The global turbocharger market is experiencing robust growth, driven by increasing demand for fuel-efficient engines and stringent emission regulations across the automotive and industrial sectors. According to Mordor Intelligence, the turbocharger market was valued at USD 27.8 billion in 2023 and is projected to reach USD 38.5 billion by 2029, growing at a CAGR of approximately 5.6% during the forecast period. A significant segment of this growth is attributed to T66 turbo models, widely used in heavy-duty trucks, construction equipment, and marine applications due to their optimal balance of performance, durability, and efficiency. As demand for high-output, reliable turbocharging solutions rises, manufacturers are investing heavily in advanced technologies such as variable geometry turbines and improved thermal management. In this expanding landscape, identifying the top-performing T66 turbo manufacturers becomes critical for OEMs and aftermarket suppliers aiming to meet evolving performance and regulatory standards. Based on market presence, innovation, product reliability, and global distribution, the following seven companies have emerged as leaders in the T66 turbocharger segment.

Top 7 T66 Turbo Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 T66 Compact Track Loader (Specs, Pricing & More)

Domain Est. 1997

Website: bobcat.com

Key Highlights: Redesigned with a focus on quality, the T66 R-Series compact track loader delivers powerful hydraulics, fast cycle times & increased lifting capabilities….

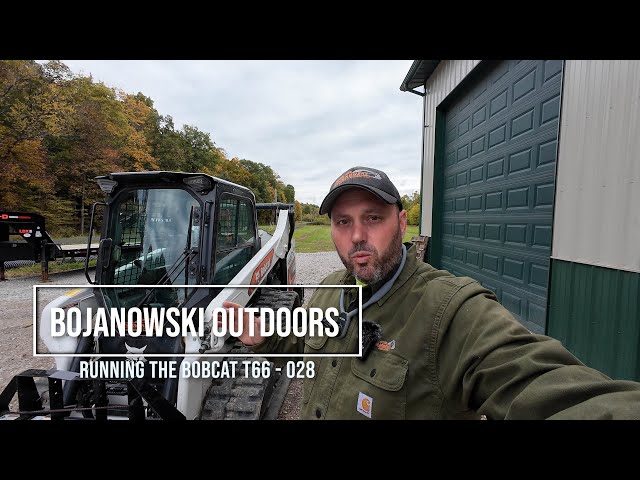

#2 Turbonetics T66 Turbocharger w/ F1 Turbine Wheel

Domain Est. 1999

#3 NE1 here running a T62, T63, T64 or even a T66 on an M3?

Domain Est. 2000

Website: bimmerforums.com

Key Highlights: I haven’t kept up entirely with the BMW forced induction crowd over the past year or so, and I’m dying to see if anyone has tried these turbos….

#4 396165084 Boost by PWTurbo 6165 T66 Turbocharger .84 A/R 56 …

Domain Est. 2011

#5 TWS Motorsport T66

Domain Est. 2012

Website: counterspacegarage.com

Key Highlights: 7-day returnsTWS Motorsport T66-F 1pc Forged Wheel 18″ Diameter – 5×130 PCD Bolt Pattern. Price per each wheel. Wheels are SPECIAL ORDER. Products will ship out as soon as ……

#6 T66 Ball Bearing Turbocharger (German)

Domain Est. 2013

Website: turboreplacement.co.za

Key Highlights: We stock turbochargers, performance parts & accessories for most vehicles at the lowest possible prices direct to the public. We also wholesale to dealers….

#7 Outlet Turbo, 7384468

Website: parts.bobcat.eu

Key Highlights: Out of stockThis Outlet Turbo, 7384468 part is a Genuine Bobcat product for your replacement needs. It is used on the below listed machines….

Expert Sourcing Insights for T66 Turbo

H2: 2026 Market Trends Outlook for T66 Turbo

As of 2026, the market landscape for the T66 Turbo—an advanced turbocharger platform commonly used in high-performance and industrial applications—reflects significant shifts driven by evolving regulatory standards, technological innovation, and changing end-user demands. The following analysis outlines key trends shaping the T66 Turbo market during this period, with a focus on growth drivers, competitive dynamics, and emerging opportunities.

-

Increased Demand in Performance and Retrofit Markets

The T66 Turbo continues to gain traction in the performance automotive and diesel aftermarket sectors. Enthusiasts and fleet operators seeking improved horsepower, torque, and fuel efficiency are increasingly adopting T66 models due to their reliability and scalability. The retrofit market, especially in aging commercial diesel engines, is a major growth vector as operators aim to meet emissions standards without replacing entire powertrains. -

Emissions and Fuel Efficiency Regulations

Stringent global emissions standards (e.g., Euro 7, U.S. EPA 2027 guidelines) are pushing manufacturers to adopt advanced forced induction technologies. The T66 Turbo’s ability to enhance combustion efficiency aligns with these regulatory demands. Its integration with exhaust gas recirculation (EGR) and selective catalytic reduction (SCR) systems makes it a preferred solution for reducing NOx and particulate matter. -

Electrification and Hybrid Synergy

While full electrification rises in light-duty vehicles, the T66 Turbo is finding new relevance in hybrid powertrains. In mild-hybrid and range-extended electric systems, the turbocharger improves transient response and downsizing efficiency, allowing smaller engines to deliver high performance. This hybrid synergy extends the relevance of internal combustion technologies well into the mid-2020s. -

Advancements in Materials and Design

By 2026, next-generation T66 variants incorporate ceramic ball bearings, 3D-printed compressor wheels, and improved turbine aerodynamics. These innovations reduce turbo lag, increase thermal tolerance, and extend service life. Manufacturers are leveraging AI-driven computational fluid dynamics (CFD) to optimize performance across diverse operating conditions. -

Growth in Emerging Markets

Demand for T66 Turbo systems is rising in Asia-Pacific, Latin America, and Africa, where industrialization and transportation infrastructure development are accelerating. Local assembly partnerships and cost-optimized versions of the T66 are expanding market penetration in construction, mining, and agricultural machinery. -

Aftermarket and Digital Integration

The aftermarket segment is evolving with smart turbo systems. Some 2026 T66 models include embedded sensors for real-time performance monitoring, predictive maintenance alerts, and integration with engine control units (ECUs). This digital shift enhances reliability and reduces downtime, appealing to commercial operators. -

Competitive Landscape

Key players such as Garrett Motion, BorgWarner, and IHI continue to innovate around the T66 platform, with a focus on customization and application-specific tuning. Competition is intensifying, leading to modular designs that support easier integration and lower total cost of ownership.

Conclusion:

The T66 Turbo remains a pivotal technology in 2026, adapting to a transitional era in powertrain development. While long-term industry trends point toward electrification, the T66 Turbo’s role in optimizing combustion efficiency, supporting hybrid systems, and serving high-demand industrial applications ensures sustained market relevance. Continued investment in materials science, digital monitoring, and global distribution will be critical for maintaining competitiveness in this dynamic environment.

Common Pitfalls Sourcing T66 Turbo (Quality, IP)

Sourcing a T66 turbocharger—especially outside official OEM channels—comes with significant risks related to both quality and intellectual property (IP). Recognizing these pitfalls is crucial to avoid performance issues, legal exposure, and financial loss.

Poor Quality and Counterfeit Components

One of the most prevalent risks when sourcing T66 turbos is receiving substandard or counterfeit products. Many suppliers, particularly in unregulated markets, offer units labeled as “T66” that deviate significantly from original specifications.

- Inferior Materials: Counterfeit turbos often use lower-grade alloys for turbine wheels, shafts, and housings, leading to premature failure under high thermal and mechanical stress.

- Inconsistent Manufacturing Tolerances: Poor machining affects balance, aerodynamics, and efficiency, reducing performance and increasing the risk of catastrophic failure.

- Lack of Testing and Certification: Genuine turbos undergo rigorous balancing and performance validation. Many knock-offs skip these steps, increasing the likelihood of in-field failures.

- Fake Branding and Packaging: Some suppliers replicate OEM logos and packaging to mimic authenticity, making visual inspection insufficient for verification.

Intellectual Property (IP) Infringement

The T66 turbo design is protected by patents, trademarks, and technical copyrights held by the original manufacturer (typically Garrett Advancing Motion or Holset, depending on application). Sourcing non-OEM versions can expose buyers to IP risks.

- Unauthorized Replication: Many “compatible” or “replacement” T66 turbos are direct copies of patented designs, violating intellectual property rights.

- Legal Liability for Buyers: While end-users are rarely targeted, companies in regulated industries (e.g., aerospace, defense, commercial transport) may face audits or penalties for using non-compliant, IP-infringing parts.

- Supply Chain Compliance Issues: Using counterfeit or unlicensed components can breach contractual obligations with OEMs or fleet operators, resulting in warranty voidance or loss of certification.

Mitigation Strategies

To avoid these pitfalls, consider the following:

- Source from Authorized Distributors: Purchase only through OEM-authorized channels or certified resellers.

- Verify Documentation: Request and review COA (Certificate of Authenticity), serial numbers, and traceability records.

- Perform Independent Inspections: Use third-party testing for critical applications to verify material composition and performance.

- Consult Legal/Compliance Teams: Especially in regulated sectors, ensure parts sourcing aligns with IP and industry regulations.

Ignoring these risks can lead to costly downtime, safety hazards, and reputational damage—making due diligence essential when sourcing T66 turbochargers.

Logistics & Compliance Guide for T66 Turbo

This guide outlines the essential logistics and compliance considerations for the transportation, handling, and regulatory adherence related to the T66 Turbo engine. Adherence to these guidelines ensures safety, regulatory compliance, and operational efficiency throughout the supply chain.

Transportation and Packaging Requirements

The T66 Turbo must be transported in accordance with international and national hazardous materials and machinery regulations. Use only certified, impact-resistant packaging designed for turbine engines. Secure the unit with vibration-dampening materials and ensure all inlets and outlets are sealed to prevent contamination. Label packages with “Fragile,” “This Side Up,” and appropriate UN classification codes if applicable (e.g., for residual lubricants). Air, sea, and ground shipments must comply with IATA, IMDG, and ADR regulations respectively.

Export Controls and Licensing

The T66 Turbo may be subject to export control regulations under the International Traffic in Arms Regulations (ITAR) or the Export Administration Regulations (EAR), depending on its configuration and end-use. Verify the Export Control Classification Number (ECCN) prior to international shipment. Obtain necessary licenses or authorizations from the relevant government agency (e.g., U.S. Department of State or Commerce) before exporting. Maintain detailed records of all export transactions for audit purposes.

Customs Documentation and Clearance

Prepare accurate and complete customs documentation, including commercial invoice, packing list, bill of lading/air waybill, and certificate of origin. Clearly describe the T66 Turbo using standardized commodity codes (HS Code: 8411.82 or equivalent). Include engine serial number, net/gross weight, and declared value. For regulated shipments, attach export licenses or technical data authorizations. Coordinate with a licensed customs broker to ensure timely clearance and avoid delays.

Environmental and Safety Compliance

Ensure compliance with environmental regulations regarding emissions, noise, and hazardous materials. The T66 Turbo must meet applicable standards such as EPA, EASA, or local environmental codes when installed and operated. During storage and transport, prevent oil or fuel leaks by securing fluid reservoirs and using absorbent pads. Dispose of packaging and waste materials in accordance with local environmental laws.

Import Regulations and Duties

Research destination country import requirements, including conformity assessment, type approval, and registration. Some countries require pre-shipment inspection (PSI) or certification by national aviation authorities. Calculate and prepare for applicable import duties, VAT, or excise taxes. Confirm whether the T66 Turbo qualifies for duty exemptions under trade agreements or temporary import programs (e.g., ATA Carnet for exhibitions or repairs).

Storage and Handling Procedures

Store the T66 Turbo in a clean, dry, temperature-controlled environment to prevent corrosion and moisture ingress. Position the engine on approved stands with protective covers on all openings. Conduct periodic inspections during long-term storage. Use certified lifting equipment and trained personnel when moving the engine. Follow OEM-recommended preservation and depreservation procedures before and after storage.

Recordkeeping and Audit Readiness

Maintain comprehensive records for a minimum of five years, including shipping manifests, export licenses, customs filings, compliance certifications, and maintenance logs. Ensure all documentation is readily accessible for internal audits or government inspections. Implement a document control system to track revisions and approvals related to compliance procedures.

Conclusion for Sourcing T66 Turbo

In conclusion, sourcing a T66 turbocharger requires careful consideration of several key factors to ensure optimal performance, reliability, and value. The T66 is a high-flow, robust turbo ideal for high-horsepower applications, commonly used in performance diesel and racing gasoline engines. When sourcing, prioritize suppliers with a proven track record of quality—whether OEM, reputable aftermarket brands, or performance rebuilders.

Key considerations include verifying compatibility with your engine platform, application requirements (e.g., horsepower goals, fuel type, and operating conditions), and whether the unit is new, remanufactured, or custom-built. Additionally, evaluating warranty coverage, technical support, and lead times is essential, especially for mission-critical or time-sensitive installations.

While cost is a factor, it should not be the sole deciding criterion—investing in a high-quality T66 turbo from a trusted source reduces the risk of premature failure and costly downtime. In summary, a well-researched sourcing strategy that balances performance, durability, and support will ensure the T66 turbo delivers maximum efficiency and longevity in your application.