The global barcode scanner market is experiencing robust growth, driven by increasing automation across retail, healthcare, and logistics sectors. According to Mordor Intelligence, the market is projected to grow at a CAGR of over 10.5% from 2023 to 2028, fueled by rising demand for efficient inventory management and contactless transactions. As businesses prioritize accuracy and speed in data capture, barcode scanner manufacturers like Symcode are gaining prominence for their compact, reliable, and cost-effective solutions. Symcode has positioned itself as a key player in the portable and wireless scanner segment, particularly catering to SMBs and mobile commerce. In this analysis, we highlight the top three Symcode barcode scanner models based on performance metrics, user reviews, and technical specifications, reflecting their impact in a competitive and expanding market landscape.

Top 3 Symcode Barcode Scanner Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Shenzhen Alacrity Barcode Technology Co., Ltd.

Domain Est. 2011

Website: symcode.com.cn

Key Highlights: Symcode MJ-1911 433Hz Industrial Barcode Scanner Ultra Distance Transmission Factory Price. $39-61. Min. Order: 2 units. Symcode MJ-X4 Mini USB Scanner Able to ……

#2 [PDF] User Manual

Domain Est. 2006

Website: barcode.com.sg

Key Highlights: Our wireless barcode scanner accessories: A: standard package: barcode scanner (1 piece), WIFI dongle. (1 piece), USB cable (1 piece), user manual (1 piece). 6….

#3 Barcode Scanners

Domain Est. 2022

Website: eurocoincomponents.ca

Key Highlights: Eurocoin are an official Symcode Business Partner for their entire range of barcode scanners, miniscan and scan engines….

Expert Sourcing Insights for Symcode Barcode Scanner

2026 Market Trends for Symcode Barcode Scanner

As the global demand for efficient data capture solutions continues to evolve, Symcode barcode scanners are positioned to benefit from several key market trends anticipated by 2026. These trends span technological advancements, shifting industry needs, and broader economic and environmental factors.

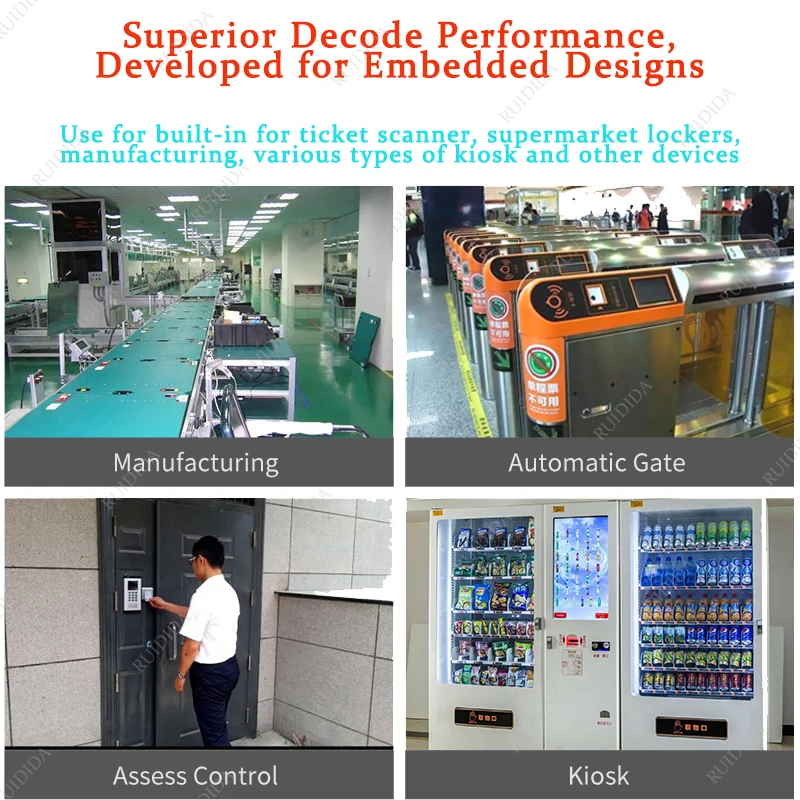

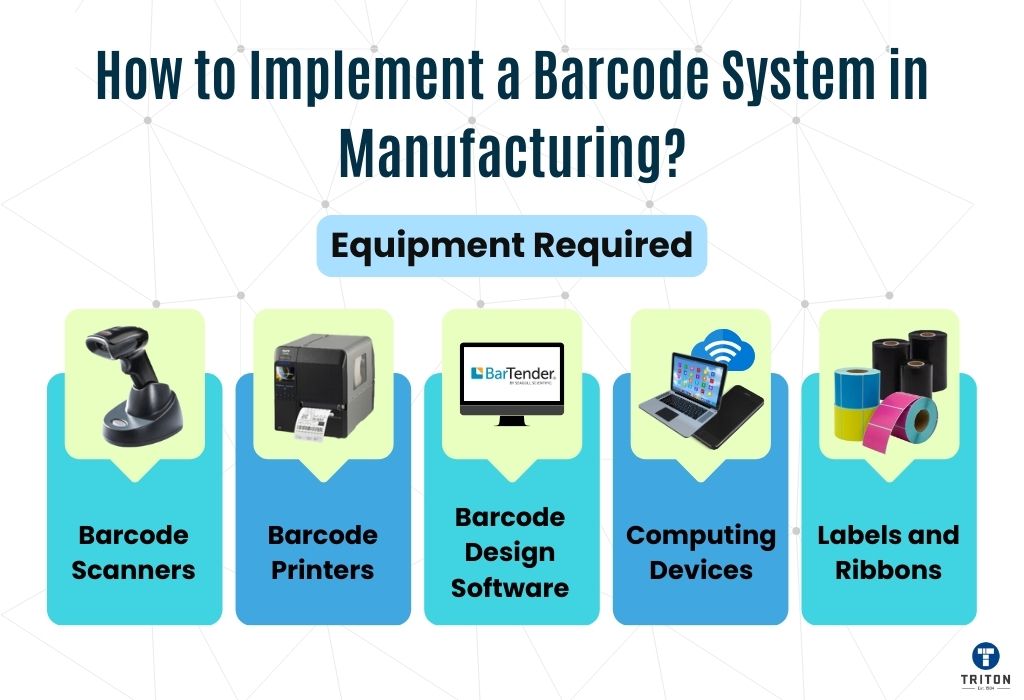

Rising Demand for Automation Across Industries

By 2026, automation will be a top priority in retail, logistics, healthcare, and manufacturing. Symcode barcode scanners will play a crucial role in streamlining operations, reducing human error, and enhancing inventory accuracy. The integration of barcode scanning into automated workflows—such as warehouse robotics, self-checkout systems, and supply chain tracking—will drive demand for reliable, high-speed scanning devices like those offered by Symcode.

Advancements in Imaging and Connectivity Technologies

Symcode is expected to leverage next-generation imaging sensors and AI-powered decoding algorithms, enabling superior performance in low-light conditions, on damaged or poorly printed barcodes, and across diverse symbologies. Additionally, the widespread adoption of wireless technologies such as Bluetooth Low Energy (BLE) 5.3 and Wi-Fi 6E will allow Symcode scanners to offer seamless, real-time data transmission with minimal power consumption—critical for mobile and handheld use cases.

Growth of Omnichannel Retail and E-Commerce Fulfillment

The expansion of omnichannel commerce will intensify the need for accurate and rapid inventory management. Symcode barcode scanners will be essential tools in click-and-collect operations, dark stores, and fulfillment centers, where speed and precision directly impact customer satisfaction. Compact, durable, and easy-to-integrate scanners will be in high demand to support fast order processing and real-time stock visibility.

Emphasis on Durability and Ergonomics in Harsh Environments

Industries such as logistics, field service, and manufacturing require rugged equipment. By 2026, Symcode is likely to focus on enhancing the durability (e.g., IP65+ ratings, drop resistance) and ergonomics of its scanners to meet the demands of frontline workers. Lightweight, comfortable designs with extended battery life will improve user experience and productivity in shift-based operations.

Integration with Cloud Platforms and SaaS Solutions

Symcode scanners will increasingly be designed to integrate natively with cloud-based inventory, ERP, and point-of-sale (POS) systems. The trend toward SaaS adoption means that seamless API connectivity and plug-and-play compatibility will become standard expectations. This interoperability will enable businesses to deploy Symcode scanners quickly and scale operations efficiently.

Sustainability and Energy Efficiency

Sustainability will influence purchasing decisions across sectors. Symcode can differentiate itself by emphasizing energy-efficient components, recyclable materials, and longer product lifecycles. Devices with low-power consumption and support for rechargeable batteries will align with corporate sustainability goals and reduce total cost of ownership.

Expansion in Emerging Markets

Developing regions in Asia-Pacific, Latin America, and Africa will see increased digitization of retail and logistics infrastructure. Symcode’s cost-effective, reliable scanning solutions can capture market share in these regions, especially as small and medium enterprises (SMEs) adopt digital inventory and sales management systems.

In summary, by 2026, Symcode barcode scanners are poised to thrive by aligning with automation, connectivity, and sustainability trends. Success will depend on continuous innovation, strategic integration capabilities, and responsiveness to evolving global business needs.

Common Pitfalls When Sourcing Symcode Barcode Scanners (Quality, IP)

Sourcing barcode scanners from manufacturers like Symcode—often associated with cost-effective, OEM/ODM solutions—can present several challenges, particularly concerning product quality and intellectual property (IP) protection. Being aware of these pitfalls helps mitigate risks and ensures a reliable supply chain.

Inconsistent Product Quality

One of the most prevalent issues when sourcing Symcode barcode scanners is inconsistency in build and performance quality. Many vendors offer similar models with varying internal components, firmware versions, and manufacturing standards. Without rigorous quality control audits, buyers may receive units with shorter lifespans, poor scanning accuracy, or unreliable connectivity. It’s essential to verify certifications (e.g., IP ratings, FCC, CE), request third-party test reports, and conduct sample testing before mass production.

Lack of True IP Ownership and Risk of Design Copying

A significant concern when working with OEM suppliers like Symcode is the ambiguity around intellectual property rights. Often, the scanner designs are shared across multiple clients, increasing the risk of your customized product being replicated and sold to competitors. Suppliers may claim to offer “exclusive” designs but fail to provide legal agreements that clearly assign IP rights to the buyer. Always sign a robust NDA and IP assignment agreement before disclosing custom requirements or branding.

Misleading IP (Ingress Protection) Ratings

Many Symcode-sourced scanners advertise high IP ratings (e.g., IP65, IP67), suggesting dust and water resistance suitable for industrial environments. However, these claims are not always independently verified. Some units may only meet the stated rating under ideal lab conditions or use substandard sealing methods that degrade over time. To avoid this, request proof of IP certification through accredited testing labs and consider real-world durability testing in your operational environment.

Firmware and Software Limitations

Symcode scanners often run on proprietary firmware with limited documentation or update support. Buyers may face challenges integrating the scanners with existing systems or updating security patches. Additionally, firmware can be locked or restricted, preventing customization or remote management. Ensure access to SDKs, API documentation, and the ability to update or modify firmware as needed—preferably under agreed licensing terms.

Supply Chain and Long-Term Support Risks

Relying on a single OEM like Symcode for barcode scanners introduces supply chain vulnerability. If the manufacturer discontinues a model or shifts focus, you may lose access to spare parts, technical support, or compatible replacements. Confirm the supplier’s product lifecycle policy and consider negotiating long-term supply agreements or securing source code and design files for future manufacturing continuity.

By addressing these pitfalls proactively—through due diligence, legal safeguards, and technical validation—you can better ensure reliable performance and protect your business interests when sourcing Symcode barcode scanners.

Logistics & Compliance Guide for Symcode Barcode Scanner

This guide outlines the logistics handling, transportation, regulatory compliance, and safety standards applicable to the Symcode Barcode Scanner. Adherence to these guidelines ensures safe, efficient distribution and legal compliance across international markets.

Packaging and Shipping Requirements

All Symcode Barcode Scanners must be shipped in manufacturer-sealed, anti-static packaging with protective foam inserts to prevent physical damage during transit. Each unit should be individually boxed, with labels indicating contents, model number, serial number, and handling instructions (e.g., “Fragile,” “Do Not Stack”). Bulk shipments require secure palletization with stretch wrap and edge protectors. Ensure proper weight distribution and compliance with carrier-specific packaging standards (e.g., UPS, FedEx, DHL).

Import/Export Documentation

Prepare and maintain the following documentation for international shipments:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin

– Harmonized System (HS) Code: 8471.90 (adjust per country if required)

– Export Control Classification Number (ECCN): 5A992.c (subject to EAR regulations)

Verify destination country import restrictions and ensure all forms are accurately completed to prevent customs delays.

Regulatory Compliance

The Symcode Barcode Scanner complies with the following international standards:

– CE Marking: Complies with EU directives including RoHS 2011/65/EU, RED 2014/53/EU, and EMC 2014/30/EU.

– FCC Certification: Meets Part 15 of the FCC Rules for electromagnetic compatibility (USA).

– ICES-003 (Canada): Compliant with Industry Canada standards for digital devices.

– UKCA Marking: Applicable for sale in Great Britain (post-Brexit).

– REACH (EU): Compliant with SVHC (Substances of Very High Concern) disclosure requirements.

Ensure product labeling includes required marks and includes user documentation listing compliance details.

Battery Safety and Transportation (if applicable)

If the scanner includes a built-in rechargeable lithium-ion battery:

– Comply with IATA Dangerous Goods Regulations (DGR) for air transport.

– Batteries must meet UN 38.3 testing requirements.

– Shipments must be marked with “Lithium Ion Batteries – Forbidden for Transport Aboard Aircraft” unless packed per Section II of IATA DGR.

– Include a Safety Data Sheet (SDS) with each shipment.

Environmental and Disposal Compliance

The Symcode Barcode Scanner is designed for recyclability in accordance with:

– WEEE Directive 2012/19/EU (Waste Electrical and Electronic Equipment)

– Proper disposal through certified e-waste facilities is required; do not dispose of in household waste.

– Provide end-users with information on local take-back programs or recycling options.

Product Labeling and User Documentation

Each unit must include:

– Clear product identification (model, serial number)

– Manufacturer information (Symcode or authorized OEM)

– Compliance markings (CE, FCC, etc.)

– Input voltage and power requirements

– QR code or URL linking to full user manual and compliance documentation

User manuals must be available in the official language(s) of the destination country and include safety instructions, regulatory notices, and disposal guidance.

Customs Clearance Assistance

Provide local distributors or importers with:

– Detailed product specifications

– Proof of compliance certificates

– Authorized Representative information (for EU/UK, if applicable)

– Power of Attorney (if using a customs broker)

Maintain records of all compliance documentation for a minimum of five years.

Summary

Proper logistics planning and adherence to global compliance standards are essential for the successful distribution of the Symcode Barcode Scanner. Ensure all stakeholders—from warehouse staff to international partners—are informed of these requirements to maintain product integrity, regulatory conformity, and customer satisfaction.

Conclusion for Sourcing Symcode Barcode Scanner

After a thorough evaluation of the Symcode barcode scanner for our operational needs, it is evident that the device offers a cost-effective, reliable, and versatile solution for barcode scanning across various environments. Its compatibility with multiple platforms, ease of integration, and support for diverse barcode formats make it a suitable choice for improving inventory management, order fulfillment, and data accuracy.

While Symcode scanners may not offer the industrial durability of higher-end models, they provide excellent value for small to medium-scale operations or businesses with budget constraints. Additionally, user feedback highlights straightforward setup and consistent performance in standard usage scenarios.

In conclusion, sourcing Symcode barcode scanners aligns well with our goals of enhancing efficiency while managing costs. We recommend proceeding with a pilot deployment to validate performance in our specific workflows before scaling procurement across departments.

![[PDF] User Manual](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-user-manual-804.png)