The global heavy-duty swivel hook market is experiencing robust growth, driven by increasing demand from industries such as construction, marine, oil & gas, and material handling. According to Grand View Research, the global lifting hooks market was valued at USD 1.3 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by rising infrastructure development, stringent safety regulations, and the need for reliable lifting and rigging solutions across industrial applications. As demand for high-performance, corrosion-resistant, and load-certified swivel hooks grows, manufacturers are focusing on advanced materials like alloy steel and innovative designs to enhance load capacity and rotational efficiency. In this competitive landscape, a select group of manufacturers has emerged as leaders in producing top-tier heavy-duty swivel hooks, setting the benchmark for quality, durability, and engineering precision. Here’s a data-driven look at the top 8 manufacturers shaping the future of this critical segment.

Top 8 Swivel Hook Heavy Duty Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

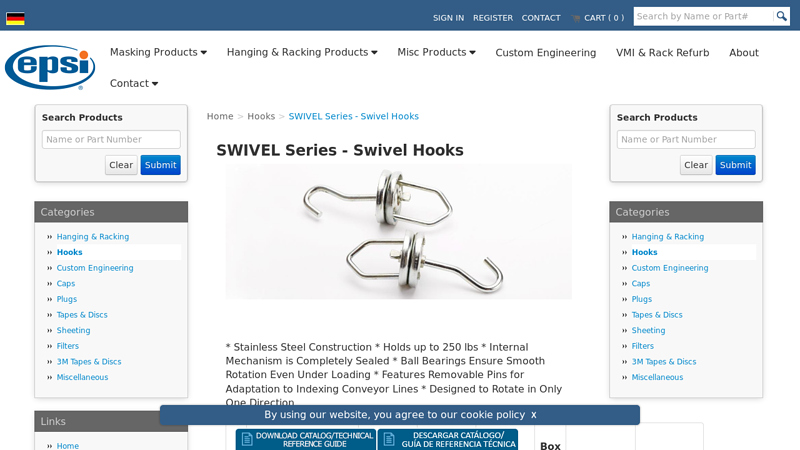

#1 EPSI SWIVEL Hooks: Industrial Finishing Solutions

Domain Est. 1997

Website: epsi.com

Key Highlights: Holds up to 250 lbs. Internal Mechanism is Completely Sealed. Ball Bearings Ensure Smooth Rotation Even Under Loading. Features Removable Pins for Adaptation….

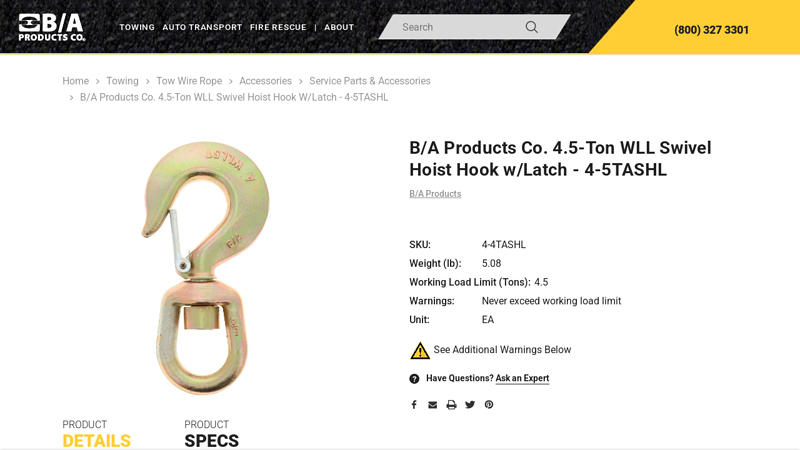

#2 B/A Products Co. 4.5

Domain Est. 1997

Website: baprod.com

Key Highlights: Built from high-quality steel for better durability, the hook is able to handle a working load limit of 4.5 tons, offering you more than enough industrial ……

#3 Swivel Hooks

Domain Est. 2004

Website: gmesupply.com

Key Highlights: Free delivery over $75 · 30-day returnsOur selection of swivel hooks will have you lifting with ease in no time. From manufacturers like Crosby and working load limits from 1 to 1…

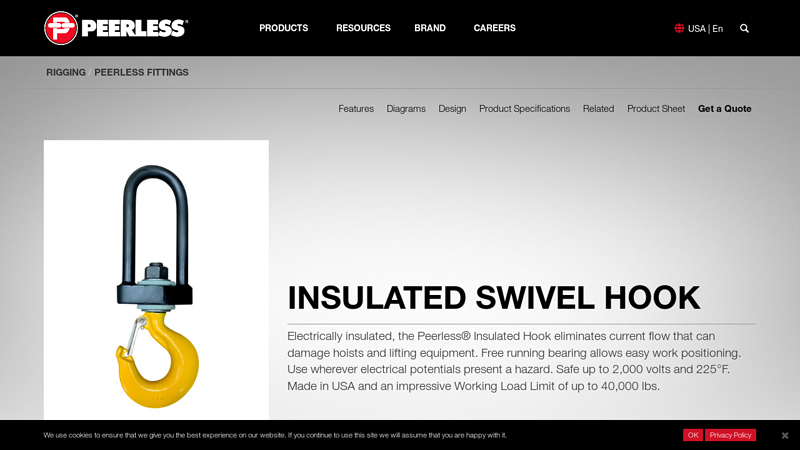

#4 Insulated Swivel Hook

Domain Est. 1995

Website: peerlesschain.com

Key Highlights: Use wherever electrical potentials present a hazard. Safe up to 2,000 volts and 225°F. Made in USA and an impressive Working Load Limit of up to 40,000 lbs….

#5 ANSI Forged Steel Swivel Snap Hook 50kN – Heavy-Duty

Domain Est. 1999

Website: usrigging.com

Key Highlights: In stock Rating 4.0 2 ProClimb ANSI certified forged steel swivel snap hook with 50kN (11240 lb) MBS. Double action self-locking gate, 360° swivel. Perfect for heavy-duty fall …..

#6 Lifting Hooks

Domain Est. 2013

#7 CM Swivel Rigging Hook, Working Load Limit 15 Ton, Part No …

Domain Est. 2018

Website: tsriggingequipment.com

Key Highlights: In stock $71.29 deliveryPart Number: M3415A · Working Load Limit: 15 Ton (metric) · Weight: 26.75 lbs. · Alloy steel. · 5:1 design factor. · Pre-drilled for latches. · Hooks are he…

#8 Swivel Hooks

Website: liftmovestore.com

Key Highlights: Made from high-grade alloy or forged steel, our Swivel Hooks offer superior tensile strength, impact resistance, and durability. Each hook is equipped with a ……

Expert Sourcing Insights for Swivel Hook Heavy Duty

H2: 2026 Market Trends for Swivel Hook Heavy Duty

The global market for heavy-duty swivel hooks is poised for significant transformation by 2026, driven by industrial expansion, technological advancements, and evolving safety standards. As critical components in lifting, rigging, and load-bearing applications, heavy-duty swivel hooks are witnessing increased demand across sectors such as construction, oil & gas, marine, logistics, and renewable energy. Below is an analysis of key market trends expected to shape the heavy-duty swivel hook landscape in 2026.

1. Rising Infrastructure and Construction Activities

With governments worldwide investing heavily in infrastructure development—especially in Asia-Pacific, the Middle East, and parts of Africa—demand for reliable lifting hardware is surging. Heavy-duty swivel hooks are essential in crane operations, scaffolding, and material handling. The push for smart cities and large-scale transportation projects will further bolster market growth through 2026.

2. Emphasis on Safety and Compliance

Regulatory bodies such as OSHA (U.S.), EU Machinery Directive, and ISO are tightening safety standards for lifting equipment. By 2026, manufacturers of swivel hooks will need to ensure compliance with certifications like CE, ASME B30.26, and LOLER. This trend is driving innovation in design, material quality, and traceability, with an increased shift toward load-rated, proof-tested, and serialized hooks.

3. Material and Design Innovation

To meet higher load requirements and harsh operating conditions, manufacturers are adopting advanced materials such as heat-treated alloy steels and corrosion-resistant coatings. Innovations like 360-degree rotation with reduced friction, self-lubricating bearings, and integrated safety latches are becoming standard in premium heavy-duty swivel hooks. Lightweight yet high-strength composite materials may begin emerging in niche applications by 2026.

4. Growth in Renewable Energy Sectors

The offshore wind energy industry, in particular, is creating new demand for robust rigging solutions. Installation and maintenance of wind turbines require heavy lifting in marine environments, where swivel hooks must resist saltwater corrosion and dynamic loads. This specialized demand is pushing manufacturers to develop marine-grade, galvanized, or stainless-steel swivel hooks with enhanced durability.

5. Automation and Smart Equipment Integration

As industries adopt Industry 4.0 principles, there is a growing interest in smart lifting systems. Although still in early stages, by 2026, expect pilot deployments of swivel hooks integrated with load sensors, IoT-enabled monitoring, and RFID tags for real-time tracking and predictive maintenance—improving safety and operational efficiency.

6. Regional Market Shifts

Asia-Pacific will remain the largest and fastest-growing market due to rapid industrialization in India, Southeast Asia, and China. North America and Europe will focus on replacing aging infrastructure and upgrading to compliant, safer equipment. Meanwhile, the Middle East and Africa are emerging as high-potential regions due to energy and construction megaprojects.

7. Sustainability and Circular Economy

Environmental concerns are influencing product lifecycle management. By 2026, leading manufacturers may offer take-back programs, remanufactured hooks, and eco-friendly packaging. Recyclable materials and energy-efficient production processes will gain importance in corporate sustainability reporting.

Conclusion

The heavy-duty swivel hook market in 2026 will be shaped by a convergence of regulatory rigor, technological innovation, and sector-specific demands. Companies that invest in R&D, quality assurance, and digital integration will gain a competitive edge. As global industrial activity continues to rise, the heavy-duty swivel hook will remain a vital—but increasingly sophisticated—component in safe and efficient operations.

Common Pitfalls When Sourcing Swivel Hook Heavy Duty (Quality, IP Rating)

Sourcing heavy-duty swivel hooks requires careful attention to both mechanical quality and environmental protection, especially when IP (Ingress Protection) ratings are involved. Overlooking key aspects can lead to product failure, safety hazards, or non-compliance. Here are common pitfalls to avoid:

Inadequate Material and Build Quality

One of the most frequent mistakes is selecting swivel hooks made from substandard materials such as low-grade steel or inferior alloys. This can result in premature wear, deformation under load, or catastrophic failure. Always verify the material specifications (e.g., forged steel, stainless steel grade) and ensure load ratings are independently tested and clearly documented.

Misunderstanding or Ignoring IP Ratings

Many buyers assume that any “weather-resistant” swivel hook is suitable for wet or dusty environments. However, without a verified IP rating (e.g., IP65, IP67), there’s no assurance of protection against dust or water ingress. Relying on marketing terms instead of actual IP certification can lead to corrosion, internal damage, or mechanical jamming in harsh conditions.

Overlooking Certification and Compliance

Failing to confirm relevant industry certifications (e.g., CE, OSHA, ASME) is a major risk. Heavy-duty hooks used in lifting or critical applications must meet specific safety standards. Sourcing from suppliers without proper documentation can result in legal liability and safety incidents.

Poor Manufacturing Consistency

Even if a sample meets specifications, inconsistent production quality can lead to defective units in bulk orders. This is common when sourcing from low-cost manufacturers without robust quality control systems. Always insist on QC inspections and request production samples from actual batches.

Inaccurate Load Capacity Claims

Some suppliers exaggerate the working load limit (WLL) or use vague terminology like “heavy duty” without substantiation. Always demand test reports and ensure the WLL is clearly marked on each unit. Never assume that size correlates directly with strength.

Neglecting Swivel Mechanism Quality

The swivel function is often overlooked, yet a poorly designed or manufactured swivel can bind, wear quickly, or fail under rotational stress. Check for smooth rotation, sealed bearings (especially in high IP-rated models), and resistance to side-loading.

Inadequate Corrosion Protection

Even stainless steel hooks can corrode if the wrong grade is used or if surface treatments (e.g., passivation, coating) are omitted. In marine or chemical environments, specify the correct stainless grade (e.g., 316) and verify corrosion resistance through salt spray testing.

Selecting the Wrong IP Rating for the Application

Choosing an IP67 hook for a dry indoor application is unnecessary and costly, while using an IP54-rated hook outdoors can lead to early failure. Match the IP rating precisely to the operating environment—consider exposure to rain, submersion, dust, or high-pressure cleaning.

Relying Solely on Supplier Claims Without Verification

Never take supplier specifications at face value. Request third-party test reports, conduct on-site audits, or use independent labs to verify material composition, load testing, and IP certification. Trust but verify.

Ignoring Long-Term Maintenance and Serviceability

Some sealed IP-rated hooks are not designed for maintenance, making it impossible to service internal components. Consider whether the application allows for replacement or requires serviceable parts—this affects total cost of ownership.

Avoiding these pitfalls ensures reliable, safe, and compliant performance of heavy-duty swivel hooks in demanding applications. Always prioritize verified quality, proper certification, and environmental suitability over initial cost savings.

Logistics & Compliance Guide for Swivel Hook Heavy Duty

Product Overview

The Swivel Hook Heavy Duty is a high-strength lifting component designed for demanding industrial applications. It features a 360-degree rotating bail for improved load alignment and reduced twisting, making it ideal for rigging, construction, and material handling operations. Constructed from forged alloy steel and heat-treated for durability, it ensures reliable performance under heavy loads.

Packaging Requirements

- Pack units in reinforced cardboard boxes or wooden crates based on order volume.

- Separate individual hooks with protective padding (e.g., foam or cardboard dividers) to prevent surface damage.

- Clearly label each package with product name, model number, weight, and handling symbols (e.g., “Do Not Stack,” “Fragile”).

- Include desiccant packs in packaging for shipments to humid environments to prevent corrosion.

Storage Conditions

- Store in a dry, indoor environment with low humidity to prevent rust and corrosion.

- Maintain temperatures between 10°C and 30°C (50°F to 86°F).

- Keep away from direct exposure to chemicals, saltwater, or abrasive materials.

- Store off the ground on pallets or shelves to avoid moisture contact.

Transportation Guidelines

- Use enclosed trucks or containers for international and long-distance shipping to protect against weather.

- Secure loads on pallets with strapping or shrink wrap to prevent shifting during transit.

- Follow weight distribution best practices to avoid overloading transport vehicles.

- For air freight, ensure packaging meets IATA standards for cargo safety.

Handling Instructions

- Always use appropriate lifting equipment when moving bulk quantities.

- Avoid dropping or impacting the hooks, as this may compromise structural integrity.

- Operators must wear protective gloves and safety footwear when handling.

- Do not drag or slide packages across surfaces.

Regulatory Compliance

- Complies with ASME B30.26 (American Society of Mechanical Engineers) standards for below-the-hook lifting devices.

- Meets OSHA 29 CFR 1910.184 regulations for sling hardware safety in the United States.

- CE marked in accordance with EU Machinery Directive 2006/42/EC and EN 13889 for lifting equipment.

- Load-rated with clearly marked WLL (Working Load Limit) on each unit.

- Accompanied by a Certificate of Conformity and Material Test Report (MTR) upon request.

Import/Export Documentation

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Test Certificates (EN 10204 3.1 optional)

- Export Declaration (as required by origin country)

- Import permit (if required by destination country)

Country-Specific Requirements

- United States: FDA does not regulate this product; CBP clearance required. No special permits beyond standard customs entry.

- European Union: Must be accompanied by a Declaration of Conformity. RoHS compliance confirmed (no restricted hazardous substances).

- Canada: Meets CSA Z1540 standards for lifting equipment. B335 certification applicable upon request.

- Australia: Complies with AS 1418.1 for cranes and hoists. Importers must meet Work Health and Safety (WHS) regulations.

Quality Assurance & Traceability

- Each batch is assigned a unique lot number for full traceability.

- Random sampling tested for tensile strength, hardness, and dimensional accuracy.

- Non-destructive testing (NDT) performed as per quality control protocol.

- Quality records retained for a minimum of 10 years.

Customer Instructions & Safety Warnings

- Inspect hook before each use for cracks, deformation, or wear.

- Never exceed the marked WLL.

- Do not use if latch is damaged or missing.

- Retire from service if any sign of structural compromise is detected.

- Only trained personnel should operate or maintain lifting assemblies.

Disposal & End-of-Life

- Recyclable as ferrous scrap metal.

- Dispose of in accordance with local environmental regulations.

- Do not incinerate; may release hazardous fumes.

- Partner with certified metal recycling facilities.

In conclusion, sourcing heavy-duty swivel hooks requires careful consideration of material quality, load capacity, durability, and compliance with industry standards to ensure safety and reliability in demanding applications. It is essential to work with reputable suppliers who provide certified products, consistent quality control, and transparent documentation. Evaluating factors such as intended use, environmental conditions, and required certifications (e.g., OSHA, CE, or ASME) will help in selecting the most suitable swivel hooks for lifting, rigging, or towing operations. By prioritizing strength, corrosion resistance, and smooth rotational performance, businesses can enhance operational efficiency, reduce equipment failure risks, and maintain workplace safety. A strategic sourcing approach, including supplier vetting, sample testing, and cost-benefit analysis, ultimately leads to long-term value and reliability in heavy-duty swivel hook procurement.