The global synchronous motor market is experiencing robust growth, driven by rising demand for energy-efficient industrial machinery, advancements in automation, and increasing investments in renewable energy infrastructure. According to a report by Mordor Intelligence, the synchronous motor market was valued at USD 5.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. Similarly, Grand View Research highlights expanding applications in power generation, oil & gas, and water treatment sectors as key growth accelerants. As industries prioritize precision, reliability, and power factor correction, synchronous motors have become essential components in large-scale industrial operations. This escalating demand has positioned leading manufacturers at the forefront of innovation and market expansion. Below, we profile the top nine synchronous motor manufacturers shaping the industry’s future through technological leadership, global reach, and sustainable engineering solutions.

Top 9 Synchronous Motor Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Baldor.com

Domain Est. 1995

Website: baldor.com

Key Highlights: ABB is the world’s number-one manufacturer of NEMA motors, and we’re proud to support you locally with the Baldor-Reliance product brand….

#2 Reuland Electric Motors

Domain Est. 1996

Website: reuland.com

Key Highlights: Reuland Electric Motor Company | Leading manufacturer of custom electric motors. Over 85 years of experience. American-made motors for various applications….

#3 Synchronous Motors: Types, Benefits, Applications

Domain Est. 1997

Website: festo.com

Key Highlights: Explore synchronous motors’ benefits, types, and applications for precise, efficient, and reliable industrial automation solutions….

#4 Synchronous Motor Manufacturer

Domain Est. 2018

Website: leili-motor.net

Key Highlights: We specialize in high-performance brushless synchronous motors, 0.55 kW to 30 kW, 12V-380V, with 98% efficiency and precision….

#5 ABB synchronous motors

Domain Est. 1990

Website: new.abb.com

Key Highlights: ABB is the market’s leading supplier of synchronous motors and generators which help customers cutting energy costs and lowering environmental impact….

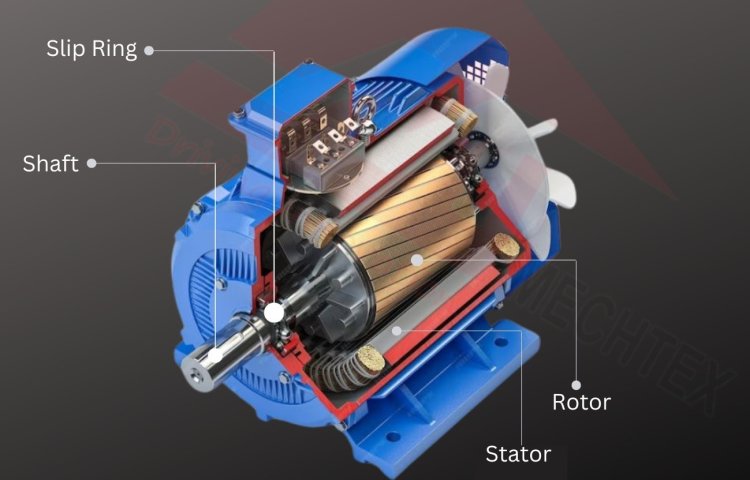

#6 Synchronous Motors : Basics

Domain Est. 1996

Website: johnsonelectric.com

Key Highlights: Synchronous ac motors are constant-speed electric motors and they operate in synchronism with mains line frequency….

#7 Hansen Corporation

Domain Est. 1996

Website: hansen-motor.com

Key Highlights: Hansen’s quality products are known around the world. These include: Synchron Motors, available with custom voltage, speed and power, durable DC Brush Motors, ……

#8 Synchronous Motors

Domain Est. 1999

Website: tecowestinghouse.com

Key Highlights: TECO-Westinghouse synchronous motors and generators provide superior value in terms of proven reliability, low maintenance performance and long life in any ……

#9 WEG

Domain Est. 2004

Website: weg.net

Key Highlights: WEG provides global solutions for electric motors, variable frequency drives, soft starters, controls, panels, transformers, and generators….

Expert Sourcing Insights for Synchronous Motor

H2: 2026 Market Trends for Synchronous Motors

The synchronous motor market is poised for significant transformation by 2026, driven by global industrial automation, energy efficiency demands, and technological advancements. Key trends shaping the landscape include:

1. Accelerated Demand for Energy Efficiency:

Regulatory pressures (e.g., IE5 efficiency standards in the EU and similar initiatives worldwide) will push industries to replace legacy motors with high-efficiency synchronous models, particularly Permanent Magnet Synchronous Motors (PMSMs). These motors offer superior power density and reduced energy losses, making them ideal for HVAC, compressors, and industrial pumps.

2. Growth in Industrial Automation and Smart Manufacturing:

As Industry 4.0 adoption expands, synchronous motors—especially those integrated with sensors and IoT connectivity—will become essential components in smart factories. Their precise speed and position control support robotics, CNC machines, and automated assembly lines, driving demand for intelligent motor systems with predictive maintenance capabilities.

3. Expansion in Electric Vehicle (EV) and Transportation Applications:

The proliferation of EVs will significantly boost the PMSM segment. These motors are favored in EV drivetrains for their high torque density and efficiency. Additionally, synchronous motors are increasingly used in rail traction systems and electric buses, further amplifying market growth.

4. Rising Adoption in Renewable Energy Systems:

Synchronous motors play a critical role in wind turbine pitch and yaw control systems. With global investments in wind energy continuing to rise, demand for reliable, high-performance synchronous motors in renewable infrastructure will increase through 2026.

5. Technological Innovation and Material Advancements:

Development of rare-earth-free or reduced-rare-earth permanent magnets will address supply chain vulnerabilities and cost concerns. Advances in motor design, such as improved thermal management and integration with advanced drives (e.g., servo and VFDs), will enhance performance and broaden application scope.

6. Regional Market Shifts:

Asia-Pacific, led by China, India, and Southeast Asia, will remain the fastest-growing region due to rapid industrialization, infrastructure development, and government support for green technologies. North America and Europe will focus on retrofitting existing systems and adopting high-efficiency motors under stringent energy regulations.

In summary, the 2026 synchronous motor market will be defined by efficiency, electrification, and digital integration. Companies investing in innovative, sustainable motor solutions and smart system integration will be best positioned to capitalize on these evolving trends.

Common Pitfalls When Sourcing Synchronous Motors: Quality and Intellectual Property Risks

Sourcing synchronous motors, especially from international or less-established suppliers, can expose companies to significant risks related to product quality and intellectual property (IP) protection. Overlooking these pitfalls can lead to operational failures, increased maintenance costs, legal disputes, and reputational damage. Below are key challenges to be aware of:

Quality-Related Pitfalls

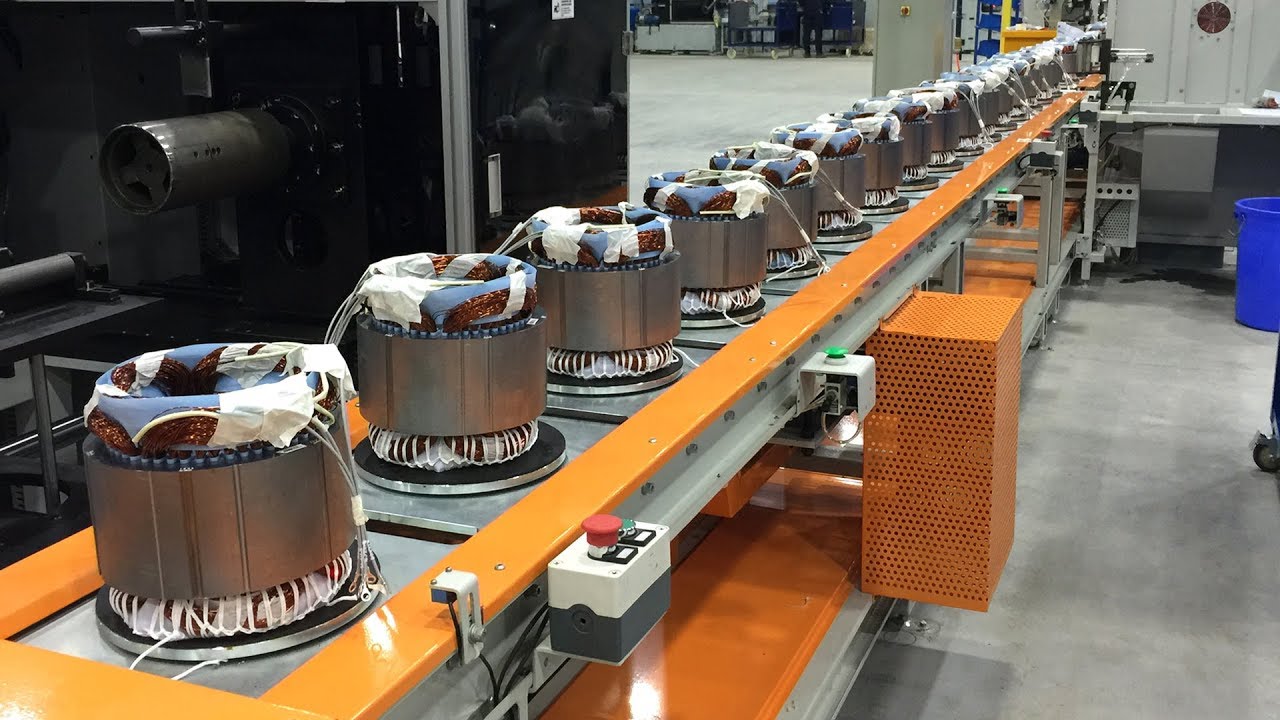

Inconsistent Manufacturing Standards

Suppliers, particularly in low-cost regions, may not adhere to international quality standards such as IEC, NEMA, or ISO. This can result in motors with inconsistent performance, premature bearing failure, or inaccurate speed control—critical flaws in applications requiring precise synchronization.

Substandard Materials and Components

To reduce costs, some manufacturers may use inferior-grade steel, copper windings with reduced conductivity, or low-quality insulation materials. These compromises reduce motor efficiency, increase heat generation, and shorten lifespan, undermining the reliability synchronous motors are known for.

Inadequate Testing and Certification

Reputable suppliers conduct rigorous testing (e.g., no-load tests, temperature rise tests, vibration analysis). Sourcing without verified test reports or third-party certifications (e.g., CE, UL, IP ratings) increases the risk of receiving motors that fail under real operating conditions.

Misrepresentation of Performance Metrics

Some suppliers exaggerate key parameters such as efficiency class (e.g., claiming IE4 when it’s only IE2), torque output, or power factor. Without independent verification or access to test data, buyers may end up with motors that underperform or consume more energy than expected.

Intellectual Property (IP) Risks

Design and Technology Infringement

Sourcing from certain regions increases exposure to counterfeit or cloned motors that replicate patented designs, rotor configurations, or control systems without authorization. Purchasing such products—even unknowingly—can expose the buyer to legal liability or customs seizures.

Lack of IP Protection in Contracts

Many procurement agreements fail to clearly define ownership of custom designs, modifications, or performance data. Without robust IP clauses, buyers risk losing rights to proprietary integrations or facing reverse engineering by the supplier.

Reverse Engineering and Technology Leakage

Suppliers with access to motor blueprints or prototypes may use that information to develop competing products. This is especially concerning when sourcing custom or high-performance synchronous motors where design innovation is a competitive advantage.

Unsecured Firmware and Control Software

Modern synchronous motors often include embedded control software or firmware. Sourcing motors with unlicensed, pirated, or poorly documented software can lead to cybersecurity vulnerabilities and violate software licensing agreements.

Mitigation Strategies

To minimize these risks, buyers should:

– Conduct thorough supplier audits, including on-site factory inspections.

– Require detailed test reports and third-party certifications.

– Perform independent lab testing on sample units.

– Include strong IP clauses in contracts, specifying design ownership and non-disclosure.

– Work with legal counsel to ensure compliance with international IP laws.

– Consider sourcing through trusted distributors or authorized partners.

By proactively addressing quality and IP concerns, organizations can ensure reliable motor performance and safeguard their technological investments.

Logistics & Compliance Guide for Synchronous Motors

Overview

Synchronous motors are precision electromechanical devices used across various industries for applications requiring constant speed and high efficiency. Due to their technical complexity, size, weight, and electrical characteristics, shipping and complying with international and local regulations requires careful planning. This guide outlines key logistics and compliance considerations for the transport, import, and operation of synchronous motors.

Packaging & Handling Requirements

Synchronous motors must be packaged to prevent mechanical shock, moisture, and contamination during transit. Use wooden crates or heavy-duty corrugated containers with internal foam or custom supports to immobilize the motor. Ensure shafts are secured with locking devices or covers, and all openings (ventilation, terminal boxes) are sealed to prevent ingress of dust or moisture. Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators.

Transport Considerations

Due to their weight and dimensions, synchronous motors often require special handling during transportation. Coordinate with freight carriers experienced in heavy industrial equipment. Use forklifts or cranes with appropriate lifting points—never lift by shafts or terminal boxes. For international shipments, ensure compliance with IATA (air), IMDG (sea), or ADR (road) regulations as applicable. Oversized loads may require special permits and route planning.

Customs Documentation

Prepare complete documentation for customs clearance, including:

– Commercial Invoice (detailing value, quantity, and technical specifications)

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Technical Datasheets (including power rating, voltage, frequency, and efficiency class)

Ensure Harmonized System (HS) codes are accurately applied—common codes include 8501.31 or 8501.32 for AC synchronous motors, depending on power output.

Regulatory Compliance

Synchronous motors must comply with relevant electrical and safety standards in the destination country. Key certifications include:

– CE Marking (EU): Compliant with Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

– UL/CSA Certification (USA/Canada): Required for motors used in North America.

– IEC Standards: IEC 60034 series for rotating electrical machines (efficiency, insulation, testing).

– Energy Efficiency Regulations: Comply with minimum efficiency standards such as IE3 or IE4 under IEC 60034-30-1.

Verify local requirements for explosion-proof or hazardous environment certifications (e.g., ATEX, IECEx) if applicable.

Import Duties & Trade Restrictions

Check for import duties, taxes, and potential trade restrictions based on the motor’s country of origin and destination. Some countries impose additional tariffs or require import licenses for high-power electrical equipment. Sanctioned regions may restrict the export of certain motor technologies—verify compliance with export control regulations (e.g., EAR in the U.S.).

On-Site Installation & Safety Compliance

Upon delivery, inspect the motor for damage before installation. Follow manufacturer guidelines for alignment, grounding, and connection. Ensure compliance with local electrical codes (e.g., NEC in the U.S., IEC in Europe). Personnel must be trained and certified for handling high-voltage equipment. Maintain records of compliance for audits and insurance purposes.

Environmental & Disposal Regulations

At end-of-life, synchronous motors must be disposed of according to environmental regulations. Components may contain copper, steel, and insulation materials requiring proper recycling. Comply with WEEE (Waste Electrical and Electronic Equipment) directives in the EU and similar programs elsewhere. Avoid landfill disposal of hazardous materials such as PCB-containing insulation (in older models).

Summary

Proper logistics and compliance management ensures the safe, legal, and efficient delivery and operation of synchronous motors. Attention to packaging, documentation, regulatory standards, and environmental responsibility minimizes risks and supports sustainable industrial operations. Always consult local authorities and regulatory bodies for up-to-date requirements specific to your region and application.

Conclusion for Sourcing a Synchronous Motor

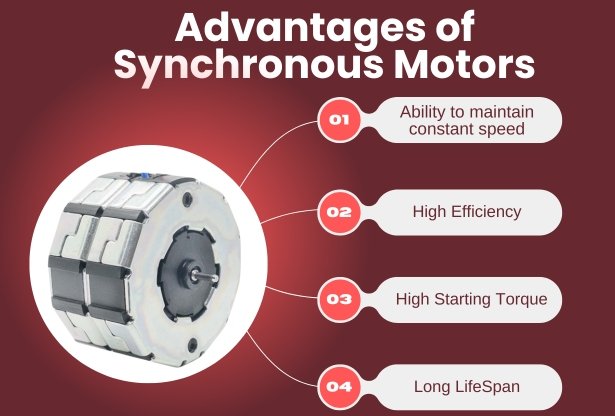

In conclusion, sourcing a synchronous motor requires a comprehensive evaluation of technical specifications, application requirements, supplier reliability, and total cost of ownership. Synchronous motors are ideal for applications demanding constant speed, high efficiency, and precise power factor control, making them suitable for industrial processes, power generation, and large-scale HVAC systems.

Key considerations in the sourcing process include selecting the appropriate motor size, speed, and power rating; ensuring compatibility with existing power systems; and evaluating features such as excitation method, cooling type, and control integration. Additionally, partnering with reputable manufacturers or suppliers who offer proven performance, technical support, and warranty coverage is crucial for long-term reliability and operational efficiency.

By carefully aligning motor specifications with operational needs and conducting thorough supplier assessments, organizations can ensure optimal performance, energy savings, and minimal downtime. Ultimately, a well-sourced synchronous motor not only enhances system efficiency but also contributes to sustainable and cost-effective industrial operations.