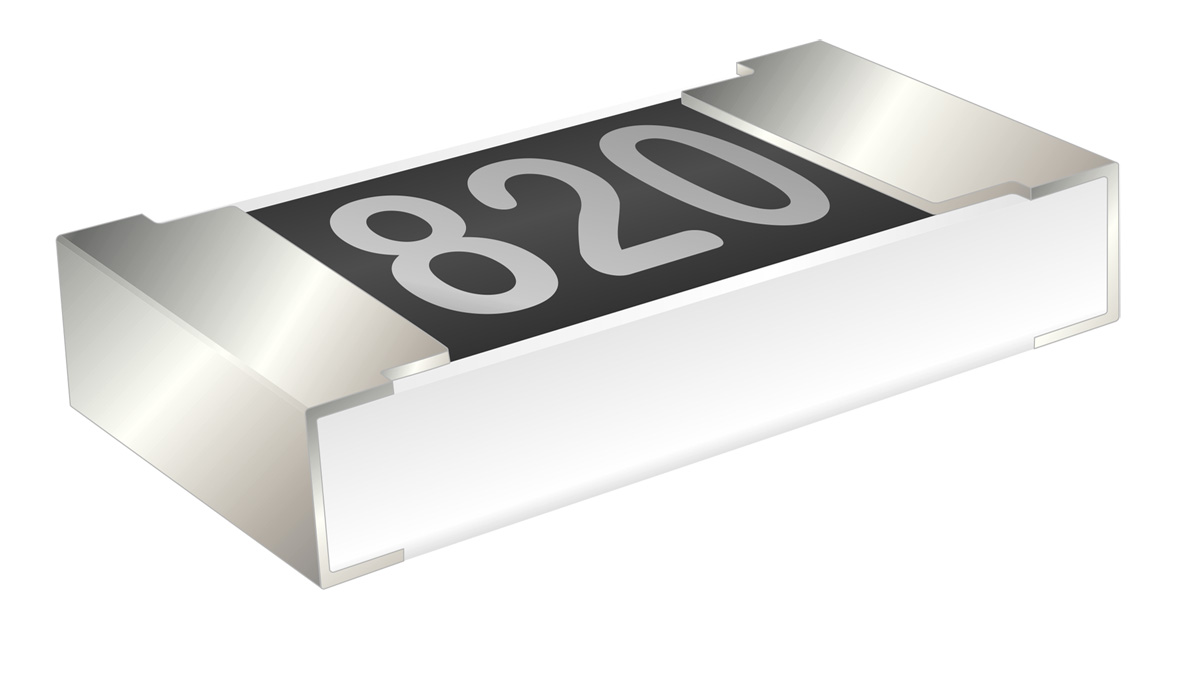

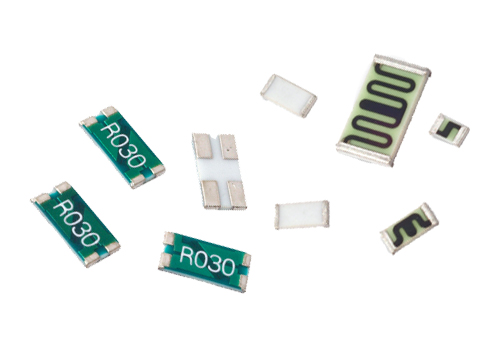

The global surface mount resistors (SMD resistors) market is experiencing steady growth, driven by rising demand in consumer electronics, automotive electronics, and industrial applications. According to Mordor Intelligence, the surface mount technology market—of which resistors are a key component—is projected to grow at a CAGR of over 5.2% from 2023 to 2028. This expansion is fueled by the miniaturization of electronic devices, increased adoption of IoT-enabled systems, and advancements in automotive electronics requiring high-reliability passive components. As industries continue shifting toward compact, high-efficiency circuit designs, surface mount resistors have become indispensable. With such momentum, identifying the leading manufacturers in the space is critical for design engineers, procurement teams, and OEMs aiming to source reliable, high-performance components. Based on market presence, product innovation, global reach, and production volume, here are the top 10 surface mount resistors manufacturers shaping the industry landscape.

Top 10 Surface Mount Resistors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Precision Resistor Company

Domain Est. 1996 | Founded: 1932

Website: precisionresistor.com

Key Highlights: Welcome to Precision Resistor Company, Inc. · Manufacturers of Custom Wire Wound Resistors Sensors and Shunts, Made in the USA since 1932 · Surface Mount · Axial ……

#2 Resistors

Domain Est. 1994

Website: murata.com

Key Highlights: Offering high resistance and small deviation values, our products enable reduced set circuit signal inconsistencies and more reliable final products. Resistor ……

#3 Power, Precision Custom Resistors & Shunts

Domain Est. 1996

Website: riedon.com

Key Highlights: Riedon is a resistor manufacturing company, specializing in Power, Precision, Surface Mount, High Temperature, High power and Custom Resistors….

#4 Surface Mount Resistors

Domain Est. 1997 | Founded: 1928

Website: seielect.com

Key Highlights: Founded in 1928, Stackpole Electronics is a leading global manufacturer of resistive components including Thick and Thin Film Surface Mount resistors, Axial ……

#5 Resistors

Domain Est. 2004

Website: yageogroup.com

Key Highlights: YAGEO Group offers a diverse range of resistors designed to meet the demands of various applications, including automotive, industrial, telecommunications, ……

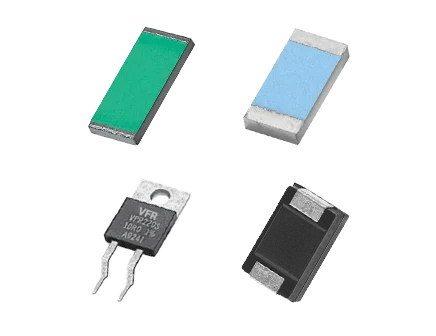

#6 Surface Mount Resistors, with High Reliability

Domain Est. 1992

Website: te.com

Key Highlights: We offer a wide variety of surface mount resistors, also known as surface mount devices (SMD), including resistors suitable for pulse, surge, and voltage ……

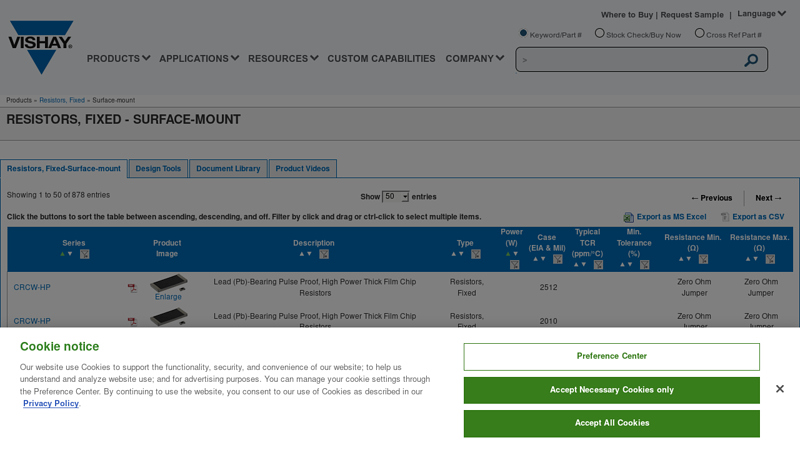

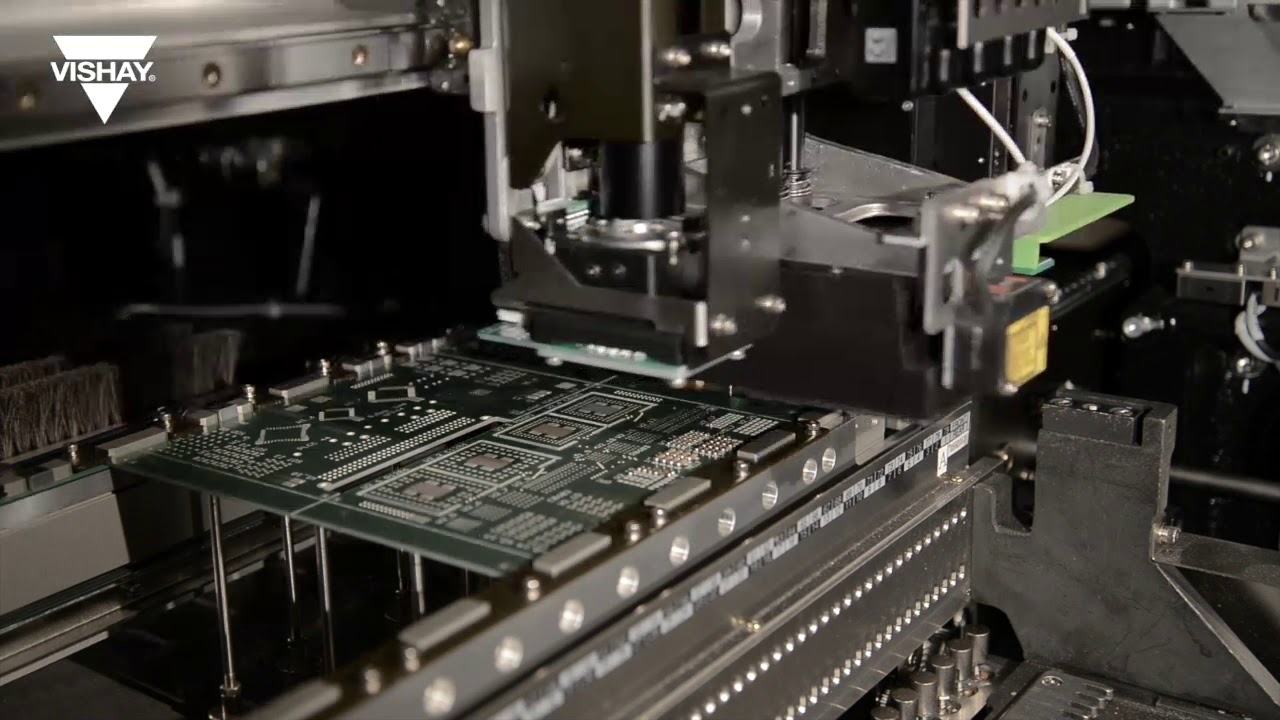

#7 Surface-mount

Domain Est. 1995

Website: vishay.com

Key Highlights: Surface-mount, Resistors, Fixed manufactured by Vishay, a global leader for semiconductors and passive electronic components….

#8 Surface Mount for Power Resistors

Domain Est. 1995

Website: ohmite.com

Key Highlights: Surface mount parts (SMD or SMT) are mounted on one side of the PCB. This offers space savings as the other side is free from a solder connection….

#9 Resistors

Domain Est. 2001

Website: smithsinterconnect.com

Key Highlights: Smiths Interconnect offers low and high power RF resistors including surface mount chips, tab & cover chips, flange mounted and rod types….

#10 Surface Mount Resistors

Domain Est. 2016

Website: vpgfoilresistors.com

Key Highlights: At VPG Foil Resistors, we specialize in providing high-quality surface mount resistors tailored to meet the demands of diverse electronic applications….

Expert Sourcing Insights for Surface Mount Resistors

2026 Market Trends for Surface Mount Resistors

The surface mount resistor (SMR) market is poised for steady evolution by 2026, driven by advancements in electronics, growing demand for miniaturization, and the proliferation of smart technologies. Key trends shaping the industry include:

Rising Demand from Consumer Electronics and IoT

Consumer electronics remain a dominant force in the SMR market. The continuous innovation in smartphones, wearables, and smart home devices necessitates smaller, more efficient components. As devices become thinner and more feature-rich, the demand for ultra-miniaturized resistors—such as 01005 and 0201 case sizes—will escalate. Concurrently, the Internet of Things (IoT) ecosystem is expanding rapidly, with billions of connected sensors and modules requiring reliable, low-power resistors. This growth across consumer and industrial IoT applications will significantly boost SMR consumption by 2026.

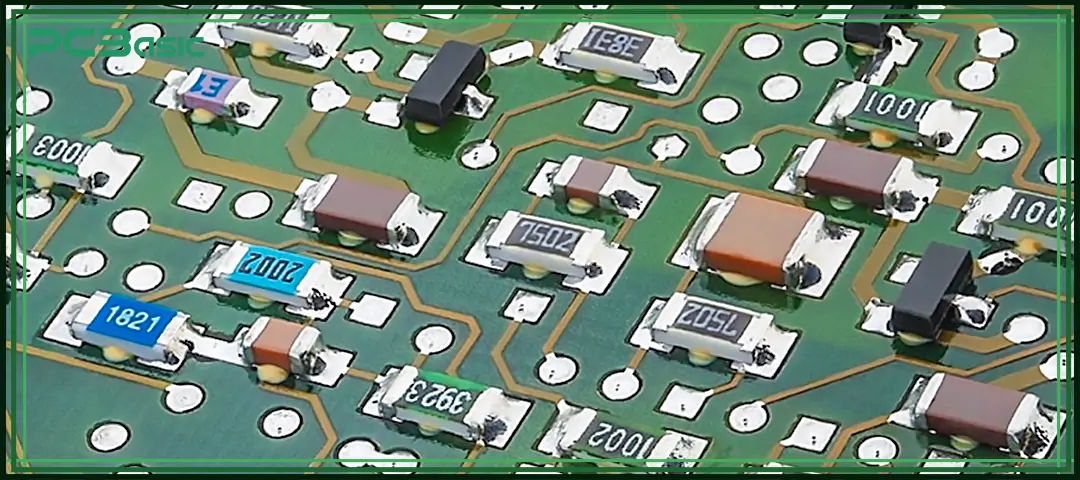

Miniaturization and High-Density Packaging

Miniaturization remains a core trend in electronics manufacturing, and SMRs are no exception. By 2026, there will be an increased adoption of advanced packaging technologies like thin-film and precision resistors in smaller form factors. Manufacturers are investing in improved deposition and laser trimming techniques to maintain accuracy and stability in ever-shrinking components. Additionally, multi-chip arrays and resistor networks will gain traction, allowing for greater circuit density and reduced board space—critical for applications in mobile computing and automotive electronics.

Growth in Automotive and Electric Vehicles (EVs)

The automotive sector, particularly electric and autonomous vehicles, will be a major growth driver for surface mount resistors. EVs require sophisticated power management, battery monitoring, and advanced driver-assistance systems (ADAS), all of which rely heavily on precision resistors. High-temperature and high-reliability SMRs capable of withstanding harsh environments are in increasing demand. By 2026, the automotive segment is expected to account for a growing share of the SMR market, fueled by stricter safety standards and the electrification of transportation.

Supply Chain Resilience and Regional Manufacturing Shifts

Post-pandemic supply chain disruptions have prompted a reevaluation of global manufacturing dependencies. By 2026, there will be a continued shift toward regionalization and nearshoring of electronic component production, including SMRs. Countries in Southeast Asia, India, and North America are investing in local semiconductor and passive component facilities to reduce reliance on traditional manufacturing hubs. This trend will enhance supply chain resilience and shorten lead times, although it may also lead to pricing fluctuations during transition periods.

Focus on Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop eco-friendly SMRs. By 2026, expect increased use of lead-free materials, recyclable packaging, and energy-efficient production processes. Innovations in resistor materials—such as low-temperature co-fired ceramic (LTCC) and advanced metal foil technologies—will improve performance while reducing environmental impact. Additionally, lifecycle assessments and compliance with RoHS and REACH directives will become standard across the supply chain.

Conclusion

By 2026, the surface mount resistor market will be defined by technological innovation, evolving end-user demands, and strategic shifts in manufacturing. Growth in IoT, automotive electrification, and consumer electronics will drive volume, while miniaturization and reliability will remain critical differentiators. Companies that invest in advanced materials, localized production, and sustainable practices will be best positioned to capitalize on these emerging trends.

Common Pitfalls in Sourcing Surface Mount Resistors (Quality, IP)

Poor Quality Control and Counterfeit Components

One of the most significant risks when sourcing surface mount resistors is receiving substandard or counterfeit parts. Low-cost suppliers, especially from unverified online marketplaces or unauthorized distributors, may offer resistors that fail to meet industry standards (e.g., IEC, AEC-Q200). These components can exhibit inconsistent resistance values, poor thermal stability, or premature failure under stress, leading to field defects and costly rework.

Inadequate or Misrepresented IP (Ingress Protection) Ratings

Surface mount resistors used in harsh environments—such as automotive, industrial, or outdoor applications—require proper environmental protection. A common pitfall is assuming that all resistors are inherently moisture- or dust-resistant. Many standard SMD resistors lack any formal IP rating, and suppliers may ambiguously claim “moisture resistance” without certification. Relying on such claims without verified IP67 or IP68 ratings (when required) can result in circuit degradation due to environmental exposure.

Lack of Traceability and Documentation

Reputable sourcing demands full component traceability, including lot numbers, RoHS compliance, and manufacturer data sheets. Many low-tier suppliers fail to provide adequate documentation, making it difficult to verify authenticity or conduct failure analysis. This lack of IP (Intellectual Property) and supply chain transparency increases risk during audits or product recalls.

Incorrect Packaging and Handling

Improper packaging—such as non-ESD-safe materials or damaged tape-and-reel—can compromise resistor integrity before assembly. Moisture-sensitive resistors stored without proper dry packaging may suffer from “popcorning” during reflow soldering, leading to internal cracks and latent failures. Always verify that packaging meets JEDEC standards, especially for humid environments.

Overlooking Long-Term Availability and Lifecycle Status

Designers often source resistors without checking the manufacturer’s product lifecycle status. Using end-of-life (EOL) or non-preferred parts introduces supply chain risk. When production ramps up, these components may become obsolete, forcing costly redesigns. Verify lifecycle status and prefer parts with long-term availability commitments to protect your IP and product roadmap.

Ignoring Manufacturer and Distributor Authorization

Purchasing from unauthorized distributors increases the risk of receiving remarked, salvaged, or out-of-spec parts. Always source from franchised distributors or directly from original manufacturers (e.g., Yageo, Vishay, TE Connectivity) to ensure quality, consistency, and protection of your design IP.

Logistics & Compliance Guide for Surface Mount Resistors

Overview

Surface Mount Resistors (SMD resistors) are essential passive components used in modern electronic circuits. Efficient logistics and strict compliance with international regulations are critical for their safe handling, transportation, storage, and integration into electronic assemblies.

Packaging and Labeling Requirements

Proper packaging ensures the integrity and traceability of surface mount resistors during transit and storage.

Packaging Standards

- Use moisture-barrier bags (MBB) for humidity-sensitive devices (typically rated MSL 2a to 4, depending on construction).

- Include desiccant packs and humidity indicator cards (HIC) inside MBBs.

- Utilize embossed carrier tapes (e.g., 7mm, 12mm, 18mm widths) on reels, sealed with cover tape.

- Reels must comply with EIA-481 and EIA-819 standards for tape dimensions and orientation.

Labeling

- Each reel and outer package must be labeled with:

- Manufacturer part number (MPN) and value (e.g., 10kΩ ±1%)

- Date code and lot number

- Quantity of components

- Moisture Sensitivity Level (MSL)

- RoHS and REACH compliance marks

- Handling symbol (e.g., “Caution: Moisture Sensitive”)

Storage Conditions

Improper storage can degrade component performance or lead to manufacturing defects.

Environmental Requirements

- Store in a dry environment with humidity ≤ 10% RH (ideally in a dry cabinet).

- Temperature range: 15°C to 30°C.

- Avoid direct sunlight, corrosive fumes, and excessive vibration.

- First-In, First-Out (FIFO) inventory management is recommended.

Shelf Life

- Typical shelf life: 12 months from date of manufacture when unopened.

- Once the moisture barrier bag is opened, the floor life begins based on MSL (e.g., MSL 3 = 168 hours at <60% RH).

Transportation Guidelines

Ensure components arrive undamaged and within compliance.

Handling

- Use ESD-safe containers and handling procedures (e.g., grounded mats, wrist straps).

- Avoid mechanical shock and static discharge during packing and transit.

- Do not stack heavy items on top of SMD resistor packaging.

Shipping

- Use anti-static, crush-resistant outer packaging.

- For international shipments, include commercial invoice, packing list, and product compliance documentation.

- Declare contents clearly to avoid customs delays.

Regulatory Compliance

Environmental Regulations

- RoHS (EU Directive 2011/65/EU): Ensure resistors are lead-free and comply with restricted substances (Pb, Cd, Hg, etc.).

- REACH (EC 1907/2006): Confirm no use of Substances of Very High Concern (SVHC) above threshold levels.

- Conflict Minerals (Section 1502 of Dodd-Frank Act): Provide sourcing transparency for tin, tantalum, tungsten, and gold (3TG).

Industry Standards

- IPC-J-STD-020: Defines moisture/reflow sensitivity for non-hermetic SMD devices.

- IEC 60062 / IEC 60063: Standard for resistor marking and preferred values.

- AEC-Q200 (for automotive): Qualification standard for passive components in automotive applications.

Import/Export Considerations

Documentation

- Provide accurate HS (Harmonized System) code: typically 8533.21 for fixed carbon resistors or 8533.31 for other fixed resistors, surface mount.

- Include certificates of compliance (CoC), material declarations (e.g., IPC-1752), and RoHS/REACH statements.

Trade Compliance

- Verify export control classifications (ECCN) under EAR (U.S. Export Administration Regulations); most SMD resistors are classified as EAR99.

- Comply with destination country regulations (e.g., China RoHS, UK REACH, India E-Waste Rules).

Handling and Usage in Manufacturing

Pre-Usage Inspection

- Verify MSL status and baked if necessary (per JEDEC J-STD-033).

- Check for reel damage, tape misalignment, or visible contamination.

Soldering Profile

- Follow reflow guidelines per IPC/JEDEC J-STD-020.

- Typical peak reflow temperature: 240–260°C (depending on solder alloy and resistor construction).

- Avoid thermal shock or excessive dwell time.

Disposal and Recycling

Non-compliant or expired components must be disposed of responsibly.

Best Practices

- Partner with certified e-waste recyclers.

- Follow local hazardous waste regulations.

- Maintain records of disposal for audit purposes.

Summary

Proper logistics and compliance ensure reliability, reduce risk, and support sustainable manufacturing. Adherence to packaging, storage, transportation, and regulatory standards is essential for all stakeholders in the surface mount resistor supply chain. Regular audits and training help maintain compliance and operational efficiency.

In conclusion, sourcing surface mount resistors requires careful consideration of several key factors including resistor specifications (such as resistance value, tolerance, power rating, and temperature coefficient), package size (e.g., 0603, 0805), material quality, and compliance with industry standards (such as RoHS). Reliable suppliers and distributors—whether direct from manufacturers like Yageo, TE Connectivity, and Vishay, or through authorized channels like Digi-Key, Mouser, and RS Components—play a critical role in ensuring component authenticity, consistency, and traceability. Additionally, evaluating cost-effectiveness, lead times, and minimum order quantities is essential, especially for high-volume production or prototyping. By balancing quality, availability, and supply chain reliability, engineers and procurement teams can successfully source surface mount resistors that meet both performance requirements and project timelines.