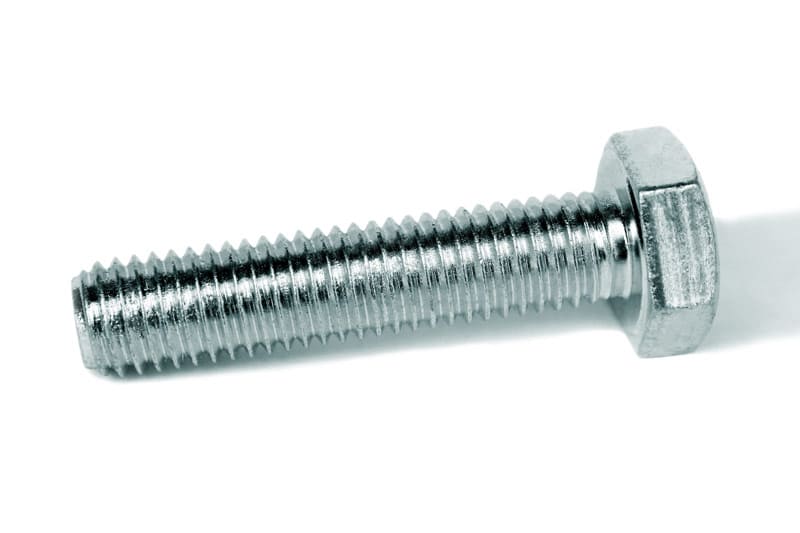

The global fastener market, driven by sustained demand from automotive, construction, and industrial manufacturing sectors, is experiencing robust growth. According to a report by Mordor Intelligence, the market was valued at USD 108.75 billion in 2023 and is projected to reach USD 147.56 billion by 2029, growing at a CAGR of 5.1% during the forecast period. A significant portion of this demand stems from specialized fasteners such as tap bolts—fully threaded mechanical bolts widely used for precise clamping and assembly applications. With increasing industrial automation and infrastructure development, particularly in the Asia Pacific and North American regions, the need for high-quality, precision-engineered tap bolts has surged. This growth trajectory has spurred consolidation and innovation among manufacturers, positioning key players to capitalize on expanding supply chain requirements. In this evolving landscape, identifying the top tap bolt manufacturers becomes critical for procurement teams and OEMs focused on reliability, compliance, and cost efficiency.

Top 10 Tap Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Portland Bolt

Domain Est. 1998 | Founded: 1912

Website: portlandbolt.com

Key Highlights: Portland Bolt has manufactured and distributed the highest-quality anchor bolts and nonstandard construction fasteners since 1912….

#2 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#3 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#4 Tap Bolts

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: Shop tap bolts—fully threaded hex bolts made for tapped holes. Available in multiple grades, materials & finishes for industrial and ……

#5 Tap Bolts Fastener

Domain Est. 2017

Website: jfeindia.com

Key Highlights: We offer a wide selection of Tap bolts that is designed for multitude uses and can be found around the home, commercial building projects, and industrial ……

#6 Hex Head Tap Bolt

Domain Est. 1996

Website: minerallac.com

Key Highlights: Products specifications ; Brand Name, Minerallac ; Sub Brand, Cully ; Type, Hex Cap Screw ; Material, 18-8 Stainless Steel ; Length, 1-1/4″….

#7 ARP

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: Fastener Tech • ARP Ultra-Torque • Find Your Kit Instructions • Fastener Installation Overview • Torque Value Lookup • Fastener Installation FAQs…

#8 Hex Tap Bolts

Domain Est. 1998

Website: boltproducts.com

Key Highlights: Find Hex Tap Bolts and other various Stainless Steel Bolts at Bolt Products. Hex Tap Bolts and Tapping Screws come in a large variety of sizes and diameters ……

#9 Hex Head Tap Bolt – Elgen Manufacturing

Domain Est. 1999

Website: elgenmfg.com

Key Highlights: Elgen Conicals are Union Made Yellow Label. Welded seams for added strength and provide low leakage. Pressure rating designed per SMACNA 3rd edition 2005 ……

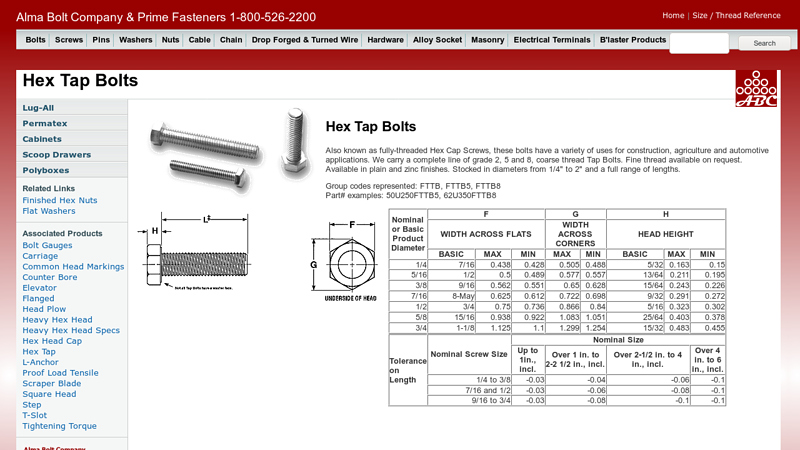

#10 Hex Tap Bolts

Domain Est. 1999

Website: almabolt.com

Key Highlights: We carry a complete line of grade 2, 5 and 8, coarse thread Tap Bolts. Fine thread available on request. Available in plain and zinc finishes….

Expert Sourcing Insights for Tap Bolt

2026 Market Trends for Tap Bolt: A H2 Forecast Analysis

The global tap bolt market is poised for significant evolution by 2026, driven by macroeconomic shifts, technological advancements, and changing industrial demands. Heading into the second half (H2) of 2026, several key trends are expected to shape the landscape:

1. Accelerated Demand from Renewable Energy & EV Infrastructure:

H2 2026 will see a pronounced surge in tap bolt consumption linked to the rapid deployment of renewable energy projects (solar farms, wind turbines) and electric vehicle (EV) charging networks. The need for durable, corrosion-resistant fasteners in outdoor and high-stress environments will drive demand for specialized tap bolts (e.g., stainless steel, high-tensile grades). Supply chains will adapt to meet the just-in-time requirements of large-scale infrastructure projects.

2. Heightened Regionalization & Supply Chain Resilience:

Geopolitical tensions and lessons from past disruptions will push manufacturers toward nearshoring and regional supply chain models by H2 2026. Companies will prioritize suppliers within key economic blocs (e.g., North America, EU, ASEAN), increasing demand for locally produced tap bolts. This trend will boost regional manufacturing capacity but may lead to price variations and fragmented standards.

3. Advancements in Smart Manufacturing & Automation:

The integration of Industry 4.0 technologies will become mainstream in H2 2026. Tap bolt producers will increasingly adopt automated quality control (AI-driven visual inspection), predictive maintenance for machinery, and digital twins for process optimization. This shift will improve precision, reduce waste, and enable mass customization—critical for meeting diverse industrial specifications.

4. Sustainability & Circular Economy Pressures:

Environmental regulations and corporate ESG goals will intensify in H2 2026. Demand will grow for tap bolts made from recycled materials and low-carbon steel. Manufacturers will face pressure to provide lifecycle assessments and adopt energy-efficient production methods. Traceability through blockchain or digital product passports may emerge as a competitive differentiator.

5. Price Volatility & Raw Material Challenges:

Fluctuations in steel, zinc, and alloy prices—driven by energy costs and trade policies—will persist into H2 2026. Suppliers will increasingly use long-term contracts and hedging strategies to stabilize pricing. Customers may shift toward standardized tap bolt designs to mitigate cost uncertainty and simplify inventory management.

6. Digitalization of B2B Procurement:

By H2 2026, digital marketplaces and e-procurement platforms will dominate tap bolt transactions. AI-powered platforms will enable dynamic pricing, real-time inventory visibility, and automated reordering. Traditional distributors will need to enhance their digital capabilities to remain competitive against direct manufacturer channels.

Conclusion:

In H2 2026, the tap bolt market will be characterized by strategic regionalization, technological integration, and sustainability imperatives. Success will depend on agility in supply chain management, investment in automation, and alignment with green manufacturing trends. Companies that anticipate these shifts and innovate accordingly will gain a decisive edge in a more competitive and complex global landscape.

Common Pitfalls Sourcing Tap Bolts (Quality, IP)

Sourcing tap bolts—especially with attention to quality and Intellectual Property (IP)—presents several challenges that can impact project timelines, safety, and compliance. Being aware of these pitfalls helps mitigate risks and ensures the selection of reliable fasteners.

Poor Quality Control and Non-Compliance with Standards

Many suppliers, particularly from low-cost regions, may offer tap bolts that appear identical to certified products but fail to meet required mechanical and dimensional standards (e.g., ISO, ASTM, DIN). Substandard materials, inadequate heat treatment, or imprecise threading can lead to bolt failure under load. Buyers often overlook third-party certifications or skip batch testing, risking structural integrity.

Misrepresentation of Material and Grade

A common issue is the mislabeling of bolt grade (e.g., selling Grade 5 as Grade 8) or using subpar steel alloys. Without proper material traceability or mill test certificates (MTCs), it’s difficult to verify claims. This becomes critical in high-stress or safety-critical applications where performance margins are narrow.

Inadequate Thread Quality and Tapping Issues

Tap bolts rely on internal threads, and poor thread formation—such as incomplete tapping, cross-threading, or burrs—can compromise assembly and performance. Some suppliers cut corners in threading processes, leading to stripped threads or difficulty in installation. Ensuring consistent thread fit (e.g., Class 2B/3B) is essential but often overlooked during inspection.

Counterfeit or IP-Infringing Products

OEM-designed tap bolts or proprietary fastener systems may be protected by patents or trademarks. Sourcing from unauthorized manufacturers can result in IP violations, legal liability, and damage to brand reputation. Counterfeit bolts may mimic branding and markings without delivering the engineered performance, especially in specialized industrial or automotive applications.

Inconsistent Coatings and Corrosion Protection

Corrosion resistance is vital in many environments, yet suppliers may apply inadequate or inconsistent coatings (e.g., zinc plating, Dacromet). Poor coating adhesion, incorrect thickness, or omission of post-plating passivation can lead to premature rust and failure. Buyers may not specify coating standards (e.g., ASTM B633), increasing exposure to quality risks.

Lack of Traceability and Documentation

Reputable sourcing requires full traceability—from raw material to finished product. Many suppliers fail to provide lot numbers, test reports, or compliance documentation. In regulated industries (e.g., aerospace, medical, defense), this absence can lead to audit failures and product rejection.

Overlooking Total Cost of Quality Failures

While low initial pricing may be attractive, hidden costs arise from field failures, warranty claims, rework, or downtime due to bolt failures. Investing in vetted suppliers with robust quality management systems (e.g., ISO 9001) reduces long-term risk.

To avoid these pitfalls, conduct supplier audits, require material certifications, perform independent testing, and ensure IP compliance through authorized channels.

Logistics & Compliance Guide for Tap Bolt

This guide outlines the essential logistics and compliance considerations for the international shipment and regulatory adherence of tap bolts—threaded fasteners designed to cut their own internal threads into pre-drilled holes in materials like metal or plastic. Adhering to these guidelines ensures smooth transportation, customs clearance, and legal compliance across global markets.

Product Classification & Documentation

Accurate product classification is critical for customs compliance and duty assessment. Tap bolts are typically classified under the Harmonized System (HS) Code based on material, dimensions, and finish.

- Standard HS Code Example: 7318.15 (for threaded steel bolts, whether or not with their nuts or washers, of iron or steel)

- Required Documentation:

- Commercial Invoice (with detailed description, quantity, value, HS code, country of origin)

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin (often required for preferential tariff treatment under trade agreements)

- Material Test Reports (MTRs) or Mill Certificates (if specified by customer or regulation)

Ensure all documentation consistently reflects product specifications to prevent delays.

Packaging & Labeling Standards

Proper packaging protects tap bolts during transit and meets international shipping requirements.

- Packaging: Use moisture-resistant, durable packaging such as poly-lined cartons, shrink-wrapped bundles, or steel/wooden crates for bulk shipments. Prevent movement within containers to reduce damage.

- Labeling: Clearly label each package with:

- Product description and part number

- Net and gross weight

- Quantity

- HS code

- Country of origin

- Handling symbols (e.g., “Fragile,” “This Way Up”)

- Compliance Labels: Include any required safety or regulatory labels (e.g., REACH, RoHS) where applicable.

Customs Compliance & Trade Regulations

Compliance with import/export regulations is mandatory to avoid fines, seizures, or shipment delays.

- Country of Origin Rules: Clearly declare the manufacturing country. Rules of origin may affect tariffs under agreements like USMCA or EU-UK Trade and Cooperation Agreement.

- Import Restrictions: Check destination-specific restrictions; some countries regulate steel products or fasteners for industrial safety standards.

- Export Controls: Verify if tap bolts fall under export control regimes (e.g., EAR in the U.S.)—typically not controlled unless for military applications.

- Duties and Taxes: Accurately calculate import duties, VAT, or GST based on HS classification and Free Trade Agreement (FTA) eligibility.

Material & Environmental Compliance

Tap bolts must meet chemical and environmental regulations, especially when shipped to the EU, UK, or California.

- REACH (EU/UK): Ensure substances in the bolt (e.g., coatings, plating) are registered and do not contain SVHCs (Substances of Very High Concern) above threshold levels.

- RoHS (EU/UK/China): Comply with restrictions on hazardous substances (e.g., lead, cadmium) if used in electrical or electronic equipment.

- Proposition 65 (California): Disclose if products contain chemicals known to cause cancer or reproductive harm (e.g., certain chromates in plating).

- Conflict Minerals (Dodd-Frank Act): Report if tin, tungsten, tantalum, or gold (3TG) are present and sourced from conflict-affected regions (rare in standard tap bolts, but assess if applicable).

Quality & Industry Standards

Meeting recognized standards ensures product acceptance and regulatory compliance.

- Common Standards:

- ISO 2341 (Tap end cutting screws)

- ASME B18.6.1 (for wood screws, may include tap bolts)

- DIN 96 / DIN 97 (German standards for tapping screws)

- ASTM A325 / A490 (for structural bolts; may overlap in application)

- Certifications: Provide test reports or certifications when required (e.g., ISO 9001 for quality management).

Shipping & Transport Logistics

Optimize transport methods based on volume, urgency, and destination.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, EXW, DDP).

- Mode of Transport:

- Sea Freight: Cost-effective for large volumes; use FCL or LCL containers.

- Air Freight: Faster but more expensive; suitable for urgent or high-value shipments.

- Land Transport: For regional distribution (e.g., North America, EU).

- Handling: Avoid exposure to moisture; use desiccants in containers if shipping overseas.

Regulatory Updates & Monitoring

Stay informed about evolving regulations.

- Subscribe to customs alerts (e.g., CBP, HMRC, EU Taxation and Customs Union).

- Monitor updates to REACH, RoHS, and trade agreements.

- Conduct periodic compliance audits for documentation, labeling, and substance use.

Conclusion

Successfully managing the logistics and compliance of tap bolts requires attention to classification, documentation, packaging, and regulatory standards. By following this guide, suppliers and distributors can ensure timely delivery, avoid penalties, and maintain market access worldwide.

Conclusion for Sourcing Tap Bolt:

In conclusion, sourcing tap bolts requires a comprehensive approach that balances quality, cost, supplier reliability, and compliance with technical specifications. It is essential to identify suppliers with proven manufacturing capabilities, adherence to international standards (such as ISO, DIN, or ASTM), and a track record of consistent delivery. Evaluating material quality, thread precision, and surface treatment is crucial to ensure the tap bolts meet the required performance criteria in their intended application.

Additionally, building strong supplier relationships, conducting regular quality audits, and considering total cost of ownership—rather than just unit price—can lead to long-term operational efficiency and reduced risk of failure. By implementing a strategic sourcing process that includes market analysis, supplier vetting, and performance monitoring, organizations can secure reliable, cost-effective tap bolt supply chains that support product integrity and project timelines.