The global flooring materials market is experiencing steady growth, driven by rising construction activities and increasing demand for durable, cost-effective installation solutions. According to Grand View Research, the global flooring market was valued at USD 321.8 billion in 2023 and is expected to expand at a compound annual growth rate (CAGR) of 5.7% from 2024 to 2030. Within this expanding landscape, tackless strips—particularly those engineered for challenging substrates like concrete—have become essential components in resilient and floating floor installations. Their role in minimizing edge curling, enabling thermal movement, and ensuring long-term carpet or laminate stability has made performance-driven tackless strips a strategic consideration for concrete-focused flooring manufacturers. As demand grows for moisture-resistant, high-adhesion solutions compatible with concrete’s unique properties, innovation in tackless strip design has accelerated. Based on technical specifications, adhesion performance, and real-world applicability, the following are the top three tackless strips tailored for use in concrete flooring manufacturing environments.

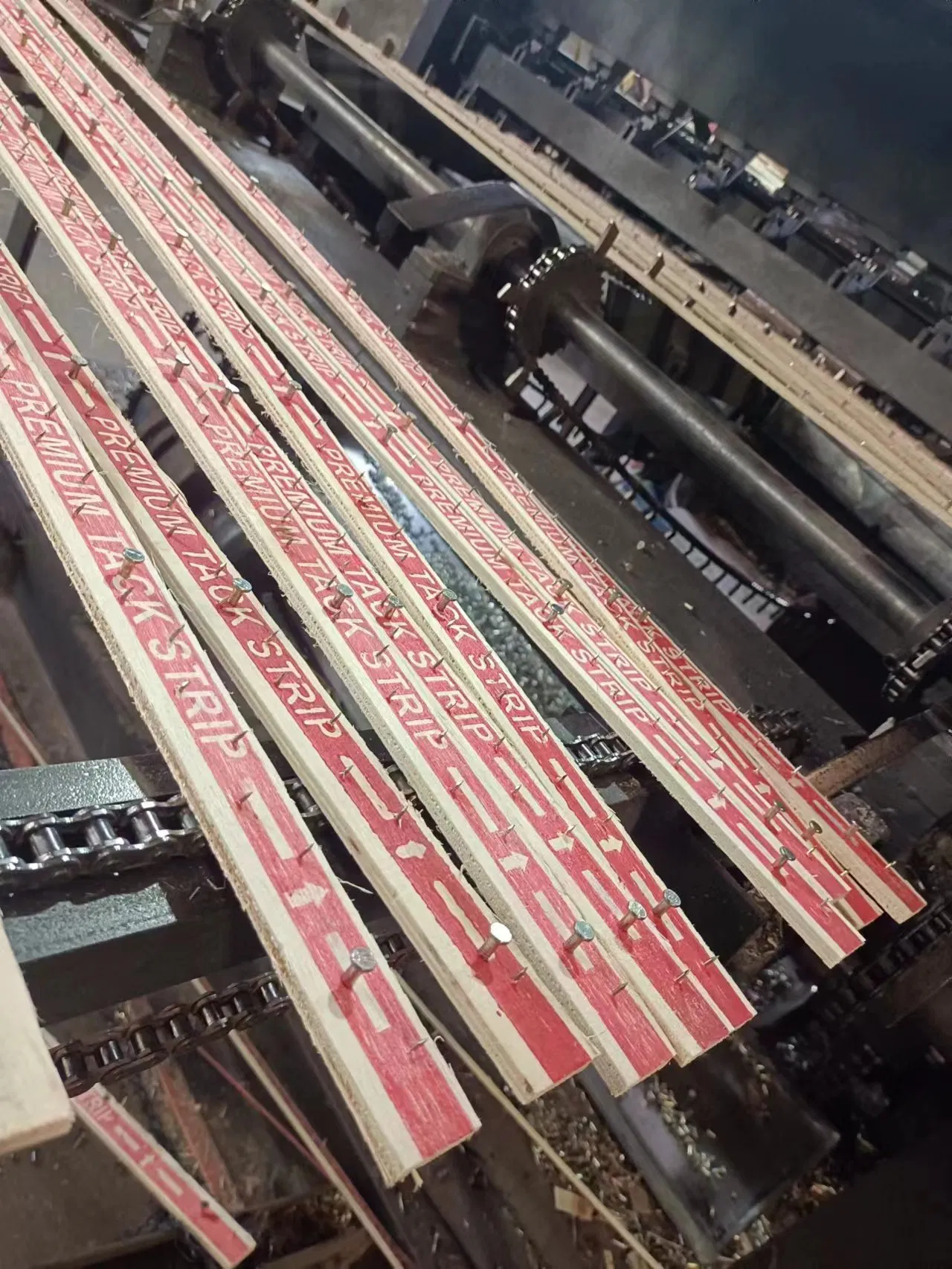

Top 3 Tackless Strips For Concrete Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Tackstrips

Domain Est. 2003

Website: powerhold.com

Key Highlights: Tackstrip & Nails 4220 7/8″ Tack Strip – Wood Substrate (14.5 Ga · Tackstrip & Nails 4240 7/8″ Tack Strip – Concrete Substrate (12 Ga · Tackstrip & Nails 4242 7/8 ……

#2 Engineered Flooring Installation Products & Tools

Domain Est. 2007

Website: traxxcorp.com

Key Highlights: Enhance flooring installations with quality tools, tapes, tack strips & moisture mitigation products. Learn more and buy from Traxx Corp now!…

#3 Power Point Regular Concrete Tack Strip 11/16″ X 12 Ga. (400

Website: galleherduffy.com

Key Highlights: Power Point Regular Concrete Tack Strip 11/16″ X 12 Ga. (400-lf). Be the first to review this product. Availability: In stock. Product#. TRXPPS4240….

Expert Sourcing Insights for Tackless Strips For Concrete

H2: 2026 Market Trends for Tackless Strips for Concrete

The global market for tackless strips used in concrete applications is poised for notable transformation by 2026, driven by advancements in construction technologies, increasing demand for durable flooring solutions, and a growing emphasis on sustainability and labor efficiency. Tackless strips—typically used to secure carpeting along the perimeter of concrete floors—are evolving from simple fastening tools into engineered solutions tailored for modern building standards.

One of the primary drivers shaping the 2026 market is the rise in commercial and residential construction, especially in emerging economies across Asia-Pacific, Latin America, and Africa. As urbanization accelerates, so does the demand for cost-effective and time-efficient flooring installation methods. Tackless strips for concrete offer a reliable anchoring system that reduces dependency on adhesives, aligning with trends toward faster project turnaround and reduced VOC emissions.

Another key trend is the integration of improved materials in tackless strip manufacturing. By 2026, manufacturers are expected to increasingly adopt high-strength polymers and corrosion-resistant alloys to enhance durability, especially in environments with high moisture exposure—common in concrete slab installations. These advancements will extend product lifespan and reduce maintenance costs, making them more attractive to contractors and property developers.

Sustainability is also influencing product development. The construction industry’s shift toward green building certifications (e.g., LEED, BREEAM) is prompting suppliers to introduce recyclable or bio-based tackless strips. Companies that prioritize eco-design and transparent supply chains are likely to gain competitive advantage in the 2026 landscape.

Furthermore, automation and precision tools in flooring installation are creating demand for standardized, easy-to-install tackless strips compatible with power-driven fastening systems. This trend supports labor efficiency and reduces human error, especially in large-scale projects like hotels, offices, and multi-family housing units built on concrete slabs.

Regionally, North America and Europe will remain dominant markets due to stringent building codes and high renovation activity. However, the fastest growth is expected in the Asia-Pacific region, where infrastructure development and rising disposable incomes are fueling demand for quality interior finishes.

In summary, the 2026 market for tackless strips for concrete will be characterized by innovation in materials, alignment with sustainable construction practices, and integration with modern installation technologies. Companies that adapt to these trends—by offering durable, eco-friendly, and installation-optimized products—are likely to lead the market.

Common Pitfalls When Sourcing Tackless Strips for Concrete (Quality and Intellectual Property)

Sourcing tackless strips for concrete applications requires careful consideration of both material quality and potential intellectual property (IP) concerns. Failing to address these aspects can lead to performance issues, legal complications, and increased project costs. Below are common pitfalls to avoid:

1. Overlooking Material Quality and Durability

One of the most frequent mistakes is selecting tackless strips that are not specifically designed for concrete substrates. Concrete environments often involve moisture, temperature fluctuations, and alkaline conditions, which can degrade substandard materials. Low-quality strips may lack UV resistance, proper tensile strength, or corrosion-resistant fastening components, leading to premature failure.

Solution: Prioritize products made from high-density polyethylene (HDPE) or other durable polymers with proven performance in concrete applications. Verify compliance with industry standards such as ASTM F710 for resilient flooring preparation.

2. Ignoring Compatibility with Subfloor Conditions

Not all tackless strips are suitable for uneven or freshly poured concrete. Strips that are too rigid or lack proper anchoring mechanisms may not secure properly, leading to carpet shifting or buckling.

Solution: Choose flexible, impact-resistant strips with aggressive anchoring teeth or dual-anchoring systems designed for variable concrete densities. Always assess the concrete subfloor’s condition before selection.

3. Falling for Counterfeit or Imitation Products

Some suppliers offer cheaper alternatives that mimic well-known branded tackless strips. These knock-offs may infringe on patented designs and often underperform due to inferior engineering.

Solution: Source directly from authorized distributors or reputable manufacturers. Verify product authenticity through batch numbers, packaging, and manufacturer certifications.

4. Violating Intellectual Property Rights

Using tackless strips that replicate patented designs—such as unique anchoring geometries, installation mechanisms, or edge profiles—without proper licensing can expose purchasers or contractors to IP infringement claims.

Solution: Conduct due diligence on product design origins. Avoid suppliers offering “generic” versions of patented systems (e.g., those resembling brands like Shaw, Mohawk, or Beaulieu). When in doubt, consult legal counsel or stick to licensed products.

5. Prioritizing Low Cost Over Long-Term Performance

While cost is a key factor, excessively cheap tackless strips often compromise on raw material quality and design integrity. This can result in higher labor costs due to rework and shorter carpet lifespan.

Solution: Perform a lifecycle cost analysis. Investing in high-quality, IP-compliant tackless strips may have a higher upfront cost but leads to better durability and fewer callbacks.

6. Inadequate Supplier Verification

Working with unverified suppliers—especially through online marketplaces—increases the risk of receiving non-compliant or counterfeit products.

Solution: Vet suppliers thoroughly. Check for industry certifications, customer reviews, and the ability to provide technical data sheets (TDS) and material safety data sheets (MSDS).

By avoiding these common pitfalls, buyers can ensure they source tackless strips for concrete that are both high-performing and legally sound.

Logistics & Compliance Guide for Tackless Strips for Concrete

Product Overview and Classification

Tackless strips for concrete are thin, durable strips typically made from plastic, metal, or composite materials. They are used in construction to secure carpeting or other floor coverings to concrete subfloors without the need for adhesives or nails. These products are often categorized under building materials or flooring accessories for regulatory and shipping purposes.

Regulatory and Safety Compliance

Ensure that tackless strips comply with relevant building codes and material safety standards. In the United States, products should meet ASTM standards for durability and performance where applicable. If made from plastic, verify compliance with EPA regulations regarding volatile organic compounds (VOCs). Additionally, confirm adherence to OSHA guidelines for workplace safety during installation.

Packaging and Handling Requirements

Tackless strips should be packaged in moisture-resistant, durable materials to prevent deformation or damage during transit. Bundles are typically secured with straps or shrink-wrapped for stability. Handle with care to avoid bending or cracking. Store in a dry, temperature-controlled environment before use to maintain product integrity.

Shipping and Transportation Guidelines

Ship via standard freight carriers capable of handling construction materials. Clearly label packages with product type, weight, and handling instructions (e.g., “Fragile,” “This Side Up”). Use pallets for bulk shipments to ensure stability and ease of loading/unloading. Confirm compliance with Department of Transportation (DOT) regulations for ground transportation of non-hazardous building materials.

Import/Export Considerations

For international shipments, classify tackless strips under the appropriate Harmonized System (HS) code—commonly 3926.30 (for plastic parts) or 7326.20 (for iron or steel parts). Provide accurate commercial invoices, packing lists, and certificates of origin. Check destination country regulations for construction product imports, including conformity assessments or local certification requirements (e.g., CE marking in the EU).

Environmental and Disposal Compliance

Tackless strips may be recyclable depending on material composition. Provide end-of-life guidance to customers, recommending separation by material type for proper recycling. Comply with local, state, and federal regulations for waste disposal, including landfill diversion targets where applicable. Avoid disposal methods that release harmful substances into the environment.

Documentation and Traceability

Maintain accurate records of material sourcing, manufacturing dates, batch numbers, and compliance certifications. Provide safety data sheets (SDS) if required, particularly for composite or treated materials. Ensure lot traceability to support quality control and warranty claims.

Installation and End-User Compliance

Educate installers and contractors on proper use in accordance with manufacturer instructions and building codes. Confirm compatibility with concrete substrates and adherence to fire safety standards when installed in commercial or residential buildings. Recommend use of personal protective equipment (PPE) during installation to comply with job site safety protocols.

In conclusion, sourcing tackless strips for concrete installations requires careful consideration of compatibility, durability, and moisture resistance. Since concrete subfloors are prone to moisture and lack the ability to securely hold nails like wood, it is essential to select tackless strips specifically designed for concrete applications—typically featuring strong, corrosion-resistant fasteners such as concrete nails or adhesive backing. Working with reputable suppliers who provide high-quality, code-compliant products ensures proper carpet installation and long-term performance. Additionally, verifying local building codes and environmental conditions will guide the right choice of materials. Overall, investing time in sourcing the appropriate tackless strips for concrete not only enhances installation efficiency but also contributes to the longevity and professionalism of the finished floor.