The global drywall and finishing products market is experiencing steady growth, driven by increasing construction activities and demand for energy-efficient, aesthetically refined interior spaces. According to Grand View Research, the global drywall market was valued at USD 40.5 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. A critical component within this ecosystem is drywall corner tape, which ensures durability, clean edges, and crack resistance in wall assemblies. As demand for high-performance joint treatment solutions grows—particularly in residential and commercial renovation—manufacturers specializing in tape for drywall corners are scaling innovation in materials and application efficiency. With North America and Europe leading in renovation expenditure and Asia-Pacific witnessing rapid urbanization, the competitive landscape is shifting toward advanced fiberglass, paper, and self-adhesive tapes that offer ease of installation and long-term reliability. In this evolving market, six manufacturers have emerged as leaders, combining product quality, technological advancement, and global reach to capture significant market share.

Top 6 Tape For Drywall Corners Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 NO

Domain Est. 1995

Website: certainteed.com

Key Highlights: NO-COAT delivers extra-tough drywall corners that stand up to severe impacts and settling without blistering, bubbling, denting, or cracking….

#2 Trim

Domain Est. 1996 | Founded: 1969

Website: trim-tex.com

Key Highlights: Since 1969, Trim-Tex has been manufacturing solutions (all made in the USA!) tailor-made to help pro drywall finishers turn the corner with their corners….

#3 RUCO ® Drywall Joint Tape

Domain Est. 1997

Website: ruco.com

Key Highlights: Ruco® Drywall Joint Tape is a quality tape for use with joint compound to reinforce Gypsum Board joints and corners prior to painting, texturing, or ……

#4 Drywall Tape

Domain Est. 2008

Website: myfbm.com

Key Highlights: Drywall mesh tape is ideal for quick fixes and minor cracks and holes, while paper tape provides a more robust finish for extensive or complex repairs. Drywall ……

#5 FibaTape Original – Drywall Tape

Domain Est. 2012

Website: adfors.com

Key Highlights: Original, self-adhesive fiberglass mesh tape that eliminates bubbles and blisters. Used for drywall finishing and wall repair jobs….

#6 Paper Joint Tape

Domain Est. 1998

Website: nationalgypsum.com

Key Highlights: Best for flat seams and inside corners · No self-adhesion; requires use of a joint compound · Resists stretching, ensuring long-term durability….

Expert Sourcing Insights for Tape For Drywall Corners

H2: 2026 Market Trends for Tape for Drywall Corners

The global market for tape for drywall corners is poised for steady growth and transformation by 2026, driven by evolving construction practices, demand for energy-efficient buildings, and innovations in material technology. Below are the key trends expected to shape the industry:

1. Rising Demand in Residential and Commercial Construction

Continued growth in residential and commercial building activities, particularly in emerging economies across Asia-Pacific, Latin America, and Africa, is expected to fuel demand for drywall corner tapes. Urbanization and infrastructure development are key drivers, with an increasing preference for drywall systems due to their speed of installation and cost efficiency.

2. Shift Toward Self-Adhesive and Reinforced Fiberglass Tapes

By 2026, self-adhesive fiberglass tapes are anticipated to dominate the market over traditional paper tapes. Their superior resistance to moisture, cracking, and mold, combined with ease of application, makes them ideal for modern construction and renovation projects. Manufacturers are investing in enhanced formulations to improve adhesion and durability.

3. Sustainability and Eco-Friendly Materials

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing manufacturers to develop sustainable drywall tapes. Expect increased use of recycled materials, low-VOC (volatile organic compound) adhesives, and biodegradable backing materials. Consumers and contractors alike are prioritizing eco-conscious products, influencing procurement decisions.

4. Technological Advancements in Application and Performance

Innovations such as pre-creased corner tapes, moisture-resistant coatings, and tapes designed for specific climates (e.g., high-humidity environments) are gaining traction. Automation in drywall finishing processes may also increase demand for tapes compatible with robotic taping tools, improving efficiency and reducing labor costs.

5. Expansion of Renovation and Retrofit Markets

The growing trend of home renovation and energy-efficient retrofitting in mature markets like North America and Western Europe will support steady demand for drywall tapes. Aging housing stock and government incentives for energy upgrades are contributing to increased remodeling activity.

6. Regional Market Dynamics

North America will remain a significant market due to high drywall usage in construction. However, the Asia-Pacific region is expected to witness the fastest growth, led by China, India, and Southeast Asian countries where construction booms and urban development are accelerating.

7. Supply Chain Optimization and Local Manufacturing

To mitigate risks from global supply chain disruptions, manufacturers are increasingly establishing regional production facilities. This shift supports faster delivery, reduces costs, and improves responsiveness to local market demands.

8. Competitive Landscape and Brand Differentiation

The market is becoming increasingly competitive, with major players like 3M, Saint-Gobain, and Mitec Corporation focusing on product differentiation through performance claims, technical support, and bundled solutions (e.g., tape and joint compound kits). Smaller regional brands are gaining ground by offering cost-effective alternatives.

In summary, the 2026 tape for drywall corners market will be characterized by innovation, sustainability, and regional growth disparities. Stakeholders who adapt to these trends—through product development, eco-friendly practices, and strategic market positioning—are likely to capture greater market share in the evolving construction landscape.

Common Pitfalls Sourcing Tape for Drywall Corners (Quality, IP)

When sourcing tape for drywall corners—especially where quality and intellectual property (IP) are concerns—several pitfalls can impact the final outcome of construction or renovation projects. Being aware of these issues helps ensure durability, compliance, and value.

Poor Adhesive Quality Leading to Delamination

One of the most frequent quality issues is substandard adhesive used in corner tapes. Low-quality tapes often use adhesives that fail to bond properly with joint compound or drywall, leading to delamination, bubbling, or peeling over time. This not only affects the aesthetics but also compromises structural integrity at corners, requiring costly rework.

Inconsistent Mesh or Material Density

Corner tapes typically use fiberglass mesh for reinforcement. Inferior products may have inconsistent mesh weave or weak fibers, reducing tensile strength. This can result in cracking at stress points, especially in high-traffic or temperature-variable environments. Always verify material specifications and perform batch testing when sourcing in bulk.

Misrepresentation of Product Specifications

Some suppliers may exaggerate performance claims—such as moisture resistance, flexibility, or tensile strength—without third-party certification. This misrepresentation can mislead buyers into selecting unsuitable tapes for specific applications (e.g., humid environments or curved walls), resulting in premature failure.

Counterfeit or IP-Infringing Products

Intellectual property violations are common in the building materials sector. Some manufacturers produce tapes that mimic patented designs or branding of reputable brands (e.g., knock-offs of well-known corner bead tapes with integrated mesh). These counterfeit products often lack the innovation and quality control of the original, and purchasing them can expose contractors or distributors to legal risk.

Lack of Compliance with Regional Building Codes

Different regions have specific standards for fire resistance, VOC emissions, and structural performance. Sourcing corner tape from non-compliant suppliers—or those without proper certifications (e.g., ASTM, UL, CE)—can lead to failed inspections or liability issues, particularly in commercial projects.

Inadequate Supplier Traceability and Documentation

Without proper documentation (e.g., material safety data sheets, certificates of conformance, IP ownership statements), it becomes difficult to verify product authenticity or resolve disputes. This lack of traceability increases the risk of using infringing or non-compliant materials unknowingly.

Overlooking Packaging and Storage Conditions

Poor packaging can expose tapes to moisture or physical damage during transit and storage. Even high-quality tape can degrade if stored improperly. Ensure suppliers use moisture-resistant, sealed packaging and provide clear storage guidelines.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting samples, verifying certifications, and understanding IP rights associated with branded products. Prioritizing quality and legal compliance from the outset prevents costly delays and ensures professional results.

Logistics & Compliance Guide for Tape for Drywall Corners

Product Overview

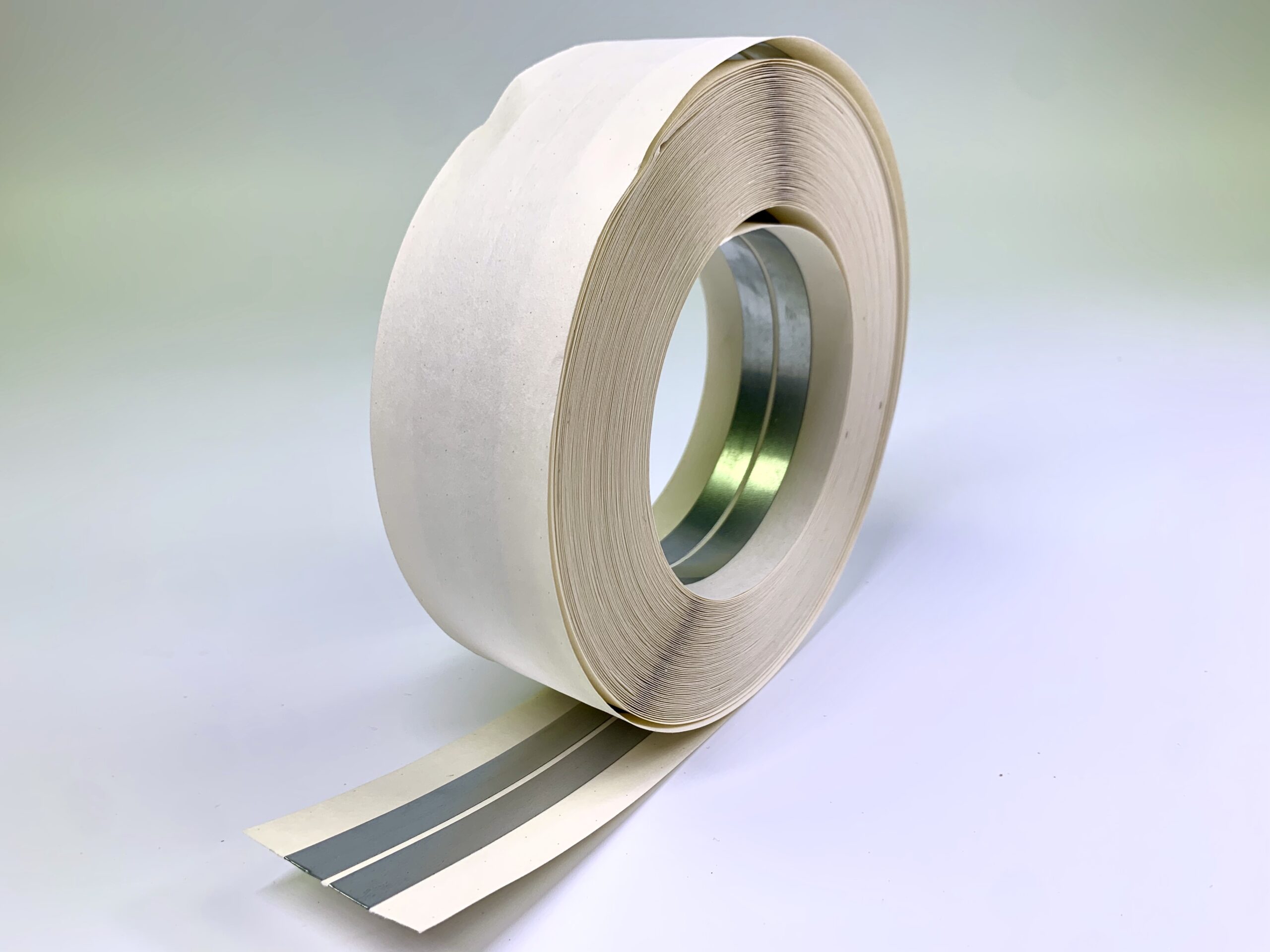

Tape for drywall corners—commonly known as corner bead tape or drywall corner tape—is a reinforcing material used in construction to protect and finish internal and external drywall corners. Typically made from paper, fiberglass, or metal-reinforced composites, this tape is applied with joint compound to create durable, crack-resistant edges. Understanding logistics and compliance considerations is essential for suppliers, distributors, and contractors.

International Shipping & Classification

When shipping tape for drywall corners internationally, proper classification under the Harmonized System (HS) Code is critical. Common classifications include:

– HS Code 6901.00: For ceramic-based or plasterboard joint tapes (if applicable)

– HS Code 5903.90: For textile-backed adhesive tapes (if fabric-reinforced)

– HS Code 3919.90: For plastic or polymer-based self-adhesive tapes

Accurate classification ensures correct duty rates and avoids customs delays. Always verify the specific code with local customs authorities based on material composition.

Packaging & Handling Requirements

Proper packaging ensures product integrity during transit:

– Rolls should be wound tightly on sturdy cardboard cores.

– Individual rolls or bundles must be wrapped in moisture-resistant polyethylene or shrink wrap.

– Bulk shipments should be palletized with edge protectors and secured with strapping.

– Label each package with product type, dimensions, batch number, and handling instructions (e.g., “Keep Dry,” “Do Not Stack Excessively”).

Avoid exposure to humidity, which can degrade paper-based tapes or reduce adhesive performance.

Storage Conditions

Store drywall corner tape in a clean, dry, and temperature-controlled environment:

– Ideal temperature range: 50°F to 77°F (10°C to 25°C)

– Relative humidity: Below 60%

– Keep away from direct sunlight and sources of heat to prevent warping or adhesive deterioration

Stack pallets no higher than recommended to prevent crushing lower layers.

Regulatory Compliance (U.S. & Canada)

Ensure compliance with regional safety and environmental standards:

– U.S. EPA TSCA (Toxic Substances Control Act): Confirm that raw materials (e.g., adhesives, resins) are listed or exempt under TSCA.

– CALGreen (California Green Building Standards): Some projects require low-VOC (volatile organic compound) materials. Verify VOC content if marketing eco-friendly products.

– CAN/ULC-S102: In Canada, surface burning characteristics may be evaluated for building code compliance in commercial applications.

Environmental & Disposal Regulations

Drywall tapes are generally non-hazardous but may contain adhesives or coatings subject to local disposal rules:

– Do not incinerate tapes with plastic or synthetic backings in uncontrolled environments.

– Follow local municipal waste regulations for construction debris.

– Recycle cardboard cores and packaging materials where possible.

Workplace Safety (OSHA & WHMIS)

While drywall corner tape is not classified as hazardous under GHS, safe handling practices should be followed:

– Use gloves and eye protection when cutting or handling fiberglass-reinforced tapes to prevent irritation.

– Provide adequate ventilation when applying with joint compounds (which may have associated SDS requirements).

– Maintain Safety Data Sheets (SDS) for any accompanying adhesives or joint compounds under OSHA’s HazCom standard (U.S.) or WHMIS (Canada).

Import/Export Documentation

For international trade, ensure all required documents are complete:

– Commercial Invoice (with detailed product description and HS code)

– Packing List (itemizing quantities, weights, and dimensions)

– Certificate of Origin (for preferential tariff treatment under USMCA or other agreements)

– Bill of Lading or Air Waybill

Verify import restrictions or labeling requirements in destination countries (e.g., CE marking is not typically required for this product in the EU, but construction materials may need to comply with EN standards if part of a system).

Quality Standards & Certifications

While not always mandatory, adherence to industry standards enhances marketability:

– ASTM C474: Standard test methods for joint treatment of gypsum board

– ASTM C1782: Standard specification for flexible drywall corner protection products

Manufacturers may pursue third-party testing or certification to demonstrate performance and durability.

Conclusion

Effective logistics and compliance management for drywall corner tape involves accurate classification, careful handling, adherence to environmental and safety regulations, and thorough documentation. By following this guide, stakeholders can ensure smooth distribution, minimize risk, and maintain product quality across supply chains.

In conclusion, sourcing the right tape for drywall corners is essential for achieving durable, professional-quality finishes in wall construction and repair. Choosing between paper tape and fiberglass mesh tape depends on project-specific needs—paper tape offers excellent adhesion and is ideal for inside corners and high-stress areas, while fiberglass tape provides ease of use, moisture resistance, and is well-suited for outside corners and quick installations. Additionally, specialty tapes like self-adhesive or pre-creased options can streamline the taping process in custom applications. When sourcing, consider factors such as quality, compatibility with joint compounds, environmental conditions, and installer expertise. Procuring from reputable suppliers ensures consistent performance and reduces the risk of issues like cracking or delamination. Ultimately, investing time in selecting and sourcing the appropriate drywall corner tape contributes significantly to the longevity and appearance of the finished walls.