The global embroidery machine market is experiencing steady growth, driven by rising demand in the apparel and textile sectors, particularly for customized and branded garments. According to a report by Mordor Intelligence, the embroidery machine market is projected to grow at a CAGR of over 5.5% from 2023 to 2028, fueled by advancements in automation, increasing adoption of computerized machines, and the booming e-commerce and customization trends. Similarly, Grand View Research valued the global textile printing and embroidery market at USD 3.9 billion in 2022, with a continued upward trajectory expected due to growing consumer preference for personalized apparel and technical innovations in digital embroidery. T-shirt embroidery, in particular, has emerged as a high-volume application, prompting apparel producers and small-to-medium businesses alike to invest in efficient, precision-driven machinery. As demand surges, manufacturers are responding with smarter, faster, and more user-friendly machines—establishing a competitive landscape led by innovators who combine engineering excellence with digital integration. Here’s a data-informed look at the top 9 T-shirt embroidery machine manufacturers shaping the industry’s future.

Top 9 T Shirt Embroidery Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial Embroidery Machines

Domain Est. 2000

Website: brother-usa.com

Key Highlights: Free delivery over $50 · 30-day returnsSingle-head, multi-needle industrial embroidery machines to customize merchandise in no time for retail, sports, experiential, or hospitalit…

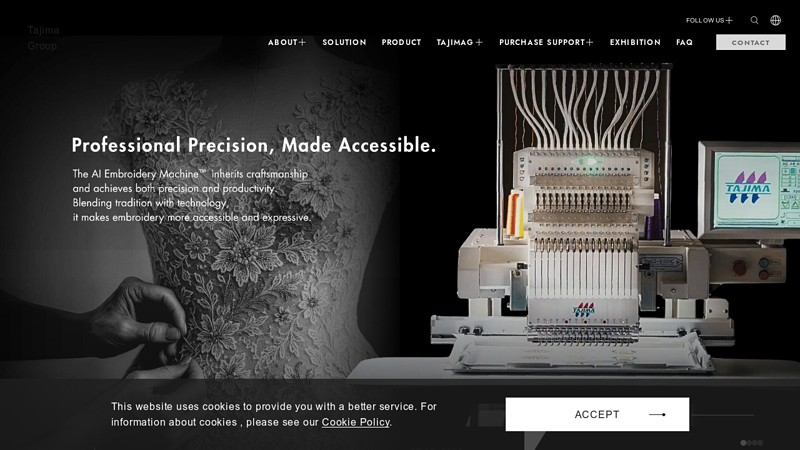

#2 Tajima Group|The World’s Favorite Embroidery machines

Domain Est. 2001

Website: tajima.com

Key Highlights: Tajima is a leading embroidery machine manufacturer. Made in Japan.| Learn more about our product information, case studies, tips and solutions for your ……

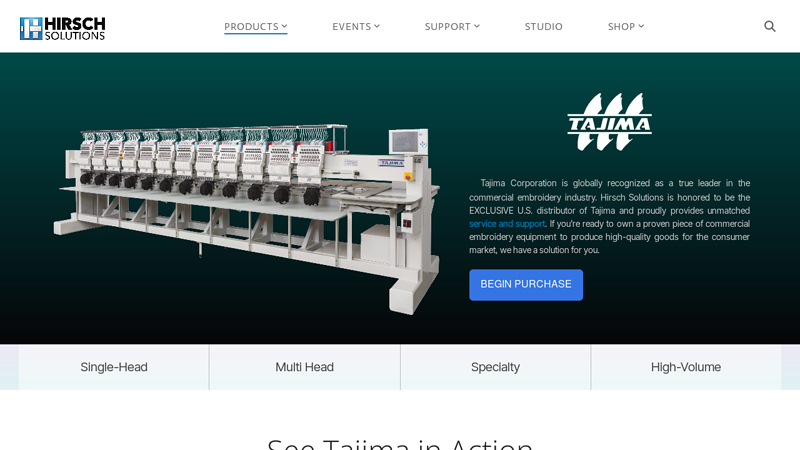

#3 Tajima

Domain Est. 2002

Website: hsi.us

Key Highlights: The MOST TRUSTED commercial embroidery machine in the industry. Tajima machines have set the standard for advanced technology and proven efficiency in ……

#4 HeFeng Computerized embroidery machines limited

Domain Est. 2006

Website: hefengmachine.com

Key Highlights: We are HEFENG factory manufacture high quality embroidery machines. Including single head embroidery machine, multi head cap t-shirt embroidery machine, ……

#5 ColDesi, Inc. Make Your Own Customized Products

Domain Est. 2010

Website: coldesi.com

Key Highlights: Leading provider of customized products equipment. Including: commercial embroidery machines, direct-to-garment printers, and more….

#6 Proemb Embroidery Machine, Emb Machine, Multi Needle …

Domain Est. 2024

Website: iproemb.com

Key Highlights: We provide a wide range of machines with powerful funtions, which can be widely used in T-shirts, hats, shoes, socks, towels, flat embroidery, etc….

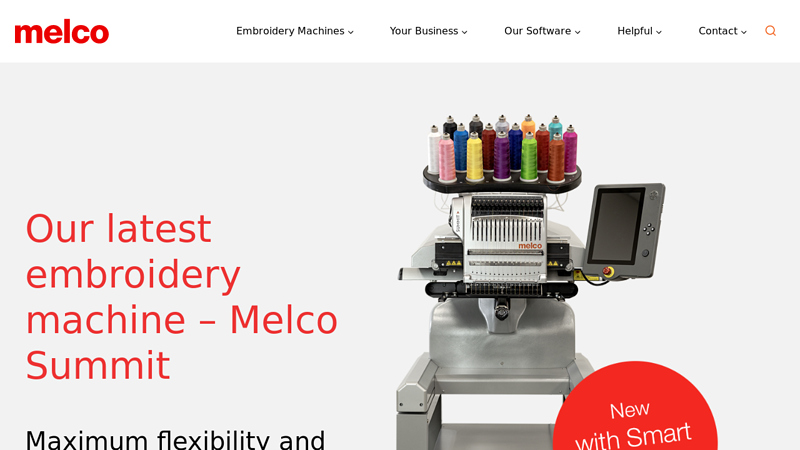

#7 Melco

Domain Est. 1993

Website: melco.com

Key Highlights: Melco has the solutions your business needs: innovative embroidery machines, DTG printers, digitizing software, and outstanding tech support….

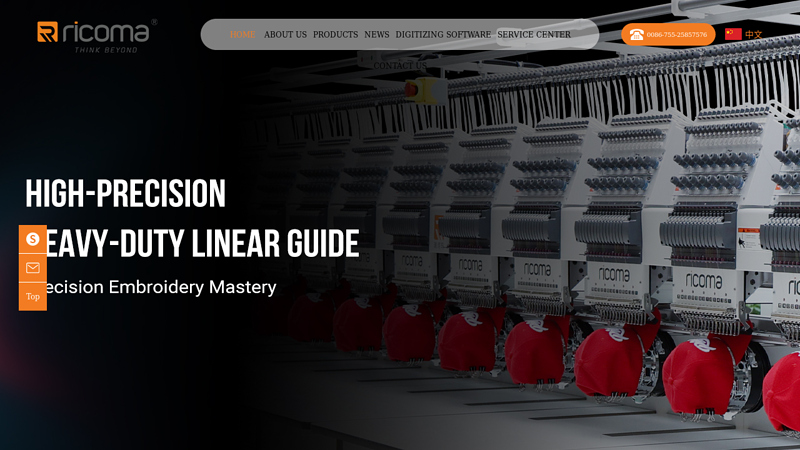

#8 Ricoma International Corporation

Domain Est. 2006

Website: ricoma.cn

Key Highlights: EM Embroidery Machine. The EM Series is a 10-needle home embroidery machine and is perfect for embroidery on caps, flats, finished garments and more!…

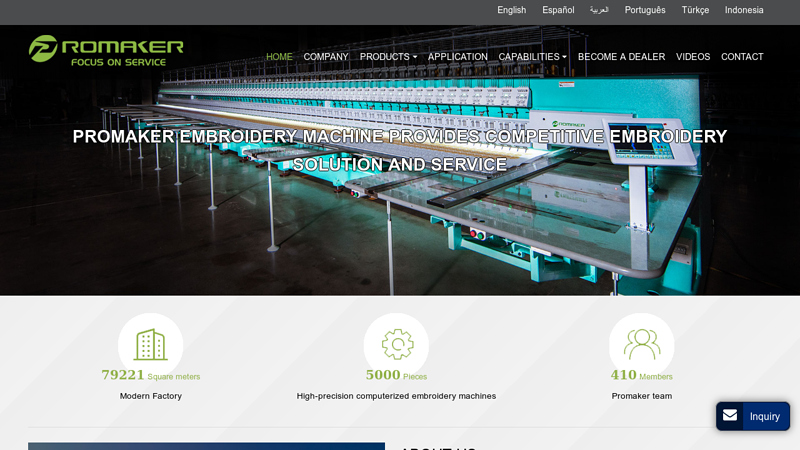

#9 Embroidery machines

Domain Est. 2020 | Founded: 2016

Website: embroidery-equip.com

Key Highlights: Established in 2016, Promaker is dedicated to the development and manufacturing of multi-needle embroidery machines for a vast range of embroidery ……

Expert Sourcing Insights for T Shirt Embroidery Machine

2026 Market Trends for T-Shirt Embroidery Machines: Key Drivers and Projections

As we approach 2026, the market for T-shirt embroidery machines is poised for significant transformation, driven by technological advancements, shifting consumer demands, and evolving business models. This analysis explores the major trends expected to shape the industry in the coming years.

Rising Demand for Customization and Personalization

Consumers increasingly seek unique, personalized apparel, fueling demand for on-demand and small-batch embroidery. By 2026, this trend will push both independent designers and larger brands to adopt flexible embroidery solutions. T-shirt embroidery machines capable of quick changeovers and handling intricate, one-off designs will be in high demand, particularly multi-needle and digital-programmable models that support customization at scale.

Integration of Smart Technology and IoT

Embroidery machines are becoming smarter through IoT (Internet of Things) integration. By 2026, expect widespread adoption of cloud-connected machines that allow remote monitoring, real-time diagnostics, and automated software updates. This connectivity enhances productivity, reduces downtime, and enables predictive maintenance—key for commercial operations aiming to maximize uptime and efficiency.

Growth of E-Commerce and On-Demand Manufacturing

The rise of e-commerce platforms and print-on-demand services will continue to accelerate, influencing embroidery machine sales. Small businesses and entrepreneurs will increasingly invest in compact, user-friendly embroidery machines to produce customized T-shirts in response to direct customer orders. This trend favors entry-level and mid-range machines with intuitive software and compatibility with online design tools.

Advancements in Automation and AI

Artificial intelligence is beginning to play a role in digitizing embroidery designs and optimizing stitch patterns. By 2026, AI-powered design software integrated with embroidery machines will reduce setup times and improve accuracy. Automation features such as automatic thread trimming, color changing, and fabric feeding will become standard, lowering labor costs and enabling higher throughput in high-volume production environments.

Sustainability and Eco-Conscious Manufacturing

Environmental concerns are influencing equipment choices. Manufacturers of embroidery machines are expected to focus on energy efficiency, reduced waste, and compatibility with sustainable materials. By 2026, machines designed to minimize thread waste and support biodegradable threads will gain market share, especially among eco-conscious brands targeting environmentally aware consumers.

Expansion of Emerging Markets

Developing regions in Asia, Latin America, and Africa are witnessing growing middle-class demand for personalized apparel. This presents a significant growth opportunity for embroidery machine suppliers. Affordable, durable, and easy-to-maintain machines tailored for smaller workshops will see increased demand, supported by localized training and technical support services.

Consolidation of Software and Hardware Ecosystems

By 2026, leading embroidery machine manufacturers will likely offer integrated ecosystems combining hardware, design software, and cloud services. Seamless workflows—from design creation to machine execution—will differentiate top brands. Compatibility with popular design platforms (e.g., Adobe Illustrator, CorelDRAW) and mobile apps will be critical for user adoption.

Conclusion

The T-shirt embroidery machine market in 2026 will be defined by innovation, connectivity, and responsiveness to consumer-driven customization. Businesses that embrace smart technology, sustainability, and flexible production models will be best positioned to capitalize on these evolving trends. As barriers to entry lower and technology becomes more accessible, the embroidery landscape will continue to democratize, empowering creators and manufacturers alike.

Common Pitfalls When Sourcing a T-Shirt Embroidery Machine (Quality & IP Concerns)

Sourcing a T-shirt embroidery machine—especially from overseas suppliers—can be cost-effective, but it comes with significant risks related to quality control and intellectual property (IP) protection. Being aware of these pitfalls is crucial for making a smart investment.

Poor Build Quality and Component Reliability

Many low-cost embroidery machines, particularly from less reputable manufacturers, use substandard materials and components. This can result in frequent mechanical failures, inconsistent stitching, and costly downtime. Motors, needles, and tension systems may wear out quickly, leading to higher maintenance costs and reduced production efficiency over time.

Inaccurate or Inconsistent Stitching Performance

Low-quality machines often lack precision engineering, leading to misaligned patterns, thread breaks, and uneven tension. This is especially problematic for detailed or dense embroidery designs on delicate fabrics like cotton T-shirts. Inconsistent performance affects product quality and can damage your brand’s reputation.

Lack of Software Compatibility and Updates

Some machines come with proprietary software that may not integrate well with industry-standard design tools (e.g., Wilcom, Pulse). Additionally, budget machines may not receive regular software updates, limiting your ability to use new features or protect against security vulnerabilities. This can also create IP risks if the software uses unauthorized or pirated code.

Counterfeit or Clone Machines Infringing IP Rights

A major risk when sourcing from certain regions is purchasing counterfeit or cloned machines that replicate patented designs, software, or technologies from established brands (e.g., Tajima, Brother, Barudan). Using such machines can expose your business to legal liability for IP infringement, including fines or seizure of equipment at customs.

Unauthorized Use of Embroidery Digitizing Software

Some suppliers bundle embroidery machines with pirated or unlicensed digitizing software. Using such software violates copyright laws and can result in legal action. Always verify software licensing and ensure compliance to protect your business from IP-related penalties.

Inadequate After-Sales Support and Spare Parts Availability

Cheap machines often come from suppliers with limited customer support networks. When a breakdown occurs, obtaining replacement parts or technical assistance can be slow or impossible, leading to prolonged downtime. This lack of support undermines long-term operational reliability.

Hidden Costs from Frequent Maintenance and Repairs

While the initial purchase price may seem attractive, poor machine quality often leads to higher total cost of ownership due to constant repairs, wasted materials, and labor inefficiencies. These hidden costs can quickly outweigh any upfront savings.

Limited Warranty and No Legal Recourse

Many low-cost suppliers offer minimal or non-enforceable warranties. If the machine fails, you may have little to no legal recourse—especially when dealing with overseas vendors in jurisdictions with weak consumer protection laws.

Risk of Customs Seizures Due to IP Violations

Importing machines that infringe on intellectual property (e.g., patented technology or pirated software) can lead to customs seizures, fines, or shipment delays. This not only disrupts your supply chain but can also damage your company’s credibility.

How to Mitigate These Risks

- Purchase from authorized dealers or reputable manufacturers with verifiable track records.

- Request proof of IP compliance, including software licensing and machine certifications.

- Invest in a quality machine with proven reliability, even if the upfront cost is higher.

- Consult legal experts when importing to ensure compliance with IP and trade laws.

- Insist on service agreements and access to genuine spare parts.

Avoiding these pitfalls ensures you get a reliable, legally compliant embroidery machine that supports your business growth without exposing it to unnecessary risk.

Logistics & Compliance Guide for T-Shirt Embroidery Machine

Equipment Classification and Import Regulations

T-shirt embroidery machines are typically classified under Harmonized System (HS) Code 8452.21 or 8452.29, depending on automation level and function. Importers must verify the correct HS code with their local customs authority to determine applicable tariffs, import duties, and restrictions. Machines may also fall under industrial machinery regulations requiring conformity assessments or technical documentation prior to entry.

Shipping and Transportation

Due to their weight and sensitivity, embroidery machines should be shipped via freight (air or sea) using palletized crates with shock-absorbing materials. Secure packaging must protect motors, embroidery frames, and electronic control panels. Coordinate with freight forwarders experienced in handling precision manufacturing equipment. Ensure proper labeling, including “Fragile,” “This Side Up,” and handling instructions.

Customs Documentation Requirements

Prepare and submit the following documents for customs clearance:

– Commercial Invoice (detailing value, quantity, and specifications)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Technical Specifications or User Manual (for compliance verification)

– Import License (if required by destination country)

Accurate valuation is critical to avoid delays or penalties.

Electrical and Safety Compliance

Embroidery machines must comply with electrical safety standards in the destination country. Common requirements include:

– CE Marking (European Union – adhering to Machinery Directive 2006/42/EC and Low Voltage Directive)

– UL or ETL Listing (United States and Canada – meeting OSHA and ANSI standards)

– CCC Certification (China)

– KC Certification (South Korea)

Ensure voltage compatibility (e.g., 110V vs. 220V) and include appropriate power adapters or transformers if needed.

Environmental and Waste Disposal Regulations

Used or non-compliant machines may be subject to environmental laws, especially regarding electronic waste (e-waste). Follow local WEEE (Waste Electrical and Electronic Equipment) directives in regions like the EU. Proper disposal or recycling through certified facilities is mandatory to avoid fines.

Intellectual Property and Branding Compliance

When importing machines with proprietary software or brand names, confirm that intellectual property rights are respected. Unauthorized cloning or distribution of branded control systems may violate international IP laws, including TRIPS Agreement provisions.

Installation and Workplace Safety

Upon delivery, ensure installation meets local occupational safety standards. Operators should receive training on safe usage, maintenance, and emergency shutdown procedures. Machines must be grounded properly and installed in well-ventilated areas away from flammable materials.

Ongoing Regulatory Monitoring

Stay updated on changes in trade policies, tariffs, or technical standards affecting embroidery machinery. Subscribe to customs alerts and maintain communication with compliance consultants or trade associations to ensure continued adherence.

In conclusion, sourcing a T-shirt embroidery machine requires careful consideration of several key factors to ensure optimal performance, efficiency, and return on investment. It is essential to evaluate machine specifications such as the number of heads, embroidery speed, stitch quality, and compatibility with various fabric types. Additionally, assessing the reliability of suppliers, availability of technical support, warranty terms, and training options plays a crucial role in long-term success.

Whether opting for new or used machines, conducting thorough market research and comparing brands and models—such as Tajima, Brother, or Barudan—can help identify the most suitable option based on production volume and budget. Automation features, software integration, and ease of operation further enhance productivity and reduce downtime.

Ultimately, investing in a high-quality T-shirt embroidery machine from a reputable supplier not only improves product consistency and turnaround time but also strengthens competitiveness in the apparel and customization market. A well-informed sourcing decision today lays the foundation for scalable growth and long-term operational success.