The global synthetic tile roofing materials market is experiencing strong momentum, driven by rising demand for durable, lightweight, and sustainable building solutions. According to Grand View Research, the global roofing market was valued at USD 127.5 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 6.8% from 2023 to 2030, with synthetic roofing materials capturing an increasing share due to their resistance to moisture, UV degradation, and extreme weather conditions. Mordor Intelligence corroborates this trajectory, noting that the expanding construction sector—particularly in residential and commercial retrofitting—alongside stricter building energy codes, is accelerating adoption of advanced synthetic alternatives to traditional clay, concrete, and slate. Innovations in polymer-based composites, recycled content integration, and improved aesthetics have positioned synthetic tiles as a cost-effective and eco-friendly option across both developed and emerging markets. As demand surges, a select group of manufacturers are leading the charge in product development, scalability, and global reach—setting new benchmarks for performance and sustainability in roofing technology.

Top 9 Synthetic Tile Roofing Materials Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials….

#2 Atlas Roofing Shingles, Underlayments & Ventilation Homepage …

Domain Est. 1996

Website: atlasroofing.com

Key Highlights: Shingles with Core4® Technology lead the industry with the highest wind and impact ratings, overall strength and durability….

#3 DECRA Metal Roofing: #1 Stone

Domain Est. 1999

Website: decra.com

Key Highlights: DECRA Metal Roofing is the #1 stone-coated steel manufacturer for residential and commercial roofing backed by a lifetime warranty to guarantee protection….

#4 BORAL Residential Roof Products

Domain Est. 2015

Website: roofle.com

Key Highlights: Boral Roofing is the nation’s largest manufacturer of sustainable, durable and affordable clay, concrete, stone coated steel and composite slate and shake roof ……

#5 Eagle Roofing

Domain Est. 1995

Website: eagleroofing.com

Key Highlights: For 30 years, Eagle Roofing Products has manufactured high quality roofing solutions that are durable, long-lasting and environmentally friendly….

#6 Enviroshake®

Domain Est. 2000

Website: enviroshake.com

Key Highlights: A leader in the synthetic roofing industry, Enviroshake engineers and manufactures premium composite roofing tiles that authentically replicate the natural ……

#7 Composite Roofing: Traditional and Authentic

Domain Est. 2009

Website: quarrix.com

Key Highlights: Quarrix Composite Roofing provides the same beautiful look as traditional clay and concrete tiles but with the benefits of a lightweight synthetic roof tile ……

#8

Domain Est. 2014

Website: vereaclaytile.com

Key Highlights: Combining old-world craftsmanship and design with modern innovation, our company is a leading resource for natural, sustainable clay roof tile manufacturing….

#9 Brava Roof Tile Products

Domain Est. 2016

Website: bravarooftile.com

Key Highlights: View a list of Brava Roof Tile products including installation guides, descriptions, specifications, test results, colors and accessories….

Expert Sourcing Insights for Synthetic Tile Roofing Materials

H2: 2026 Market Trends for Synthetic Tile Roofing Materials

The synthetic tile roofing materials market is poised for significant transformation by 2026, driven by technological innovation, environmental concerns, and evolving consumer preferences. As homeowners and commercial developers increasingly prioritize durability, sustainability, and aesthetic flexibility, synthetic alternatives to traditional clay, concrete, and slate tiles are gaining traction. Below is an analysis of the key market trends expected to shape the synthetic tile roofing industry by 2026.

1. Rising Demand for Sustainable and Eco-Friendly Materials

Environmental regulations and green building certifications (such as LEED and ENERGY STAR) are pushing demand for roofing solutions with lower carbon footprints. By 2026, manufacturers are expected to increase the use of recycled and bio-based polymers in synthetic tiles. Additionally, recyclability at end-of-life and energy-efficient production processes will become key selling points, aligning with global net-zero initiatives.

2. Advancements in Material Technology

Innovations in polymer composites, including polypropylene, rubber, and composite blends, are enhancing the performance of synthetic tiles. By 2026, next-generation products are expected to offer improved resistance to UV degradation, extreme weather, and impact (e.g., hail), while mimicking the appearance of natural materials more convincingly. Nanocoating technologies may also be integrated to provide self-cleaning and algae-resistant properties.

3. Growth in Residential Retrofits and New Construction

The U.S., Europe, and parts of Asia-Pacific are expected to see strong growth in both new construction and roof replacements. Aging housing stock in North America and Europe is driving demand for lightweight, cost-effective roofing alternatives. Synthetic tiles, which are significantly lighter than concrete or clay, reduce structural load and installation costs—making them ideal for retrofitting older buildings.

4. Expansion in Emerging Markets

Countries in Southeast Asia, Latin America, and the Middle East are witnessing urbanization and infrastructure development, creating new opportunities for synthetic tile roofing. Favorable climatic conditions—such as high temperatures, humidity, and exposure to storms—make durable and low-maintenance synthetic options particularly attractive in these regions.

5. Integration with Smart Roofing Systems

By 2026, synthetic tiles are expected to increasingly integrate with smart home technologies. Roofing systems may include embedded sensors for monitoring structural integrity, temperature, and moisture, as well as compatibility with solar shingles or photovoltaic systems. This convergence supports the broader trend toward energy-efficient and intelligent buildings.

6. Competitive Pricing and Long-Term Cost Savings

Although initial costs of synthetic tiles can be higher than asphalt shingles, their lifespan (often 50+ years) and minimal maintenance requirements offer long-term savings. As production scales and material efficiencies improve, prices are expected to become more competitive, further accelerating adoption.

7. Impact of Regulatory and Insurance Factors

Building codes in hurricane- and wildfire-prone areas are evolving to require more resilient materials. Synthetic tiles that meet high standards for wind uplift resistance and fire ratings (Class A) are gaining favor with insurers and code officials. In regions like Florida and California, this regulatory push is expected to boost market penetration by 2026.

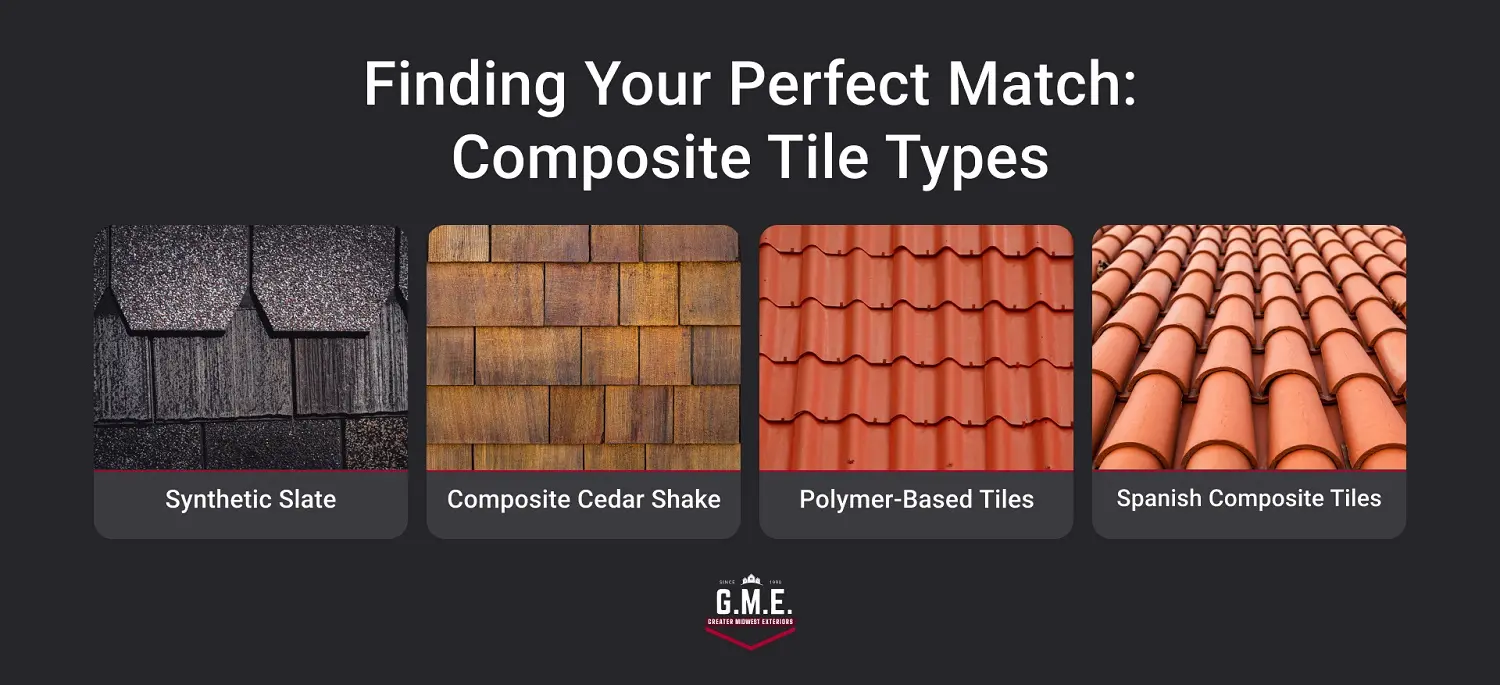

8. Brand Differentiation and Aesthetic Customization

Manufacturers are focusing on design diversity, offering synthetic tiles in a wide range of colors, textures, and profiles (e.g., Spanish barrel, mission, slate). Digital printing and advanced molding techniques allow for hyper-realistic finishes, enabling homeowners to achieve premium aesthetics at a fraction of the cost.

Conclusion

By 2026, the synthetic tile roofing market is projected to expand at a compound annual growth rate (CAGR) of approximately 6–8%, driven by sustainability, technological innovation, and regulatory support. As performance gaps with traditional materials continue to close and consumer awareness grows, synthetic tiles are set to become a mainstream choice in both residential and commercial construction. Companies that invest in R&D, eco-friendly manufacturing, and strategic market positioning will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Synthetic Tile Roofing Materials (Quality, IP)

Sourcing synthetic tile roofing materials offers benefits like durability and design flexibility, but it comes with significant risks related to quality consistency and intellectual property (IP) protection. Overlooking these pitfalls can lead to project delays, financial losses, and legal complications.

Inconsistent Material Quality and Performance

One of the most frequent challenges is the wide variation in quality among synthetic roofing tiles. Lower-tier manufacturers may use substandard polymers or improper additives, leading to premature degradation, warping, or fading under UV exposure. Buyers must scrutinize product specifications, request third-party test reports (e.g., ASTM standards for impact resistance, fire rating, and wind uplift), and verify long-term warranty terms. Relying solely on visual samples or manufacturer claims without due diligence can result in poor installation outcomes and customer dissatisfaction.

Lack of Transparency in Material Composition

Many suppliers do not fully disclose the resin types, UV stabilizers, or filler content used in their synthetic tiles. This opacity makes it difficult to assess long-term performance or compliance with building codes. Some manufacturers may blend cheaper recycled plastics or excessive fillers to cut costs, compromising structural integrity. Insist on material data sheets (MDS) and request independent lab verification to ensure the product meets advertised specifications.

Counterfeit or IP-Infringing Products

The popularity of premium synthetic tile designs has led to widespread counterfeiting and unauthorized replication of patented technologies. Sourcing from unverified suppliers—especially in regions with weak IP enforcement—risks acquiring products that infringe on design patents, texture patterns, or interlocking mechanisms. Using such materials can expose contractors and developers to legal liability, including cease-and-desist orders or damages. Always verify supplier credentials, request proof of IP ownership or licensing, and avoid deals that seem unusually low-priced, as they may signal IP violations.

Inadequate or Misleading Warranties

Some synthetic roofing products come with extensive warranty claims that sound comprehensive but contain hidden exclusions—such as prorated terms, strict installation requirements, or voids for minor deviations. These limitations may not become apparent until a claim is denied. Scrutinize warranty documents carefully, confirm whether it’s transferable, and verify that the manufacturer has a reliable track record of honoring claims.

Supply Chain and Certification Gaps

Reliable sourcing demands visibility into the full supply chain. Issues like inconsistent batch quality, lack of traceability, or non-compliance with environmental and safety standards (e.g., REACH, RoHS) can arise when suppliers subcontract production without oversight. Ensure suppliers provide certifications relevant to your region and confirm they adhere to ethical manufacturing practices to avoid reputational or compliance risks.

Logistics & Compliance Guide for Synthetic Tile Roofing Materials

Overview of Synthetic Tile Roofing Materials

Synthetic tile roofing materials are engineered products designed to mimic traditional roofing materials like clay, slate, or concrete tiles. Typically made from polymer composites, recycled plastics, or rubber, these materials offer lightweight, durable, and environmentally friendly alternatives. Due to their composition and application, specific logistics and compliance considerations must be addressed to ensure safe handling, transportation, and regulatory adherence.

Regulatory Compliance Requirements

Environmental Regulations

Synthetic roofing materials may contain recycled content or plastic-based polymers subject to environmental regulations. Compliance with the following standards is essential:

– EPA Guidelines: Ensure materials meet environmental protection standards regarding volatile organic compounds (VOCs) and emissions during manufacturing.

– REACH and RoHS (for international shipments): Confirm that chemical components comply with European Union regulations on hazardous substances.

– Local Recycling and Disposal Laws: Provide documentation on end-of-life recyclability or disposal procedures.

Building Code Compliance

Synthetic tiles must meet regional and national building codes, including:

– International Building Code (IBC) and International Residential Code (IRC): Verify compliance with wind, fire, and impact resistance standards.

– FM Global and UL Certifications: Obtain necessary testing certifications for fire rating (e.g., Class A), wind uplift resistance, and impact classification (e.g., Class 4 hail resistance).

– ICC-ES Evaluation Reports: Provide evidence of code compliance through evaluation service listings.

Product Labeling and Documentation

Proper labeling and documentation ensure regulatory transparency:

– Include manufacturer details, material composition, fire rating, and installation instructions.

– Maintain Safety Data Sheets (SDS) for all chemical components.

– Provide warranty documentation and lifetime performance data.

Logistics and Transportation Guidelines

Packaging and Handling

To prevent damage during transit:

– Use robust, weather-resistant packaging with edge protection and secure strapping.

– Stack tiles uniformly on pallets; avoid overloading to prevent crushing.

– Handle with mechanical equipment (e.g., forklifts) to minimize breakage or deformation.

Storage Conditions

Store synthetic tiles in a controlled environment:

– Keep materials under cover, away from direct sunlight and extreme temperatures.

– Elevate pallets off the ground to prevent moisture absorption.

– Avoid stacking beyond manufacturer-recommended heights.

Transportation Considerations

- Use enclosed or covered trucks to protect against weather exposure.

- Secure loads with straps or restraints to prevent shifting during transit.

- Follow weight distribution guidelines to comply with DOT regulations and avoid fines.

Import/Export Compliance (For International Shipments)

Customs Documentation

Ensure all shipments include:

– Commercial invoice with HS (Harmonized System) code (e.g., 6807.10 or 3925.90 depending on material).

– Bill of lading, packing list, and certificate of origin.

– Import permits if required by destination country.

Tariff and Duty Classifications

- Consult the Harmonized Tariff Schedule (HTS) to determine applicable duties.

- Leverage NAFTA/USMCA or other trade agreements if eligible for duty reductions.

Restricted Substances and Import Bans

- Verify that materials do not contain banned substances (e.g., certain phthalates or heavy metals).

- Confirm compliance with destination country’s environmental and construction standards.

Sustainability and Recycling Compliance

Recycled Content Reporting

- Accurately report post-consumer and post-industrial recycled content percentages.

- Support claims with third-party certifications (e.g., SCS Global Services).

End-of-Life Management

- Provide guidance on recyclability or disposal through certified waste handlers.

- Participate in take-back programs if available.

Conclusion

Adhering to logistics and compliance standards ensures that synthetic tile roofing materials are safely transported, legally sold, and environmentally responsible. Proactive engagement with regulatory bodies, proper documentation, and best practices in handling and storage are critical for success in both domestic and international markets.

In conclusion, sourcing synthetic tile roofing materials presents a compelling option for modern construction and roofing projects due to their durability, aesthetic versatility, and environmental benefits. These materials—typically made from recycled polymers, rubber, or composite blends—offer a lightweight yet resilient alternative to traditional concrete or clay tiles, with enhanced resistance to impact, fire, and extreme weather conditions. Additionally, their ability to mimic the appearance of natural roofing materials allows for architectural authenticity without the associated maintenance or structural demands.

When sourcing synthetic tiles, it is essential to consider factors such as product quality, manufacturer reputation, warranty offerings, and compliance with local building codes and sustainability standards. Engaging with reputable suppliers and evaluating lifecycle costs rather than initial price alone can lead to long-term savings and superior performance.

Ultimately, synthetic tile roofing represents a forward-thinking choice that balances aesthetics, functionality, and sustainability. As the construction industry continues to prioritize eco-friendly and high-performance materials, synthetic roofing tiles are well-positioned to meet evolving demands—making them a strategic investment for residential, commercial, and historical restoration projects alike.