Imagine turning your wildest doodles, favorite quotes, or inside jokes into wearable art—without the hassle of inventory, printing presses, or upfront costs. That’s the magic of custom T-shirt design in today’s digital age, where creativity meets commerce at the click of a button. Thanks to the explosive rise of Print on Demand (POD) platforms, anyone with a vision can launch a clothing line from their laptop, tapping into global trends while staying true to their unique style. From eco-conscious dyes to hyper-personalized graphics, POD is reshaping how we think about fashion—one custom tee at a time. Welcome to the revolution where your imagination is the only limit.

Top 10 Best T Shirts Custom Design Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#2 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

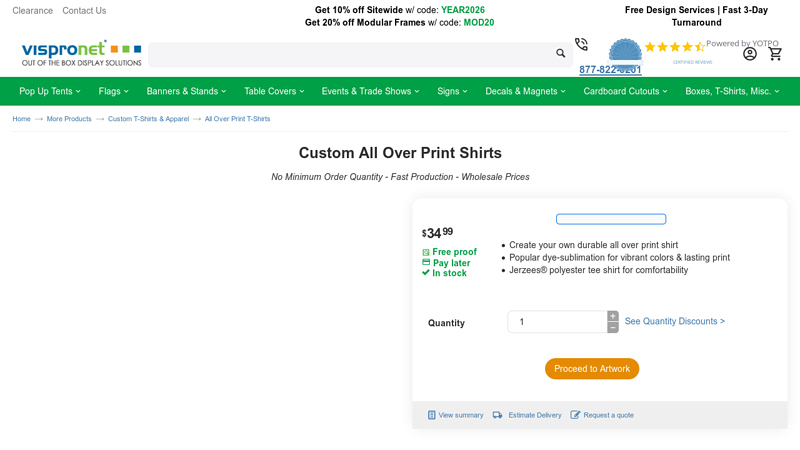

#3 Custom All Over Print Shirts

Online Since 2007

Website: vispronet.com

In stock Rating 4.4 (31) Create all over print shirts online. Long-lasting dye sublimation printing. Adult and youth sizes. No minimum order quantities. Fast turnaround.

#4 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#5 Custom T-Shirt Printing

Online Since 1997

Website: instantimprints.com

We create t-shirts with custom designs using the latest technologies in direct to garment, heat transfers, lettering and screen printing which allows for …

#6 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#7 Custom Print Shop

Online Since 2003

#8 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#9 Custom Print Shop

Online Since 1995

Website: bonfire.com

Order custom shirts and apparel with ease on Bonfire. ✓Premium products. ✓No minimums. ✓Bulk discounts. ✓No upcharge for plus sizes. Start your order today!

#10 Personalized Work Shirts, Custom Printed T

Online Since 2009

Website: tshirtbydesign.com

Free delivery over $50 30-day returnsWe offer a variety of unique and personalized work shirt templates that are designed to help your business get started with custom printed company shirts.

Expert Guide: Ordering t shirts custom design

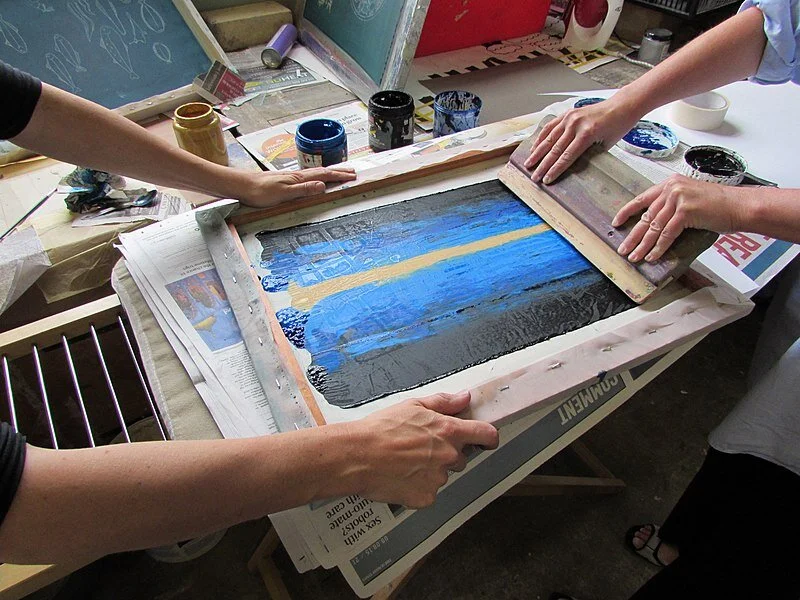

Comparison of T-Shirt Custom Design Methods

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | High-volume orders, simple designs, bold colors | High – lasts many washes with proper care | Low to medium per unit (cost decreases with volume) |

| DTG (Direct-to-Garment) | Detailed, full-color designs, photos, low-volume orders | Medium – may fade after repeated washing | Higher per unit, especially for small runs |

| Heat Transfer | Small orders, complex designs, quick turnaround | Low to medium – can crack or peel over time | Low setup cost, higher per unit for large quantities |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: Your Guide to Choosing Fabrics for Custom T-Shirts

When designing custom t-shirts, the fabric you choose impacts comfort, durability, appearance, and print quality. Understanding the key differences between 100% cotton, 50/50 blends, and tri-blends will help you select the perfect material for your project.

100% Cotton

Pros:

– Soft and Breathable: Naturally comfortable, especially in warm weather.

– Eco-Friendly: Biodegradable and often preferred for sustainable apparel.

– Great for Printing: Holds ink well, making it ideal for detailed screen printing and vibrant designs.

– Classic Feel: Offers a traditional t-shirt texture that many customers love.

Cons:

– Prone to Shrinking: May shrink if not pre-shrunk or washed improperly.

– Less Durable: Can wear out faster and develop pilling over time.

– Wrinkles Easily: Tends to crease and lose shape with repeated washing.

– Absorbs Moisture: Holds sweat, which may feel damp during physical activity.

Best For: Casual wear, eco-conscious brands, vintage-style tees, and screen-printed designs with bold colors.

50/50 Blend (50% Cotton, 50% Polyester)

Pros:

– Durable and Resilient: Resists shrinking, fading, and pilling better than 100% cotton.

– Budget-Friendly: Typically more affordable than tri-blends.

– Low Maintenance: Holds its shape well and requires less ironing.

– Good Print Surface: Works well with screen printing and direct-to-garment (DTG) methods.

Cons:

– Less Breathable: Polyester content can trap heat, making it less comfortable in hot weather.

– Slightly Stiffer Feel: Not as soft as 100% cotton or tri-blends initially (though it softens with wear).

– Static and Pilling: May attract lint and develop small fabric balls over time.

Best For: Promotional events, uniforms, workwear, and active environments where durability matters.

Tri-Blends (Typically 50% Polyester, 25% Cotton, 25% Rayon)

Pros:

– Ultra-Soft Hand Feel: Feels buttery soft and drapes beautifully—similar to a vintage tee.

– Excellent Drape: Flattering fit that moves with the body.

– Fade Resistant: Retains color vibrancy after multiple washes.

– Moisture Wicking: Polyester helps wick sweat, making it more performance-friendly.

Cons:

– Higher Cost: Usually more expensive than cotton or 50/50 blends.

– Less Durable: More delicate; can snag or wear faster with heavy use.

– Print Limitations: May require special DTG settings; not ideal for plastisol screen printing.

Best For: Fashion-forward apparel, boutique brands, women’s cuts, and soft-style designs with a vintage aesthetic.

How to Choose the Right Fabric

- Prioritize Comfort? → Go for 100% cotton or tri-blends.

- Need Durability on a Budget? → Choose a 50/50 blend.

- Want a Premium, Soft Look? → Tri-blend is ideal.

- Planning Heavy Use or Frequent Washing? → 50/50 or tri-blend offer better longevity.

- Focusing on Sustainability? → 100% organic cotton is the top eco-choice.

By matching your fabric to your audience, purpose, and design style, you’ll create custom t-shirts that look great and feel even better.

How to Get the Best Price for Custom T-Shirts (Bulk Quantity Breaks & Artwork Tips)

Ordering custom T-shirts in bulk can be a cost-effective way to promote your brand, team, or event—but only if you know how to optimize your order. By leveraging quantity breaks and preparing artwork efficiently, you can significantly reduce your per-unit cost. Here’s how:

Understand Bulk Quantity Breaks

Most screen printing and print-on-demand companies offer tiered pricing based on order volume. The more shirts you order, the lower the price per unit.

-

Typical Quantity Tiers:

Common breaks include 25, 50, 100, 250, and 500 units. For example, 25 shirts might cost $10 each, while 100 shirts drop to $6 each. -

Maximize Your Break Point:

If you’re close to the next tier (e.g., 90 shirts), consider increasing your order to 100. The small additional cost often results in a much lower price per shirt. -

Group Orders:

Collaborate with friends, team members, or departments to pool orders and reach higher quantity breaks.

Choose the Right Printing Method

The printing technique affects both cost and quality. Select the method that fits your design and budget.

-

Screen Printing:

Most cost-effective for large orders (50+ units) with simple designs and limited colors. Setup costs are high, but per-unit price drops significantly with volume. -

DTG (Direct-to-Garment):

Best for complex, full-color designs or small batches. Higher per-unit cost, but no setup fees—ideal if you can’t meet screen printing minimums. -

Heat Transfer or Vinyl:

Suitable for small runs or specialty fabrics. Less durable over time and not ideal for large orders.

Simplify Your Design to Reduce Costs

Printing costs often depend on design complexity.

-

Limit the Number of Colors:

Each additional color in screen printing requires a separate screen and increases setup time. Stick to 1–3 colors to minimize expenses. -

Minimize Print Area:

Smaller prints use less ink and labor. Opt for standard placements like left chest or center back. -

Avoid Gradients and Photorealistic Images (for Screen Printing):

These are better suited to DTG, which is more expensive. Simplify artwork into flat colors when possible.

Prepare Print-Ready Artwork

Well-prepared artwork reduces setup time and avoids costly corrections.

-

Use Vector Files (AI, EPS, SVG):

These scale infinitely without losing quality—essential for clean prints. Avoid low-resolution JPEGs or PNGs. -

Set Correct Dimensions and DPI:

For DTG or detailed prints, provide high-resolution files (300 DPI at actual print size). -

Outline Fonts and Convert to Paths:

Prevents font issues during printing. Ensure all text is converted so the printer doesn’t need your font files. -

Include a Mockup:

Helps the printer understand your vision and reduces back-and-forth communication.

Select Affordable, High-Quality Blank T-Shirts

The blank shirt makes up a big part of the cost.

-

Choose Basic, Reliable Brands:

Gildan, Bella+Canvas, and Hanes offer quality at competitive prices. Premium brands (e.g., American Apparel) cost more. -

Stick to Standard Colors:

White and black shirts are usually cheaper than specialty colors. -

Consider Fabric Weight and Blend:

100% cotton is affordable and widely available. Blends (e.g., cotton-polyester) may cost more but offer durability and moisture-wicking.

Get Multiple Quotes and Negotiate

Don’t settle for the first quote.

-

Compare at Least 3 Suppliers:

Use online quote tools from companies like Custom Ink, Printful, Inkthreadable, or local screen printers. -

Ask About Hidden Fees:

Confirm if setup fees, color charges, or shipping are included. -

Negotiate for Large Orders:

If ordering 250+ units, ask for a custom discount. Some suppliers offer free setups or reduced rates for repeat customers.

Order Samples First

Always request a physical sample (or “press check”) before full production.

-

Verify Print Quality and Fit:

Avoid costly mistakes in color, sizing, or design alignment. -

Test Durability:

Wash the sample to ensure the print holds up.

Time Your Order Strategically

-

Avoid Rush Fees:

Place orders well in advance. Rush processing can increase costs by 25–50%. -

Watch for Promotions:

Many suppliers offer seasonal discounts, first-time customer deals, or free shipping.

By combining smart bulk ordering, efficient artwork, and strategic supplier selection, you can achieve high-quality custom T-shirts at the best possible price. Plan ahead, simplify where you can, and always compare options to maximize your savings.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value. Start by assessing the quality of materials and printing techniques offered—opt for providers that use durable fabrics and proven printing methods like screen printing or direct-to-garment for long-lasting results. Consider customization options, including design flexibility, color choices, and available styles, to ensure the provider can meet your specific needs.

Evaluate the provider’s reputation by reading customer reviews and examining sample work. Turnaround time and shipping options are also crucial, especially for time-sensitive orders. Look for transparent pricing with no hidden fees, and take advantage of quotes or small test orders before committing to large quantities. Lastly, prioritize excellent customer service and support to address any concerns efficiently.

Ultimately, the best custom t-shirt provider balances quality, affordability, and service to bring your vision to life reliably and professionally.