The global cotton candy market is experiencing steady expansion, driven by rising demand in amusement parks, entertainment venues, and food service industries. According to Grand View Research, the global confectionery machines market—of which cotton candy machines are a niche but growing segment—was valued at approximately USD 3.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increased consumer interest in experiential foods and the proliferation of mobile food vending. As demand rises, so does the need for reliable, high-performance sugar specifically designed for cotton candy machines. Manufacturers are now focusing on producing fine-grain, optimized melting point sugars that ensure consistent floss production, minimal waste, and machine longevity. In this evolving landscape, selecting the right sugar supplier has become critical for operators seeking efficiency and superior product quality. Below are the top nine sugar manufacturers catering specifically to cotton candy machine needs, selected based on purity standards, granulation consistency, compatibility across machine brands, and commercial availability.

Top 9 Sugar For A Cotton Candy Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Homepage

Domain Est. 1998

Website: faygo.com

Key Highlights: Made in Detroit, Michigan. © 2026 Faygo Beverages, Inc., a National Beverage company. … ZERO SUGAR COTTON CANDY. ZERO SUGAR COTTON CANDY. Available Sizes. Share…

#2 Wholesale Cotton Candy Floss Sugar

Domain Est. 1994

Website: sugars.com

Key Highlights: Get the sweetest delight with Indiana Sugars’ premium cotton candy sugar: fluffier, tastier, and a rainbow of vibrant colors!…

#3 Product Category

Domain Est. 1996

Website: gmpopcorn.com

Key Highlights: Pure Simplicity: Using the right equipment and supplies, cotton candy is easy to make. Just add Flossugar to the machine and in moments the sugar swirls into a ……

#4 Cotton Candy Supplies

Domain Est. 1999

#5 Cotton Candy Supplies

Domain Est. 1999

Website: popcornsupply.com

Key Highlights: 30-day returnsCotton Candy Supplies & Accessories. Large selection for the home or professional. Discounted Prices. Fast Shipping….

#6 Cotton Candy Sugar

Domain Est. 2002

Website: ultimatebaker.com

Key Highlights: 2–6 day delivery 30-day returnsCrafted from premium, all-natural ingredients, this gourmet cotton candy sugar guarantees a melt-in-your-mouth experience that’s perfect for both pro…

#7 Flavored Sugar

Domain Est. 2012

#8 Cotton Candy Sugar

Domain Est. 2015

Website: candyflossland.com

Key Highlights: Cotton Candy sugar flavours are sold in 2lb increments which will produce approximately 35-40 cones or 20-30 bags….

#9 Gourmet Cotton Candy Floss Sugar

Domain Est. 2016

Website: cottoncandysugarfloss.com

Key Highlights: Free deliveryGourmet Cotton Candy Floss Sugars Hand Blended With Finest Natural Ingredients for Superior Flavor, Color and Texture, 80 Unique Flavors, All 100% Allergen Free ……

Expert Sourcing Insights for Sugar For A Cotton Candy Machine

H2: 2026 Market Trends for Sugar for a Cotton Candy Machine

The global market for sugar used in cotton candy machines is poised for notable transformation by 2026, driven by evolving consumer preferences, technological advancements, and increasing demand across both commercial and residential sectors. This analysis explores the key trends expected to shape the industry in the coming years.

-

Growing Demand in Entertainment and Foodservice Sectors

By 2026, the resurgence of live events, amusement parks, fairs, and food trucks post-pandemic recovery is expected to significantly boost the demand for cotton candy sugar. With experiential consumption on the rise, cotton candy remains a popular novelty treat, especially among younger demographics. Foodservice operators are increasingly investing in high-capacity cotton candy machines, driving parallel demand for compatible and high-performance sugar. -

Expansion of Flavored and Colored Sugar Varieties

Consumers in 2026 are seeking more personalized and visually appealing treats. As a result, manufacturers are innovating with an expanded range of flavored and naturally colored cotton candy sugars—such as sour apple, blue raspberry, bubblegum, and even exotic flavors like matcha or lavender. The use of natural dyes (e.g., beetroot, turmeric, spirulina) is gaining traction to meet clean-label demands, particularly in North America and Europe. -

Rise in Home-Use Cotton Candy Machines

The popularity of at-home entertainment and DIY food experiences continues to grow. E-commerce platforms report increasing sales of compact cotton candy machines for household use, especially during holiday seasons and children’s parties. This trend is expected to sustain demand for pre-packaged, easy-to-use cotton candy sugar, often sold in multi-flavor kits tailored for families and hobbyists. -

Sustainability and Eco-Friendly Packaging

Environmental concerns are influencing product development. By 2026, leading brands are anticipated to shift toward biodegradable or recyclable packaging for cotton candy sugar. Additionally, some producers are exploring organic and non-GMO sugar options to appeal to health- and eco-conscious consumers, particularly in premium market segments. -

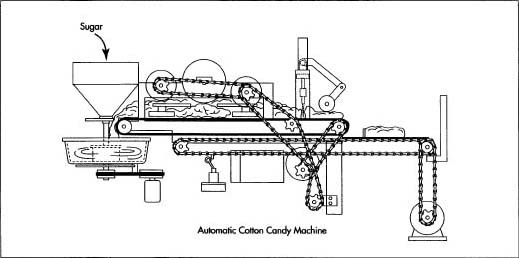

Technological Integration and Machine Compatibility

As cotton candy machines evolve with features like temperature control, automatic spinning, and app connectivity, sugar formulations are being optimized for better performance. In 2026, expect to see machine-specific sugar blends engineered for faster melt, reduced clogging, and improved fluff consistency—especially for commercial-grade equipment. -

Regional Market Growth in Asia-Pacific and Latin America

While North America and Europe remain dominant markets, the Asia-Pacific and Latin American regions are projected to experience the highest growth rates by 2026. Increasing urbanization, rising disposable incomes, and the globalization of Western-style treats are fueling demand in countries like India, China, Brazil, and Mexico. Local manufacturers are beginning to produce regionally adapted sugar flavors to cater to local tastes. -

E-Commerce and Direct-to-Consumer Sales Surge

Online retail channels are becoming a primary distribution method for cotton candy sugar. Subscription models, bundling with machines, and influencer marketing on platforms like Instagram and TikTok are helping niche brands reach wider audiences. By 2026, a significant share of sales is expected to occur via digital marketplaces, especially for specialty and gourmet sugar varieties.

In conclusion, the 2026 market for sugar used in cotton candy machines will be characterized by innovation, diversification, and increased accessibility. As consumer experiences become more dynamic and health- and sustainability-focused, suppliers who adapt with flavorful, eco-conscious, and technologically compatible products will gain a competitive edge in this sweet and spinning segment of the confectionery industry.

Common Pitfalls Sourcing Sugar for a Cotton Candy Machine (Quality, IP)

When sourcing sugar specifically for cotton candy machines, businesses often encounter challenges that impact both product quality and intellectual property (IP) considerations. Overlooking these pitfalls can lead to subpar results, customer dissatisfaction, and potential legal risks.

Poor Sugar Quality Leading to Machine Malfunctions

One of the most frequent issues is using low-grade sugar that hasn’t been properly processed for cotton candy use. Cotton candy machines require ultra-fine, finely granulated sugar that melts evenly and spins into fine threads. Coarse or inconsistently sized sugar crystals can clog the spinning head, cause uneven melting, or result in brittle, clumpy cotton candy. Impurities, excessive moisture, or incorrect particle size distribution can also reduce machine efficiency and increase maintenance needs.

Incorrect Sugar Composition Affecting Flavor and Texture

Generic sugars may lack the precise formulation needed for optimal cotton candy production. Some cotton candy sugars include added flavors, colors, or flow agents (like citric acid or anti-caking agents) designed to enhance taste and performance. Sourcing unlabeled or unverified sugar blends can lead to inconsistent flavor profiles, poor melt characteristics, or undesirable textures. This compromises the end product’s quality and brand reputation.

Lack of Food-Grade Certification and Compliance

Sourcing sugar without proper food safety certifications (e.g., FDA compliance, GMP, or HACCP) poses serious health and regulatory risks. Using non-food-grade sugar—even if chemically similar—can introduce contaminants or unauthorized additives. This not only endangers consumers but can also result in legal liability, product recalls, and damage to brand credibility.

Intellectual Property Infringement with Branded Sugar Formulations

Many premium cotton candy sugars are proprietary blends protected by trademarks or trade secrets. Sourcing counterfeit or knock-off versions that mimic branded products (e.g., flavored sugar blends with protected names or packaging) can lead to IP infringement claims. Even replicating a competitor’s unique flavor profile too closely may raise legal concerns, especially if it involves misrepresentation or trade dress confusion.

Inadequate Supply Chain Transparency and Traceability

When sourcing from unknown or unvetted suppliers, businesses risk inconsistencies in sugar quality and ethical sourcing practices. Lack of traceability makes it difficult to verify origin, processing standards, or allergen controls—especially important for specialty markets (e.g., organic, non-GMO, or allergen-free). This opacity can also hinder compliance with labeling regulations and damage consumer trust.

Overlooking Packaging and Shelf-Life Considerations

Sugar for cotton candy must be stored in moisture-resistant, sealed packaging to prevent clumping and degradation. Poor packaging from unreliable suppliers can compromise sugar quality before it even reaches the machine. Additionally, extended lead times or improper storage during transit can reduce shelf life and performance, leading to wasted inventory and inconsistent output.

Avoiding these pitfalls requires due diligence: partnering with reputable suppliers, verifying certifications, understanding formulation specifics, and respecting intellectual property rights in product development and branding.

Logistics & Compliance Guide for Sugar for a Cotton Candy Machine

Product Classification and HS Code

Sugar used specifically for cotton candy machines is typically classified under the broader category of sugar or confectionery products. The most common Harmonized System (HS) code for granulated sugar is 1701.99, which covers “Cane or beet sugar and chemically pure sucrose, in solid form, other.” However, if the sugar is specially processed, colored, or flavored for cotton candy, it may fall under 1704.90 (“Other sugar confectionery”). Accurate classification is essential for determining import duties, taxes, and regulatory requirements in the destination country.

Packaging and Labeling Requirements

Sugar intended for cotton candy machines must be packaged to maintain freshness, prevent clumping, and ensure food safety. Packaging should be:

– Airtight and moisture-resistant (e.g., resealable plastic bags or sealed pouches)

– Made from food-grade materials compliant with local food contact regulations (e.g., FDA in the U.S., EU Framework Regulation (EC) No 1935/2004)

– Clearly labeled with:

– Product name (e.g., “Cotton Candy Sugar” or “Granulated Sugar for Cotton Candy Machines”)

– Net weight

– Ingredients list (e.g., “100% Sugar” or “Sugar, Natural Flavors, Colors”)

– Allergen information (if applicable)

– Manufacturer or distributor name and address

– Country of origin

– Batch number and expiration or “best before” date

For flavored or colored sugar, compliance with food additive regulations (e.g., FDA 21 CFR or EU Food Additives Regulation EC 1333/2008) is required.

Regulatory Compliance

United States (FDA)

- Must comply with FDA food safety regulations under the Food Safety Modernization Act (FSMA)

- Facilities involved in manufacturing or packing must register with the FDA

- Sugar must be produced in a facility following Current Good Manufacturing Practices (cGMPs)

- If flavors or colors are added, they must be approved for food use (e.g., FD&C colors)

European Union

- Must comply with Regulation (EC) No 178/2002 (General Food Law)

- Subject to the EU’s food hygiene regulations (EC) No 852/2004

- Any added colors or flavors must be authorized and listed under EU legislation

- Pre-market notification may be required for novel foods or additives

Other Markets

- Canada: Complies with Safe Food for Canadians Regulations (SFCR); labeling in English and French required

- Australia/New Zealand: Must meet standards set by FSANZ (Food Standards Australia New Zealand)

- Always verify local requirements for food imports, including ingredient approvals and labeling

Import and Export Documentation

Key documents required for international shipment include:

– Commercial Invoice

– Packing List

– Bill of Lading or Air Waybill

– Certificate of Origin (may be required for tariff preferences)

– Phytosanitary Certificate (rarely required for refined sugar, but check destination rules)

– FDA Prior Notice (for U.S. imports of food)

– Import Permit (if required by destination country)

Storage and Handling

- Store in a cool, dry, and well-ventilated area away from direct sunlight

- Maintain temperatures between 15°C and 25°C (59°F–77°F) to prevent clumping

- Avoid exposure to moisture and strong odors

- Use FIFO (First In, First Out) inventory rotation

- Ensure transport vehicles are clean, dry, and food-safe

Transportation Considerations

- Use sealed, non-leaking containers to prevent contamination

- Avoid mixing with hazardous or strong-smelling goods

- For global shipping, ensure compliance with international transport regulations (e.g., IMDG for sea, IATA for air—though sugar is generally non-hazardous)

- Monitor for temperature and humidity during transit, especially in tropical climates

Sustainability and Ethical Sourcing

- Consider sourcing sugar that is certified by recognized programs such as Fair Trade, Rainforest Alliance, or Bonsucro

- Provide documentation if making sustainability claims on packaging

- Ensure supply chain transparency to meet growing consumer and regulatory expectations

Summary

Successfully managing the logistics and compliance of sugar for cotton candy machines requires attention to accurate product classification, adherence to food safety regulations, proper labeling, and careful handling throughout the supply chain. Always verify country-specific requirements before shipping to avoid delays or customs rejections.

In conclusion, sourcing the right type of sugar for a cotton candy machine is essential for achieving the perfect texture, flavor, and overall quality of the final product. Standard granulated white sugar with a fine particle size is typically the best choice, as it melts smoothly and spins into delicate, airy strands. While specialty sugars and flavorings can enhance taste and presentation, they should be used carefully to avoid machine clogs or inconsistent results. When selecting a supplier, prioritize consistency in sugar quality, cost-effectiveness, and reliable availability. By choosing the appropriate sugar and a trustworthy source, operators can ensure optimal performance of their cotton candy machine, satisfy customer expectations, and maintain efficient, profitable operations.