Ever glanced at someone’s tee and thought, “I wish I had that design?” You’re not alone. Custom t-shirt printing has exploded from a niche hobby into a full-blown cultural phenomenon—and it’s easier than ever to turn your wildest ideas into wearable art. Thanks to the rise of Print on Demand (POD) technology, aspiring designers, influencers, and small businesses no longer need massive inventories or upfront costs to launch their own clothing lines. With just a click, a unique design can go from digital sketch to doorstep, printed fresh and shipped straight to customers. As POD platforms integrate seamlessly with e-commerce giants and sustainability becomes a priority, the world of custom t-shirt printing is not just growing—it’s evolving. Welcome to the future of fashion, one custom tee at a time.

Top 8 Best T Shirt Printing Custom Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#2 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

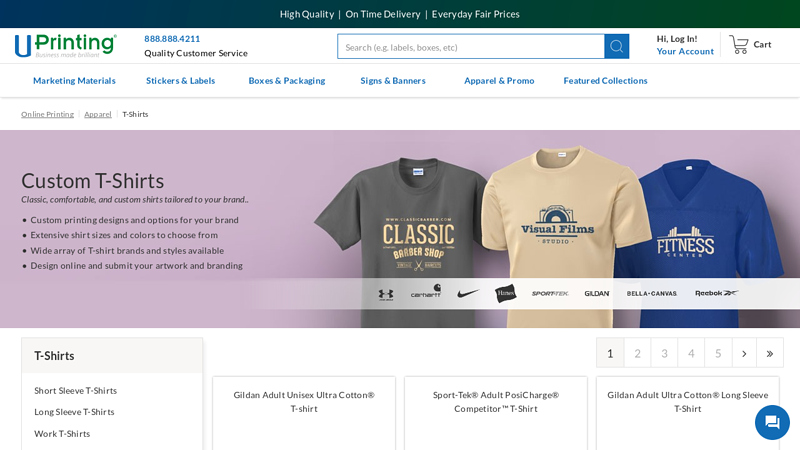

#3 – Screen Printing & T-Shirt Design

Online Since 2004

Website: uprinting.com

1–5 day deliveryPromote your brand with affordable custom t-shirts. Choose from various colors, fits, and decoration options like printing, screen-printing, or embroidery.

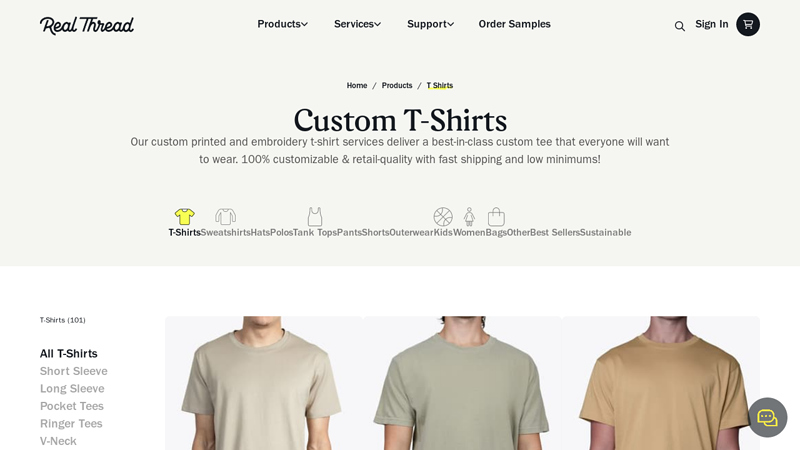

#4 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

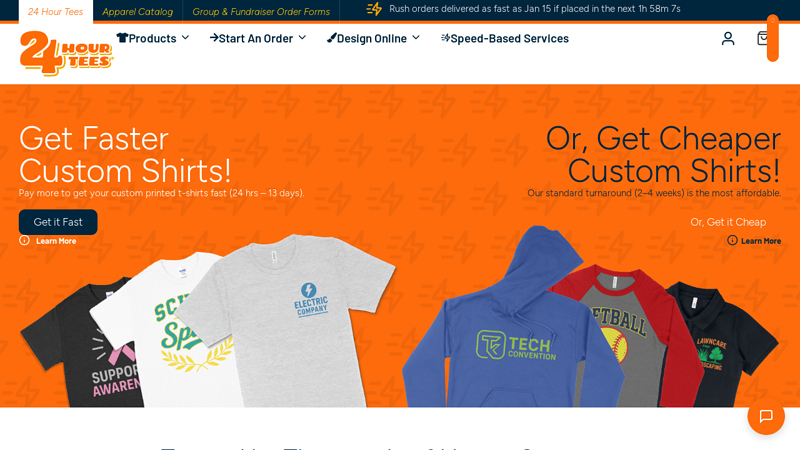

#5 Custom Printed T-Shirts in 24 Hrs

Online Since 2013

Website: 24hrtees.net

Upload your art and buy rush custom printed t-shirts & more in minutes! Fast custom t-shirt printing ships in as few as 24 hours. No minimums!

#6 Custom Print Shop

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsCreate custom t-shirts with your designs. High-quality printing, fast delivery, and endless customization options. Start designing your personalized tees …

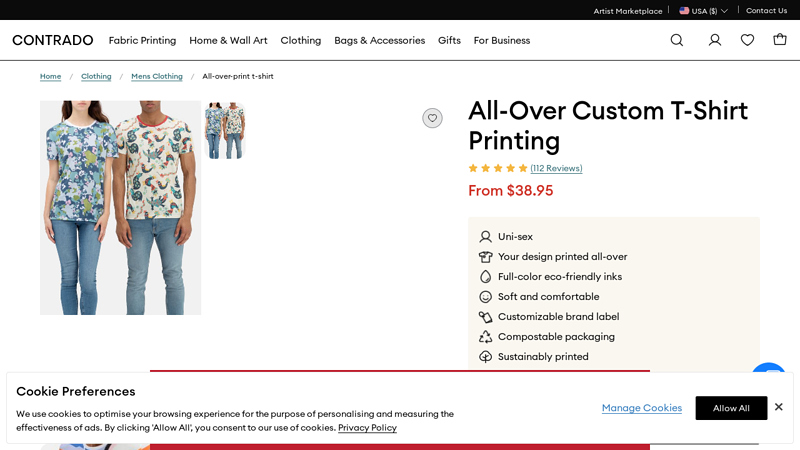

#7 All

Online Since 2004

Website: contrado.com

In stock Rating 4.8 (112) Made to measure t-shirts featuring your designs and artwork. Handmade to order from soft Jersey fabric. All-over custom t-shirt printing.

#8 ooShirts: Cheap Custom T

Online Since 2007

Website: ooshirts.com

Custom t-shirts for less! ooShirts is the leader in affordable t-shirt printing. Free shipping & setup. Design your own t-shirts at awesomely low prices!

Expert Guide: Ordering t shirt printing custom

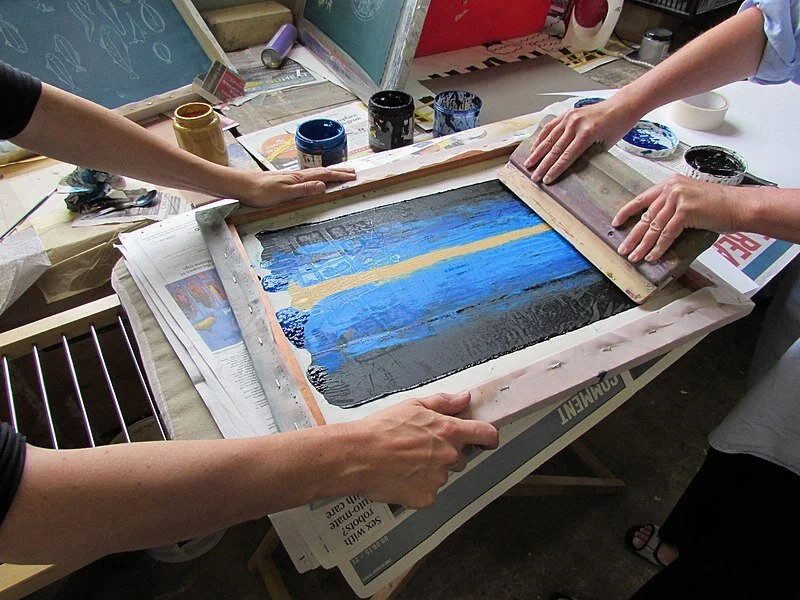

Comparison of T-Shirt Printing Methods: Screen Printing, DTG, and Heat Transfer

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs, bold colors | High – lasts many washes | Low per unit (high setup cost for small runs) |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, photos | Medium – may fade after 30–50 washes | Medium – higher per unit, no setup fees |

| Heat Transfer | Small batches, quick turnaround, custom names/numbers | Low to Medium – can crack or peel over time | Low setup cost, higher per unit for large quantities |

Guide to Choosing Fabrics for Custom T-Shirt Printing: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

When designing custom t-shirts, the fabric you choose significantly impacts comfort, appearance, durability, and print quality. The three most popular options—100% cotton, 50/50 blends, and tri-blends—each have unique characteristics. Understanding their pros and cons helps you select the best material for your project.

100% Cotton

100% cotton t-shirts are made entirely from natural cotton fibers. They are a classic choice known for their softness and breathability.

Pros:

– Soft and Comfortable: Feels gentle against the skin, especially after a few washes.

– Breathable: Allows air circulation, making it ideal for warm weather or active wear.

– Eco-Friendly: Biodegradable and made from a renewable resource.

– Excellent for Printing: Absorbs ink well, resulting in vibrant, crisp prints—especially with screen printing and direct-to-garment (DTG) methods.

Cons:

– Prone to Shrinking: May shrink if not pre-shrunk or washed improperly.

– Less Durable: Can wear out faster over time, especially with frequent washing.

– Wrinkles Easily: Tends to crease and lose shape more than blended fabrics.

– Absorbs Moisture: Can feel damp when sweaty since it retains moisture.

Best For: Everyday wear, casual events, screen printing, and customers who prefer natural fibers.

50/50 Blend (50% Cotton, 50% Polyester)

A 50/50 blend combines equal parts cotton and polyester, offering a balance between natural and synthetic fibers.

Pros:

– Durable and Resilient: Resists pilling and tearing better than 100% cotton.

– Minimal Shrinkage: More stable through washes due to polyester content.

– Wrinkle-Resistant: Holds its shape and appearance longer.

– Moisture-Wicking: Polyester helps draw moisture away, keeping wearers drier.

– Cost-Effective: Often less expensive than 100% cotton or tri-blends.

Cons:

– Less Breathable: Not as airy as 100% cotton, which may feel warmer.

– Slightly Less Soft: Can feel stiffer than pure cotton, though modern blends are improving.

– Printing Challenges: May require pretreatment for DTG printing to prevent ink bleed.

Best For: Promotional apparel, workwear, events, and environments where durability and consistent sizing matter.

Tri-Blend (Typically 50% Polyester, 25% Cotton, 25% Rayon)

Tri-blend fabric combines polyester, cotton, and rayon (often modal or viscose) for a premium, vintage-style feel.

Pros:

– Luxuriously Soft: Known for a silky, smooth texture that feels high-end.

– Vintage Aesthetic: Develops a slightly heathered, worn-in look over time.

– Lightweight and Drapes Well: Ideal for fitted or fashion-forward styles.

– Color Retention: Holds dye well, enhancing print vibrancy and longevity.

Cons:

– More Expensive: Higher cost due to materials and manufacturing.

– Less Durable: Rayon can weaken when wet, making it prone to stretching or tearing with rough handling.

– Special Care Needed: Requires gentle washing and drying to maintain quality.

– Print Precision: Requires precise settings in DTG printing to avoid bleeding or fading.

Best For: Fashion apparel, boutique brands, gift items, and customers seeking a premium, soft hand-feel with a modern look.

Choosing the Right Fabric for Your Project

- Prioritize Comfort & Natural Feel? → Choose 100% Cotton.

- Need Durability & Cost Efficiency? → Go with a 50/50 Blend.

- Want a Premium, Soft, Fashion-Forward Look? → Opt for Tri-Blend.

Consider your audience, use case, printing method, and budget when making your decision. Many print providers offer samples—test each fabric to see which best aligns with your brand and design goals.

How to Get the Best Price for Custom T-Shirt Printing (Bulk Quantity Breaks & Artwork Tips)

Getting custom t-shirts printed in bulk can be a cost-effective way to promote your brand, event, or team. However, to ensure you’re getting the best possible price without sacrificing quality, it’s essential to understand bulk pricing structures and how to prepare your artwork correctly. Here’s a comprehensive guide to help you save money and get professional results.

Understand Bulk Quantity Breaks

Most printing companies offer tiered pricing based on order volume—commonly referred to as quantity breaks. The more shirts you order, the lower the cost per unit. Here’s how to maximize savings:

-

Know the Thresholds: Typical quantity breaks occur at 25, 50, 100, 250, and 500 units. For example, ordering 99 shirts may cost significantly more per shirt than ordering 100. Always check the pricing tiers and aim to meet the next threshold.

-

Consolidate Orders: If you anticipate future needs, consider combining orders to reach a higher volume tier. For example, order a little extra to cover future team members or events.

-

Stick to One Design (When Possible): Printing multiple designs increases setup and labor costs. If you can use one design across all shirts, you’ll save significantly.

-

Limit Colors in Your Design: Each additional color in screen printing requires a separate screen and setup fee. Designs with 1–3 colors are generally the most economical. Opt for simpler designs to reduce costs.

Optimize Your Artwork for Cost Efficiency

The way you prepare your artwork can impact both pricing and print quality. Follow these tips to get a clean, professional result at the lowest cost:

-

Use Vector Files (AI, EPS, SVG): Vector artwork scales perfectly and is ideal for screen printing and embroidery. It ensures crisp lines and avoids pixelation. If you’re working with a designer, request vector files.

-

Stick to High-Resolution Raster Images (300 DPI): If using a raster image (like PNG or JPG), ensure it’s high resolution (at least 300 DPI at the intended print size). Low-res images may require costly recreation.

-

Simplify Your Design: Complex designs with gradients, fine details, or many colors increase printing time and expense. Simplify logos and text where possible.

-

Use Spot Colors, Not Full Color: Full-color (CMYK) printing is expensive. Use spot colors (Pantone or solid colors) and limit the palette to 1–3 colors for screen printing savings.

-

Provide Accurate Color Codes: Specify exact Pantone (PMS) or HEX color codes to avoid delays and incorrect matches. This reduces reprints and adjustments.

Choose the Right Printing Method

Different printing techniques suit different designs and budgets:

-

Screen Printing: Best for bulk orders (50+ units) with simple, limited-color designs. Low per-unit cost after setup.

-

DTG (Direct-to-Garment): Ideal for complex, full-color designs or small batches. Higher per-unit cost but no setup fees for multiple colors.

-

Heat Transfer: Good for prototypes or very small runs. Less durable than screen printing and not ideal for bulk.

For bulk orders with simple designs, screen printing typically offers the best price per unit.

Additional Money-Saving Tips

-

Choose Standard Shirt Colors: White or light-colored shirts are usually cheaper to print on. Dark shirts require an underbase layer, increasing ink usage and cost.

-

Buy Blank Shirts in Bulk: Some companies let you supply your own garments. Purchasing blanks wholesale can reduce total costs if you find a good supplier.

-

Get Multiple Quotes: Compare pricing from at least 3–5 reputable printers. Be sure they’re quoting for the same specs (shirt brand, print method, location, ink colors).

-

Ask About Setup Fee Waivers: Some printers waive or reduce setup fees for large orders or repeat customers.

By leveraging bulk quantity breaks, optimizing your artwork, and selecting the right printing method, you can get high-quality custom t-shirts at the best possible price. Plan ahead, simplify your design, and communicate clearly with your printer to ensure a smooth and cost-effective process.

When choosing the right custom t-shirt provider, it’s essential to balance quality, customization options, pricing, customer service, and turnaround time. Start by clearly defining your needs—whether it’s for an event, business branding, or personal use—and then evaluate providers based on fabric quality, print techniques (like screen printing, DTG, or embroidery), and customization capabilities. Read customer reviews and request samples if possible to assess the product firsthand. Compare pricing transparently, ensuring there are no hidden costs, and check the provider’s turnaround and shipping times to meet your deadlines. Lastly, prioritize companies with responsive customer support and easy-to-use design tools. By carefully weighing these factors, you can select a reliable and professional custom t-shirt provider that meets your specific requirements and delivers a great final product.