The global textile market, particularly the segment for specialty lining fabrics such as taffeta, has experienced steady growth due to rising demand from the apparel and fashion industries. According to Mordor Intelligence, the global textile market was valued at USD 1.1 trillion in 2023 and is projected to grow at a CAGR of approximately 5.2% from 2024 to 2029. A key driver within this expansion is the increasing need for high-quality lining materials that offer durability, smooth texture, and aesthetic appeal—attributes for which taffeta lining fabric is particularly prized. Taffeta, traditionally made from silk or synthetic fibers like polyester, is widely used in luxury garments, bridal wear, and tailored outerwear. As garment manufacturers emphasize fit, comfort, and finish, demand for reliable taffeta lining suppliers continues to rise, especially in Asia-Pacific, which remains the dominant production hub. With sustainability and technical innovation shaping sourcing decisions, leading taffeta lining fabric manufacturers are investing in eco-friendly production methods and performance-enhancing finishes. Based on market presence, production capacity, innovation, and global reach, the following eight manufacturers stand out as key players in the taffeta lining fabric industry.

Top 8 Taffeta Lining Fabric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Taffeta Lining

Domain Est. 2023

Website: yns-chine.com

Key Highlights: Factory Price 100% polyester taffeta fabric lining waterproof shading 210t taffeta fabric for Curtain tent · Factory Price 100% polyester taffeta fabric lining ……

#2 Taffeta Fabric Manufacturers

Domain Est. 2012

Website: goodada.com

Key Highlights: Taffeta Fabric Manufacturers. Goodada puts you in direct contact with Taffeta Fabric suppliers and manufacturers from around the world….

#3 taffeta lining fabric Manufacturer & Supplier in China

Domain Est. 2016

Website: dotextile.com

Key Highlights: Taffeta lining is characterized by its amazing strength and endurance, first of all. Because the fabric is meant to be so durable to use on a daily basis, it’s ……

#4 Deadstock Taffeta Lining Fabric Royal

Domain Est. 1992

Website: minerva.com

Key Highlights: Free delivery over $200 30-day returnsFree delivery when you spend US$200.00. Deadstock Taffeta Lining Fabric Royal. US$8.99. yard. Qty….

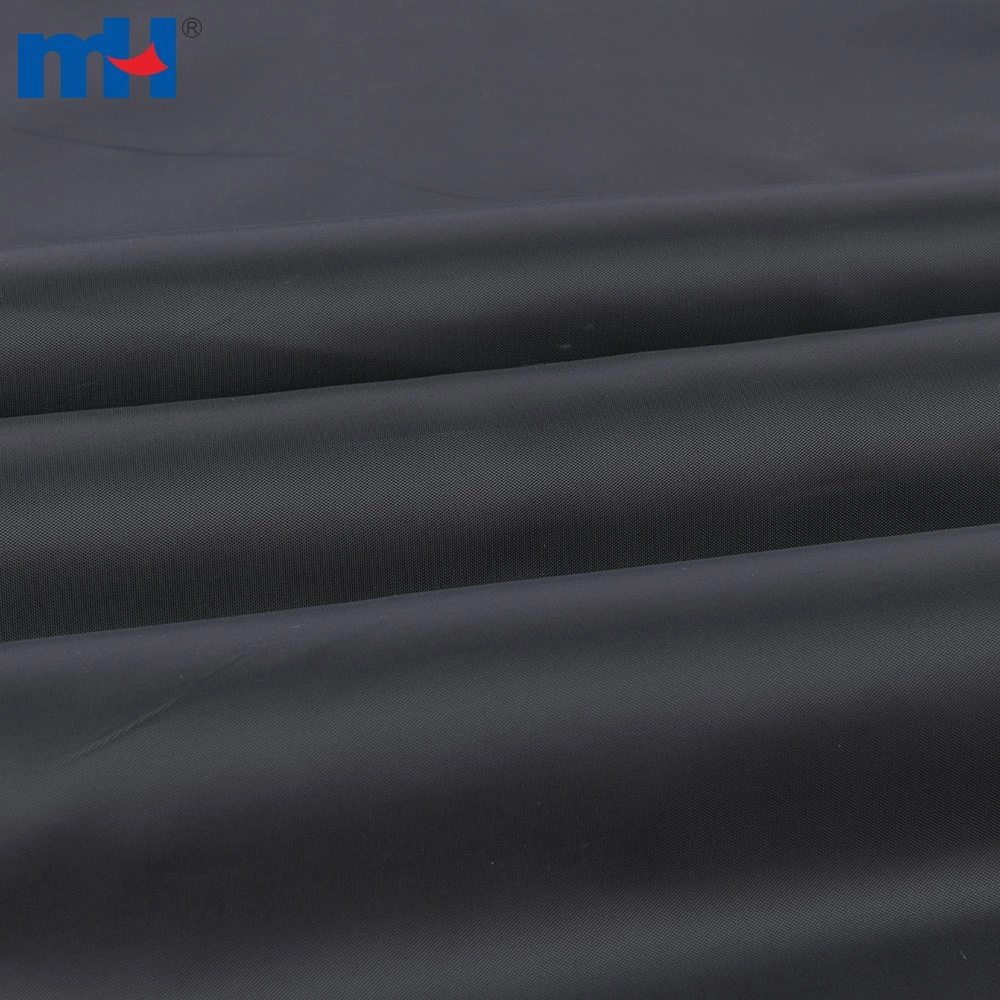

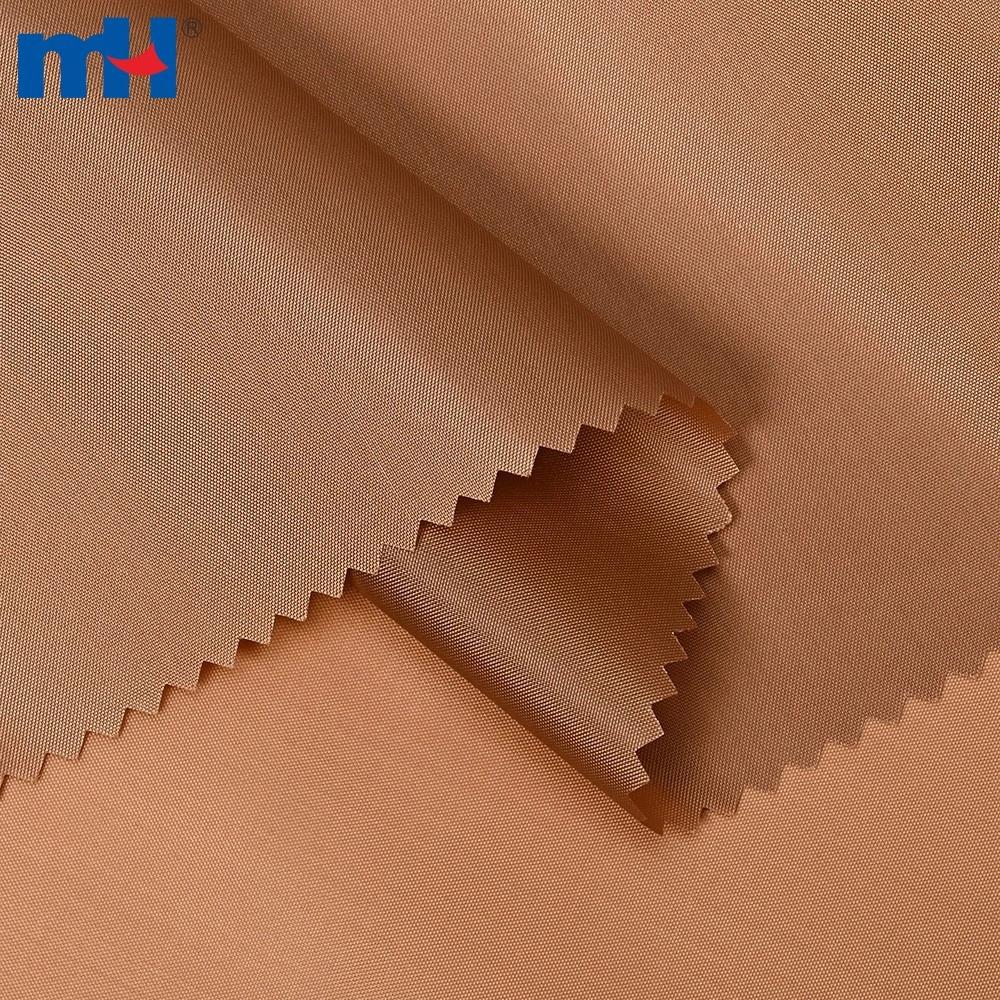

#5 MH Wholesale 100 Polyester Taffeta Lining Fabric for Workwear

Domain Est. 2001

Website: mh-chine.com

Key Highlights: MH Taffeta fabric is used for clothing linings, jackets, down jackets, workwear, luggage, tents, shower curtains, and tablecloths….

#6 Taffeta Fabric By The Yard

Domain Est. 2014

Website: fabricwholesaledirect.com

Key Highlights: Free delivery over $99Taffeta fabric is a luxurious fabric that’s crisp, shiny, & popularly used to sew elegant dresses, gowns, & evening wear. Shop taffeta fabric online!…

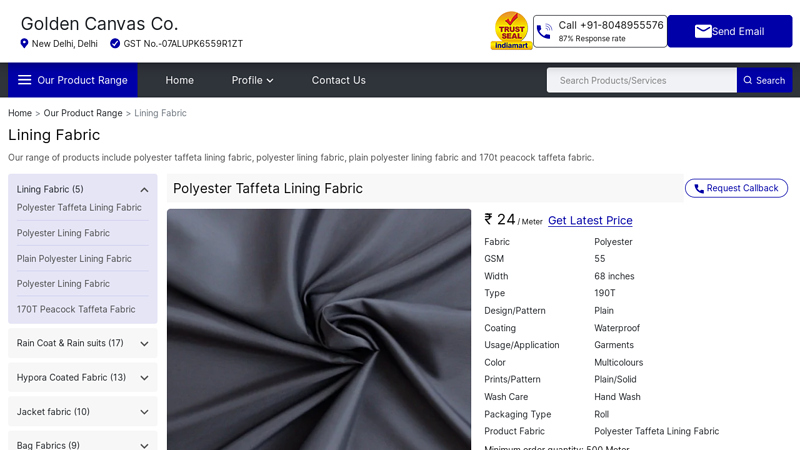

#7 Lining Fabric

Domain Est. 2016

Website: goldencanvas.in

Key Highlights: Product Fabric: Polyester Taffeta Lining Fabric; Minimum Order Quantity: 500 Meter. We have a big range of fabric for manufacturing Car & Bike body covers ……

#8 210T Lining Polyester Taffeta Fabric

Domain Est. 2017

Website: kmtextilesupplier.com

Key Highlights: Product Name, Polyester Taffeta Fabric. Model No. KMC-032. Style, Plain. Composition, 100%polyester. Weight, 60GSM. Width, 58″. MOQ, 3000m. Sample, A4 Size….

Expert Sourcing Insights for Taffeta Lining Fabric

2026 Market Trends for Taffeta Lining Fabric

Rising Demand for Sustainable and Eco-Friendly Materials

By 2026, the taffeta lining fabric market is expected to see a significant shift toward sustainability. Consumers and fashion brands alike are prioritizing eco-conscious production, driving demand for taffeta linings made from recycled polyester, bio-based fibers, and low-impact dyes. Certifications such as GRS (Global Recycled Standard) and OEKO-TEX will become key differentiators, as brands seek to align with environmental, social, and governance (ESG) goals. Innovations in biodegradable taffeta alternatives may also emerge, catering to circular fashion models.

Growth in High-End Fashion and Bridal Wear

The luxury apparel sector, particularly bridal gowns, evening wear, and tailored formal garments, will continue to be a primary driver for taffeta lining fabric. Taffeta’s crisp texture, excellent drape, and ability to add structure make it ideal for designer collections. As global demand for premium fashion grows—especially in emerging markets like China, India, and the Middle East—suppliers will focus on offering high-quality, customizable taffeta linings in a wide range of colors and finishes.

Technological Advancements in Fabric Performance

In 2026, expect increased integration of performance-enhancing technologies in taffeta linings. Moisture-wicking, anti-static, thermal-regulating, and wrinkle-resistant treatments will be incorporated to improve comfort and functionality, particularly in transitional and outerwear. Smart textiles may also begin to influence the market, with taffeta linings embedded with temperature sensors or RFID tags for brand authentication and supply chain tracking.

Supply Chain Localization and Resilience

Following global disruptions in recent years, brands are reshoring or nearshoring textile production to mitigate risks. This trend will impact the taffeta lining market, with increased regional manufacturing in North America, Europe, and Southeast Asia. Localized production reduces lead times and transportation emissions, supporting sustainability goals while improving responsiveness to fast-changing fashion cycles.

Competitive Pressure from Alternative Linings

Taffeta will face growing competition from lightweight alternatives such as cupro, viscose, and microfiber linings, which offer softer hand feel and better breathability. To maintain market share, taffeta producers will need to innovate by enhancing softness, reducing noise (the classic “rustle”), and improving eco-profiles. Hybrid blends combining taffeta with natural or recycled fibers may gain traction.

E-Commerce and Customization Trends

The expansion of online fashion retail will encourage demand for customizable and on-demand taffeta lining solutions. Digital platforms will enable designers and small brands to order small batches with custom colors, widths, or finishes. 3D sampling and digital fabric libraries will streamline the design process, reducing waste and accelerating time-to-market.

In summary, the 2026 taffeta lining fabric market will be shaped by sustainability, technological innovation, and evolving consumer preferences. Success will depend on adaptability, transparency, and the ability to blend tradition with modern performance and environmental standards.

Common Pitfalls When Sourcing Taffeta Lining Fabric (Quality & Intellectual Property)

Sourcing taffeta lining fabric involves navigating both material quality concerns and intellectual property (IP) risks. Overlooking these aspects can lead to product failures, delays, legal disputes, and reputational damage. Here are key pitfalls to watch for:

Quality-Related Pitfalls

Inconsistent Fabric Weight and Thickness

Taffeta varies in weight (measured in grams per square meter or mommes). Sourcing without clear specifications can result in linings that are too heavy (causing garment stiffness) or too light (leading to poor drape and durability). Inconsistencies between batches can compromise final product uniformity.

Poor Color Fastness and Dye Lot Variations

Low-quality dyes or improper finishing can cause fading, bleeding, or color transfer—especially problematic when in contact with delicate fabrics. Inadequate batch control may result in visible shade differences across production runs, leading to mismatched garments.

Lack of Proper Finishing Treatments

Taffeta should have anti-static, moisture-wicking, or wrinkle-resistant finishes depending on the end use. Skipping or poorly applying these treatments can result in linings that cling, feel uncomfortable, or require excessive care.

Substandard Fiber Composition

While polyester is common, some suppliers may substitute lower-grade polymers or blend in inferior fibers to cut costs. This affects luster, strength, and softness. Always verify fiber content through lab testing or certifications.

Insufficient Fabric Strength and Seam Slippage

Low tenacity yarns or loose weaves can lead to tearing during garment construction or wear. Seam slippage—where threads pull apart at stitched seams—is a frequent issue with poorly constructed taffeta, particularly in high-stress areas.

Intellectual Property (IP)-Related Pitfalls

Unauthorized Use of Branded or Patented Textures

Some taffeta weaves, finishes, or performance technologies are protected by patents or trademarks (e.g., specific anti-static or eco-friendly treatments). Sourcing fabrics that mimic these without license exposes buyers to infringement claims.

Counterfeit or Replica Fabrics

Suppliers may falsely advertise premium or branded taffeta (e.g., dupes of luxury mill fabrics). These replicas often fall short in quality and violate IP rights. Always verify mill authenticity and request provenance documentation.

Design Infringement in Printed or Embellished Taffeta

When sourcing printed linings, ensure the patterns, logos, or artwork are either original or properly licensed. Using copyrighted or trademarked designs—even on internal linings—can lead to legal action.

Lack of IP Compliance in Supply Chain

Even if your supplier appears legitimate, they may source materials from unauthorized subcontractors. Conduct due diligence to confirm IP compliance down the supply chain, especially in regions with weak IP enforcement.

Mitigation Strategies

- Clearly define technical specifications (weight, fiber content, finish, color fastness standards).

- Request lab test reports (e.g., for colorfastness, pilling, tensile strength).

- Conduct sample testing and pre-production approvals.

- Vet suppliers for IP compliance; use contracts that include IP indemnification clauses.

- Work with reputable mills or certified suppliers, especially for specialized or branded fabrics.

Avoiding these pitfalls ensures durable, high-performing taffeta linings while protecting your brand from legal and quality risks.

Logistics & Compliance Guide for Taffeta Lining Fabric

Overview

Taffeta lining fabric, a lightweight, crisp woven textile typically made from silk, acetate, or synthetic fibers like polyester, is widely used in garment manufacturing for linings in jackets, dresses, and coats. Proper logistics planning and regulatory compliance are essential to ensure quality, timely delivery, and adherence to international trade standards.

Classification & HS Code

The Harmonized System (HS) code for taffeta lining fabric depends on fiber composition and finish:

– Polyester Taffeta: 5407.42 or 5407.43 (depending on weight and width)

– Acetate Taffeta: 5407.61

– Silk Taffeta: 5007.20

Accurate classification is critical for determining import duties, taxes, and regulatory requirements in the destination country.

Packaging & Handling

- Roll Packaging: Taffeta fabric is typically wound on cardboard tubes with protective plastic wrapping to prevent creasing, dust, and moisture.

- Labeling: Each roll must be clearly labeled with product details (fiber content, color, width, length, batch number), country of origin, and care instructions.

- Palletization: Rolls should be securely stacked on wooden or plastic pallets, shrink-wrapped to prevent shifting during transit.

- Storage Conditions: Store in a dry, temperature-controlled environment away from direct sunlight and humidity to prevent mildew or fiber degradation.

Transportation & Shipping

- Mode of Transport: Ocean freight is most common for bulk shipments due to cost efficiency; air freight may be used for urgent or sample orders.

- Container Requirements: Use dry, clean, and ventilated containers. Desiccant bags are recommended to reduce moisture risk.

- Documentation: Essential documents include:

- Commercial Invoice

- Packing List

- Bill of Lading (or Air Waybill)

- Certificate of Origin

- Textile Declaration (fiber content)

- Lead Times: Plan for 2–6 weeks for ocean freight depending on origin and destination, plus customs clearance time.

Import Regulations & Compliance

- Textile Regulations: Comply with labeling laws (e.g., FTC in the U.S., EU Textile Regulation 1007/2011) requiring accurate fiber content and country of origin.

- REACH & SVHC: Ensure compliance with EU REACH regulations regarding Substances of Very High Concern (SVHC), especially for dyes and chemical treatments.

- Flammability Standards: Some end-use applications may require compliance with flammability standards (e.g., CPAI-84 for tents, though less common for linings).

- Country-Specific Requirements:

- USA: FTC Care Labeling Rule, CBP import procedures

- EU: CE marking not required for linings, but full traceability and chemical compliance are mandatory

- UK: UKCA marking considerations post-Brexit; adherence to GB regulations

Quality Assurance & Testing

- Pre-Shipment Inspection: Conduct quality checks for color consistency, width, weight, and fabric defects (snags, holes, shading).

- Laboratory Testing: Recommended tests include:

- Fiber content analysis (via quantitative chemical analysis)

- Colorfastness (to rubbing, washing, light)

- Shrinkage testing

- pH level (to ensure skin safety)

- Compliance Certifications: Provide test reports (e.g., Oeko-Tex Standard 100, if applicable) to demonstrate product safety.

Sustainability & Ethical Compliance

- Environmental Standards: Ensure manufacturing processes comply with environmental regulations (e.g., wastewater treatment for dyeing).

- Social Compliance: Verify suppliers adhere to ethical labor practices (e.g., SA8000, BSCI audits).

- Recyclability: For polyester taffeta, consider offering recycled fiber options (e.g., rPET) to meet sustainability goals.

Risk Management

- Supply Chain Transparency: Maintain traceability from fiber source to finished fabric.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP).

- Insurance: Secure cargo insurance covering damage, loss, or delay during transit.

- Contingency Planning: Identify alternative suppliers or shipping routes to mitigate disruptions.

Conclusion

Successful logistics and compliance for taffeta lining fabric require attention to classification, proper handling, regulatory alignment, and quality control. Partnering with experienced freight forwarders and certified suppliers ensures smooth international trade and product integrity. Regular audits and documentation updates help maintain compliance across evolving global standards.

In conclusion, sourcing taffeta lining fabric requires a careful balance of quality, cost, sustainability, and supplier reliability. Taffeta, known for its crisp texture, smooth finish, and excellent drape, is a preferred choice for linings in high-end apparel, formal wear, and structured garments. When sourcing, it is essential to evaluate fabric composition (such as acetate, cupro, or silk taffeta), weight, color fastness, and environmental impact—especially as demand for eco-friendly textiles grows.

Establishing relationships with reputable suppliers, whether domestic or international, ensures consistent quality and ethical production practices. Attending trade shows, requesting samples, and verifying certifications can further support informed decision-making. Additionally, considering minimum order quantities and lead times helps align sourcing strategies with production needs and timelines.

Ultimately, a well-executed sourcing plan for taffeta lining fabric not only enhances the performance and aesthetics of the final product but also supports brand integrity, sustainability goals, and long-term supply chain efficiency.