Looking for a t-shirt customizer near me—and actually getting something that stands out—can feel like searching for a needle in a haystack. Whether you’re launching a side hustle, promoting a local event, or just want a wardrobe full of personalized flair, the demand for unique, on-demand apparel has never been hotter. Enter the era of Print on Demand (POD): a game-changing trend where custom designs go from screen to shirt without any inventory headaches. With POD, creativity meets convenience, and small-town creators now have the same tools as major brands. The best part? Many of these cutting-edge customizers are probably closer than you think. Let’s explore how this booming trend is reshaping local printing—and how you can find (or become) the next go-to t-shirt customizer in your neighborhood.

Top 10 Best T Shirt Customizer Near Me Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#2 T-Shirt & Apparel Printing

Online Since 2001

Website: undergroundshirts.com

Design custom t-shirts and apparel with Underground Printing. Offering screen printing, embroidery, and fast delivery on all orders.

#3 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#4 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#5 Works in Progress NYC

Online Since 2006

Website: worksinprogressnyc.org

You can pre-order t-shirts or tote bags from us in advance, or your guests can bring their own garments to be printed. You can silk screen a company logo or any …

#6 Queensboro

Online Since 1996

Website: queensboro.com

Queensboro.com specializes in custom shirts, polos, hats & promotional products with no minimums, free logo setup, and fast turn-around.

#7 Custom T-Shirt Printing Near Me

Online Since 2017

Website: thestitchnprintstore.com

Get high-quality custom T-shirt printing Near Me at Stitch N Print Store. Order online or call 888-547-4767 to design your own unique apparel and products.

#8 Minuteman Press

Online Since 1995

Website: minuteman.com

High quality and high volume printing products and services from experienced professionals. We specialize in custom orders to make your business stand out!

#9 Design and Print

Online Since 1991

Website: office.fedex.com

Search for your next project, continue your designs, and easily gain inspiration for new ideas from our huge example product catalog.

#10 Same

Online Since 1995

Website: staples.com

Free delivery over $35 · 14-day returnsWith same-day printing, you can design, order and pickup essentials like flyers, menus, banners and more – all in one day. Easy-to-make same-day print products.

Expert Guide: Ordering t shirt customizer near me

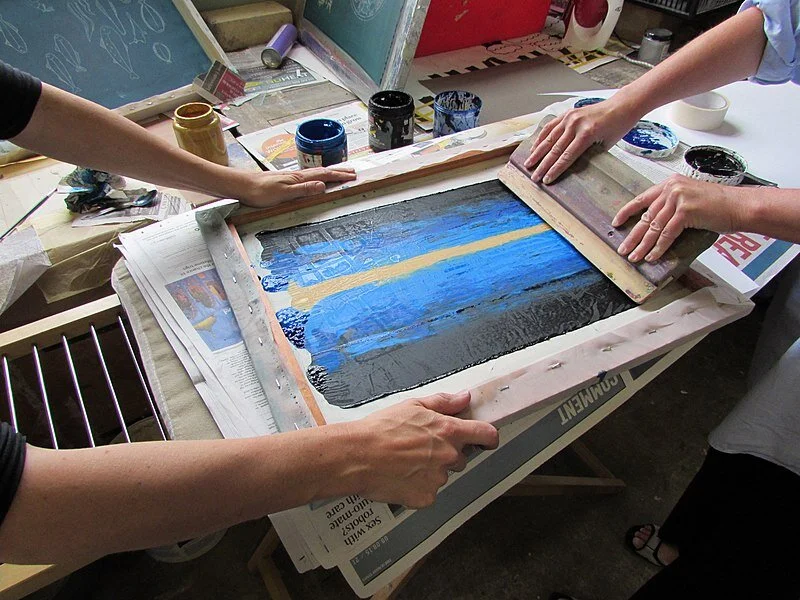

Comparison of T-Shirt Printing Methods: Screen Printing, DTG, and Heat Transfer

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs with limited colors, bold graphics | High – lasts many washes if cured properly | Low per unit for bulk orders; higher setup cost |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, photos, soft hand feel | Medium to High – may fade slightly over time with frequent washing | Higher per unit; no setup fees, ideal for one-offs |

| Heat Transfer | Quick turnaround, small batches, complex designs or text-heavy graphics | Low to Medium – can crack or peel over time, especially with frequent washing | Low setup cost; higher per unit for bulk, varies by transfer type |

Guide to Choosing Fabrics for T-Shirt Customizer Near Me: 100% Cotton vs. 50/50 Blend vs. Tri-Blends

When customizing a t-shirt from a local print shop or online designer, the fabric choice significantly impacts comfort, durability, and print quality. Understanding the differences between 100% cotton, 50/50 blends, and tri-blends helps you pick the perfect tee for your needs.

100% Cotton: Classic Comfort and Softness

100% cotton t-shirts are made entirely from natural cotton fibers, offering a soft, breathable feel that’s ideal for everyday wear.

Pros:

– Soft and comfortable, especially after a few washes

– Highly breathable, great for warm weather

– Excellent for printing – absorbs ink well for vibrant designs

– Natural and biodegradable material

Cons:

– Prone to shrinking, especially if not pre-shrunk

– Less durable under frequent washing and wear

– Can wrinkle easily and lose shape over time

Best for: Casual wear, screen printing, eco-conscious buyers, and those who prefer a traditional cotton feel.

50/50 Blend: The Balanced Performer

A 50/50 blend combines 50% cotton and 50% polyester, offering a balanced mix of comfort and performance.

Pros:

– Resists shrinking and wrinkling better than 100% cotton

– Durable and long-lasting, withstands frequent washing

– Affordable and widely available

– Good print surface for logos and graphics

Cons:

– Less breathable than pure cotton

– Can feel slightly synthetic or less soft to some

– May pill over time with heavy use

Best for: Promotional shirts, workwear, events, and everyday wear where durability matters.

Tri-Blends: Softness Meets Performance

Tri-blend t-shirts typically mix 50% polyester, 25% cotton, and 25% rayon (often modal or viscose), creating a lightweight, ultra-soft fabric with a slight drape.

Pros:

– Exceptionally soft and smooth – often compared to a vintage feel

– Lightweight and breathable with a silky texture

– Minimal shrinkage and excellent shape retention

– Great for detailed prints and soft-hand inks

Cons:

– Higher price point than cotton or 50/50 blends

– Less eco-friendly due to synthetic content

– May not be as durable for heavy-duty use

Best for: Fashion-forward tees, boutique apparel, women’s cuts, and premium custom designs.

How to Choose the Right Fabric for Your Custom T-Shirt

Consider these factors when selecting your fabric:

– Intended use: Everyday wear? Events? Gifts?

– Comfort preference: Do you like soft, natural feel or performance durability?

– Print complexity: Detailed designs often shine on tri-blends or cotton.

– Budget: 50/50 blends offer great value; tri-blends are premium.

– Care requirements: Tri-blends and blends resist shrinking better than cotton.

When visiting a “t-shirt customizer near me,” ask to feel fabric samples in person. This hands-on experience helps you make the best choice for your custom design and comfort needs.

How to Get the Best Price for a T-Shirt Customizer Near You (Bulk Quantity Breaks & Artwork Tips)

Finding a local t-shirt customizer for bulk orders doesn’t have to break the bank. By understanding pricing structures and preparing your artwork correctly, you can secure significant savings. Here’s how:

Leverage Bulk Quantity Breaks for Maximum Savings

Most custom t-shirt printers offer tiered pricing, meaning the more you order, the lower the cost per shirt. Here’s how to maximize these breaks:

- Know the Thresholds: Ask potential local printers for their exact quantity tiers (e.g., 25, 50, 100, 250, 500+). Prices often drop significantly at 50, 100, and 250 units. Ordering just above a breakpoint (e.g., 101 instead of 100) rarely offers a better per-unit rate than hitting the next full tier.

- Consolidate Designs: If you need multiple designs, see if combining quantities across similar designs (e.g., different colors of the same design, or very similar designs) allows you to hit a higher quantity tier for a single “design run.” Printing the same design on more shirts is much cheaper than setting up for many different designs.

- Standardize Sizes & Colors: Ordering a wider range of sizes (S-XXL) or multiple shirt colors often doesn’t increase the base printing cost per shirt significantly compared to a single size/color, but it does increase the total quantity. This helps you reach a higher tier faster. Focus on popular sizes to minimize waste.

- Negotiate: Once you have quotes based on their standard tiers, ask if they can offer an even better rate for your target quantity, especially if it’s a substantial order or you anticipate repeat business. Mention competitor quotes if you have them.

- Consider Future Needs: If you think you’ll need more shirts in the next 6-12 months, ordering a larger initial batch to hit a better tier can save money overall, even if you store some inventory.

Optimize Your Artwork to Reduce Costs & Avoid Fees

Poor artwork is a major source of hidden costs (re-dos, delays, setup fees). Follow these tips:

- Use Vector Files (SVG, EPS, AI): This is the gold standard. Vector graphics scale infinitely without losing quality, making them perfect for different shirt sizes and printing methods. Provide your design in vector format whenever possible.

- High-Resolution Raster Files (300 DPI): If you must use a raster image (JPG, PNG, TIFF), ensure it’s 300 DPI (dots per inch) at the actual print size. A 72 DPI web image will look pixelated and unprintable. Save it as a high-res PNG or TIFF.

- Simplify for Screen Printing (Most Common for Bulk):

- Limit Colors: Screen printing charges per ink color. A 1-color or 2-color design is much cheaper than a 5-color design. Simplify complex logos or artwork to fewer colors.

- Separate Color Layers: Provide your artwork with each color on its own layer or as a separate file (if vector) to make the printer’s job easier and avoid setup fees.

- Avoid Subtle Gradients/Photographs: These are difficult and expensive to screen print. They often require simulated process printing (many screens) or DTG (Direct-to-Garment), which has different cost structures. Discuss options with your printer.

- Specify Exact Placement & Size: Clearly indicate where the design should go (center chest, left chest, full back, sleeve) and the exact dimensions (e.g., 10″ wide). This prevents errors and reprints.

- Confirm Color Matching: Provide Pantone (PMS) color codes for critical brand colors. While exact matches aren’t always guaranteed, it gives the printer a target. Be aware that fabric color affects how ink appears (e.g., red ink on black fabric looks different than on white).

- Get a Physical Proof (Recommended): Pay for a physical print proof (often $25-$50) before the full run. This allows you to see the exact colors, placement, and quality on the actual garment, avoiding costly mistakes on hundreds of shirts. Digital proofs are less reliable for color accuracy.

By strategically using bulk quantity breaks and providing print-ready artwork, you’ll not only get the best possible price from your local t-shirt customizer but also ensure a smooth, high-quality production process. Always get quotes from multiple local printers to compare their tier structures, setup fees, and artwork requirements.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, reliability, and value. Start by evaluating the provider’s product quality—look for a range of fabric options, durable prints, and consistent stitching. Assess printing techniques (such as screen printing, direct-to-garment, or sublimation) to match your design needs and budget.

Next, consider customization options, including available sizes, colors, and design flexibility. A user-friendly design tool and support for complex artwork can streamline the process. Turnaround time and shipping options are also crucial, especially for time-sensitive orders, so opt for providers with clear timelines and tracking.

Customer service and reputation matter—read reviews, check return policies, and test responsiveness before committing. Lastly, compare pricing transparently, watching for hidden fees. The best provider balances affordability with high standards and excellent support, ensuring your custom t-shirts reflect your vision and meet your expectations.