The global textile and apparel market is undergoing a steady resurgence, driven by increasing consumer demand for custom-fit clothing and sustainable fashion. According to Mordor Intelligence, the global apparel market is projected to grow at a CAGR of 5.3% from 2023 to 2028, fueling parallel demand for specialized tools across the garment production pipeline. One such essential—often overlooked yet critical in precision tailoring—is tailor’s chalk. Used for marking fabric without permanent damage, tailor chalks are indispensable in both industrial and artisanal sewing environments. With the custom tailoring segment expanding alongside the rise of made-to-measure services and boutique fashion houses, the demand for high-quality, fade-resistant, and fabric-safe tailor chalks has surged. As of 2023, Grand View Research reported that the global textile auxiliary chemicals market—which includes marking tools and related products—is expected to grow at a CAGR of 5.2% through 2030, underscoring the importance of reliable suppliers in this niche. In this evolving landscape, identifying leading tailor chalk manufacturers with a consistent track record in quality, innovation, and distribution becomes vital for professionals and businesses alike. Below, we explore the top six manufacturers shaping the tailor chalk industry with performance-driven products backed by market relevance and user trust.

Top 6 Tailor Chalks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tailor Chalks Manufacture

Domain Est. 2001

Website: b2bchinasources.com

Key Highlights: All qualify products of tailor chalks made in China & Taiwan, connecting reliable Chinese manufacturers, suppliers, exporters, factories & contract ……

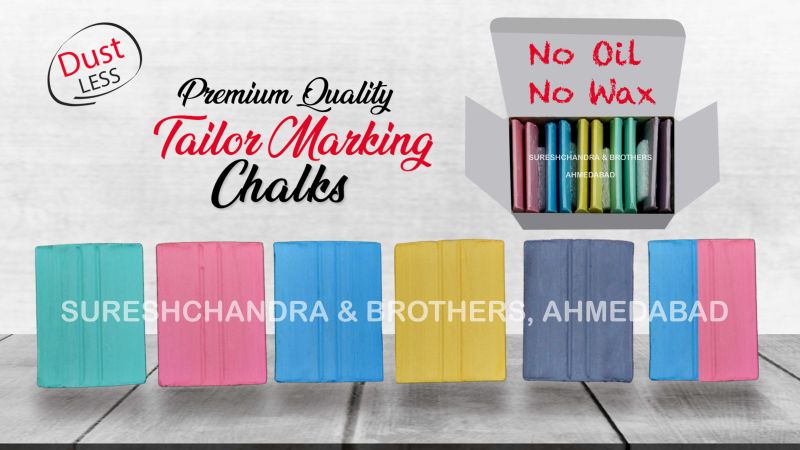

#2 Dustless Chalk Manufacturer,Slate Pencils Exporter,Supplier from …

Domain Est. 2021

Website: tailoringchalk.com

Key Highlights: SURESHCHANDRA & BROTHERS, is an eminent Manufacturer,Supplier and Exporter of Dustless Chalk and Slate Pencils based in Ahmedabad, Gujarat, India….

#3 Tailor Marking Chalk Manufacturer Exporter Supplier from …

Website: tailorchalk.co.in

Key Highlights: Leading Manufacturers, Exporters, Wholesaler and Trader of Dustless Tailor Marking Chalk, Gold Double Colour Tailor Marking Chalk and GOLD Tailor Chalk Double ……

#4 Colonial Tailor’s Chalk

Domain Est. 2001 | Founded: 1906

Website: colonialtailorschalk.com

Key Highlights: Colonial Tailor’s Chalk. Made in the USA since 1906. Our Best-Selling Products. Perfection Master Tailor’s Chalk. Quick View….

#5 New Tailor Chalk Products

Domain Est. 2003 | Founded: 1985

Website: manufacturers.com.tw

Key Highlights: Founded in 1985, Donwei Machinery Industry Company has taken the lead in Taiwan for sewing machinery parts including Tailor Chalk, cutting mats, scissors, ……

#6 Shop

Domain Est. 2024

Website: rajaraniproduct.com

Key Highlights: … Double Color Tailor Chalk. Out of stock Sale · Double Color Tailor Chalk. Rs. 20.00 Rs. 35.00. Embroidery Tool Kit. Out of stock ……

Expert Sourcing Insights for Tailor Chalks

2026 Market Trends for Tailor Chalks

The tailor chalk market, while a niche segment within the broader sewing and apparel industry, is poised for notable shifts by 2026 driven by sustainability, digital integration, and evolving consumer behaviors. Here are the key trends shaping its future:

Growing Demand for Eco-Friendly and Biodegradable Materials

By 2026, environmental consciousness will significantly influence purchasing decisions. Consumers and professional tailors alike are increasingly favoring tailor chalks made from natural, non-toxic, and biodegradable ingredients such as rice flour, clay, or plant-based waxes. Brands that prioritize sustainable sourcing, plastic-free packaging, and clear labeling of compostable components will gain a competitive edge. Regulatory pressure and green certifications may further accelerate this shift, making eco-design a standard rather than a differentiator.

Expansion in the Home Sewing and DIY Fashion Movement

The resurgence of homemade clothing, mending, and upcycling—fueled by social media platforms like TikTok and Instagram—will continue to boost demand for accessible sewing tools. Tailor chalks, as essential marking tools, will benefit from this democratization of garment creation. In 2026, expect increased product innovation targeting hobbyists, including colorful, easy-to-use chalk variants and starter kits bundled with other sewing essentials. Educational content partnerships (e.g., with craft influencers) will be key marketing channels.

Product Diversification and Specialization

The market will see a rise in specialized tailor chalk formulations catering to specific fabrics (e.g., chalks for denim, silk, or stretch fabrics) and application needs (e.g., water-soluble, air-erasable, or heat-erasable). Dual-ended chalk markers and ergonomic designs will appeal to both professionals and enthusiasts seeking precision and convenience. Custom branding opportunities for boutique ateliers and fashion schools may also emerge as a B2B growth segment.

E-Commerce and Direct-to-Consumer Dominance

Online retail will remain the primary sales channel for tailor chalks by 2026, especially through marketplaces like Amazon, Etsy, and brand-owned websites. Enhanced product visuals, customer reviews, and video demonstrations will be crucial for conversion. Subscription models for replenishment and bundling with digital sewing patterns may gain traction among frequent users.

Integration with Digital Design and Pattern-Making Tools

As digital sewing technology advances, tailor chalks may play a complementary role in hybrid workflows. For example, chalks could be marketed alongside apps that generate printable or projected patterns, where physical marking is still needed for alignment or adjustments. While augmented reality and smart fabric markers are emerging, traditional chalks will retain relevance due to their simplicity, affordability, and tactile precision.

In summary, the 2026 tailor chalk market will be defined by sustainability, user-centric innovation, and alignment with broader trends in circular fashion and digital craftsmanship. Companies that adapt to these shifts with eco-conscious, versatile, and digitally integrated offerings will be best positioned for growth.

Common Pitfalls When Sourcing Tailor Chalks: Quality and Intellectual Property Concerns

Sourcing tailor chalks—commonly used in the fashion and textile industries for marking fabric—can present several challenges, particularly regarding product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable supply, brand integrity, and legal compliance.

Quality-Related Pitfalls

Inconsistent Composition and Performance

Not all tailor chalks are created equal. Sourcing from unverified suppliers may result in chalks made with low-grade materials that crumble easily, fail to mark fabric clearly, or leave permanent stains. Poorly formulated chalks may also fade too quickly or not wipe off cleanly, compromising garment construction.

Lack of Color Accuracy and Range

Mismatched or inconsistent colors can disrupt workflow, especially when specific shades are required for different fabric types. Suppliers may offer limited or poorly labeled color options, making it difficult to maintain consistency across production batches.

Poor Packaging and Shelf Life

Tailor chalks exposed to moisture or improperly stored during shipping can degrade. Inadequate packaging—such as flimsy boxes or absence of moisture barriers—can lead to breakage or reduced usability before the product reaches end users.

Non-Compliance with Safety and Environmental Standards

Some chalks may contain harmful substances like lead or toxic dyes, especially if sourced from regions with lax regulations. Failure to meet REACH, CPSIA, or other safety standards can result in product recalls or legal issues.

Intellectual Property (IP) Risks

Trademark and Brand Infringement

Sourcing generic or unbranded tailor chalks may seem cost-effective, but counterfeit or imitation products can infringe on established trademarks (e.g., brands like Dritz or Prym). Unintentionally distributing such products exposes your business to legal liability and reputational damage.

Copycat Designs and Packaging

Suppliers may mimic the appearance, labeling, or packaging of well-known tailor chalk brands to appear legitimate. This not only violates IP rights but can also mislead customers and erode trust in your sourcing practices.

Lack of IP Due Diligence in Private Labeling

When creating a private-label product, it’s essential to ensure that the design, name, and packaging are original or properly licensed. Failing to conduct IP clearance checks can lead to cease-and-desist letters or litigation from rights holders.

Unclear Supplier Agreements on IP Ownership

If you’re customizing tailor chalks (e.g., with unique shapes, colors, or branding), the contract with the supplier should clearly define who owns the resulting IP. Ambiguity can result in disputes over design rights or usage restrictions.

By proactively addressing these quality and IP-related pitfalls—through vetted suppliers, product testing, compliance verification, and legal review—businesses can source tailor chalks that meet performance standards and safeguard their brand integrity.

Logistics & Compliance Guide for Tailor Chalks

Tailor chalks are specialized marking tools used in the textile and garment industry. Proper logistics and compliance management are essential to ensure product safety, regulatory adherence, and efficient distribution. This guide outlines key considerations for handling, transporting, and complying with regulations related to tailor chalks.

Product Classification and Regulatory Oversight

Tailor chalks are typically composed of natural or synthetic materials such as clay, wax, or chalk-based compounds. Depending on their formulation, they may fall under the regulatory scope of consumer products, cosmetics, or industrial supplies. In most jurisdictions, they are considered low-risk but may still be subject to labeling, safety, and environmental requirements.

- Globally Harmonized System (GHS): If tailor chalks contain any hazardous substances (e.g., solvents or pigments), they must be classified and labeled according to GHS standards.

- Consumer Product Safety Commission (CPSC) – USA: Ensure compliance with general product safety standards, especially if marketed for use by children or in educational settings.

- REACH & CLP Regulations – EU: Confirm that all chemical components are registered under REACH and properly classified and labeled under CLP (Classification, Labelling and Packaging).

Packaging and Labeling Requirements

Proper packaging and labeling are critical for compliance and safe handling.

- Primary Packaging: Use moisture-resistant and durable materials to prevent smudging or breakage.

- Labeling: Include essential information such as:

- Product name and description

- Manufacturer or distributor details

- Batch or lot number

- Expiry date (if applicable)

- Safety warnings (e.g., “Avoid inhalation of dust,” “Keep out of reach of children”)

- Compliance marks (e.g., CE marking in the EU)

- Multilingual Labels: For international shipments, provide labels in the official language(s) of the destination country.

Transportation and Storage

Tailor chalks are generally non-hazardous but require careful handling to maintain quality.

- Storage Conditions:

- Store in a cool, dry place away from direct sunlight and extreme temperatures.

- Avoid high humidity to prevent softening or clumping.

-

Keep sealed in original packaging until distribution.

-

Transportation:

- Classify under UN 3480 (Lithium batteries not applicable) or as a general consumer product unless otherwise specified.

- Use sturdy, crush-resistant packaging to prevent breakage during transit.

- Follow IATA, IMDG, or ADR regulations only if hazardous components are present.

- Maintain proper documentation, including commercial invoices, packing lists, and safety data sheets (SDS) when required.

Import/Export Compliance

When shipping internationally, ensure adherence to customs and import regulations.

- HS Code Classification: Tailor chalks typically fall under HS Code 9610.00 (Slates and slat pencils; crayons, tailor’s chalks and similar articles). Confirm with local customs authorities for accuracy.

- Import Duties & Tariffs: Check duty rates and preferential trade agreements (e.g., USMCA, EU free trade agreements) to minimize costs.

- Documentation: Prepare accurate documentation including:

- Bill of Lading or Air Waybill

- Commercial Invoice

- Certificate of Origin (if required)

- SDS (if applicable)

Environmental and Sustainability Considerations

- Waste Disposal: Tailor chalks are generally non-toxic but should be disposed of in accordance with local waste management regulations. Avoid littering or uncontrolled disposal.

- Sustainable Sourcing: Prioritize suppliers that use responsibly sourced raw materials and eco-friendly packaging.

- Recyclability: Encourage recyclable or biodegradable packaging materials to reduce environmental impact.

Quality Assurance and Traceability

- Batch Tracking: Implement a system to track production batches for quality control and recall management.

- Testing: Conduct periodic quality checks for consistency, colorfastness, and break resistance.

- Compliance Audits: Regularly review logistics and compliance procedures to align with evolving regulations.

Summary

Effective logistics and compliance for tailor chalks involve accurate classification, proper labeling, safe storage and transport, and adherence to international trade regulations. By following this guide, businesses can ensure the safe and lawful distribution of tailor chalks while minimizing risks and maintaining customer trust.

In conclusion, sourcing tailor chalks requires careful consideration of quality, supplier reliability, cost-efficiency, and specific end-use requirements. By evaluating suppliers based on material composition, color variety, ease of use, and customer reviews, businesses can ensure they procure a product that meets both performance and budgetary needs. Establishing strong relationships with reputable suppliers, whether local or international, enhances supply chain stability and supports consistent production. Additionally, prioritizing eco-friendly and sustainable options can align sourcing decisions with broader corporate social responsibility goals. Ultimately, a strategic and well-researched approach to sourcing tailor chalks contributes to improved operational efficiency and customer satisfaction in the fashion and textile industries.