The global aluminum tubing market is experiencing robust growth, driven by increasing demand from industries such as aerospace, automotive, construction, and renewable energy. According to Mordor Intelligence, the aluminum tubing market is projected to grow at a CAGR of over 5.2% from 2023 to 2028, fueled by the metal’s high strength-to-weight ratio, corrosion resistance, and recyclability. T6061 aluminum tubing, in particular, remains a preferred choice due to its excellent mechanical properties and weldability, making it ideal for structural and precision applications. As demand rises, manufacturers are scaling production capacity and investing in advanced extrusion technologies to meet stringent quality standards. Based on market presence, production volume, innovation, and global reach, the following eight companies have emerged as leading manufacturers of T6061 aluminum tubing, shaping the future of lightweight material solutions across key industrial sectors.

Top 8 T6061 Aluminum Tubing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Seamless Aluminum Pipe

Domain Est. 1998

Website: continentalsteel.com

Key Highlights: 6061 is the least expensive and most versatile of the heat-treatable aluminum alloys. It has most of the good qualities of aluminum.Missing: t6061 manufacturer…

#2 Aluminum Round Tubes (6061 & 6063)

Domain Est. 1999

Website: industrialmetalsupply.com

Key Highlights: 30-day returns6061-t6 aluminum tubing is used across all industries for its strength, weldability, machinability, formability, and versatility….

#3 6061 Aluminum Manufacturers

Domain Est. 2015

Website: aluminummanufacturers.org

Key Highlights: Find top USA manufacturers of 6061 aluminum with diverse grades, advanced equipment, custom solutions, and swift delivery….

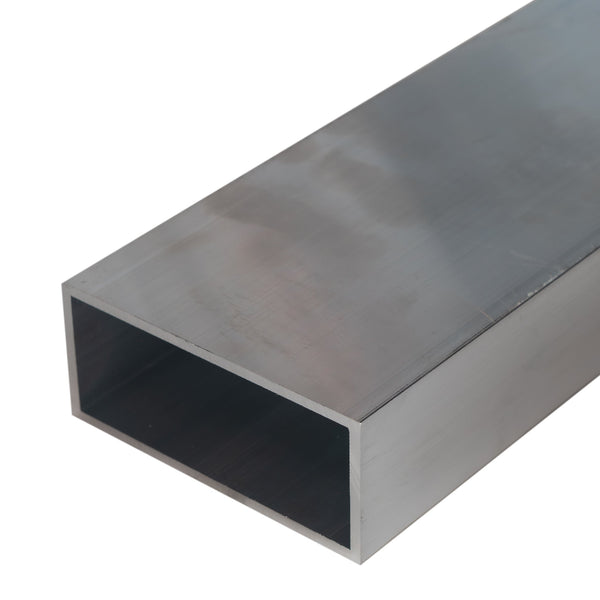

#4 6061 Aluminum Rectangle, Square Tube & Pipe

Domain Est. 1996

Website: alro.com

Key Highlights: Alro stocks 6061 aluminum alloy in pipe, plate, sheet, rectangular tube, square tube, and tread plate. Request a quote for further pricing details….

#5 6061 Extruded Aluminum Tubing

Domain Est. 1997

Website: twmetals.com

Key Highlights: 6061 extruded aluminum tubing is a magnesium and silicon alloyed aluminum product that is the preferred alloy when welding or brazing is required….

#6 Aluminum Metal Supplier

Domain Est. 2013

Website: thyssenkrupp-materials-na.com

Key Highlights: thyssenkrupp Materials NA is your supplier for Aluminum Long Bar, Long, Tube, Pipe, Sheet, Coil, and Plate products….

#7 6061 T6 Aluminum Tubular Buspipe

Domain Est. 2017

Website: chalcoaluminum.com

Key Highlights: 6061 aluminum tube, composed of magnesium and silicon, offers excellent performance with moderate strength, corrosion resistance, and formability….

#8 6061 T6 Aluminum Round Tube

Domain Est. 2018

Expert Sourcing Insights for T6061 Aluminum Tubing

H2: Projected Market Trends for T6061 Aluminum Tubing in 2026

The global market for T6061 aluminum tubing is expected to experience steady growth by 2026, driven by rising demand across key industrial sectors, advancements in manufacturing technologies, and increasing emphasis on lightweight, corrosion-resistant materials. This section outlines the major market trends shaping the T6061 aluminum tubing landscape in 2026.

1. Expansion in Automotive and Transportation Applications

The automotive industry continues to be a primary driver for T6061 aluminum tubing demand. With automakers striving to meet stringent fuel efficiency and emissions regulations, lightweighting remains a critical strategy. T6061, known for its excellent strength-to-weight ratio and weldability, is increasingly used in structural components, frames, and suspension systems for electric vehicles (EVs) and hybrid models. By 2026, the EV market’s expansion is expected to significantly boost aluminum tubing consumption, particularly in North America and Europe.

2. Growth in Renewable Energy Infrastructure

T6061 aluminum tubing is gaining traction in solar panel mounting systems, wind turbine components, and energy storage frameworks due to its durability and resistance to environmental degradation. As global investments in renewable energy accelerate under climate commitments (e.g., net-zero targets), demand for corrosion-resistant structural materials like T6061 is projected to rise. Emerging markets in Southeast Asia and Latin America are expected to contribute substantially to this growth.

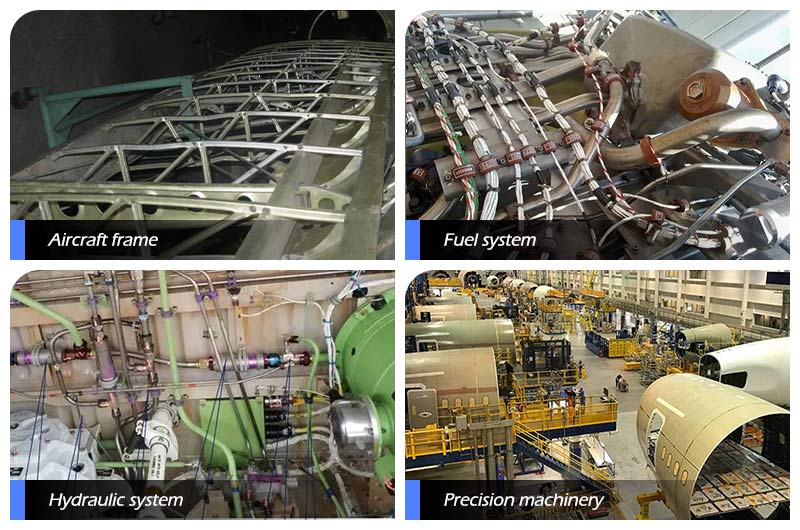

3. Advancements in Aerospace and Defense

The aerospace sector remains a high-value market for T6061 tubing, especially in non-critical structural applications, drone manufacturing, and ground support equipment. With increased defense spending and the commercialization of urban air mobility (UAM) and unmanned aerial vehicles (UAVs), demand for lightweight, high-performance aluminum alloys is set to grow. By 2026, tighter integration of T6061 in modular and scalable aerospace designs is anticipated.

4. Regional Production Shifts and Supply Chain Resilience

Geopolitical factors and supply chain disruptions have prompted manufacturers to diversify sourcing and localize production. In 2026, North American and European producers are expected to expand domestic capacity for aluminum extrusion, reducing reliance on Asian imports. Additionally, recycling initiatives and the use of secondary aluminum are gaining momentum, supporting sustainability goals and lowering production costs.

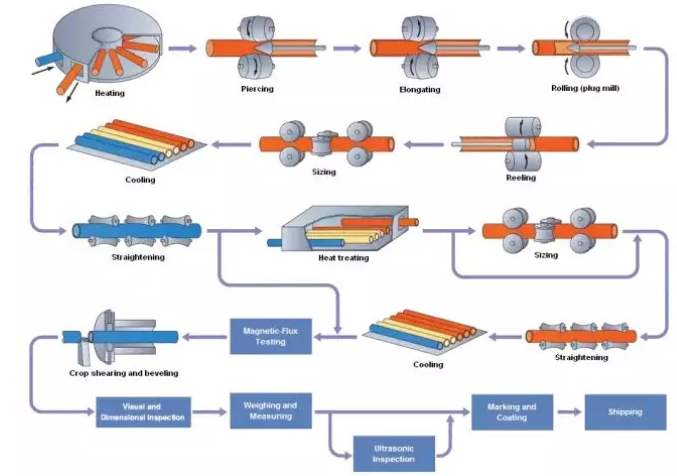

5. Technological Improvements in Extrusion and Finishing

Innovations in precision extrusion, heat treatment processes, and surface finishing are enhancing the mechanical properties and aesthetic quality of T6061 tubing. Improved tolerances and custom profile capabilities are enabling broader use in high-precision industries such as medical devices and robotics. Digital twin technology and AI-driven quality control are also being adopted to optimize production efficiency.

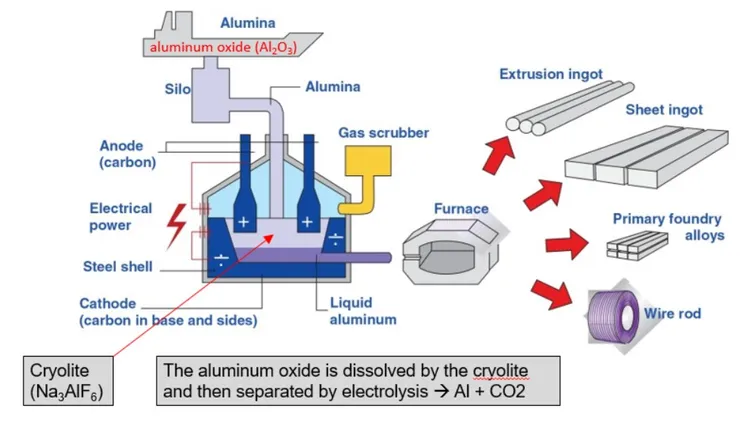

6. Price Volatility and Raw Material Challenges

Despite growth, the market faces challenges related to fluctuating alumina and energy prices, which can impact the cost of primary aluminum. The transition to greener production methods (e.g., inert anode technology) may initially raise costs but is expected to stabilize long-term pricing as regulatory pressures mount.

Conclusion

By 2026, the T6061 aluminum tubing market is poised for robust expansion, supported by structural demand from automotive, renewable energy, and aerospace sectors. Manufacturers that invest in sustainable practices, technological innovation, and regional supply chain resilience are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls When Sourcing T6061 Aluminum Tubing (Quality & IP)

Sourcing T6061 aluminum tubing can be straightforward, but several critical pitfalls related to quality assurance and intellectual property (IP) can lead to project delays, cost overruns, or legal issues. Being aware of these common issues helps ensure you receive material that meets specifications and complies with regulations.

Inadequate Quality Verification

One of the most frequent issues is assuming that all T6061 tubing meets required standards without proper documentation or testing. Suppliers may provide material that visually appears correct but fails to meet mechanical or chemical specifications.

- Lack of Mill Test Reports (MTRs): Failing to request or verify MTRs (also known as Certificates of Conformance) means you have no traceable proof of compliance with ASTM B221 or other relevant standards. Always require MTRs that confirm alloy composition, temper (T6), and mechanical properties like tensile strength and yield strength.

- Inconsistent Temper Verification: The “T6” designation indicates a specific heat treatment process. Some suppliers may misrepresent or inconsistently apply this temper. Verify through hardness testing or third-party lab analysis if high performance is critical.

- Dimensional Inaccuracies: Poor tolerances in outer diameter (OD), inner diameter (ID), or wall thickness can cause fitment issues in assemblies. Specify required tolerances (e.g., ±0.005”) and confirm they are met upon receipt.

Risk of Counterfeit or Substandard Material

The global supply chain increases exposure to counterfeit or downgraded aluminum. Some suppliers may substitute lower-grade alloys (e.g., 6063 instead of 6061) or use recycled content without disclosure, affecting strength and performance.

- Unverified Supply Chain: Materials sourced through brokers or secondary suppliers may lack traceability. Work with reputable, direct suppliers or distributors with transparent sourcing practices.

- Absence of Material Traceability: Without heat/lot numbers and full traceability, it’s difficult to investigate quality failures or recalls. Ensure traceability is maintained from mill to delivery.

Intellectual Property (IP) and Specification Infringement

Using T6061 tubing in custom-designed components can inadvertently lead to IP conflicts, especially in competitive industries like aerospace, automotive, or consumer electronics.

- Copying Proprietary Designs: Manufacturing tubing with dimensions, finishes, or geometries that mimic patented products (e.g., specific extrusion profiles) can lead to infringement claims. Always verify that your design does not replicate protected IP.

- Unauthorized Use of Trademarked Processes or Grades: While T6061 is a standard alloy designation, certain proprietary treatments or brand-specific variants (e.g., “Aero-T6”) may be trademarked. Ensure your sourcing and marketing do not imply use of protected technologies.

- Breach of Confidentiality in Custom Extrusions: If you provide a unique profile design to a supplier for extrusion, ensure a Non-Disclosure Agreement (NDA) is in place to prevent them from selling the same design to competitors.

Mitigation Strategies

To avoid these pitfalls:

– Require full MTRs and verify them against purchase specs.

– Perform incoming inspection (dimensional checks, hardness testing).

– Audit suppliers and prioritize those with ISO or AS9100 certification.

– Conduct IP due diligence before finalizing designs; consider freedom-to-operate (FTO) searches.

– Use legal agreements (NDAs, IP assignment clauses) when sharing custom designs.

By proactively addressing quality and IP concerns, you ensure reliable performance and legal compliance when sourcing T6061 aluminum tubing.

Logistics & Compliance Guide for T6061 Aluminum Tubing

T6061 aluminum tubing is widely used in aerospace, automotive, construction, and industrial applications due to its excellent strength-to-weight ratio, corrosion resistance, and weldability. Ensuring smooth logistics and compliance throughout the supply chain is essential for on-time delivery, cost-efficiency, and regulatory adherence. This guide outlines key considerations for the transportation, handling, documentation, and regulatory compliance of T6061 aluminum tubing.

Material Specifications and Identification

T6061 aluminum tubing must meet specific material standards to ensure quality and performance. Key specifications include:

– Alloy Designation: 6061-T6 (temper T6 indicates solution heat-treated and artificially aged)

– Applicable Standards:

– ASTM B241: Standard Specification for Seamless and Welded Aluminum and Aluminum-Alloy Pipe and Tube

– AMS QQ-A-200/8: Federal specification for aluminum alloy extruded products

– ISO 6361: Wrought aluminum and aluminum alloy sheets, strips, and plates

– Chemical Composition: Must conform to specified ranges for elements such as magnesium (Mg), silicon (Si), and chromium (Cr)

– Mechanical Properties: Typical tensile strength ≥ 42,000 psi, yield strength ≥ 35,000 psi, elongation ≥ 8%

Ensure all tubing is clearly marked with alloy designation, temper, heat number, size, and applicable standard for traceability.

Packaging and Handling Requirements

Proper packaging prevents surface damage, deformation, and contamination during transit:

– Bundle Configuration: Tubing should be bundled with protective spacers (e.g., cardboard or plastic) to avoid scratching. Use banding straps made of steel or polyester for secure bundling.

– End Protection: Apply plastic or wooden caps to both ends to prevent dents and contamination.

– Moisture Protection: Wrap bundles in moisture-resistant material (e.g., VCI paper or plastic film) to prevent corrosion, especially in humid environments or during ocean freight.

– Palletization: Secure bundles to wooden or recyclable plastic pallets using strapping. Pallet dimensions should comply with standard shipping container and warehouse racking requirements (e.g., 48” x 40”).

– Labeling: Include labels with product details (alloy, size, length, quantity, heat number), handling instructions (“Fragile,” “This Side Up”), and safety warnings.

Handle tubing with non-marring equipment (e.g., padded forklifts or vacuum lifters) to avoid surface damage.

Transportation and Freight Logistics

Select appropriate transport modes based on destination, volume, and lead time:

– Domestic Shipping (U.S./North America):

– Truckload (TL) or Less-Than-Truckload (LTL): Use flatbed or enclosed trailers. Secure loads with straps and load-distribution bars.

– Rail: Suitable for large volumes; ensure proper loading and bracing in railcars.

– International Shipping:

– Ocean Freight: Use 20’ or 40’ dry containers. Ensure moisture protection and secure stowage to prevent shifting. Comply with IMSBC Code and ISPM 15 for wooden packaging.

– Air Freight: For urgent shipments; verify weight and dimensional restrictions with carriers.

Coordinate with freight forwarders to manage customs clearance, insurance, and Incoterms (e.g., FOB, CIF, EXW).

Regulatory Compliance and Documentation

Ensure compliance with international, national, and industry-specific regulations:

– Customs Documentation:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin (required for preferential trade agreements like USMCA)

– Material Test Report (MTR) or Mill Test Certificate (per ASTM or customer requirements)

– Export Controls:

– Verify if T6061 aluminum tubing is subject to export regulations (e.g., EAR – Export Administration Regulations). While typically not controlled, dual-use applications may require a license.

– Check HTS (Harmonized Tariff Schedule) codes—typically 7608.10.1000 (aluminum tubes, seamless, circular, alloy 6061).

– Import Requirements:

– Comply with destination country’s customs duties, anti-dumping regulations (if applicable), and product standards.

– Some countries may require third-party inspection or certification (e.g., CE marking in Europe, JIS in Japan).

– Environmental and Safety Regulations:

– T6061 is non-hazardous and not regulated under DOT or ADR for transport as a dangerous good.

– Follow OSHA and WHMIS/GHS guidelines for workplace handling, though aluminum tubing poses minimal health risk.

– Recyclability: Clearly label as recyclable (Aluminum Recycling Code #41).

Quality Assurance and Traceability

Maintain full traceability throughout the supply chain:

– Retain heat certificates and MTRs for each batch.

– Implement a documented quality management system (e.g., ISO 9001).

– Conduct in-process and final inspections for dimensions, surface finish, and straightness.

– Use barcodes or RFID tags for inventory tracking if applicable.

Key Best Practices

- Supplier Qualification: Source from mills or distributors with certified quality systems.

- Inventory Management: Use FIFO (First In, First Out) to prevent aging or oxidation.

- Customer Communication: Provide complete documentation and lead time updates.

- Contingency Planning: Identify backup logistics providers and alternative routes for delays.

By adhering to this logistics and compliance guide, stakeholders can ensure the efficient, safe, and lawful distribution of T6061 aluminum tubing across global markets.

Conclusion for Sourcing T6061 Aluminum Tubing:

Sourcing T6061 aluminum tubing offers a strong balance of mechanical properties, corrosion resistance, and lightweight performance, making it a preferred choice across industries such as aerospace, automotive, construction, and manufacturing. Its excellent machinability, weldability, and high strength-to-weight ratio contribute to cost-effective and efficient fabrication processes.

When sourcing T6061 aluminum tubing, it is essential to work with reputable suppliers who provide material certification (such as mill test reports) to ensure compliance with industry standards (e.g., ASTM B221 or AMS 4027). Key considerations include dimensional accuracy, temper condition (commonly T6), surface finish, and delivery timelines. Evaluating suppliers based on quality assurance, consistency, and competitive pricing will help optimize both performance and cost.

In conclusion, T6061 aluminum tubing is a reliable and versatile material solution; strategic sourcing with attention to quality, specifications, and supply chain reliability ensures long-term project success and operational efficiency.