The global road construction equipment market continues to expand, driven by rising infrastructure development and government investments in transportation networks. According to a report by Mordor Intelligence, the road construction equipment market was valued at USD 33.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Tandem rollers, a critical component in asphalt compaction, represent a significant segment within this market due to their efficiency in delivering uniform density and smooth surface finishes. With increasing urbanization and highway expansion projects across Asia-Pacific, North America, and the Middle East, demand for high-performance tandem rollers has surged. This growth has spurred innovation and competition among manufacturers, leading to advancements in compaction technology, fuel efficiency, and smart machine integration. As procurement teams and contractors seek reliable, high-quality equipment, identifying the leading tandem roller manufacturers becomes essential for informed decision-making in a rapidly evolving landscape.

Top 10 Tandem Roller Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Ammann Tandem Rollers

Domain Est. 1996

Website: ammann.com

Key Highlights: Series Light Tandem Rollers, Articulated Tandem Rollers, Pivot-Steer Tandem Roller. Engine Stage V / Tier 4f, Stage V / Phase III, e-Drive Technology….

#2 Tandem Vibratory Rollers

Domain Est. 1993

Website: cat.com

Key Highlights: Cat Tandem Vibratory Rollers are available in a range of sizes and configurations to meet any application. Large double-drums are simple to set up for ……

#3 EZ Loader

Domain Est. 1995

Website: ezloader.com

Key Highlights: Trusted Boat Trailers Built For Every Load. Buy EZ Loader roller or bunk style trailers. Choose from galvanized, powder-coated, aluminum, wet-painted systems ……

#4 Asphalt rollers

Domain Est. 1996

Website: bomag.com

Key Highlights: BOMAG tandem rollers – at home on construction sites worldwide. TANDEM ROLLERS with a weight of up to 5 t are suitable for repair and finishing work in road ……

#5 Vibratory Tandem Rollers

Domain Est. 1997

Website: jcb.com

Key Highlights: JCB’s vibratory tandem road rollers are designed to be class leaders. Our compaction equipment is developed for reliability, low cost of operation, operation ……

#6 Tandem Rollers

Domain Est. 1997

Website: bobcat.com

Key Highlights: Compact, intuitive and dependable – Bobcat Tandem Rollers are versatile tools available with off-set or in-line “one-side-free” configuration for working right ……

#7 Tandem road roller

Domain Est. 1999

Website: directindustry.com

Key Highlights: Light tandem rollers for soil compaction and asphalt patching. Ideal for footpaths and repair work as well as finishing work in road construction. Compact BOMAG ……

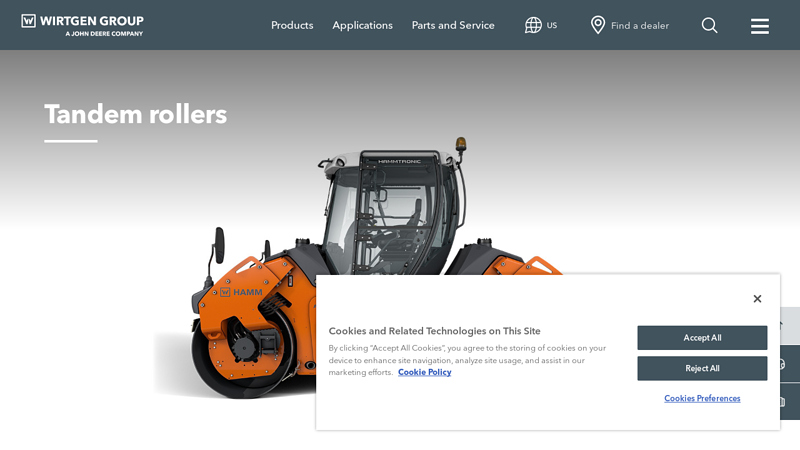

#8 Tandem rollers for asphalt compaction

Domain Est. 2000

Website: wirtgen-group.com

Key Highlights: The articulated compact rollers in the HD CompactLine, with operating weights of between 1.4 and 4.5 t, are real all-rounders for asphalt construction, ……

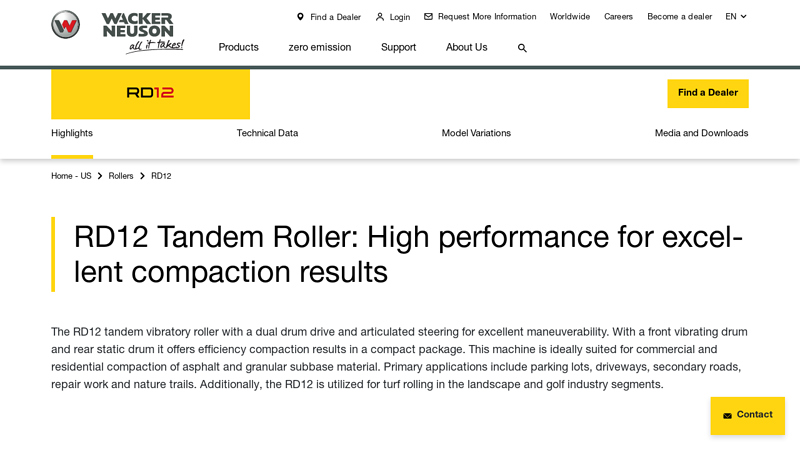

#9 RD12 Tandem Roller

Domain Est. 2007

Website: wackerneuson.com

Key Highlights: The RD12 tandem vibratory roller from Wacker Neuson features a dual drum drive and articulated steering for excellent maneuverability. Learn more!…

#10 TANDEM ROLLERS

Domain Est. 2022

Website: rhinoequipment.us

Key Highlights: Tandem Rollers, designed for superior compaction and precision. Achieve smooth, durable surfaces with reliable performance and efficiency….

Expert Sourcing Insights for Tandem Roller

2026 Market Trends for Tandem Rollers: Key Drivers and Outlook

The tandem roller market is poised for steady evolution by 2026, shaped by technological innovation, sustainability imperatives, and shifting infrastructure demands. As a critical piece of compaction equipment in road construction and civil engineering, tandem rollers are adapting to meet the needs of a more efficient, data-driven, and environmentally conscious industry.

Growing Infrastructure Investment Driving Demand

A primary catalyst for the tandem roller market through 2026 is the global surge in infrastructure development. Governments in emerging economies—particularly in Asia-Pacific (India, Southeast Asia) and Africa—are prioritizing road networks, urban expansion, and transportation upgrades. Simultaneously, developed regions like North America and Europe are focusing on renovating aging infrastructure. This sustained capital expenditure directly increases demand for reliable compaction equipment, with tandem rollers remaining essential for asphalt paving projects due to their superior finish and compaction efficiency.

Technological Advancements: Smart Compaction and Automation

By 2026, smart compaction technology will become increasingly mainstream in tandem rollers. Integration of GPS, IoT sensors, and real-time data analytics enables Intelligent Compaction (IC) systems that monitor and document compaction levels, ensuring uniform density and reducing rework. Machine learning algorithms will optimize roller pass patterns and vibration settings, enhancing productivity. Furthermore, advancements in automation, including semi-autonomous operation and remote monitoring, will improve site safety and operational efficiency, especially on large-scale projects.

Sustainability and Electrification Gaining Momentum

Environmental regulations and corporate sustainability goals are pushing manufacturers toward greener solutions. By 2026, the adoption of electric and hybrid tandem rollers is expected to accelerate. Battery-electric models, already emerging in the market, offer zero tailpipe emissions, reduced noise pollution, and lower operating costs—critical advantages in urban construction zones and environmentally sensitive areas. While challenges around battery life and charging infrastructure remain, ongoing improvements in energy density and fast-charging solutions will enhance their viability for mainstream use.

Focus on Operator Comfort and Safety

Enhanced operator cabins featuring improved ergonomics, climate control, noise reduction, and advanced visibility will remain a competitive differentiator. Safety features such as rear-view cameras, collision avoidance systems, and automated shutdown mechanisms will become standard, aligning with stricter workplace safety regulations and reducing accident risks on busy construction sites.

Regional Market Dynamics and Competitive Landscape

The Asia-Pacific region is expected to dominate market growth due to rapid urbanization and government-led infrastructure programs. North America and Europe will see steady demand driven by modernization efforts and the adoption of high-tech, fuel-efficient models. Market competition will intensify, with leading manufacturers like Volvo CE, Bomag, Caterpillar, and Ammann focusing on innovation, service support, and fleet connectivity solutions to maintain market share.

Conclusion

By 2026, the tandem roller market will reflect a convergence of performance, intelligence, and sustainability. Demand will be robust, supported by global infrastructure initiatives, while technological innovation—especially in electrification and smart systems—will redefine industry standards. Companies that prioritize eco-friendly designs, digital integration, and operational efficiency will be best positioned to lead in this evolving landscape.

Common Pitfalls When Sourcing Tandem Rollers (Quality and Intellectual Property)

Sourcing tandem rollers, especially for critical applications in industries like paper, steel, or printing, involves navigating several potential pitfalls related to both quality and intellectual property (IP). Overlooking these can lead to performance issues, legal risks, and increased total cost of ownership.

Poor Material and Manufacturing Quality

One of the most frequent pitfalls is selecting tandem rollers based solely on upfront cost without evaluating the quality of materials and manufacturing processes. Low-quality rollers may use substandard steel, improper heat treatment, or inadequate surface finishes, leading to premature wear, deformation, or failure under load. This results in frequent downtime, higher maintenance costs, and potential damage to associated machinery.

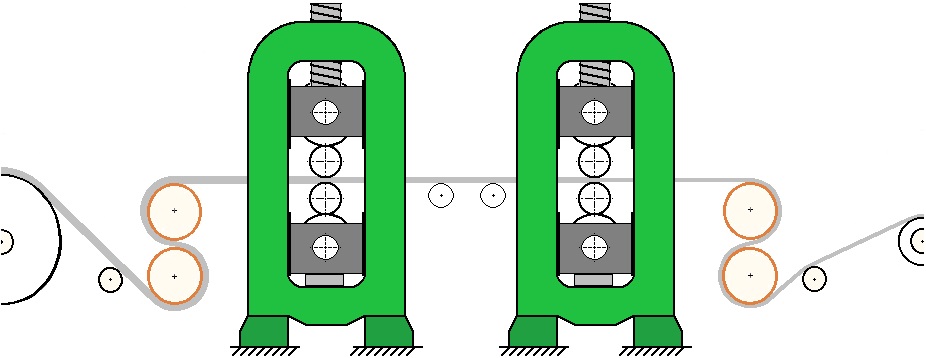

Inadequate Balancing and Precision Tolerances

Tandem rollers must operate at high speeds with minimal vibration. Poorly balanced rollers or those manufactured outside tight tolerance specifications (e.g., runout, concentricity) can cause excessive vibration, uneven material processing, and accelerated bearing wear. Sourcing from suppliers without proper precision machining capabilities or quality control processes increases the risk of receiving out-of-spec components.

Lack of Traceability and Certification

Reputable applications require material traceability (e.g., mill test certificates) and compliance with industry standards (e.g., ISO, ASTM). Sourcing rollers without proper documentation makes it difficult to verify quality, troubleshoot failures, or meet regulatory requirements—especially in regulated industries such as food processing or pharmaceuticals.

Intellectual Property Infringement

A significant but often overlooked risk is inadvertently sourcing tandem rollers that infringe on patented designs or proprietary technologies. Some suppliers may replicate patented roller geometries, bearing arrangements, or coating technologies without authorization. Purchasing such components exposes the buyer to legal liability, potential product seizures, and reputational damage.

Use of Counterfeit or Reverse-Engineered Components

In global supply chains, there is a risk of receiving counterfeit rollers that falsely claim to be from a trusted manufacturer. These components may mimic branding but lack the original engineering, materials, and performance characteristics. Reverse-engineered rollers, while not always illegal, often fail to meet the same reliability and safety standards as genuine parts.

Insufficient IP Due Diligence in Supplier Selection

Buyers often fail to assess whether their roller supplier respects IP rights. Choosing suppliers with no transparency about design origins or who offer “compatible” or “equivalent” parts at suspiciously low prices increases the risk of IP violations. Conducting due diligence—such as reviewing supplier certifications, design ownership, and manufacturing history—is essential to mitigate this risk.

Hidden Costs from Poor Quality and IP Risks

While low-cost rollers may appear economical initially, the long-term costs of poor quality—downtime, repairs, replacement parts—and potential legal expenses from IP infringement can far exceed the initial savings. A total cost of ownership analysis that includes these risks is crucial when sourcing tandem rollers.

To avoid these pitfalls, prioritize suppliers with proven quality management systems (e.g., ISO 9001), transparent manufacturing practices, full documentation, and a clear commitment to respecting intellectual property rights.

Logistics & Compliance Guide for Tandem Roller

Overview

A tandem roller, also known as a double-drum roller, is a type of compaction equipment used in road construction and civil engineering projects. Proper logistics planning and compliance with international and local regulations are essential for the safe, timely, and legal transportation and operation of this heavy machinery.

Pre-Shipment Preparation

Ensure the tandem roller is thoroughly cleaned, drained of excess fuel and hydraulic fluids (as per shipping standards), and secured with protective covers. Complete all required documentation, including an equipment specification sheet, bill of sale, and export declaration.

Packaging & Securing

Due to its weight and dimensions, tandem rollers are typically shipped as break-bulk cargo or on flat-rack containers. Use steel chains or heavy-duty straps to secure the machine to the transport platform. Wheel chocks and anti-sway braces must be employed to prevent movement during transit.

Transportation Modes

Tandem rollers can be transported via road, rail, or sea, depending on the project location. For international shipments, sea freight using roll-on/roll-off (RoRo) vessels or containerized transport is common. Domestic moves often use low-boy trailers with appropriate permits for oversized loads.

Export & Import Compliance

Verify compliance with export controls in the country of origin (e.g., U.S. Department of Commerce regulations). Importing countries may require conformity assessments, customs duties, and value-added tax (VAT) payments. Obtain an Importer Security Filing (ISF) for shipments entering the United States.

Required Documentation

Essential documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Export/Import Licenses (if applicable)

– Equipment Conformity Certificate (e.g., CE, EPA)

Regulatory Standards

Ensure the tandem roller meets environmental and safety standards such as:

– EPA Tier 4 Final (for U.S. emissions compliance)

– CE Marking (for EU market access)

– ISO 15867 (safety requirements for soil compactors)

Customs Clearance

Work with a licensed customs broker to facilitate clearance. Provide accurate HS (Harmonized System) codes—typically 8429.40 for road rollers. Duties and taxes vary by country and free trade agreements.

On-Site Handling & Unloading

Use certified lifting equipment and trained personnel for unloading. Conduct a post-arrival inspection to verify no transport damage occurred. Retain shipping records for warranty and compliance audits.

Environmental & Safety Compliance

Dispose of any residual fluids in accordance with local environmental regulations (e.g., EPA or equivalent). Operators must be trained and certified per OSHA (U.S.) or local safety standards before machine operation.

Recordkeeping & Audit Trail

Maintain detailed records of shipment, compliance certifications, maintenance logs, and operator training. These documents are essential for audits and regulatory inspections.

Conclusion for Sourcing a Tandem Roller

Sourcing a tandem roller requires a comprehensive evaluation of project requirements, machine specifications, budget constraints, and long-term operational needs. After assessing various suppliers, models, and pricing options, it is evident that selecting the right tandem roller involves balancing upfront costs with durability, performance, and after-sales support. Opting for reputable manufacturers with strong service networks ensures reliability, reduced downtime, and better return on investment. Additionally, considering factors such as compaction efficiency, maneuverability, maintenance requirements, and compliance with environmental standards further enhances project productivity and quality. Ultimately, a well-informed sourcing decision will contribute to improved asphalt compaction results, project timelines, and overall construction efficiency.