Picture this: you wake up, grab your favorite coffee mug, and slip on a T-shirt that’s anything but ordinary. Maybe it’s a bold graphic that makes people smile, a witty slogan that sparks a conversation, or a design that perfectly captures your personality. That’s the magic of custom T-shirt design—turning fabric into self-expression.

But here’s the real game-changer: you don’t need a warehouse, inventory, or even a sewing machine to launch your own unique apparel line. Thanks to the booming world of Print on Demand (POD), creating custom T-shirts has never been easier—or more accessible. From indie artists to side-hustlers and full-time entrepreneurs, POD is reshaping the fashion landscape, letting creativity lead the way without the risk of overproduction.

In this post, we’ll dive into the vibrant world of T-shirt custom design, explore how POD technology is fueling innovation, and show you how to turn your ideas into wearable art—one print at a time.

Top 9 Best T Shirt Custom Design Services (2026 Review)

Reviewed for Print Quality, Pricing & Turnaround Time

#1 T

Online Since 1999

Website: customink.com

Create your own t-shirt design from scratch, upload your own artwork or ask an expert for design help. It’s all possible in our state-of-the-art design lab.

#2 Custom Print Shop

Online Since 2003

Website: rushordertees.com

Free delivery · Free 45-day returnsDesign and print high-quality custom t-shirts at affordable prices. No Minimums. Free Shipping. Fast turnaround. Rush delivery options. Expert service.

#3 Threadbird: Custom T Shirt Printing, High

Online Since 2010

Website: threadbird.com

At Threadbird, we are all about customization and we are committed to making your custom t shirt printing & apparel dreams come true.

#4 Custom T-Shirt Printing

Online Since 1997

Website: instantimprints.com

Personalized shirts with your logo or design. We create t-shirts with custom designs using the latest technologies in direct to garment, heat transfers, …

#5 : Design & Print Shirts Online

Online Since 1999

Website: vistaprint.com

Starting from $10.00 4.8 5.9K · 3–8 day deliveryDesign and print your own high quality custom t-shirts at an affordable price. Browse shirts across various styles, price points and brands.

#6 at Real Thread

Online Since 2009

Website: realthread.com

14-day returnsOur custom printed and embroidery t-shirt services deliver a best-in-class custom tee that everyone will want to wear. 100% customizable & retail-quality …

#7 Custom Print Shop

Online Since 1995

Website: bonfire.com

Order custom shirts and apparel with ease on Bonfire. ✓Premium products. ✓No minimums. ✓Bulk discounts. ✓No upcharge for plus sizes. Start your order today!

#8 Custom Print Shop

Online Since 2001

Website: undergroundshirts.com

Free delivery over $50 30-day returnsCreate custom t-shirts with your designs. High-quality printing, fast delivery, and endless customization options. Start designing your personalized tees …

#9 Personalized Work Shirts, Custom Printed T

Online Since 2009

Website: tshirtbydesign.com

Free delivery over $50 30-day returnsWe offer a variety of unique and personalized work shirt templates that are designed to help your business get started with custom printed company shirts.

Expert Guide: Ordering t shirt custom design

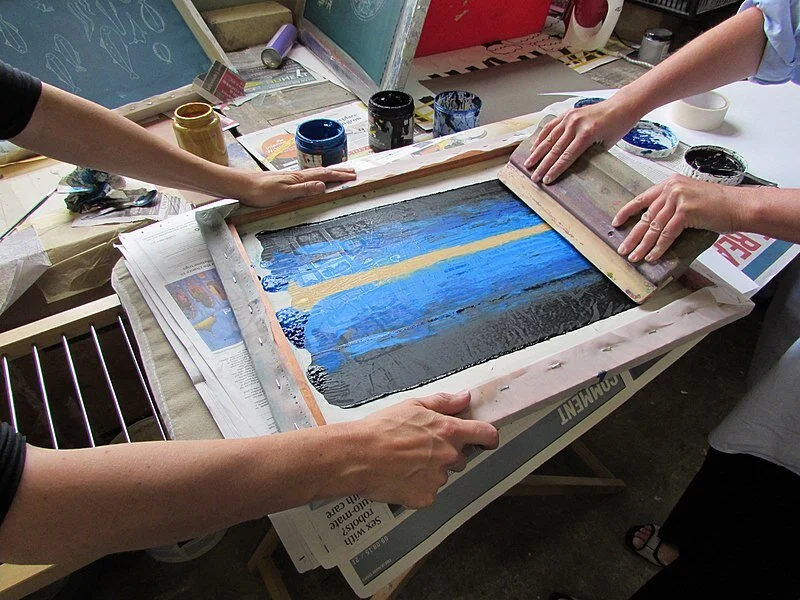

Comparison of T-Shirt Custom Design Methods

| Method | Best For | Durability | Cost |

|---|---|---|---|

| Screen Printing | Large orders, simple designs, bold colors | High – lasts many washes | Low to medium (cost-effective for bulk) |

| DTG (Direct-to-Garment) | Small orders, detailed/full-color designs, photos | Medium – may fade over time with frequent washing | Medium to high (more expensive per unit for small runs) |

| Heat Transfer | Small batches, quick turnaround, complex designs | Low to medium – can crack or peel over time | Low (low setup cost, but per-unit cost adds up) |

100% Cotton vs. 50/50 Blend vs. Tri-Blends: Choosing the Best Fabric for Your Custom T-Shirt Design

When creating custom t-shirts, selecting the right fabric is just as important as the design itself. The material affects comfort, durability, appearance, and how well your graphics print. Here’s a breakdown of the three most popular options: 100% cotton, 50/50 blends, and tri-blends.

100% Cotton

Pros:

– Soft and Breathable: Offers a classic, natural feel that’s ideal for warm weather and everyday wear.

– Excellent Printability: Provides a smooth, absorbent surface perfect for vibrant screen printing and direct-to-garment (DTG) printing.

– Eco-Friendly Option: Biodegradable and often available in organic varieties, appealing to environmentally conscious customers.

Cons:

– Prone to Shrinkage: May shrink up to 5–7% after washing if not pre-shrunk.

– Less Durable: Can wear out faster, especially after repeated washings.

– Wrinkles Easily: Requires ironing for a crisp look and tends to hold creases.

Best for: Casual wear, vintage-style designs, eco-focused brands, and customers who prefer a traditional cotton feel.

50/50 Blend (50% Cotton / 50% Polyester)

Pros:

– Reduced Shrinkage: More stable than 100% cotton, maintaining shape and size after washing.

– Durable and Resilient: Polyester adds strength, making the shirt more resistant to wear and fading.

– Affordable: Often less expensive than tri-blends, offering a budget-friendly option with good performance.

Cons:

– Less Breathable: Can feel warmer and less comfortable in hot climates due to reduced moisture absorption.

– Slightly Stiffer Feel: The polyester content can make the fabric feel less soft compared to pure cotton.

– Pilling: May develop small fabric balls over time with friction.

Best for: Promotional events, sports teams, workwear, and situations where durability and cost-efficiency are priorities.

Tri-Blend (Typically 50% Polyester / 25% Cotton / 25% Rayon)

Pros:

– Ultra-Soft Texture: Combines the softness of cotton, durability of polyester, and drape of rayon for a luxurious, vintage feel.

– Excellent Drape: Flatters the body with a smooth, slightly fitted silhouette.

– Minimal Shrinkage: Very stable in the wash and retains shape well.

– Vintage Aesthetic: Ideal for retro or fashion-forward designs due to its heathered look and muted finish.

Cons:

– Higher Cost: Typically the most expensive of the three options.

– Sensitivity to Heat: Rayon can weaken under high heat, so low-temperature washing and drying are recommended.

– Less Absorbent: Not ideal for high-sweat activities due to reduced moisture-wicking compared to pure cotton.

Best for: Fashion apparel, boutique brands, lifestyle designs, and premium custom tees where comfort and style are key.

Final Tips for Choosing

- Consider the Use Case: Is the shirt for daily wear, athletic use, or promotional giveaways?

- Think About Your Design: Bold graphics pop on 100% cotton and 50/50 blends, while tri-blends enhance soft, artistic prints.

- Know Your Audience: Prioritize softness for lifestyle brands, durability for teams, and sustainability for eco-conscious markets.

By matching your fabric choice to your design goals and target audience, you’ll ensure your custom t-shirts not only look great but feel great too.

How to Get the Best Price for Custom T-Shirt Design (Bulk Quantity Breaks & Artwork Tips)

Ordering custom T-shirts in bulk can be a cost-effective way to promote your brand, event, or team—but only if you know how to maximize savings. Two key factors that significantly impact your bottom line are leveraging bulk quantity breaks and preparing print-ready artwork. Here’s how to get the best price without sacrificing quality.

Understand and Leverage Bulk Quantity Breaks

Most screen printing and direct-to-garment (DTG) companies offer tiered pricing based on order volume. The more shirts you order, the lower the per-unit cost. Here’s how to take full advantage:

-

Know the Break Points: Common quantity breaks occur at 25, 50, 100, 250, and 500 units. For example, ordering 99 shirts might cost $10 each, but 100 could drop to $7.50. Always ask for the full pricing schedule before finalizing your order.

-

Consolidate Designs: If you need multiple designs, see if you can combine them into one order. Some printers charge lower setup fees when multiple designs are printed together.

-

Standardize Sizes and Colors: Ordering in a single shirt color and fewer size variations reduces setup and inventory complexity, often leading to lower costs.

-

Choose Simpler Printing Methods: Screen printing is generally cheaper for large runs (100+ units), especially with fewer print colors. DTG is better for small runs or complex designs but costs more per shirt.

Optimize Your Artwork to Reduce Costs

High-quality artwork not only looks better but also reduces production issues and extra charges:

-

Use Vector Files (AI, EPS, SVG): Vector graphics scale infinitely without losing quality, making them ideal for printing. This prevents pixelation and reduces the need for costly file corrections.

-

Stick to Fewer Print Colors: Each additional color in screen printing requires a separate screen and setup. Simplifying your design to 1–3 colors can dramatically cut costs.

-

Provide High-Resolution Raster Files (300 DPI): If you must use PNG or JPEG, ensure it’s at least 300 dpi at the intended print size (e.g., 10″x10″ at 300 dpi).

-

Avoid Small Text and Fine Details: Tiny text or intricate lines may not print clearly, especially with screen printing. Simplify and enlarge key elements.

-

Confirm Color Matching: Use Pantone (PMS) colors for brand consistency. Providing exact color codes avoids miscommunication and costly reprints.

Bonus Tips for Maximum Savings

-

Compare Multiple Vendors: Get quotes from at least 3–5 reputable printers. Use the same specs to make comparisons accurate.

-

Ask About Setup Fees and Minimums: Some vendors waive setup fees for large orders or offer discounts for repeat customers.

-

Order Slightly More Than Needed: Running out and needing a small reorder is expensive. A 5–10% buffer is often cheaper than a second production run.

-

Time Your Order: Avoid peak seasons (e.g., back-to-school, holidays) when demand is high and prices may rise.

By strategically using bulk quantity breaks and preparing professional artwork, you can dramatically reduce your custom T-shirt costs while ensuring a high-quality finished product. Plan ahead, communicate clearly with your printer, and always request a sample or proof before full production.

When choosing the right custom t-shirt provider, it’s essential to consider several key factors to ensure quality, value, and reliability. Start by evaluating the quality of materials and construction—opt for providers that use soft, durable fabrics and offer a variety of fits and styles to suit your needs. Next, assess the printing methods available (such as screen printing, direct-to-garment, or heat transfer) and choose one that aligns with your design complexity and quantity requirements.

Price is important, but balance affordability with quality—cheaper options may compromise on fabric or print longevity. Look for transparent pricing with no hidden fees. Customer service and ease of ordering also matter; a responsive support team and user-friendly design tool can streamline the process. Additionally, check turnaround times and shipping options to ensure they meet your timeline.

Finally, read customer reviews and request samples if possible to gauge real-world performance. By prioritizing quality, customization options, reliable service, and value, you can confidently select a custom t-shirt provider that meets both your creative vision and practical needs.