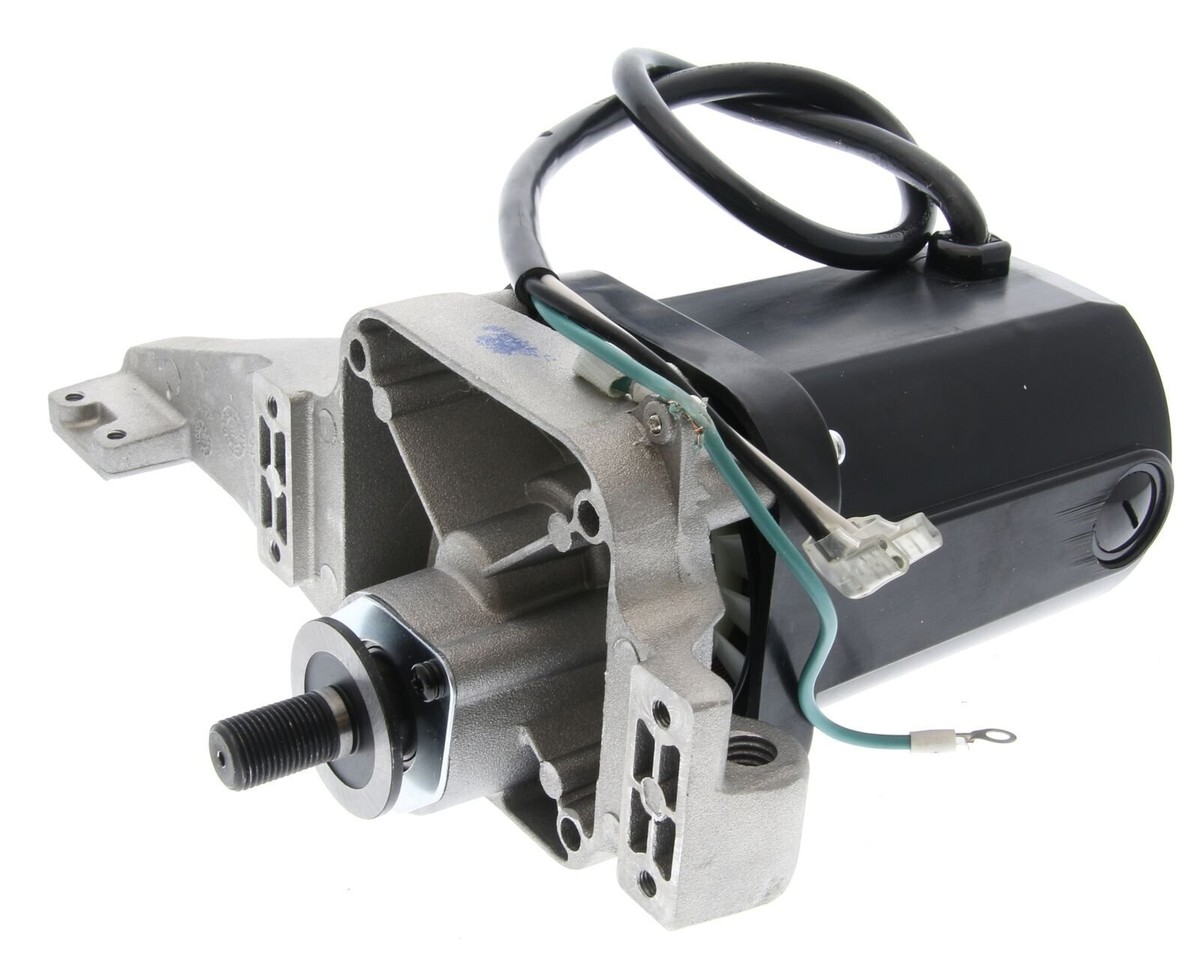

The global table saw motor market has experienced steady growth, driven by increasing demand in residential construction, woodworking industries, and do-it-yourself (DIY) projects. According to a 2023 report by Mordor Intelligence, the power tools market—which includes key components like table saw motors—is projected to grow at a CAGR of over 5.2% from 2023 to 2028, fueled by advancements in motor efficiency, rising adoption of cordless technology, and expansion in emerging markets. Additionally, Grand View Research reported in 2022 that the global power tools market size was valued at USD 30.5 billion and is expected to expand at a CAGR of 4.8% through 2030, with electric motors for stationary tools like table saws representing a significant segment. As manufacturers prioritize performance, durability, and energy efficiency, innovation in motor design—particularly in brushless DC and induction motors—has become a key competitive differentiator. Against this backdrop, the following nine companies have emerged as leading table saw motor manufacturers, combining engineering excellence with scalable production to meet evolving industry demands.

Top 9 Table Saw Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Gemini Saw Company Inc.

Domain Est. 1997

Website: geminisaw.com

Key Highlights: Learn more about our experience as precision saw manufacturers. Over the years, we’ve become one of the leading providers of precision saws worldwide….

#2 Table Saw Motors

Domain Est. 2004

Website: ereplacementparts.com

Key Highlights: 1–2 day delivery · 365-day returnsShop for the OEM replacement Motors you need to repair your Table Saw. eReplacementParts.com offers genuine manufacturer parts, repair help, and …

#3 All Manufacturers » Table Saw

Domain Est. 1999

Website: eurtonelectric.com

Key Highlights: Eurton Electric rewinds armatures, field coils, other coils, rotors and stators for all types of electric motors and electrical equipment in every industry ……

#4 Fusion Tablesaws

Domain Est. 1996

Website: lagunatools.com

Key Highlights: Free delivery · 30-day returnsLaguna Tools table saws are designed to maximize efficiency and promote user safety. Explore our line of table saws today to learn more….

#5 Delta Machinery

Domain Est. 1996

Website: deltamachinery.com

Key Highlights: Today, DELTA continues to design and manufacture high-quality stationary and benchtop tools — from table saws and band saws to jointers, planers, lathes, and ……

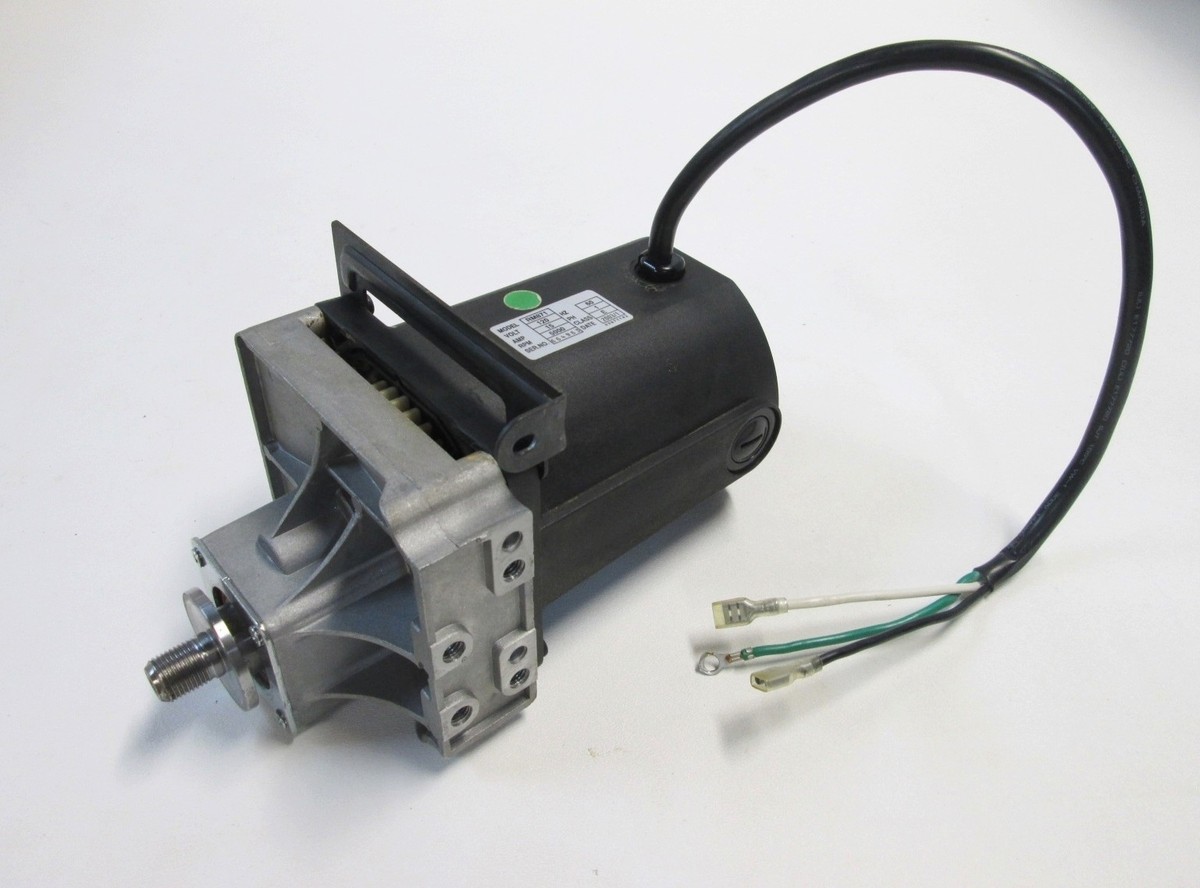

#6 Table Saw Motors

Domain Est. 1996

Website: sqone.com

Key Highlights: 30-day returnsElectric motor designed for woodworking equipment such as lathes, table saws, planers, etc. Totally enclosed designs prevent motor problems caused by wood dust ……

#7 Original Saw Company

Domain Est. 1998

Website: originalsaw.com

Key Highlights: Original Saw Company is the industry leader in American made cutting equipment. We manufacture Radial Arm Saws, Beam Saws, Crosscut Power Saws, Saw Extension ……

#8 Tagged “Type: Table Saw”

Domain Est. 2000

Website: store.evolutionpowertools.com

Key Highlights: Free delivery · Free 45-day returnsBlade Size, 10 In. Warranty, 3 Years. Power, Corded. Max. Cut Depth, 3-1/4”. Max. Miter. Left: 45°; Right: 45°. Add to cart….

#9 Sliding table saws and edge banding machines

Domain Est. 2018

Website: altendorfgroup.com

Key Highlights: We bring Altendorf sliding table saws and edge banding machines together under one roof. We know the needs and requirements of the companies exactly….

Expert Sourcing Insights for Table Saw Motor

H2: 2026 Market Trends for Table Saw Motors

The global table saw motor market is poised for significant evolution by 2026, driven by technological innovation, shifting consumer preferences, and sustainability imperatives. Key trends shaping this sector include:

-

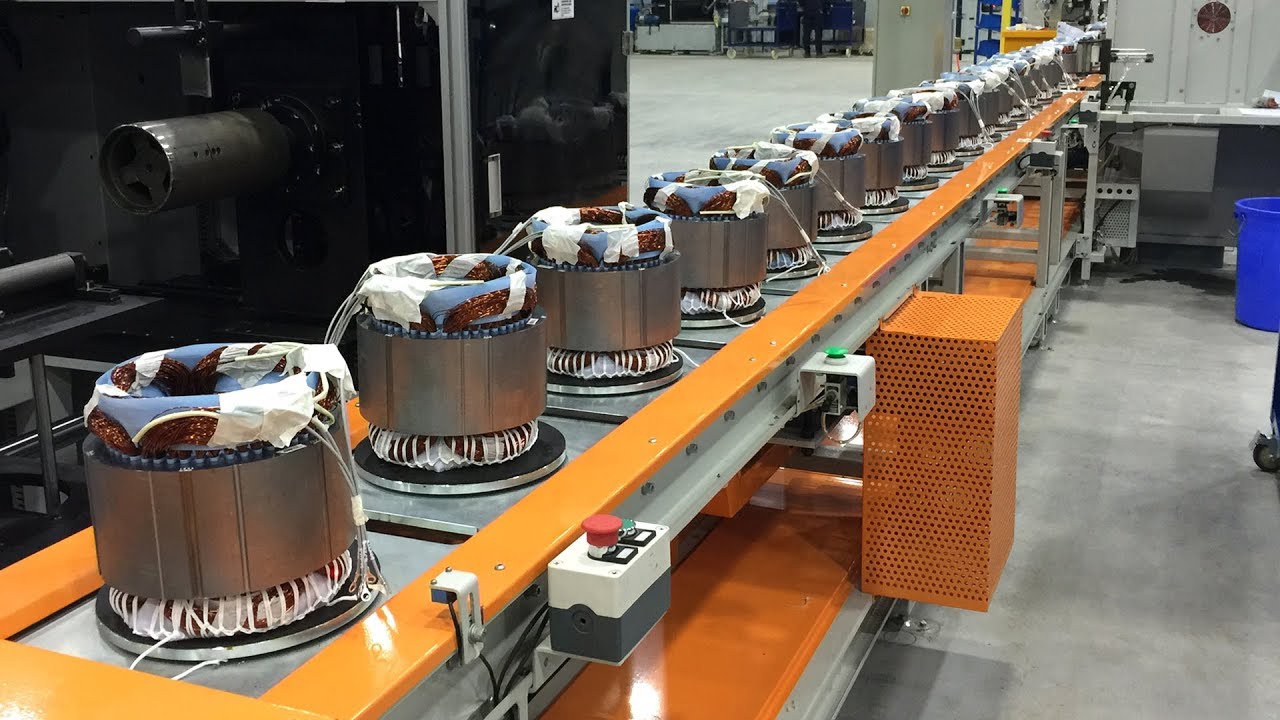

Increased Adoption of Brushless DC Motors

By 2026, brushless DC (BLDC) motors are expected to gain substantial market share due to their superior energy efficiency, longer lifespan, and reduced maintenance compared to traditional brushed motors. Their precision control and improved torque delivery make them ideal for high-end table saws used in professional woodworking and construction. -

Integration with Smart Technology

Connectivity and smart features are becoming increasingly prevalent. Table saw motors are being embedded with IoT capabilities, enabling remote monitoring, performance diagnostics, and predictive maintenance via mobile applications. This trend supports the broader Industry 4.0 movement in manufacturing and DIY tool ecosystems. -

Focus on Energy Efficiency and Regulatory Compliance

Stricter energy efficiency regulations in North America and the EU are pushing manufacturers to develop motors that comply with standards such as ENERGY STAR and the Ecodesign Directive. This is accelerating R&D in high-efficiency induction and permanent magnet motors, particularly in commercial-grade table saws. -

Demand for Compact and Lightweight Designs

As portability becomes a key selling point, especially among contractors and DIY enthusiasts, motor designs are trending toward smaller footprints and lighter weight without sacrificing power. Advances in materials (e.g., aluminum housings, high-strength composites) are enabling this shift. -

Growth in Cordless Table Saws

The rise of lithium-ion battery technology is fueling demand for cordless table saws. Motor manufacturers are optimizing power-to-weight ratios and thermal management systems to meet the performance expectations of corded models, expanding use in remote or mobile job sites. -

Sustainability and Circular Economy Initiatives

By 2026, sustainability will play a central role in motor production. Companies are exploring recyclable materials, modular designs for easier repair, and remanufacturing programs. This aligns with consumer and regulatory demands for environmentally responsible products. -

Regional Market Expansion

Emerging markets in Asia-Pacific and Latin America are witnessing growing construction and woodworking activity, creating new demand for affordable, durable table saw motors. Localized manufacturing and cost-optimized motor designs are expected to cater to these regions.

In summary, the 2026 table saw motor market will be defined by innovation in efficiency, intelligence, and sustainability, with manufacturers adapting to both technological advancements and evolving end-user needs across residential, commercial, and industrial segments.

Common Pitfalls When Sourcing a Table Saw Motor (Quality and IP Rating)

When sourcing a table saw motor, overlooking key quality and Ingress Protection (IP) rating factors can lead to premature failure, safety hazards, and reduced performance. Here are the most common pitfalls to avoid:

Choosing Motors Without Adequate IP Rating

A frequent mistake is selecting a motor with an insufficient IP rating for the workshop environment. Table saws generate dust, moisture, and occasional coolant splashes. A motor with a low IP rating (e.g., IP20 or unsealed) allows sawdust and debris to enter the windings, causing overheating, insulation breakdown, and eventual motor failure. Always opt for a motor with at least IP55 protection to ensure effective resistance against dust ingress and water jets.

Prioritizing Price Over Build Quality

Sourcing based solely on cost often leads to substandard motors with inferior materials—such as low-grade copper windings, weak bearings, or poor insulation. These compromises result in reduced efficiency, shorter lifespan, and higher maintenance costs. Investing in a high-quality motor from a reputable manufacturer ensures better thermal management, durability, and consistent performance under load.

Overlooking Thermal Protection Features

Many low-cost motors lack built-in thermal overload protection. Without this safety feature, the motor is at risk of overheating during prolonged use or high-load cutting, which can permanently damage windings. Always verify that the motor includes thermal cut-off or is designed for continuous duty (S1 rating) with adequate cooling mechanisms.

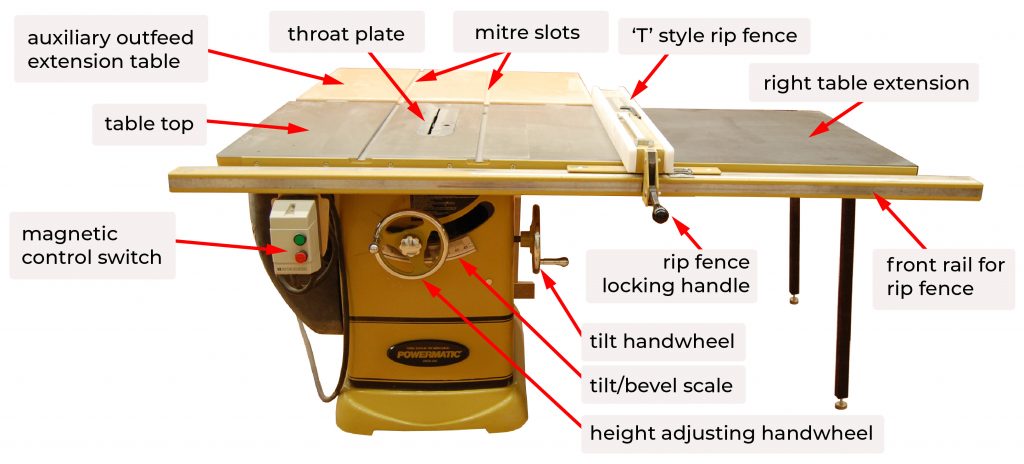

Ignoring Shaft and Mounting Compatibility

Even a high-quality motor is useless if it doesn’t mechanically fit your table saw. Common errors include mismatched shaft diameter, incorrect keyway size, or incompatible mounting flanges (e.g., D-flange vs. B14). Always cross-check the motor’s mechanical dimensions and mounting specifications with your saw’s requirements before purchase.

Assuming All “Industrial” Motors Are Suitable

Not all industrial-rated motors are designed for the variable loads and duty cycles of table saws. Some may be optimized for constant-speed applications like pumps or fans, lacking the torque characteristics needed for wood cutting. Ensure the motor is rated for intermittent or continuous high-torque applications typical in woodworking.

Neglecting Noise and Vibration Levels

Low-quality motors often produce excessive noise and vibration due to imprecise balancing or poor bearing quality. This not only affects operator comfort but can also compromise cut accuracy and lead to premature wear of saw components. Look for motors designed for low vibration and acoustic emissions, especially in precision woodworking environments.

Avoiding these pitfalls ensures you select a reliable, long-lasting table saw motor that enhances performance and safety in your workshop.

Logistics & Compliance Guide for Table Saw Motor

Product Classification & HS Code

Identify the correct Harmonized System (HS) code for the table saw motor to ensure accurate customs clearance and tariff assessment. Common classifications include:

– 8501.31 or 8501.32: For AC motors with output under 750W or over 750W, respectively.

– Confirm classification with local customs authorities or a licensed customs broker based on motor specifications (voltage, power, type).

Packaging & Labeling Requirements

Ensure motors are securely packaged to prevent damage during transit:

– Use corrugated cardboard or wooden crates with internal cushioning (foam, bubble wrap).

– Label each package with:

– Product name and model number

– Manufacturer information

– Power rating (voltage, wattage, frequency)

– Safety warnings (e.g., “High Voltage,” “Do Not Open”)

– CE, UL, or other relevant certification marks (if applicable)

Regulatory Compliance

Adhere to international and destination-specific regulations:

– Electrical Safety: Comply with standards such as:

– UL 1012 (USA) – Power Units Other Than Class 2

– IEC 60034 (International) – Rotating Electrical Machines

– EN 60204-1 (EU) – Safety of machinery – Electrical equipment

– EMC Compliance: Meet electromagnetic compatibility standards (e.g., FCC Part 15 in the U.S., EMC Directive 2014/30/EU in the EU).

– RoHS & REACH (EU): Ensure restricted hazardous substances are below permissible limits.

– Energy Efficiency: Comply with local energy performance regulations (e.g., DOE rules in the U.S.).

Import/Export Documentation

Prepare essential paperwork for smooth cross-border movement:

– Commercial Invoice (with detailed product description, value, and HS code)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Test Reports or Compliance Certificates (e.g., UL, CE)

– Import License (if required by destination country)

Transportation & Handling

Follow best practices for safe shipping:

– Use freight carriers experienced in handling electrical components.

– Clearly mark packages as “Fragile” and “This Side Up.”

– Avoid exposure to moisture, extreme temperatures, and physical shock.

– For international air freight, comply with IATA regulations for lithium content (if motor includes electronic controls with batteries).

Country-Specific Requirements

Verify local market entry rules:

– United States: UL certification typically required; FCC certification for motors with electronic controls.

– European Union: CE marking mandatory; compliance with Low Voltage Directive (2014/35/EU) and EMC Directive.

– Canada: CSA certification often required; adherence to CSA C22.2 No. 0 and No. 1.

– Australia: Must meet AS/NZS standards; require RCM (Regulatory Compliance Mark).

After-Sales & Warranty Considerations

- Include multilingual user manuals and safety instructions.

- Establish a local service or warranty support network if required by law (e.g., EU’s consumer rights directive).

- Maintain records for traceability and potential product recalls.

Environmental & Disposal Compliance

- Provide information on proper end-of-life disposal per WEEE (EU) or local e-waste regulations.

- Design for recyclability and avoid prohibited materials.

Ensure all logistics partners and distributors are aware of compliance obligations to mitigate risk and ensure smooth market access.

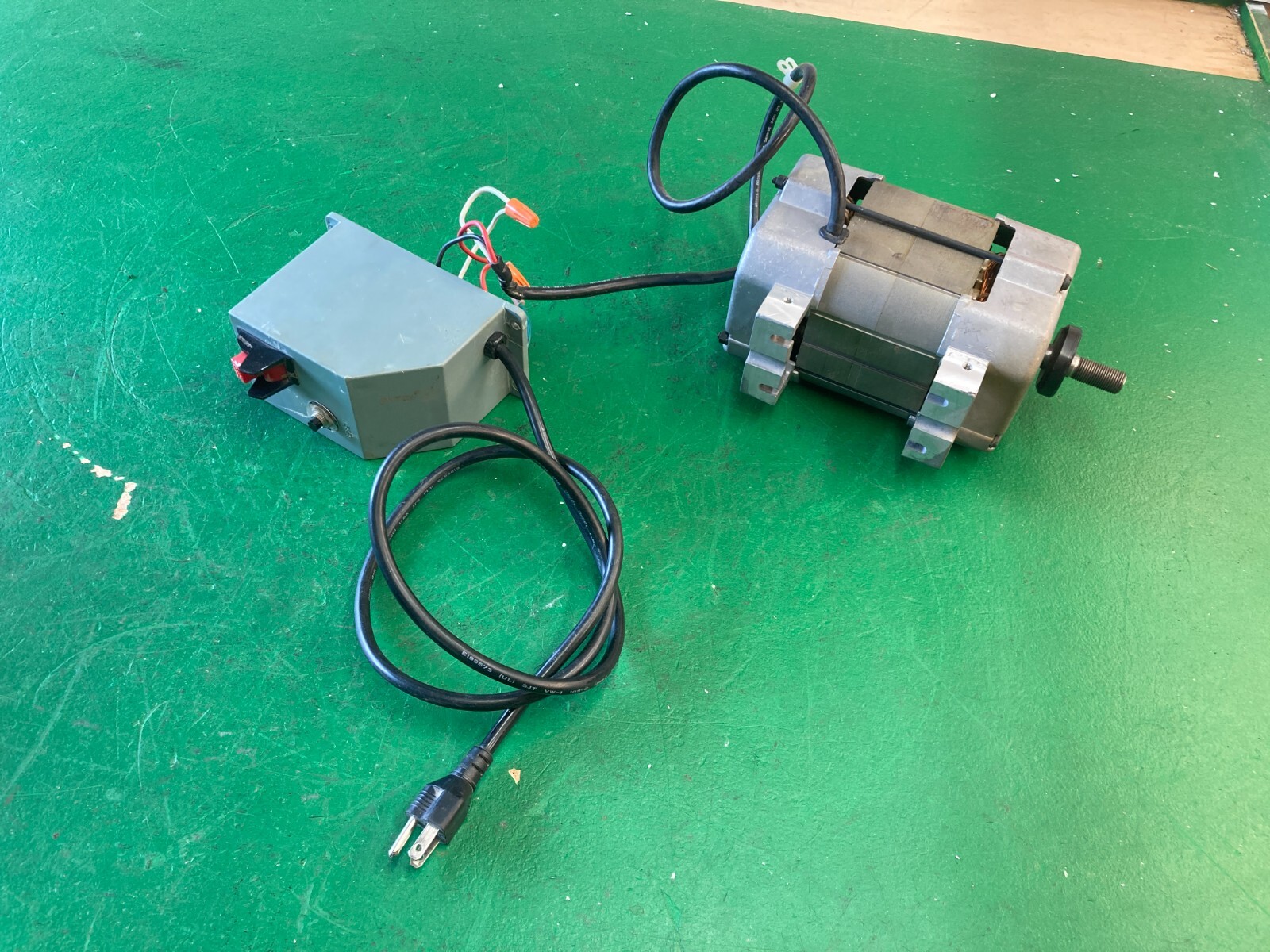

In conclusion, sourcing a table saw motor requires careful consideration of several key factors, including power requirements (horsepower and voltage), compatibility with the existing saw model, motor type (such as induction or universal), duty cycle, and noise levels. It is essential to match the motor specifications to the table saw’s design to ensure optimal performance, safety, and longevity. Additionally, evaluating supplier reliability, warranty, and cost-effectiveness will contribute to a successful procurement decision. Whether replacing a damaged motor or upgrading for enhanced performance, thorough research and attention to detail will result in a dependable and efficient solution for your woodworking needs.