The global ceiling grid market is experiencing robust growth, driven by rising construction activity, demand for acoustic and modular ceiling solutions, and increasing focus on energy-efficient building designs. According to a report by Mordor Intelligence, the ceiling systems market—encompassing T-bar grids, suspended ceilings, and related components—is projected to grow at a CAGR of over 5.8% from 2023 to 2028. Similarly, Grand View Research estimates that the global suspended ceiling market size was valued at USD 32.5 billion in 2022 and is expected to expand at a CAGR of 6.1% through 2030, fueled by commercial infrastructure development and retrofitting in residential and institutional buildings. With North America and Europe maintaining strong demand and Asia-Pacific emerging as a high-growth region due to urbanization and industrial expansion, the T ceiling grid segment remains a critical component in modern architectural design. As competition intensifies and innovation accelerates, identifying the leading manufacturers becomes essential for contractors, architects, and developers seeking quality, sustainability, and performance. Here are the top 8 T ceiling grid manufacturers shaping the industry landscape.

Top 8 T Ceiling Grid Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

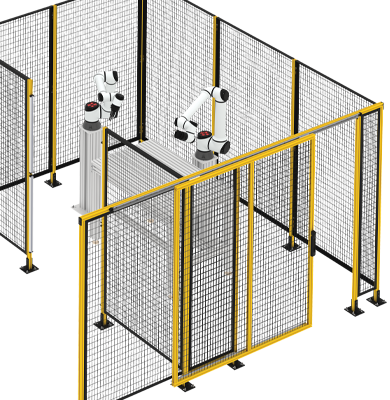

#1 80/20 Aluminum T-slot Building Systems

Domain Est. 1997

Website: 8020.net

Key Highlights: T-Slots, aluminum extrusions, and parts. Architectural solutions and frames for industrial machine guards, workstations, data center enclosures, and more….

#2 Armstrong World Industries

Domain Est. 1995

Website: armstrong.com

Key Highlights: Armstrong World Industries is a leader in the design, innovation and manufacture of ceiling and wall system solutions, transforming how people design, ……

#3 Ceilings

Domain Est. 1996

Website: usg.com

Key Highlights: Arctic™ Acoustical Panels are fine-textured ceiling panels perfect for open workspaces, classrooms and healthcare facilities. Astro® Acoustical Panels. Quick ……

#4 Ceiling, Grid & Wall …

Domain Est. 1999

Website: armstrongceilings.com

Key Highlights: Armstrong World Industries is a global leader in the design and manufacture of innovative commercial ceiling, suspension system and wall solutions….

#5 Ceilume Ceiling Tiles and Ceiling Panels

Domain Est. 2003

Website: ceilume.com

Key Highlights: Decorative vinyl ceiling tiles and drop ceiling panels that are affordable, easy to install/maintain, mold/mildew resistant, and dust (and rust!) free….

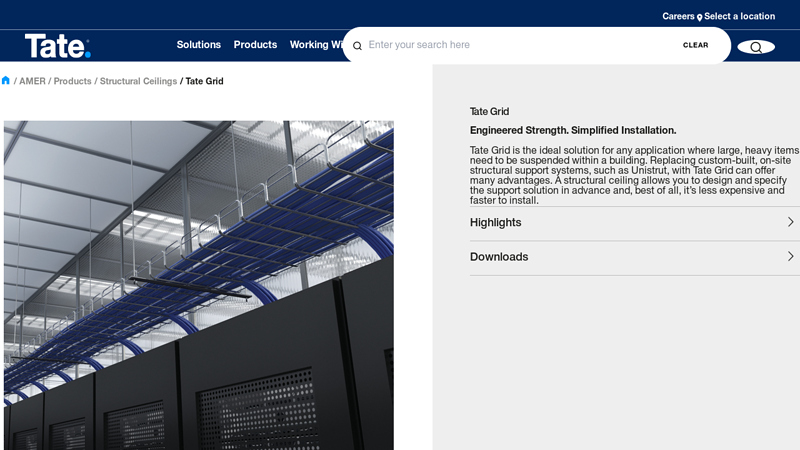

#6 Tate Grid

Domain Est. 2007

Website: tateglobal.com

Key Highlights: Tate Grid is a pre-engineered structural ceiling system designed to support heavy loads, offering faster installation and lower costs than custom-built ……

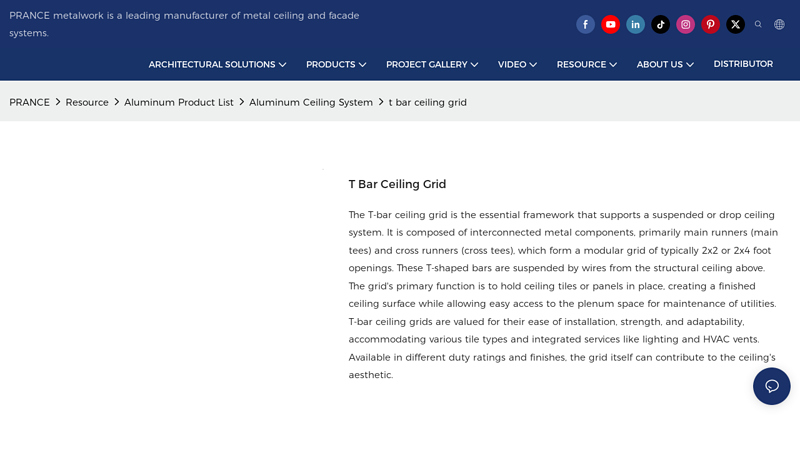

#7 T Bar Ceiling Grid

Domain Est. 2015

Website: prancebuilding.com

Key Highlights: The T-bar ceiling grid is the essential framework that supports a suspended or drop ceiling system. It is composed of interconnected metal components, ……

#8 Acoustic Solutions for the Open Office

Domain Est. 2016

Website: turf.design

Key Highlights: Simple yet mesmerizing, Step takes the standard grid ceiling up a level, dropping in to stand out. View Step. Stone has never felt so inspired. Introducing ……

Expert Sourcing Insights for T Ceiling Grid

H2: Projected 2026 Market Trends for T Ceiling Grid

The T ceiling grid market, a foundational component of suspended ceiling systems, is poised for significant transformation by 2026, driven by evolving construction demands, technological advancements, and shifting sustainability priorities. Here’s an analysis of key trends expected to shape the market:

1. Accelerated Demand for Sustainability and Recycled Content

* Trend: Environmental regulations and green building certifications (like LEED, BREEAM) will intensify pressure on manufacturers to offer grids with high recycled content (especially post-consumer aluminum and steel) and low embodied carbon.

* Impact by 2026: Products boasting 80-100% recycled aluminum and Cradle-to-Cradle certified options will become standard expectations, not just differentiators. Transparency in material sourcing and end-of-life recyclability will be critical purchasing factors.

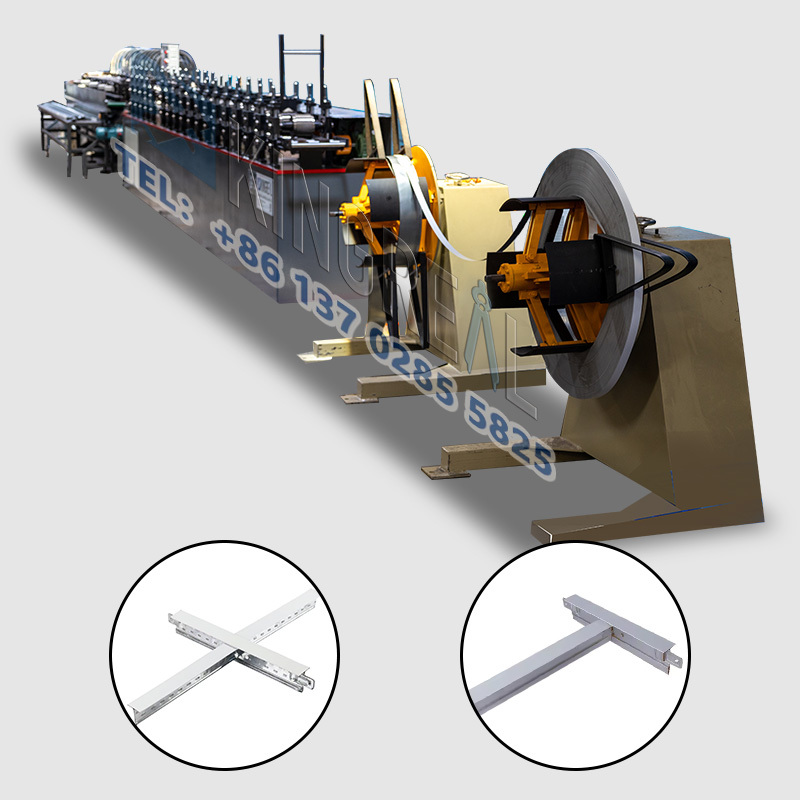

2. Growth in Light Gauge Steel (LGS) Grid Adoption

* Trend: While aluminum dominates high-end and humid environments, lighter, more cost-effective, and increasingly corrosion-resistant light gauge steel grids are gaining share, particularly in commercial retrofits and mid-tier projects.

* Impact by 2026: Expect significant innovation in LGS coatings (e.g., enhanced zinc-aluminum alloys, organic coatings) to improve durability and aesthetics, narrowing the performance gap with aluminum and driving wider adoption.

3. Integration with Smart Building Systems and Acoustics

* Trend: Ceilings are becoming platforms for technology. T grids will need to seamlessly integrate with sensors, lighting, HVAC components, and advanced acoustic solutions (integrated baffles, enhanced sound absorption).

* Impact by 2026: “Smart-ready” grid systems with pre-designed pathways for wiring, standardized mounting points for IoT devices, and optimized performance with high-NRC (Noise Reduction Coefficient) or CAC (Ceiling Attenuation Class) ceiling tiles will be in high demand for offices, healthcare, and education.

4. Focus on Design Flexibility and Aesthetics

* Trend: Beyond function, ceilings are key design elements. Demand for concealed grid systems, linear reveals, integrated trim, and custom colors/finishes will rise. Exposed grid systems in commercial settings will also see growth for an industrial or architectural look.

* Impact by 2026: Manufacturers will expand offerings in powder-coated finishes (beyond standard white), anodized aluminum, and specialty profiles. Systems enabling complex geometries (curves, drops) with standard T-grid components will be developed.

5. Supply Chain Resilience and Regionalization

* Trend: Post-pandemic and geopolitical uncertainties highlight vulnerabilities in global supply chains. The 2022-2024 period saw significant price volatility for aluminum and steel.

* Impact by 2026: Manufacturers will prioritize regional production, strategic raw material hedging, and diversified sourcing to ensure stability. This may lead to slightly higher costs but improved reliability and reduced lead times.

6. Labor Efficiency and Installation Innovation

* Trend: Skilled labor shortages and pressure to reduce construction timelines drive demand for faster, easier installation systems.

* Impact by 2026: Wider adoption of tool-less or semi-automated connection systems, pre-assembled grid sections, clearer digital installation guides (AR/VR), and grids designed for single-person handling will accelerate, reducing installation time and cost.

7. Performance in Resilient Construction

* Trend: Increased focus on building resilience (seismic, fire, moisture) will influence grid specifications, especially in high-risk areas.

* Impact by 2026: Demand for grids meeting stringent seismic codes (e.g., IBC, ASCE 7) and enhanced fire-rated assemblies will grow. Corrosion-resistant grids for humid environments (hospitals, pools) will remain crucial.

In summary, the 2026 T ceiling grid market will be characterized by sustainability as a baseline, technological integration as a norm, design versatility as a key differentiator, and a relentless focus on installation efficiency and supply chain stability. Manufacturers who innovate across these fronts will capture significant market share.

Common Pitfalls When Sourcing T Ceiling Grid (Quality, IP)

Sourcing T ceiling grid systems—especially those involving Intellectual Property (IP) considerations—can present several challenges. Overlooking these pitfalls can lead to compromised product quality, legal exposure, and project delays. Here are key issues to watch for:

Poor Material Quality and Durability

Many suppliers offer T grid systems made from low-grade steel or aluminum with inadequate corrosion resistance. Thin gauges or substandard finishes may lead to warping, sagging, or rusting over time—especially in high-humidity environments. Always verify material specifications, coating standards (e.g., ISO 9227 for salt spray testing), and compliance with ASTM C635/C636.

Inconsistent Dimensional Accuracy

Low-quality grids often suffer from inconsistent cross-T dimensions or poor slot tolerances, making tile installation difficult and leading to visible misalignments. This impacts aesthetics and structural integrity. Request samples and inspect for uniformity before bulk ordering.

Lack of Certification and Testing Documentation

Reputable T grid systems should come with third-party test reports for load capacity, fire resistance, and seismic performance. Suppliers who cannot provide documentation (e.g., UL, Intertek, or local building code compliance) may be cutting corners, risking non-compliance during inspections.

Intellectual Property (IP) Infringement Risks

Some manufacturers produce grid systems that replicate patented designs (e.g., unique clip mechanisms or suspension details) without licensing. Sourcing from such suppliers can expose contractors or project owners to legal liability. Always verify whether the product design is proprietary and confirm the supplier holds proper IP rights or licenses.

Misrepresentation of Brand or Origin

Counterfeit or “gray market” products may be labeled as premium brands but fail to meet original performance standards. This is common with globally sourced materials. Confirm the supplier’s authenticity through authorized distributor lists and request traceable batch documentation.

Inadequate Technical Support and Installation Guidance

Lower-tier suppliers may not provide detailed installation manuals, load span charts, or engineering support. This increases the risk of improper installation and system failure. Ensure access to technical resources and trained support staff.

Hidden Costs from Poor Logistics and Lead Times

Some suppliers quote low prices but lack reliable logistics, leading to project delays or unexpected freight charges. Evaluate supplier track records for on-time delivery and supply chain transparency.

By addressing these pitfalls proactively—through due diligence, sample testing, and IP verification—buyers can ensure they source T ceiling grid systems that are both high-quality and legally compliant.

Logistics & Compliance Guide for T Ceiling Grid

This guide outlines key logistics considerations and compliance requirements for the transportation, handling, storage, and installation of T Ceiling Grid systems. Adhering to these guidelines ensures product integrity, safety, and regulatory compliance throughout the supply chain and construction process.

Product Specifications and Handling

T Ceiling Grid components—including main tees, cross tees, wall angles, and accessories—are typically made from galvanized steel or aluminum. Handle with care to prevent deformation, coating damage, or contamination. Always wear appropriate personal protective equipment (PPE), such as gloves and safety glasses, when handling materials to prevent injury from sharp edges.

Avoid dragging or dropping bundles. Use mechanical lifting equipment (e.g., forklifts or pallet jacks) when moving heavy loads. Store materials on level, dry surfaces using pallets or skids to prevent moisture exposure and warping.

Packaging and Transportation

T Ceiling Grids are shipped in labeled bundles or on pallets, secured with strapping or shrink wrap. Ensure packaging remains intact during transit to prevent damage. When transporting, protect materials from extreme weather conditions, especially moisture and temperature fluctuations.

Use covered trucks or containers for long-distance or outdoor transport. Secure loads to prevent shifting. Provide dunnage between stacked materials to avoid crushing. Maintain a clear chain of custody and inspect shipments upon delivery for damage or discrepancies.

Storage Requirements

Store T Ceiling Grid components indoors in a clean, dry, and well-ventilated area. Keep materials off the ground on pallets or racks, ideally at least 15 cm (6 inches) above floor level. Avoid storage near sources of moisture, such as exterior doors or plumbing.

Do not stack bundles higher than recommended by the manufacturer (typically no more than 2–3 pallets high) to prevent collapse or deformation. Protect from direct sunlight, which may degrade packaging and affect material finish. Rotate stock using a first-in, first-out (FIFO) system to prevent long-term storage issues.

Regulatory and Compliance Standards

T Ceiling Grid systems must comply with relevant building codes and safety standards. In the United States, this includes adherence to the International Building Code (IBC), International Fire Code (IFC), and requirements from OSHA for safe handling and installation.

Materials should meet ASTM standards, such as ASTM C635 for dimensional stability and ASTM C645 for proper installation methods. Fire-rated assemblies must comply with ASTM E119 or UL 263 for fire resistance. Verify that products carry necessary certifications (e.g., UL, Intertek) and are labeled accordingly.

Environmental and Sustainability Compliance

Ensure T Ceiling Grid products comply with environmental regulations, including restrictions on hazardous substances (e.g., RoHS, REACH). Many grid systems contain recycled content and are themselves recyclable—verify manufacturer documentation for environmental product declarations (EPDs) or compliance with LEED credit requirements.

Dispose of damaged or excess materials through approved recycling channels. Avoid open burning or landfill disposal when possible. Maintain records of material safety data sheets (MSDS/SDS) for all components.

Installation and Safety Compliance

Only trained and qualified personnel should install T Ceiling Grid systems. Follow manufacturer instructions and job site safety protocols. Comply with OSHA regulations for fall protection, ladder safety, and working at heights.

Ensure ceiling grid installations support the intended ceiling tiles and any added loads (e.g., lights, HVAC units). Perform regular inspections during and after installation to verify alignment, stability, and compliance with design specifications.

Documentation and Recordkeeping

Maintain accurate records for all logistics and compliance activities, including:

- Bills of lading and delivery receipts

- Inspection reports and damage logs

- Certificates of compliance and test reports

- SDS and manufacturer specifications

- Installation checklists and quality audits

These documents support quality assurance, warranty claims, and regulatory audits.

Conclusion

Proper logistics management and strict adherence to compliance standards are essential for the successful deployment of T Ceiling Grid systems. By following this guide, stakeholders can ensure product performance, worker safety, and regulatory conformity from warehouse to installation site. Always consult manufacturer guidelines and local building authorities for project-specific requirements.

In conclusion, sourcing a T-bar ceiling grid requires careful consideration of material quality, gauge thickness, compatibility with ceiling tiles, and adherence to project specifications. It is essential to evaluate suppliers based on reliability, pricing, lead times, and product availability to ensure timely and cost-effective delivery. Additionally, considering factors such as corrosion resistance, load-bearing capacity, and sustainability can enhance long-term performance and durability of the ceiling system. By conducting thorough research and comparing options, procurement teams can secure a high-quality T-grid solution that meets both technical requirements and budget constraints, ultimately contributing to a successful installation and satisfied end-users.