The global tank liquid level indicator market is experiencing robust growth, driven by increasing demand for process automation, stringent safety regulations, and the need for real-time monitoring across industries such as oil and gas, water and wastewater treatment, chemicals, and power generation. According to a report by Mordor Intelligence, the liquid level measurement market was valued at USD 9.43 billion in 2023 and is projected to reach USD 12.87 billion by 2029, growing at a CAGR of 5.3% during the forecast period. This expansion is further supported by rising investments in smart infrastructure and industrial IoT, which are enhancing the functionality and adoption of advanced level sensing technologies. With such strong market momentum, identifying leading manufacturers becomes critical for stakeholders seeking reliable, innovative, and scalable solutions. Based on market presence, product innovation, technological expertise, and global reach, the following nine companies stand out as key players in the tank liquid level indicator industry.

Top 9 Tank Liquid Level Indicator Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

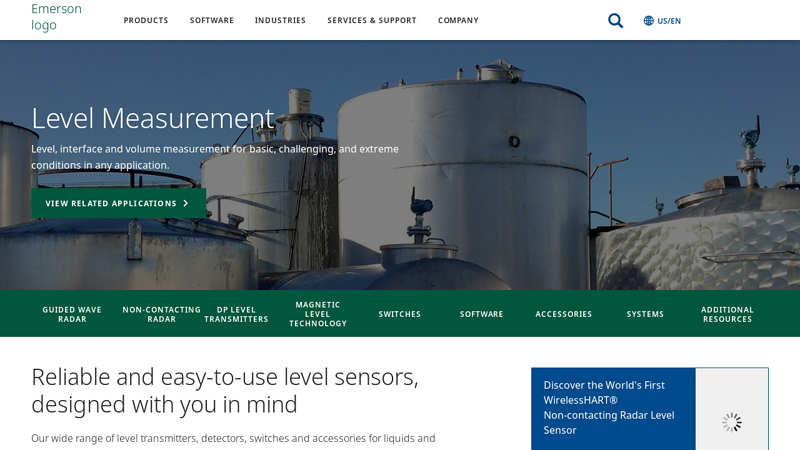

#1 Level Measurement

Domain Est. 1995

Website: emerson.com

Key Highlights: Liquid level switches measure point level within a vessel. Emerson’s portfolio is based on vibrating fork technology and offers a safe, reliable and cost- ……

#2 Custom Level Indicator Manufacturer

Domain Est. 1999

Website: ksentry.com

Key Highlights: For over 75 years we have manufactured over three million liquid-level gauges. We provide high-quality custom tank gauges for a variety of industries and ……

#3 Level Indicator Manufacturer

Domain Est. 2004

Website: fivalsrl.com

Key Highlights: We produce level indicators for tanks that guarantee a constant, continuous and extremely precise measurement….

#4 Liquid Level Indicators & Tank Gauges

Domain Est. 1996

Website: liquidlevel.com

Key Highlights: Innovative Components manufactures Tank Level Indicators and Tank Level Gauges for many liquid level sensing and measurement applications….

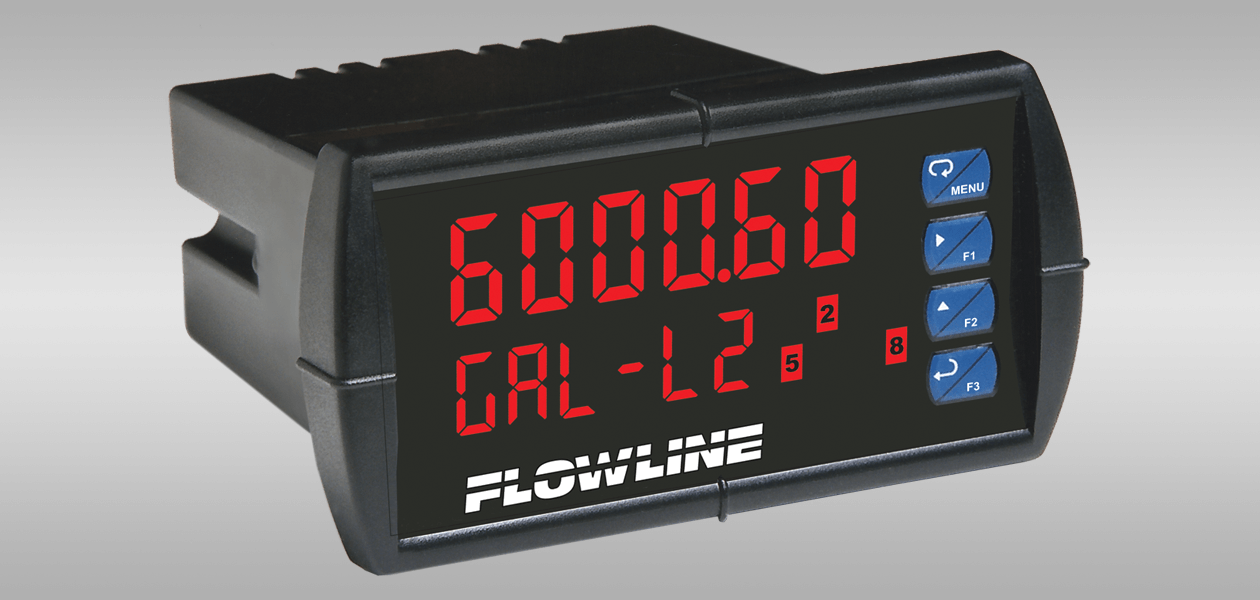

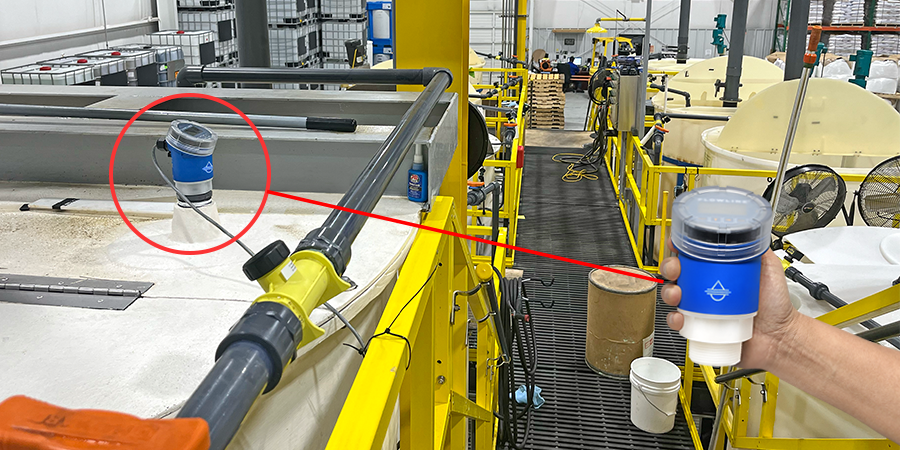

#5 Flowline Level Sensor, Transmitter, Switch & Control

Domain Est. 1996

Website: flowline.com

Key Highlights: We manufacture reliable level measurement, switch and control solutions for your chemical, water, wastewater, oil and dry solids applications….

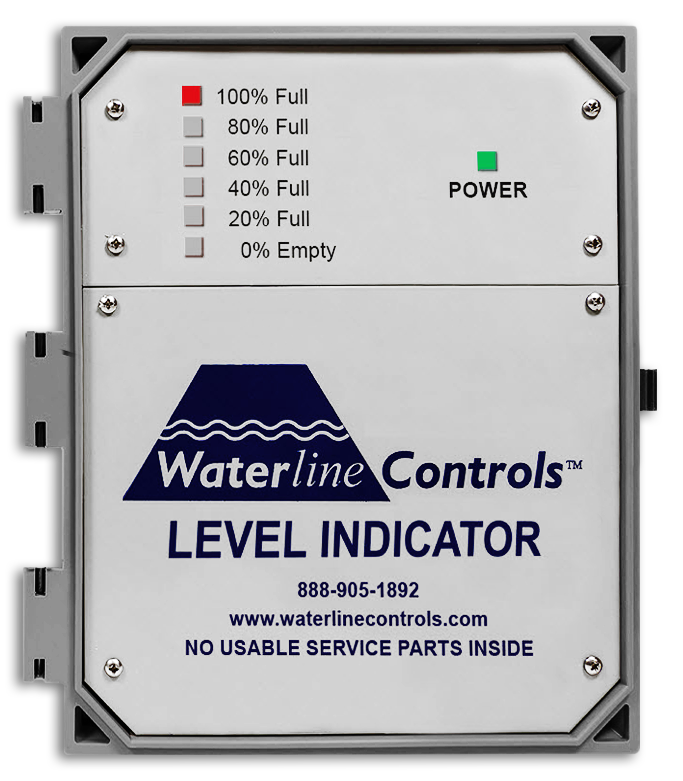

#6 Water Level Controls & Liquid Level Sensors by Waterline Controls®

Domain Est. 2007

Website: waterlinecontrols.com

Key Highlights: Solid state electronic water level controls and sensors. We provide the most precise and reliable controllers in the industry. Our automatic microprocessor ……

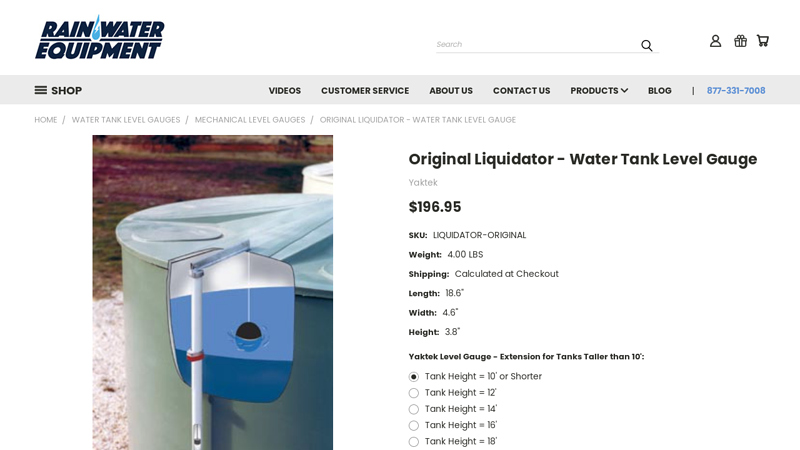

#7 Original Liquidator

Domain Est. 2015

#8 Homepage

Domain Est. 2020

Website: rochestersensors.com

Key Highlights: Rochester Sensors is a global organization with the expertise, resources and capabilities to solve any challenge related to liquid level measurement….

#9 Magnetic level indicators

Domain Est. 2023

Website: ametek-measurement.com

Key Highlights: Magnetic Level Indicators (MLI) have revolutionized the global visual indication market by offering a safer, reliable, and high-visibility alternative to common ……

Expert Sourcing Insights for Tank Liquid Level Indicator

H2: Market Trends for Tank Liquid Level Indicators in 2026

By 2026, the global market for tank liquid level indicators is expected to experience significant growth and technological transformation, driven by advancements in industrial automation, increasing demand for process efficiency, and stricter regulatory standards across key sectors such as oil & gas, water and wastewater management, chemical processing, and food & beverage.

One of the dominant trends is the rising adoption of smart and wireless level indicators. These devices, integrated with IoT (Internet of Things) platforms, enable real-time remote monitoring and predictive maintenance, enhancing operational efficiency and reducing downtime. The integration of digital communication protocols like HART, Modbus, and Foundation Fieldbus allows seamless data exchange with SCADA and DCS systems, supporting Industry 4.0 initiatives.

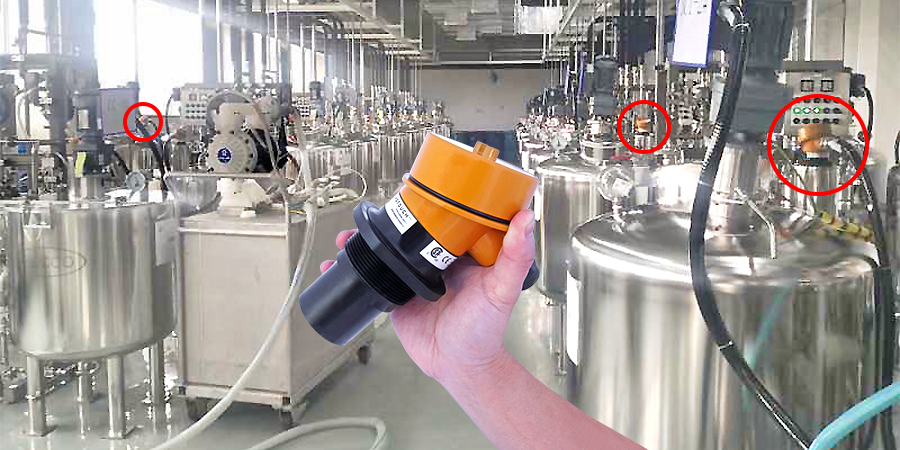

Another key trend is the shift toward non-contact level measurement technologies, such as radar (guided and non-guided wave radar) and ultrasonic sensors. These technologies offer higher accuracy, minimal maintenance, and suitability for harsh environments or applications involving corrosive or viscous liquids. In contrast, traditional float-based and sight glass indicators are being gradually replaced in critical applications, although they remain prevalent in cost-sensitive or less complex systems.

Regulatory emphasis on safety and environmental protection is also influencing market dynamics. Industries are increasingly deploying intrinsically safe and explosion-proof level indicators in hazardous environments. Certifications such as ATEX, IECEx, and SIL are becoming essential for product acceptance, especially in the oil & gas and chemical sectors.

Regionally, Asia-Pacific is anticipated to lead market growth due to rapid industrialization, urbanization, and investments in infrastructure and water treatment facilities—particularly in China, India, and Southeast Asia. North America and Europe will maintain strong demand, driven by modernization of aging infrastructure and stringent environmental regulations.

Additionally, sustainability and energy efficiency are shaping product development. Manufacturers are focusing on energy-efficient designs and eco-friendly materials to align with corporate sustainability goals and comply with environmental regulations.

In summary, the 2026 tank liquid level indicator market is characterized by digitalization, enhanced connectivity, regulatory compliance, and technological innovation, positioning smart and reliable level monitoring solutions as critical components in modern industrial operations.

Common Pitfalls Sourcing Tank Liquid Level Indicator (Quality, IP)

Sourcing a reliable Tank Liquid Level Indicator requires careful evaluation to avoid costly failures, safety risks, and operational downtime. Overlooking critical quality and Ingress Protection (IP) factors is a frequent source of problems. Below are key pitfalls to watch for:

Overlooking IP Rating Suitability for the Environment

One of the most common mistakes is selecting an indicator with an IP rating inadequate for its operating environment. Using an IP65-rated device outdoors in heavy rain or washdown areas may lead to water ingress, corrosion, and sensor failure. Conversely, specifying an unnecessarily high IP68 rating for a dry indoor application increases costs without added benefit. Always match the IP rating to actual conditions—consider exposure to dust, water jets, submersion, or chemical cleaning agents.

Assuming All Indicators Meet Stated Quality Standards

Many suppliers claim compliance with international standards (e.g., ISO, IEC, ATEX), but not all products undergo proper certification or third-party testing. Counterfeit or substandard components may pass initial inspection but fail prematurely under stress. Always verify certifications with documentation and prefer suppliers with a traceable quality management system (e.g., ISO 9001).

Ignoring Material Compatibility and Build Quality

Low-cost indicators often use inferior materials such as non-stainless housings or plastic floats unsuitable for corrosive or high-temperature liquids. This leads to degradation, leakage, or inaccurate readings. Ensure materials (e.g., 316L stainless steel, PVDF) are compatible with the stored medium and process conditions. Inspect welds, seals, and gaskets for signs of poor craftsmanship.

Failing to Validate Long-Term Reliability and Testing Data

Some suppliers provide limited performance data or omit lifecycle testing results. Without proof of durability—such as vibration resistance, thermal cycling, or continuous operation tests—there’s a high risk of field failure. Request test reports, MTBF (Mean Time Between Failures) data, and references from similar applications.

Neglecting Electromagnetic Compatibility (EMC) in Sensitive Areas

In industrial settings with high electromagnetic interference, poorly shielded indicators can deliver erratic readings or communication faults. Ensure the device complies with EMC directives (e.g., IEC 61326) and has proper shielding, especially for analog or digital signal outputs.

Underestimating Installation and Maintenance Requirements

Some indicators require precise alignment, specialized tools, or frequent recalibration. Poor design can make servicing difficult or unsafe, especially in confined spaces or hazardous areas. Evaluate ease of installation, accessibility for maintenance, and availability of spare parts before procurement.

By proactively addressing these pitfalls—especially around IP rating accuracy and quality assurance—buyers can ensure reliable, safe, and cost-effective performance of tank liquid level indicators over their operational lifespan.

Logistics & Compliance Guide for Tank Liquid Level Indicator

This guide outlines the key logistics considerations and compliance requirements for the transportation, handling, storage, and use of Tank Liquid Level Indicators (TLLIs). Adherence to these guidelines ensures safe, efficient operations and regulatory compliance across the supply chain.

Regulatory Compliance Requirements

All Tank Liquid Level Indicators must comply with applicable international, national, and industry-specific regulations. Key standards include:

– ATEX/IECEx: Required for devices used in potentially explosive atmospheres (e.g., fuel, chemical storage tanks). Ensure proper certification marking for Zone classification (e.g., Zone 1, Zone 2).

– RoHS & REACH: Compliance with Restriction of Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) is mandatory for components and materials, particularly within the European Union.

– Pressure Equipment Directive (PED): If the TLLI is part of a pressurized system, conformity with PED 2014/68/EU may be required.

– NEMA/UL Standards: In North America, devices should meet relevant UL (Underwriters Laboratories) standards and appropriate NEMA (National Electrical Manufacturers Association) enclosure ratings for environmental protection.

– Marine & Offshore Certifications: For maritime or offshore applications, compliance with DNV, ABS, or other classification society rules may be necessary.

– Country-Specific Approvals: Verify local requirements (e.g., INMETRO in Brazil, KC in South Korea, PSE in Japan).

Documentation including Declaration of Conformity, technical files, and test reports must accompany shipments and be available upon request.

Packaging and Handling Instructions

Proper packaging and handling are critical to prevent damage during transit and storage.

– Protective Packaging: Use anti-static, shock-absorbent materials to protect electronic components. Seal in moisture-resistant bags if required, especially for humid environments.

– Secure Mounting: Fragile sensing elements (e.g., float arms, probe tubes) must be immobilized during shipping using foam inserts or transit locks.

– Labeling: Clearly label packages with:

– “Fragile – Handle with Care”

– “This Side Up”

– Hazard symbols if applicable (e.g., battery warnings)

– Model number, serial number, and handling instructions

– Handling: Use appropriate lifting equipment for heavy units. Avoid dropping, bending, or applying force to sensing components.

Transportation Guidelines

Follow these practices to ensure safe and compliant transportation:

– Mode of Transport: Suitable for air, sea, and ground freight. For air transport, verify compliance with IATA Dangerous Goods Regulations if batteries (especially lithium types) are included.

– Temperature Control: Avoid exposure to extreme temperatures (typically below -20°C or above +60°C) during transit. Use climate-controlled transport if necessary.

– Stacking & Weight Limits: Adhere to manufacturer-specified stacking heights and weight limits to prevent crushing.

– Hazardous Materials: If the TLLI contains batteries or pressurized components, classify and label according to IMDG Code (sea), ADR (road), or other relevant regulations.

Storage Conditions

Store Tank Liquid Level Indicators in a controlled environment prior to installation:

– Environment: Dry, clean, and temperature-stable area (recommended: 5°C to 35°C, <80% relative humidity, non-condensing).

– Shelf Life: Observe manufacturer-recommended maximum storage duration, particularly for sealed units or those with sensitive electronics.

– Orientation: Store upright unless otherwise specified. Avoid prolonged exposure to direct sunlight or corrosive fumes.

– Inventory Management: Implement FIFO (First In, First Out) practices to minimize obsolescence and ensure product integrity.

Installation and Operational Compliance

Ensure proper installation and ongoing use meet safety and regulatory standards:

– Qualified Personnel: Installation and calibration must be performed by trained and certified technicians.

– Environmental Suitability: Confirm device rating matches the operational environment (e.g., explosive zones, submersion depth, chemical compatibility).

– Grounding & Electrical Safety: Follow manufacturer instructions for grounding, wiring, and connection to control systems to prevent electrical hazards.

– Periodic Inspection & Maintenance: Schedule regular checks per manufacturer guidelines and regulatory requirements (e.g., API, ISO standards) to ensure continued accuracy and safety.

Documentation and Record Keeping

Maintain accurate records throughout the product lifecycle:

– Shipping Documentation: Include commercial invoices, packing lists, certificates of origin, and compliance certificates.

– Installation Records: Log installation date, location, technician, calibration data, and commissioning reports.

– Maintenance Logs: Document all inspections, calibrations, repairs, and component replacements.

– Traceability: Retain batch/serial numbers for full traceability in case of recalls or audits.

Adherence to this guide supports operational safety, regulatory compliance, and product reliability for Tank Liquid Level Indicators across all stages of deployment.

Conclusion for Sourcing a Tank Liquid Level Indicator

In conclusion, selecting the appropriate tank liquid level indicator requires a careful evaluation of several key factors, including the type of liquid, operating environment, required accuracy, installation constraints, and budget considerations. Various technologies—such as float switches, ultrasonic sensors, capacitive probes, pressure transducers, and magnetostrictive level indicators—offer distinct advantages depending on the application.

After assessing technical specifications, reliability, maintenance needs, and long-term cost-effectiveness, it is recommended to source a level indicator that aligns with both current operational requirements and potential future scalability. Emphasis should be placed on durable, industry-compliant devices from reputable suppliers to ensure safety, precision, and minimal downtime.

Ultimately, investing in a well-suited liquid level indicator enhances process efficiency, improves safety, and supports optimal tank management, making it a critical component in industrial, commercial, and municipal liquid handling systems.