The global tarpaulin material market is experiencing steady expansion, driven by rising demand across construction, agriculture, transportation, and leisure sectors. According to a report by Mordor Intelligence, the global tarpaulin market was valued at USD 10.3 billion in 2023 and is projected to grow at a CAGR of 5.8% through 2029. This growth is fueled by increasing infrastructure development in emerging economies, heightened focus on weather-resistant protective covers, and the rising adoption of high-performance materials such as polyethylene (PE), polyvinyl chloride (PVC), and polyethylene terephthalate (PET). Additionally, Grand View Research highlights the surge in demand for UV-stabilized and flame-retardant tarpaulins as a key trend shaping manufacturer innovation. With sustainability and durability becoming critical purchasing factors, leading producers are investing in advanced coating technologies and recyclable formulations. As competition intensifies, a select group of manufacturers are positioning themselves at the forefront through scalability, R&D, and global distribution networks—setting the stage for the top 10 tarpaulin material manufacturers shaping the industry’s future.

Top 10 Tarpaulin Material Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tarpaulin Suppliers in Dubai, UAE

Domain Est. 2023

Website: hptarp.com

Key Highlights: Leading tarpaulin supplier & manufacturer in UAE. We offer PE, PVC, canvas tarpaulins & custom covers in Dubai for tents, transport & industrial use….

#2 Tarpaulin Manufacturers On B2BManufactures.com from China …

Domain Est. 2003 | Founded: 1977

Website: manufacturers.com.tw

Key Highlights: Since 1977, Yi Chun has focused on manufacturing PVC Tarpaulin fabrics for luggage & bags. The features of our products are stretchable and lightweight….

#3 PVC Tarp

Domain Est. 2006

Website: derflex.com

Key Highlights: As a professional PVC tarp manufacturer, DERFLEX provides reliable tarpaulin solutions that meet international standards and demanding application requirements ……

#4 Lamifab Industries, Sarigam

Domain Est. 2006

Website: lamifab.com

Key Highlights: Manufacturer of HDPE Tarpaulin, Waterproof Tarpaulins & HDPE Fabric offered by Lamifab Industries from Sarigam, Gujarat, India….

#5 Frank Industries

Domain Est. 2019

Website: frankindustries.in

Key Highlights: Incepted in the year 2009, we Frank Industries have established ourselves as one of the reputed manufacturers and traders of Tarpulins Products in India….

#6 Durable PVC Coated Fabric Supplier

Domain Est. 2022

Website: der-factory.com

Key Highlights: DER New Material is a professional PVC tarpaulin manufacturer in China, specializing in durable, waterproof, UV-resistant, and flame-retardant ……

#7 Supreme Multilayer Cross Laminated XF Films and Products.

Domain Est. 2003

Website: supreme.co.in

Key Highlights: Our tarpaulin covers – Silpaulin comprises several layers of plastic films placed in a criss-cross pattern and bonded by a patented cold-roll technique….

#8 HDPE Tarpaulin

Website: mohitpolyfab.com

Key Highlights: At Mohit Polyfab Industries, we manufacture UV-stabilized HDPE tarpaulins engineered for heavy outdoor use in agriculture, logistics, and construction. These ……

#9 Tandhan Polyplast

Domain Est. 2018

Website: tandhanpolyplast.com

Key Highlights: Tandhan Polyplast is the leading tarpaulin manufacturer in kolkata and east India who manufacturer super tarpaulins like Ecopaulin, Ecoraksha and many more….

#10 About The Tarpaulin Manufacturer And Best Quality Tirpal

Website: vktarpaulin.com

Key Highlights: Tarpaulin is a flexible and waterproof sheet made of strong materials such as polyester, canvas, plastic, H.D.P.E and many other materials. Use ……

Expert Sourcing Insights for Tarpaulin Material

2026 Market Trends for Tarpaulin Material

The global tarpaulin material market is poised for significant transformation by 2026, driven by a confluence of technological innovation, evolving end-user demands, and a heightened focus on sustainability. As industries ranging from construction and agriculture to logistics and advertising continue to rely on durable, protective covers, manufacturers and suppliers must adapt to several key trends shaping the market landscape.

Advancements in Sustainable and Eco-Friendly Materials

Environmental regulations and consumer demand for greener products are accelerating the shift toward sustainable tarpaulin solutions. By 2026, biodegradable and recyclable tarpaulins made from materials such as recycled polyethylene (rPE), polypropylene (PP), and bio-based polymers are expected to gain substantial market share. Innovations in manufacturing processes—including reduced plasticizers and non-toxic coatings—are further enhancing the eco-profile of tarpaulins. Brands emphasizing circular economy principles, such as take-back programs and closed-loop recycling, will likely differentiate themselves in competitive markets.

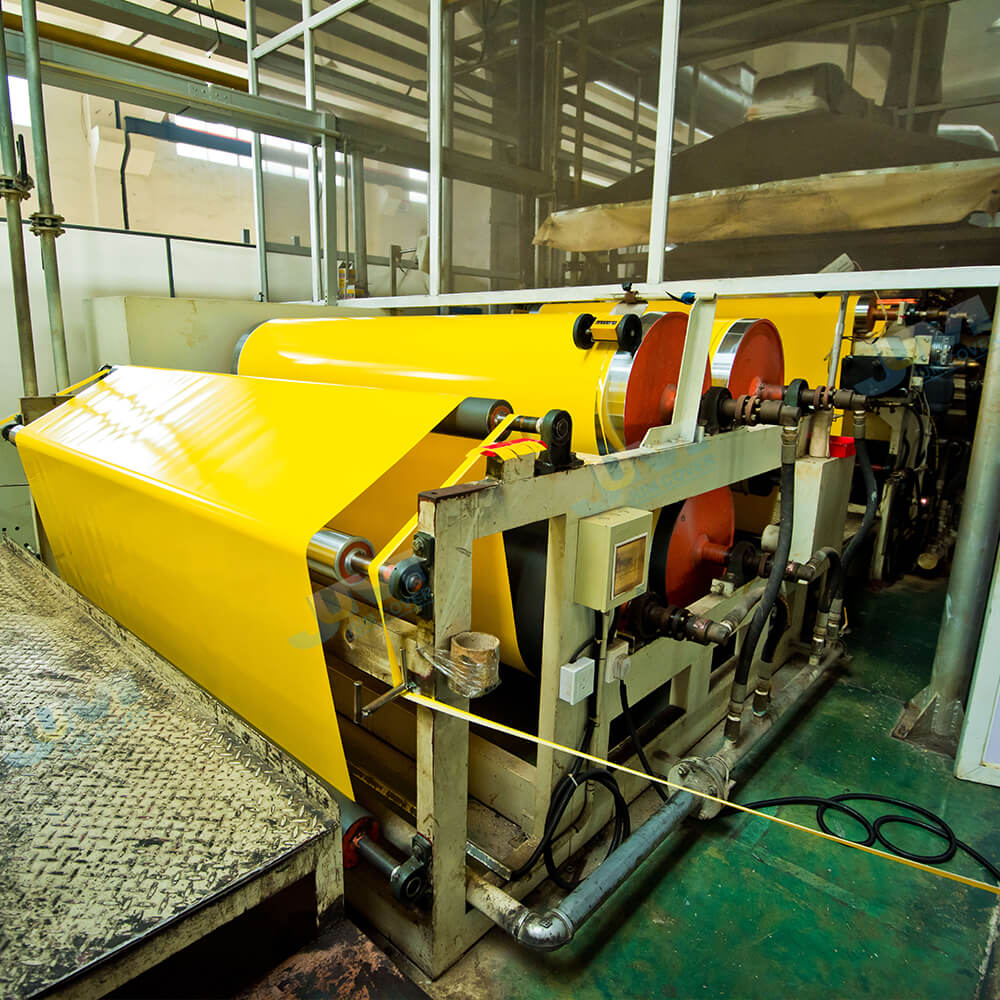

Growth in High-Performance and Specialty Tarpaulins

Demand for high-performance tarpaulins with enhanced durability, UV resistance, and fire-retardant properties is rising, particularly in industrial and military applications. By 2026, expect increased adoption of multi-layered laminated fabrics, reinforced polyethylene (HDPE), and PVC-coated polyester tarpaulins engineered for extreme conditions. Additionally, smart tarpaulins embedded with sensors for monitoring cargo conditions (e.g., temperature, humidity, and security) are emerging, especially in logistics and cold-chain transport, aligning with Industry 4.0 trends.

Expansion in Emerging Markets and Construction Sectors

Rapid urbanization and infrastructure development in Asia-Pacific, Latin America, and Africa are fueling demand for tarpaulins in construction, agriculture, and disaster relief. Countries like India, Indonesia, and Nigeria are expected to be high-growth regions due to ongoing building projects and monsoon-related cover needs. The agricultural sector is also adopting tarpaulins for crop protection, silage storage, and greenhouse applications, further expanding market reach.

Digitalization and Customization in Production and Distribution

By 2026, digital platforms and e-commerce are expected to streamline tarpaulin procurement, enabling faster delivery and customized solutions. Digital printing technologies allow for branded, promotional, or color-customized tarpaulins, meeting the needs of advertising and temporary shelter applications. Manufacturers investing in on-demand production and AI-driven supply chain management will improve efficiency and reduce waste.

Regulatory and Safety Compliance Pressures

Stricter international standards on flame retardancy, chemical emissions (e.g., REACH, RoHS), and product lifespan are influencing material formulation and testing protocols. Tarpaulin producers must ensure compliance to access key markets in North America and Europe, driving investment in certified, safer materials and transparent supply chains.

In conclusion, the tarpaulin material market in 2026 will be defined by sustainability, technological integration, and regional growth. Companies that innovate in eco-materials, embrace digital tools, and cater to specialized industrial needs will be best positioned to capture emerging opportunities.

Common Pitfalls Sourcing Tarpaulin Material (Quality, IP)

Sourcing tarpaulin material can be cost-effective and efficient when done correctly, but several pitfalls—particularly related to quality and intellectual property (IP)—can lead to operational disruptions, legal exposure, or reputational damage. Being aware of these risks helps mitigate potential issues.

Inconsistent or Substandard Material Quality

One of the most frequent challenges is receiving tarpaulin that fails to meet specified quality standards. Suppliers—especially low-cost or offshore manufacturers—may use inferior raw materials (e.g., recycled polyethylene with low UV stabilizer content), leading to premature degradation, reduced tensile strength, or poor water resistance. Buyers may not discover these issues until after the product is in use, resulting in costly replacements and downtime.

Misrepresentation of Specifications

Suppliers may exaggerate or misrepresent key performance metrics such as thickness (measured in microns or mils), tear resistance, UV protection, or flame retardancy. For example, a tarp may be labeled as “12-mil” when testing reveals it is significantly thinner. Without independent verification or third-party testing, buyers risk acquiring materials unsuitable for their intended application, especially in harsh environments.

Lack of Quality Control and Certifications

Many suppliers, particularly in unregulated markets, lack standardized quality control processes or certifications (e.g., ISO, ASTM, or REACH compliance). Without verifiable documentation, it’s difficult to confirm the tarpaulin’s durability, safety, or environmental compliance. This absence increases the risk of receiving non-compliant or hazardous materials.

Intellectual Property Infringement Risks

When sourcing branded or specialized tarpaulins (e.g., those with patented coatings, weave patterns, or logos), there is a risk of inadvertently purchasing counterfeit or IP-infringing products. Unauthorized duplication of proprietary technologies—such as high-performance coatings or reinforced edge designs—can expose the buyer to legal liability, especially in regulated industries or international markets where IP enforcement is strict.

Unauthorized Use of Trademarks or Designs

Suppliers may affix well-known brand names or logos to generic tarps to increase perceived value. Purchasing such products, even unknowingly, can result in trademark infringement claims against the buyer. This is particularly problematic when the tarps are used in commercial projects or resold.

Supply Chain Transparency Gaps

Limited visibility into the manufacturing process makes it difficult to verify ethical sourcing, material origins, or adherence to environmental standards. This lack of transparency can become a reputational risk, especially if downstream customers or stakeholders demand sustainable or ethically produced materials.

Inadequate Contractual Protections

Purchase agreements often fail to include detailed quality assurance clauses, IP indemnification, or clear recourse for non-compliance. Without strong contracts, buyers may have limited legal standing to claim damages or return substandard goods.

Conclusion

To avoid these pitfalls, buyers should conduct thorough due diligence, request material test reports, verify supplier credentials, include robust IP and quality clauses in contracts, and consider third-party inspections. Proactive risk management ensures reliable supply, legal compliance, and long-term cost savings.

Logistics & Compliance Guide for Tarpaulin Material

Tarpaulins—commonly known as tarps—are widely used across industries for protection against weather, containment, and transportation purposes. Ensuring proper logistics handling and regulatory compliance is essential to maintain safety, product integrity, and legal adherence. This guide outlines key considerations for the transportation, storage, and regulatory compliance of tarpaulin materials.

Classification and Material Types

Tarpaulins are typically made from polyethylene (PE), polyvinyl chloride (PVC), canvas, or polyethylene-coated polyester. Each material has specific handling, storage, and regulatory requirements:

- Polyethylene (PE) Tarps: Lightweight, UV-resistant, and commonly used for construction and agriculture. Non-hazardous under most transport regulations.

- PVC Tarps: Heavier, more durable, and often fire-retardant. May contain regulated additives (e.g., phthalates) requiring compliance with REACH or RoHS.

- Canvas Tarps: Natural fiber-based; biodegradable but susceptible to mold and mildew. Require dry storage conditions.

- Coated Polyester Tarps: High tensile strength; commonly used in trucking and marine applications.

Proper identification of material composition is critical for compliance with environmental, safety, and customs regulations.

Packaging and Handling

- Rolling vs. Folding: Tarps are typically shipped rolled around a cardboard or plastic core to prevent creasing and damage. Avoid folding unless specified, as it may cause permanent creases or weaken material integrity.

- Protective Wrapping: Use plastic wrap or shrink film to protect against moisture, dust, and contamination during transit.

- Labeling: Clearly label packages with:

- Material type

- Dimensions and weight

- Manufacturer information

- Batch/lot number

- Handling symbols (e.g., “This Side Up”, “Protect from Moisture”)

Storage Requirements

- Environment: Store in a dry, well-ventilated area away from direct sunlight and extreme temperatures. UV exposure can degrade polyethylene and PVC over time.

- Stacking: Avoid stacking heavy items on top of stored tarps to prevent compression damage. Store vertically if possible to avoid deformation.

- Moisture Control: Prevent mold and mildew by ensuring tarps are completely dry before storage. Canvas and cotton-based tarps are particularly vulnerable.

- Chemical Separation: Keep tarps away from strong oxidizers, acids, or solvents that may degrade the material or coatings.

Transportation and Logistics

- Mode of Transport: Tarps can be transported via truck, rail, sea, or air. Rolled tarps are generally palletized and secured with strapping or stretch wrap.

- Weight and Dimensions: Confirm that tarp rolls or bundles comply with carrier size and weight restrictions, especially for air freight.

- Hazardous Classification: Most tarps are non-hazardous. However, if treated with flame retardants or biocides, check SDS (Safety Data Sheet) for classification under ADR, IATA, or IMDG regulations.

- Temperature Sensitivity: PVC tarps may stiffen in cold temperatures; avoid flexing during unloading in freezing conditions.

Regulatory Compliance

- REACH (EU): Ensure PVC and coated tarps comply with REACH regulations, particularly regarding restricted substances like phthalates (e.g., DEHP, BBP).

- RoHS (EU): Applicable if tarps contain electronic components (e.g., tarp systems with sensors), but generally not applicable to standard fabric tarps.

- Proposition 65 (California, USA): Verify that tarps do not contain listed chemicals (e.g., lead, certain phthalates) above allowable limits.

- Customs Documentation: For international shipments, provide accurate HS codes:

- Example: 3926.20 (Plastic hats and other articles of plastics) or 6306.22 (Tarpaulins of synthetic textile materials)

- Country-Specific Requirements: Some countries impose import restrictions or require certification (e.g., NFPA 701 for fire-resistant tarps in the U.S.).

Safety and Environmental Considerations

- Fire Safety: Flame-retardant tarps must meet local fire codes (e.g., NFPA 701, BS 5438). Maintain certification documentation.

- Recycling and Disposal: PE and PVC tarps are recyclable but require proper sorting. PVC recycling may be restricted in some regions due to chlorine content.

- Waste Management: Follow local regulations for disposal of contaminated or used tarps, especially if exposed to hazardous substances.

Documentation and Traceability

Maintain the following records for compliance and quality assurance:

- Material Safety Data Sheets (MSDS/SDS)

- Certificates of Compliance (CoC)

- Test reports (e.g., UV resistance, tensile strength, flammability)

- Batch tracking logs

- Customs and import documentation

Best Practices Summary

- Clearly identify tarp material and treatment type.

- Use appropriate packaging and labeling for safe handling.

- Store in dry, temperature-controlled environments.

- Comply with regional chemical and safety regulations.

- Maintain full documentation for audits and customs clearance.

Adhering to this logistics and compliance guide ensures safe, efficient handling of tarpaulin materials while minimizing legal and operational risks.

Conclusion for Sourcing Tarpaulin Material:

In conclusion, sourcing the right tarpaulin material requires a careful evaluation of several key factors including durability, weather resistance, intended application, cost-efficiency, and supplier reliability. High-quality tarpaulins made from materials such as polyethylene, PVC, or canvas offer distinct advantages depending on whether the use is for construction, agriculture, transportation, or advertising. By prioritizing material strength, UV protection, waterproofing, and tear resistance, businesses can ensure longevity and optimal performance. Additionally, establishing relationships with reputable suppliers who provide consistent quality, competitive pricing, and timely delivery is essential for operational efficiency. Ultimately, a strategic and informed sourcing approach to tarpaulin materials contributes to enhanced product performance, cost savings, and overall project success.