterly; external audits may occur annually or as required by regulatory bodies. Prepare for audits by ensuring all documentation is current and accessible.

Conclusion for Sourcing Taylor Press Products

Sourcing Taylor Press products presents a strategic opportunity for businesses seeking high-quality, precision-engineered components and stampings. Known for their expertise in metal stamping, fabrication, and custom manufacturing, Taylor Press delivers reliable performance, advanced production capabilities, and a strong commitment to quality control. Their extensive experience across industries such as automotive, medical, and industrial equipment ensures that they can meet rigorous specifications and support complex supply chain requirements.

By partnering with Taylor Press, companies benefit from consistent product quality, scalable production capacity, and responsive customer service. Additionally, their investment in lean manufacturing and technological innovation contributes to cost efficiency and timely delivery. However, potential buyers should conduct due diligence on lead times, minimum order quantities, and geographic logistics—especially for international procurement.

In conclusion, Taylor Press is a reputable and capable supplier whose strengths align well with businesses prioritizing durability, precision, and long-term reliability in their component sourcing. Establishing a relationship with Taylor Press can enhance supply chain resilience and support the production of high-performance end products.