The global tap spindle market is experiencing robust growth, driven by rising demand for precision machining solutions across industries such as automotive, aerospace, and industrial manufacturing. According to Grand View Research, the global machine tools market—of which tap spindles are a critical component—is projected to grow at a CAGR of 7.8% from 2023 to 2030, fueled by automation, CNC technology adoption, and advancements in smart manufacturing. Similarly, Mordor Intelligence forecasts a steady expansion in the machine tool accessories sector, with tap spindles gaining prominence due to their role in enhancing threading accuracy and production efficiency. As manufacturers seek reliable, high-performance spindle systems to minimize downtime and improve output, the competitive landscape has intensified. This growing demand has spotlighted a select group of innovators pushing the boundaries of speed, rigidity, and integration capabilities. Below, we highlight the top 9 tap spindle manufacturers leading this evolution through technological excellence and market responsiveness.

Top 9 Tap Spindle Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High-Quality Cutting Tools

Domain Est. 1996

Website: widia.com

Key Highlights: WIDIA offers a wide range of cutting tools and solutions for industrial applications. Explore their website for high-quality tools and expert advice….

#2 Griner Engineering Inc

Domain Est. 1996

Website: griner.com

Key Highlights: As specialists in high volume precision turned parts, we produce sensor bodies, mechanical components, fluid handling, construction equipment, and more….

#3 Haas Automation Inc.

Domain Est. 1996

Website: haascnc.com

Key Highlights: Haas Automation is the largest machine tool builder in the western world, manufacturing a complete line of CNC vertical machining centers, ……

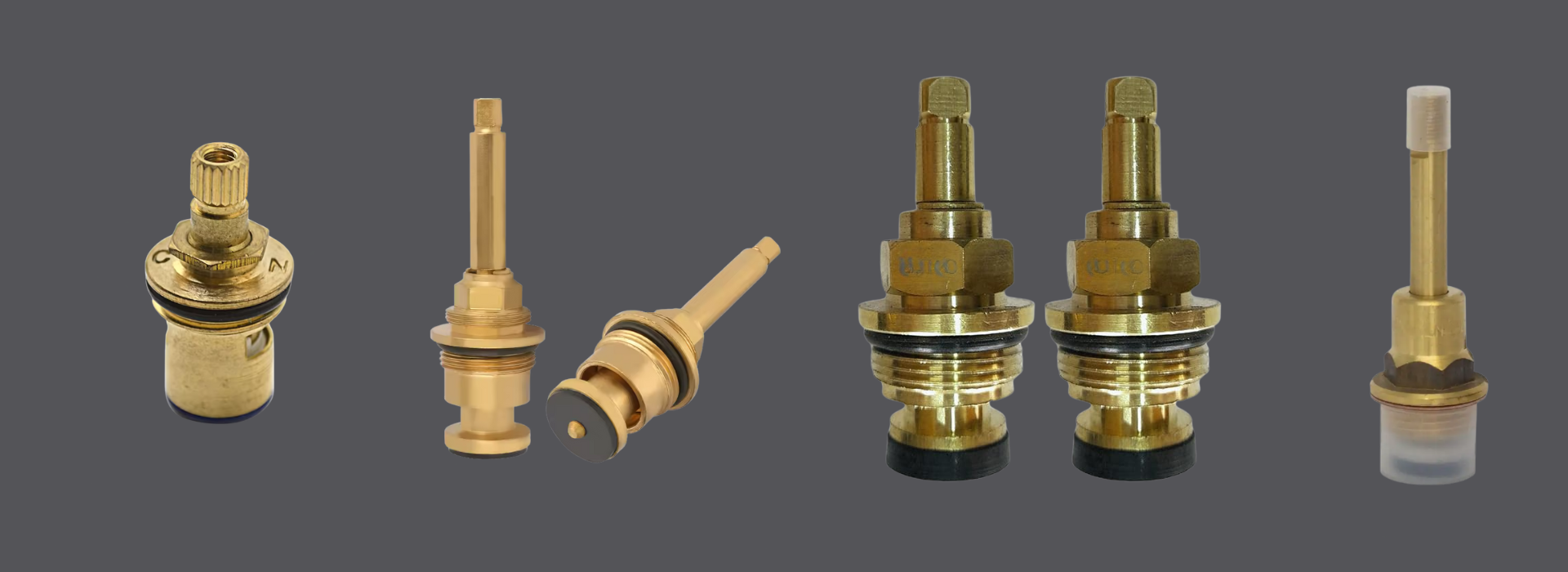

#4 Brass Spindle Fittings

Domain Est. 2011

Website: truptibrass.com

Key Highlights: TRUPTI BRASS INDUSTRIES. is one of the best Manufacturer, Supplier, Exporter of Brass Spindle Fittingswe are based in Jamnagar, Gujarat….

#5 Brass Spindle Manufacturer in China

Domain Est. 2021

Website: hmaking.com

Key Highlights: HM is a leading manufacturer of the brass spindle in China. We offer an extensive range of brass tap spindles, different thread sizes, shapes, screw sizes, etc….

#6 M.A.Ford® Offers Excellent Service And Tools You Need

Domain Est. 1997

Website: maford.com

Key Highlights: M.A.Ford® offers excellent service and durable standard, high performance and custom cutting tools f….

#7 Setco: Precision Spindle Repair & Rebuild

Domain Est. 1998

Website: setco.com

Key Highlights: Explore Setco for top-notch spindle repair, slide repair, and milling head services. Experience quality and reliability for all your manufacturing needs!…

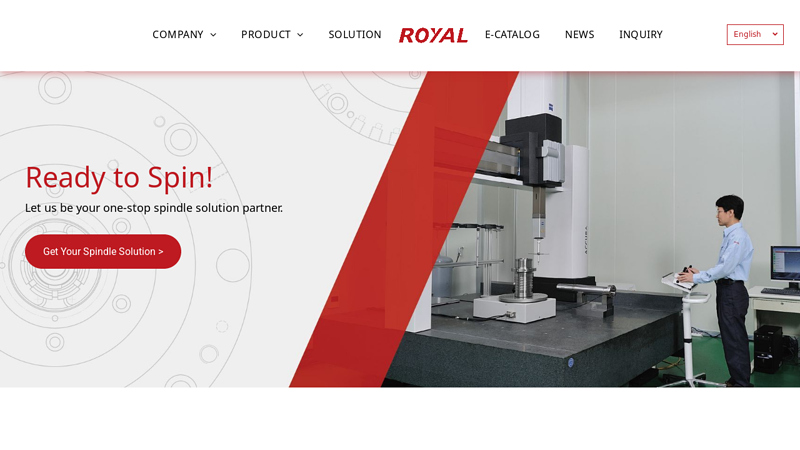

#8 ROYAL

Domain Est. 2016

Website: royal-spindles.com

Key Highlights: ROYAL has specialized in high precision machine tool spindles for various machine types as milling, turning, mill-turn, multi-spindle, tapping and grinding….

#9 Brass Spindle

Domain Est. 2024

Website: yantranshspindle.com

Key Highlights: This 38 mm Golden Brass Tap Spindle is expertly crafted for durability and performance, making it an essential component for any plumbing system….

Expert Sourcing Insights for Tap Spindle

H2: Market Trends for Tap Spindle in 2026

As we approach 2026, the tap spindle market is poised for significant transformation driven by advancements in automation, increasing demand for precision machining, and the global push toward smart manufacturing. Tap spindles—precision tools used in CNC machines for threading operations—are witnessing renewed relevance due to evolving industrial needs across aerospace, automotive, medical device manufacturing, and general metalworking sectors.

-

Growth in Automation and Industry 4.0 Integration

The integration of tap spindles into automated production lines and smart factories is accelerating. By 2026, a growing number of manufacturers are adopting IoT-enabled tap spindles equipped with real-time monitoring, torque sensing, and predictive maintenance capabilities. These intelligent spindles reduce downtime, improve thread quality, and optimize tool life—key performance indicators in high-efficiency environments. -

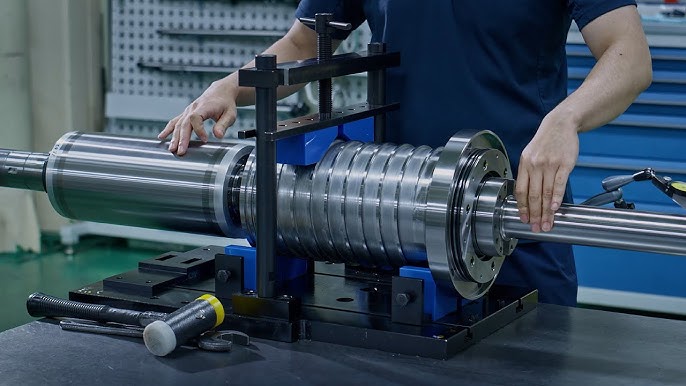

Demand for High-Speed and High-Precision Spindles

With tighter tolerances required in advanced engineering applications, especially in electric vehicles (EVs) and aerospace components, demand is shifting toward high-speed, high-torque tap spindles capable of handling difficult materials like titanium, Inconel, and high-strength steel. Innovations in motor design, such as brushless DC motors and through-spindle coolant systems, are enhancing performance and reliability. -

Expansion in Emerging Markets

Asia-Pacific, particularly China, India, and Southeast Asia, continues to be a major growth engine for the tap spindle market. Rising industrialization, government initiatives promoting manufacturing (e.g., “Make in India,” “China Manufacturing 2025”), and expanding automotive sectors are driving demand for advanced tapping solutions. Local production of CNC machines also boosts spindle integration at the OEM level. -

Sustainability and Energy Efficiency

By 2026, energy-efficient spindle designs are becoming a competitive differentiator. Manufacturers are focusing on reducing power consumption and heat generation through improved thermal management and regenerative braking systems. This aligns with broader ESG (Environmental, Social, and Governance) goals in industrial supply chains. -

Customization and Modular Designs

End users increasingly demand modular tap spindles that can be easily integrated into existing CNC systems or swapped for different tapping operations. Customization for specific applications—such as deep-hole tapping or micro-tapping in medical devices—is a growing trend, supported by agile manufacturing and digital prototyping technologies. -

Supply Chain Resilience and Localization

Following disruptions in global supply chains, many tap spindle manufacturers are reshoring or nearshoring production. By 2026, regional manufacturing hubs are expected to reduce lead times and increase responsiveness to customer needs, particularly in North America and Europe. -

Competition and Technological Differentiation

The market is becoming increasingly competitive, with key players investing in R&D to differentiate through smart features, longer service intervals, and compatibility with multi-tasking machines. Partnerships between spindle manufacturers and CNC control system providers are fostering tighter integration and improved user experience.

Conclusion

By H2 2026, the tap spindle market will be characterized by intelligence, precision, and adaptability. The convergence of digital manufacturing, material science, and sustainable engineering is redefining product expectations. Companies that embrace innovation, customization, and regional responsiveness are likely to capture significant market share in this evolving landscape.

Common Pitfalls When Sourcing Tap Spindles (Quality and IP)

Sourcing tap spindles—critical components in automated tapping units—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to operational failures, increased downtime, and legal risks. Below are key pitfalls to avoid:

Poor Quality Control and Inconsistent Manufacturing Standards

Many suppliers, especially low-cost manufacturers, lack rigorous quality control processes. This can result in tap spindles with dimensional inaccuracies, substandard materials, or inadequate heat treatment, leading to premature wear, misalignment, or breakage during operation. Always verify the supplier’s certifications (e.g., ISO 9001), request sample testing, and inspect material traceability and machining tolerances.

Use of Inferior Materials and Components

Low-grade spindle housings, bearings, or seals can compromise performance and lifespan. For instance, using non-chrome-molybdenum steel in high-torque applications leads to fatigue failure. Ensure the supplier specifies material grades (e.g., AISI 4140, 8620) and uses precision bearings from reputable brands (e.g., SKF, NSK) to maintain reliability under load and speed.

Lack of IP Protection and Risk of Counterfeiting

Tap spindle designs often incorporate proprietary engineering, especially in sealed or automatic feed mechanisms. Sourcing from suppliers with weak IP safeguards increases the risk of receiving counterfeit or reverse-engineered products that infringe on patents. Always perform IP due diligence: check for valid patents, require warranty of non-infringement in contracts, and avoid suppliers offering “compatible” versions of branded units without licensing.

Inadequate Technical Support and Documentation

Poorly documented spindles—missing assembly drawings, torque specs, or maintenance guidelines—hinder integration and troubleshooting. Suppliers without robust technical support may fail to assist during commissioning or failure analysis. Prioritize vendors who provide comprehensive documentation and responsive engineering support.

Non-Compliance with Industry Standards

Tap spindles used in regulated industries (e.g., aerospace, medical) must meet specific standards (e.g., ISO, DIN). Sourcing non-compliant units can lead to audit failures or safety issues. Confirm that the spindle design and manufacturing adhere to relevant industry norms and include necessary certifications.

Hidden Costs from Poor Serviceability

Some low-cost spindles are built as sealed units with no serviceable parts, forcing full replacement after minor failures. This increases long-term costs and downtime. Opt for modular designs that allow bearing or seal replacement, and confirm spare parts availability before purchasing.

Conclusion

To mitigate risks, conduct thorough supplier vetting, demand quality evidence (test reports, material certs), and protect IP through legal agreements. Investing time upfront ensures reliable, compliant, and legally sound tap spindle sourcing.

Logistics & Compliance Guide for Tap Spindle

This guide outlines the key logistics and compliance considerations for the distribution, handling, and use of Tap Spindle products. Adhering to these guidelines ensures regulatory compliance, product integrity, and operational efficiency across the supply chain.

Product Classification and Documentation

Ensure all Tap Spindle products are accurately classified under the appropriate Harmonized System (HS) codes for international trade. Maintain up-to-date product specifications, safety data sheets (SDS), and certificates of conformance (CoC). Required documentation must accompany shipments to avoid customs delays.

Packaging and Labeling Standards

Package Tap Spindles securely to prevent damage during transit. Use industry-standard cushioning and moisture-resistant materials. Labels must include product name, model number, batch/lot number, manufacturing and expiration dates (if applicable), handling instructions, and compliance markings (e.g., CE, RoHS where required).

Shipping and Transportation

Ship Tap Spindles via approved carriers that comply with IATA, IMDG, or ground transport regulations as applicable. Temperature-sensitive models must be shipped under controlled conditions. Use trackable shipping methods and provide real-time tracking information to customers. Avoid extended storage in transit hubs.

Import/Export Compliance

Verify export control classifications (e.g., EAR99) and obtain necessary export licenses if required. Screen all international transactions against denied party lists (e.g., OFAC, BIS). Ensure compliance with destination country regulations, including import permits, conformity assessments, and local labeling requirements.

Regulatory Certifications

Confirm that Tap Spindle units comply with relevant regional standards such as:

– CE marking for European Economic Area (EMC, LVD, RoHS)

– UL/CSA for North America

– PSE for Japan

– KC for South Korea

Maintain certification records and update them as standards evolve.

Inventory Management and Traceability

Implement a robust inventory system that supports batch-level traceability from manufacture to end-user. Conduct regular cycle counts and audits to ensure stock accuracy. Store products in a clean, dry, temperature-controlled environment to preserve performance and longevity.

Returns and Reverse Logistics

Establish a clear process for handling returns, including inspection, refurbishment, or disposal. All returned Tap Spindles must be evaluated for compliance and safety before re-entry into inventory. Follow environmental regulations for the disposal of non-repairable units, particularly concerning electronic and metallic components.

Customer Compliance Support

Provide customers with necessary compliance documentation and technical guidance to ensure proper installation and usage in accordance with local regulations. Offer training materials or support to promote safe and compliant operation of Tap Spindle equipment.

Adherence to this guide ensures that Tap Spindle products are delivered efficiently, legally, and safely to global markets. Regular reviews and updates to this document are recommended to reflect changes in regulations or business operations.

Conclusion for Sourcing Tap Spindles:

Sourcing tap spindles requires a strategic approach that balances quality, cost, reliability, and technical compatibility. After evaluating potential suppliers, assessing manufacturing capabilities, and considering factors such as precision, durability, and after-sales support, it is clear that selecting the right supplier is critical to ensuring optimal performance in tapping operations. A successful sourcing decision involves thorough due diligence, including verification of certifications, material standards, and production consistency. Additionally, building strong supplier relationships and maintaining clear communication can enhance delivery reliability and support future scalability. Ultimately, investing time and resources in sourcing high-quality tap spindles from reputable manufacturers not only improves machining efficiency and tool life but also contributes to overall production uptime and cost-effectiveness.