T-shirts have long been more than just wardrobe staples—they’re canvases for self-expression, moving billboards for ideas, and quiet declarations of identity. Today, thanks to the booming world of custom printing and the rise of Print on Demand (POD) technology, turning a bold idea into a wearable masterpiece has never been easier—or more accessible. No longer reserved for big brands or screen-printing pros, custom tees are now within reach of artists, entrepreneurs, and creatives everywhere. With POD platforms eliminating the need for inventory, up-front costs, and complex logistics, the power to design, sell, and ship personalized apparel is literally at your fingertips. Dive in as we explore how custom t-shirt printing is reshaping fashion, one unique design at a time.

Top 8 Best T-Shirt Custom Printing Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#2 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

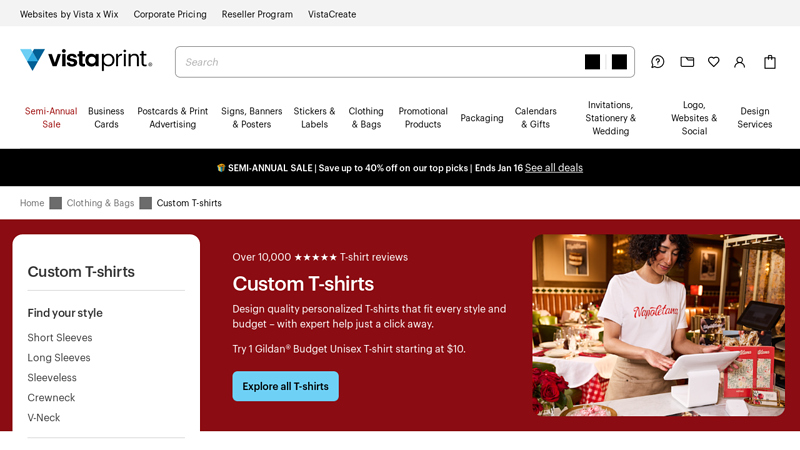

#3 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

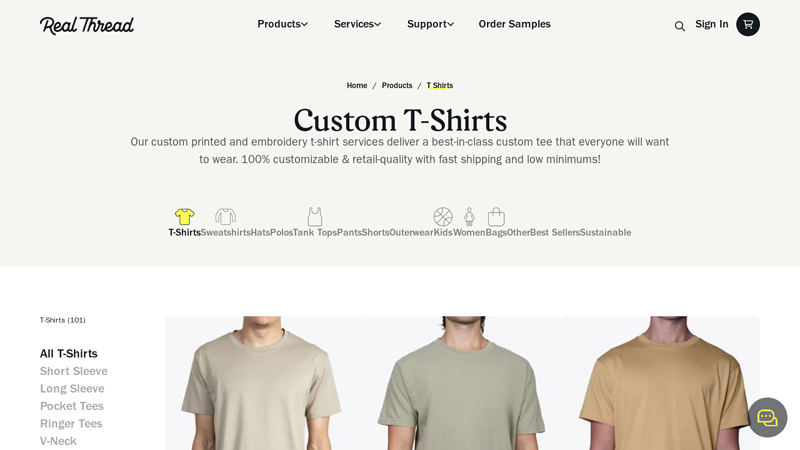

#4 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

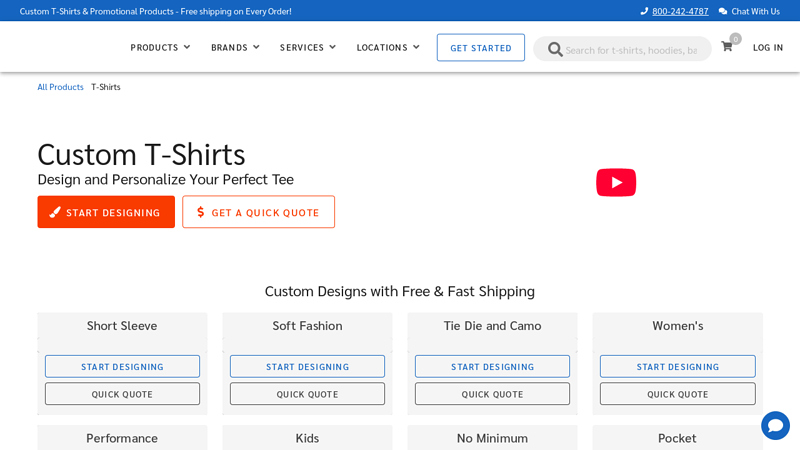

#5 Custom Print Shop

Online Since 1995

Website: bonfire.com

Order custom shirts and apparel with ease on Bonfire. ✓Premium products. ✓No minimums. ✓Bulk discounts. ✓No upcharge for plus sizes. Start your order today!

#6 Custom Print Shop

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsCreate custom t-shirts with your designs. High-quality printing, fast delivery, and endless customization options. Start designing your personalized tees …

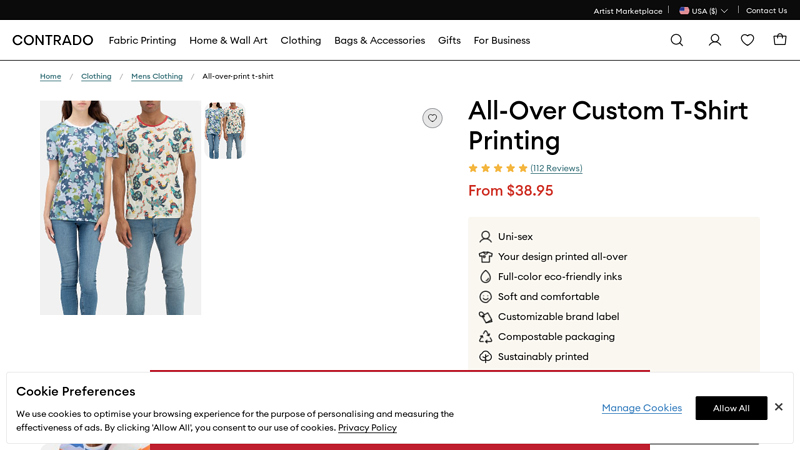

#7 All

Online Since 2004

Website: contrado.com

In stock Rating 4.8 (112) Made to measure t-shirts featuring your designs and artwork. Handmade to order from soft Jersey fabric. All-over custom t-shirt printing.

#8 ooShirts: Cheap Custom T

Online Since 2007

Website: ooshirts.com

Custom t-shirts for less! ooShirts is the leader in affordable t-shirt printing. Free shipping & setup. Design your own t-shirts at awesomely low prices!

Expert Guide: Ordering t-shirt custom printing

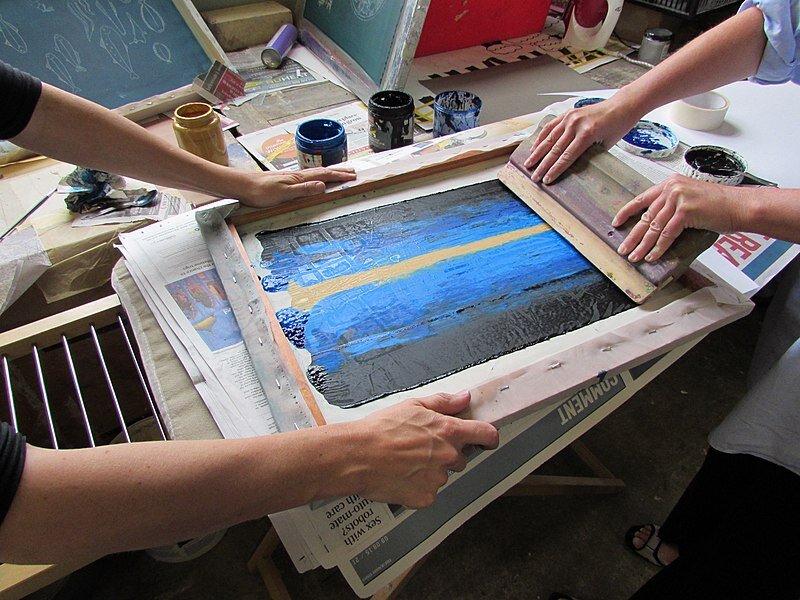

Comparison: Screen Printing, DTG, and Heat Transfer for T-Shirt Custom Printing

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large, solid-color designs; bulk orders (50+ units) | High – lasts many washes if cured properly | Low per unit for bulk; high setup cost |

| DTG (Direct-to-Garment) | Detailed, full-color designs; small runs or single items | Moderate to High – softer feel, may fade over time | Higher per unit; no setup fees |

| Heat Transfer | Quick turnaround; complex designs; small quantities | Low to Moderate – can crack or peel over time | Low initial cost; higher per unit |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: Your Guide to Choosing the Perfect Fabric for Custom T-Shirt Printing

When customizing t-shirts, the fabric you choose dramatically impacts comfort, durability, appearance, and how your design turns out. Understanding the differences between 100% cotton, 50/50 blends, and tri-blends helps you make the best choice for your needs.

100% Cotton: The Classic Choice

100% cotton t-shirts are made entirely from natural cotton fibers. They’re a popular go-to for their soft feel and breathable quality.

Pros:

– Soft and Comfortable: Feels gentle against the skin, especially after a few washes.

– Breathable: Ideal for warm weather or active wear due to excellent moisture absorption.

– Eco-Friendly Option: Biodegradable and often available in organic varieties.

– Great for Printing: Absorbs ink well, making it ideal for vibrant screen printing and direct-to-garment (DTG) printing.

Cons:

– Prone to Shrinking: May shrink if not pre-shrunk or washed in hot water.

– Less Durable: Can wear out faster and develop holes or thin spots over time.

– Wrinkles Easily: Tends to crease and lose shape without proper care.

– Fades Over Time: Colors may fade with repeated washing.

Best For: Casual wear, eco-conscious brands, and designs with bold, detailed prints.

50/50 Blend: The Balanced Option

A 50/50 blend combines 50% cotton and 50% polyester, offering a middle ground between natural and synthetic fibers.

Pros:

– Durable and Long-Lasting: Polyester adds strength, resisting shrinkage and wear.

– Less Wrinkling: Holds its shape better and resists creasing.

– Affordable: Often more budget-friendly than 100% cotton or tri-blends.

– Lightweight and Comfortable: Retains cotton’s softness while improving performance.

Cons:

– Less Breathable: Polyester doesn’t absorb moisture as well, which can feel less comfortable in heat.

– Pilling Over Time: May develop small fabric balls (pills) with frequent use.

– Ink Absorption: May require pretreatment for DTG printing for optimal results.

Best For: Promotional giveaways, events, and high-volume orders where durability and cost matter.

Tri-Blends: The Premium Feel

Tri-blend t-shirts typically combine cotton, polyester, and rayon (often in ratios like 50% poly, 25% cotton, 25% rayon). This blend creates a soft, lightweight, and slightly drapey fabric.

Pros:

– Ultra-Soft Hand Feel: Feels luxurious and broken-in right from the start.

– Excellent Drape: Flatters the body with a smoother, more flowing fit.

– Color Retention: Vibrant prints that resist fading due to rayon and polyester content.

– Lightweight and Comfortable: Great for layering or warmer climates.

Cons:

– Higher Price Point: More expensive than cotton or 50/50 blends.

– Less Durable: Softer fibers may be more prone to snags or thinning.

– Special Care Required: Often needs gentle washing to maintain softness and shape.

– Not Ideal for Heavy Prints: Lightweight fabric may not support thick ink applications.

Best For: Fashion-forward apparel, boutique brands, and soft-hand feel designs like vintage or retro styles.

How to Choose the Right Fabric

- For Maximum Comfort and Breathability: Choose 100% cotton.

- For Durability and Budget-Friendly Options: Go with a 50/50 blend.

- For a Soft, Premium Look and Feel: Opt for a tri-blend.

Consider your audience, use case, printing method, and desired look when selecting your fabric. Each option offers unique benefits—matching the right fabric to your project ensures your custom t-shirts look great and feel even better.

How to Get the Best Price for T-Shirt Custom Printing

Ordering custom-printed t-shirts in bulk can be a cost-effective way to promote your brand, team, or event — but only if you know how to maximize savings. From leveraging quantity breaks to optimizing your artwork, here’s how to get the best price without sacrificing quality.

Understand Bulk Quantity Breaks

Most printing companies offer tiered pricing based on the number of shirts ordered. These are known as “quantity breaks.”

- Start with minimums: Many suppliers offer discounts starting at 24 or 50 units. Ordering just above a break point (e.g., 51 instead of 49) can drastically lower the per-unit cost.

- Compare tiers: Get quotes for 50, 100, 250, and 500 units to see where the biggest cost savings occur. Often, jumping from 100 to 250 shirts cuts the price per shirt by 20–30%.

- Consolidate orders: If you’ll need more shirts in the future, order in larger quantities now to save. Store extras properly to avoid wear and tear.

Choose the Right Printing Method

Different printing techniques affect both price and quality. Select the most cost-efficient method for your design.

- Screen Printing: Best for large orders (50+ units) and simple, bold designs. Lower per-unit cost at scale.

- DTG (Direct-to-Garment): Ideal for detailed, full-color designs or small batches. Higher per-shirt cost, but no setup fees for complex artwork.

- Heat Transfer: Good for short runs or specialty fabrics. Can be more expensive over time and less durable.

- Dye Sublimation: Best for all-over prints on polyester. Higher upfront cost, but great for performance wear.

Opt for Basic, Durable T-Shirts

The shirt itself impacts your total cost.

- Stick to standard colors: White or black are usually the cheapest. Neon or specialty colors cost more.

- Choose value brands: Gildan, Hanes, and Bella+Canvas offer quality at lower prices than premium labels.

- Standard cuts: Crewnecks are cheaper than v-necks or women’s fitted styles.

Simplify Your Artwork to Save Money

Complex designs increase printing costs — especially with screen printing.

- Limit print colors: Each color requires a separate screen. Stick to 1–3 colors to reduce setup fees.

- Use vector files: Supply artwork in vector format (AI, EPS, or SVG) to avoid redraw fees. High-resolution PNGs (300 DPI) work for DTG.

- Avoid gradients and fine details: They can blur in screen printing. Simplify logos and text for cleaner, cheaper prints.

- One print location: Chest or back only (not both) reduces labor and setup time.

Get Multiple Quotes and Negotiate

Don’t settle for the first quote.

- Compare 3–5 suppliers: Look at both online printers and local shops. Online often has better bulk rates.

- Ask about package deals: Some vendors offer discounts for repeat customers or bundled services (design help, packaging).

- Negotiate: If you’re ordering 250+ units, ask for a custom quote. Many suppliers will lower prices to secure large orders.

Plan Ahead and Avoid Rush Fees

Timing affects pricing.

- Order early: Rush processing can add 25–50% to your total cost.

- Account for production time: Most printers need 7–14 days. Schedule orders at least 3–4 weeks before your event.

- Avoid holidays: Printing demand spikes around major events (e.g., holidays, graduations). Order during off-peak months for better rates.

Bundle Sizes and Colors Strategically

You can often maintain the same price per unit across different sizes and colors — as long as the total quantity stays within a tier.

- Mix sizes, not colors: It’s cheaper to order 100 shirts in various sizes (S–XXL) than to split 50 white and 50 blue, which may count as two smaller batches.

- Stick to one color per design: If you want different shirt colors, print the same design on each to avoid re-screening.

By understanding bulk pricing, simplifying your design, and choosing the right supplier, you can significantly reduce your custom t-shirt printing costs — without cutting corners on quality.

Choosing the right custom t-shirt provider requires careful consideration of several key factors to ensure quality, value, and a smooth experience. Start by assessing the provider’s print quality and fabric options—high-resolution printing techniques like screen printing or direct-to-garment, combined with durable, comfortable materials, are essential for professional-looking results. Consider customization options, including design flexibility, color choices, and printing methods, to match your vision.

Next, evaluate pricing and minimum order requirements. While competitive pricing is important, be wary of unusually low costs that may signal compromised quality. Look for transparent pricing with no hidden fees. Customer service and turnaround time also matter—reliable support and on-time delivery are crucial, especially for time-sensitive events.

Reading customer reviews and requesting samples can provide real-world insights into a provider’s reliability and product quality. Finally, ensure the provider offers easy-to-use design tools and file compatibility to streamline the ordering process.

By balancing quality, price, customization, and customer support, you can confidently select a custom t-shirt provider that meets your needs and delivers excellent results every time.