The global snack processing equipment market is experiencing robust growth, driven by rising consumer demand for healthy, on-the-go snacks such as sweet potato chips. According to Grand View Research, the global snack food market was valued at USD 68.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This surge in consumption has amplified the need for efficient, high-capacity cutting and slicing machinery tailored to root vegetables like sweet potatoes. As manufacturers seek consistent thickness, high throughput, and food-grade safety standards, specialized sweet potato chip cutter producers are rising to meet industry demands. Leveraging data from Mordor Intelligence, which notes increasing automation in food processing and a shift toward vegetable-based snacks, we’ve identified the top 8 manufacturers leading innovation in precision, durability, and scalability within this niche segment.

Top 8 Sweet Potato Chip Cutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Custom Sweet Potato Chips Slicer Factory

Domain Est. 2018

Website: m.fsdalle.com

Key Highlights: Looking for a reliable sweet potato chips slicer factory? Contact Foshan Dalle Technology Co., Ltd. for high-quality slicers and machinery….

#2 Snacks – Herr’s Forever Good

Domain Est. 1996 | Founded: 1946

Website: herrs.com

Key Highlights: Discover Herr’s: family-owned since 1946, making over 300 crave-worthy snacks including chips, cheese curls, pretzels, popcorn, and more….

#3 China Sweet Potato Chips Cutting Machine Manufacturers …

Domain Est. 2018

Website: taibomachine.com

Key Highlights: We’re professional sweet potato chips cutting machine manufacturers and suppliers in China, specialized in producing high quality food processing machine….

#4 High Capacity Potato Cutting Equipment

Domain Est. 1996

Website: urschel.com

Key Highlights: Urschel offers advanced equipment to meet all your potato processing needs, including slicing, French fry cutting, dicing, shredding, and producing potato ……

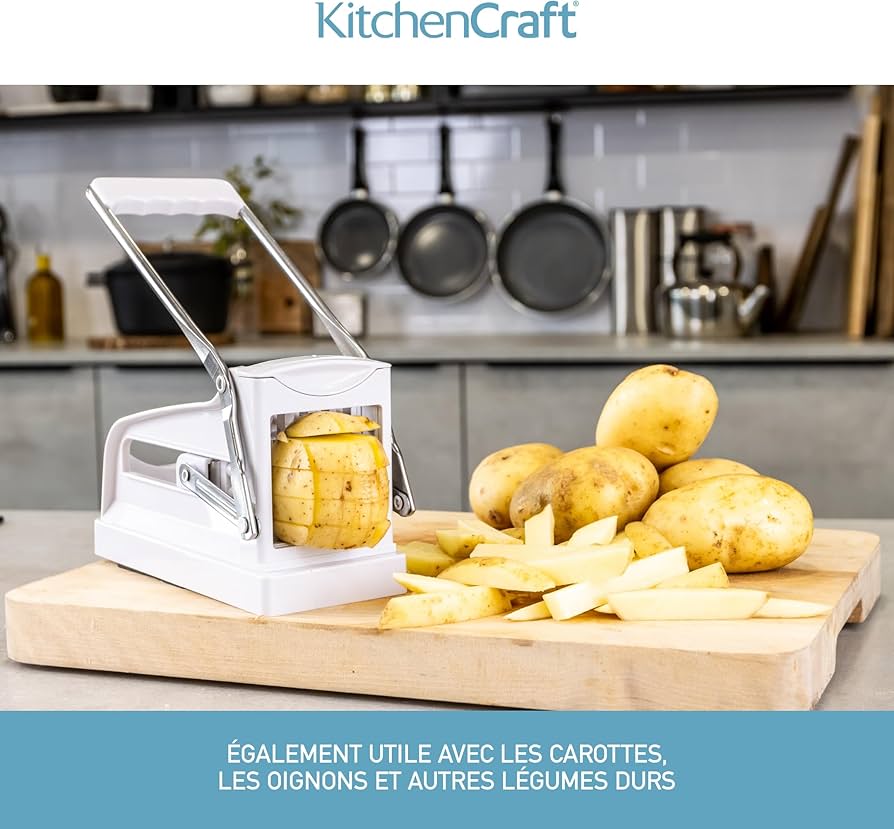

#5 Buy a potato chip cutter for horeca or professional kitchens

Domain Est. 1999

#6 Automatic Potato Slicing Machines for Potato Chips Making Business

Domain Est. 2013

Website: potatochipsmachinery.com

Key Highlights: Rating 4.9 (26) The multifunctional potato slicing machines can cut potatoes, sweet potatoes into slices, wavy slices, strips. Thickness from 0.5-10mm….

#7 Sweet Potato Chips Crisp French Fries Cutting Making Machine

Domain Est. 2019

Website: fxfoodmachine.com

Key Highlights: FC-502 can cut potatoes, sweet potatoes, onions and carrots into pieces or strips. The cutting surface is smooth and has no damage; the materials being cut can ……

#8 Buy Commercial Best French Fry Cutter for Sweet Potatoes

Domain Est. 2016

Website: frymachine.com

Key Highlights: High speed Frenc fry cutter machine is ideal cutter for cutting sweet potatoes, carrots, potatoes, eggplant, papaya, pumpkin and other root vegetables and ……

Expert Sourcing Insights for Sweet Potato Chip Cutter

2026 Market Trends for Sweet Potato Chip Cutters

The sweet potato chip cutter market is poised for dynamic shifts by 2026, driven by evolving consumer preferences, technological advancements, and expanding production demands. Here’s an analysis of key trends shaping this niche equipment sector:

1. Rising Demand for Healthy, Natural Snacks Fuels Equipment Growth

Consumer preference for nutritious, minimally processed snacks continues to propel the sweet potato chip segment. As sweet potatoes offer perceived health benefits (high in fiber, vitamins A and C, lower glycemic index than white potatoes), demand for fresh, homemade, and artisanal sweet potato chips is increasing. This trend directly boosts the need for reliable, efficient chip cutters—from small-scale home models to commercial-grade units—for both households and small-batch producers capitalizing on the clean-label movement.

2. Technological Integration and Automation Accelerate

By 2026, sweet potato chip cutters are expected to incorporate smarter features such as adjustable blade settings via digital interfaces, automated feeding systems, and IoT connectivity for performance monitoring. Commercial models will increasingly emphasize high-throughput capabilities, consistent cut quality, and ease of cleaning to meet food safety standards. Innovations in blade materials (e.g., food-grade stainless steel with anti-corrosion coatings) will extend equipment lifespan and reduce maintenance costs.

3. Expansion of Artisanal and Direct-to-Consumer Brands

The rise of micro-snack brands and farm-to-table food businesses will drive demand for mid-tier commercial cutters that balance affordability with professional performance. These entrepreneurs require versatile equipment capable of handling irregularly shaped sweet potatoes and producing uniform, visually appealing chips for branding purposes. Equipment manufacturers will respond with modular designs and customizable cutting patterns (waffle, crinkle, ripple) to differentiate products in a crowded market.

4. Sustainability and Energy Efficiency Become Key Differentiators

Environmental concerns will influence purchasing decisions at both consumer and industrial levels. Equipment manufacturers will prioritize energy-efficient motors, reduced water usage in cleaning cycles, and recyclable packaging. Additionally, durability and repairability will gain importance as businesses seek to reduce equipment turnover and align with circular economy principles.

5. Geographic Market Diversification and Emerging Regions

While North America and Europe remain strong markets, growth in Asia-Pacific, Latin America, and Africa—driven by rising health awareness and urbanization—will open new opportunities. Localized production of sweet potato-based snacks in these regions will increase demand for cost-effective, robust cutters suited to varying infrastructure and power conditions.

6. E-Commerce and Direct Sales Channels Reshape Distribution

Online platforms will dominate the sale of home and small commercial cutters, with detailed product videos, customer reviews, and subscription-based accessory bundles (extra blades, cleaning tools) enhancing customer engagement. B2B equipment suppliers will leverage digital catalogs and virtual demonstrations to reach small food processors globally.

In summary, the 2026 sweet potato chip cutter market will be defined by innovation, health-driven demand, and a blend of artisanal craftsmanship with scalable technology. Manufacturers that prioritize versatility, sustainability, and user-friendly design will be best positioned to capture value across both consumer and commercial segments.

Common Pitfalls When Sourcing Sweet Potato Chip Cutters (Quality and Intellectual Property)

Sourcing sweet potato chip cutters, especially for commercial or large-scale production, involves navigating several critical challenges related to product quality and intellectual property (IP) risks. Being aware of these pitfalls can help buyers make informed decisions and avoid costly mistakes.

Quality-Related Pitfalls

Inconsistent Cutting Precision

One of the most common quality issues is inconsistent chip thickness or shape due to poor blade alignment or low-grade materials. Inconsistent cuts affect cooking uniformity, leading to uneven frying or baking and reduced product appeal.

Use of Substandard Materials

Some suppliers use inferior stainless steel or non-food-grade materials to cut costs. This compromises hygiene, durability, and can lead to contamination or rapid wear and tear, increasing long-term operational costs.

Lack of Durability Under High-Volume Use

Many sweet potato chip cutters marketed for commercial use fail under continuous operation. Poor motor strength, inadequate blade reinforcement, or weak structural design result in frequent breakdowns and downtime.

Inadequate Safety Features

Cheaper models often lack essential safety mechanisms such as blade guards, emergency stop functions, or non-slip bases. This increases the risk of workplace injuries, especially in fast-paced food processing environments.

Poor After-Sales Support and Spare Parts Availability

Even high-quality machines can fail over time. Sourcing from suppliers without reliable customer service or accessible spare parts can lead to extended downtimes and increased maintenance costs.

Intellectual Property (IP) Risks

Infringement of Patented Designs

Some manufacturers produce machines that closely mimic patented cutter designs or mechanisms. Purchasing such equipment can expose buyers to legal liability, especially if the product is used in a jurisdiction that enforces IP rights strictly.

Counterfeit or Copycat Equipment

Suppliers may offer “branded” cutters at suspiciously low prices, which are actually counterfeit versions. These often perform poorly and carry hidden legal risks, particularly if they incorporate protected technology or branding.

Lack of IP Documentation or Transparency

Reputable suppliers provide evidence of IP ownership or licensing. When sourcing, failing to verify whether the equipment design is legally protected—or whether the supplier has the right to manufacture and sell it—can lead to supply chain disruptions or legal challenges.

Risk of Being Complicit in IP Violations

Importing or using equipment that infringes on IP rights—even unknowingly—can result in customs seizures, fines, or injunctions, particularly in markets like the U.S., EU, or Japan where IP enforcement is robust.

Conclusion

To mitigate these risks, buyers should conduct thorough due diligence—request product certifications, inspect materials and build quality, verify IP status, and work with reputable suppliers who provide warranties and technical documentation. Investing time upfront can prevent long-term quality failures and legal complications.

Logistics & Compliance Guide for Sweet Potato Chip Cutter

Product Classification & HS Code

The Sweet Potato Chip Cutter is typically classified under the Harmonized System (HS) code 8205.59.00, which covers “other hand tools not elsewhere specified or included.” Accurate classification is essential for international shipping, customs clearance, and duty assessment. Confirm the correct HS code with local customs authorities, as classifications may vary slightly by country.

Import/Export Regulations

Ensure compliance with both origin and destination country regulations. Exporters must comply with the export control policies of the manufacturing country, including any licensing requirements. Importers should verify that the product meets food safety and machinery standards in the target market. Some countries may require import permits or registrations for food-processing equipment.

Safety & Electrical Compliance (if applicable)

If the Sweet Potato Chip Cutter is electric-powered, it must meet electrical safety standards such as:

– CE Marking (European Union) – complying with the Low Voltage Directive (LVD) and Electromagnetic Compatibility (EMC) Directive.

– UL/ETL Listing (United States) – certified to applicable UL standards for food equipment.

– PSE Certification (Japan) or CCC Mark (China), if applicable.

Battery-operated or manual models may be exempt from electrical certifications but must still meet general product safety requirements.

Food Contact Materials Compliance

Any components that contact sweet potatoes or other food must comply with food safety regulations:

– FDA 21 CFR (USA) – materials must be non-toxic and suitable for food contact.

– EU Regulation (EC) No 1935/2004 – ensures safety and inertness of materials.

– LFGB (Germany) or DGCCRF (France), if targeting specific EU markets.

Documentation such as a Declaration of Compliance (DoC) or Food Contact Notification may be required.

Packaging & Labeling Requirements

Packaging must protect the product during transit and comply with environmental regulations:

– Use recyclable or FSC-certified materials where possible.

– Include multilingual labels if shipping internationally, featuring product name, model number, manufacturer details, safety warnings, and compliance marks.

– For electrical models, include voltage, power rating, and manufacturer contact information.

Shipping & Transportation

- Classify under appropriate freight category (e.g., machinery or kitchen equipment).

- Use durable packaging to prevent damage; consider moisture-resistant materials for ocean freight.

- Declare accurate weight, dimensions, and value on shipping documents (commercial invoice, packing list, bill of lading).

- Consider Incoterms (e.g., FOB, CIF) to clarify responsibilities between buyer and seller.

Customs Documentation

Essential documents include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (may be required for preferential tariffs)

– Test reports or compliance certificates (e.g., for electrical safety or food contact)

Environmental & Sustainability Standards

Comply with regulations such as:

– RoHS (EU) – restriction of hazardous substances in electrical and electronic equipment.

– REACH (EU) – registration, evaluation, and authorization of chemicals.

– WEEE Directive – ensure proper disposal instructions are provided if the product contains electronic components.

After-Sales & Warranty Compliance

Provide warranty information in local language and ensure service support is available or outlined. Adhere to consumer protection laws in the destination country regarding returns, repairs, and liability.

Summary

To ensure smooth logistics and compliance for the Sweet Potato Chip Cutter: verify correct HS code, meet safety and food contact standards, prepare complete documentation, and adhere to regional regulatory requirements. Partner with certified testing labs and customs brokers to streamline international distribution.

In conclusion, sourcing a sweet potato chip cutter requires careful consideration of factors such as durability, cutting consistency, production capacity, ease of cleaning, and compliance with food safety standards. Whether opting for manual, semi-automatic, or fully automatic models, it is essential to align the equipment specifications with your production needs and budget. Evaluating suppliers based on reputation, after-sales support, and customer reviews ensures reliability and long-term performance. By investing in the right sweet potato chip cutter, businesses can enhance efficiency, maintain product quality, and meet market demand effectively, ultimately contributing to operational success and customer satisfaction.