The global structural beam clamps market is experiencing steady growth, driven by rising construction activity, infrastructure development, and increasing demand for modular and prefabricated building systems. According to a report by Grand View Research, the global scaffolding market—of which beam clamps are a critical component—was valued at USD 11.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. Similarly, Mordor Intelligence projects continued expansion in the construction hardware sector, citing increased investments in commercial and industrial infrastructure, particularly across Asia-Pacific and North America. As safety standards tighten and the need for versatile, load-bearing support solutions grows, beam clamps have become essential in steel-framed structures, temporary supports, and suspended systems. With manufacturers focusing on load capacity, corrosion resistance, and ease of installation, the competitive landscape is evolving to meet stringent regulatory and performance demands. This growing demand has elevated the importance of reliable, high-performance beam clamps, positioning leading manufacturers at the forefront of innovation and market share.

Top 10 Structural Beam Clamps Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Girder Clamps

Domain Est. 1995

Website: lindapter.com

Key Highlights: Lindapter’s versatile Girder Clamps can be configured to suit almost any steel-to-steel connection. Both faster and safer than welding….

#2 Beam Clamps

Domain Est. 1995

#3 Beam clamps and accessories

Domain Est. 1996

Website: eaton.com

Key Highlights: Eaton offers a wide variety of B-Line series beam clamps and accessories to attach electrical and mechanical components to structural beams….

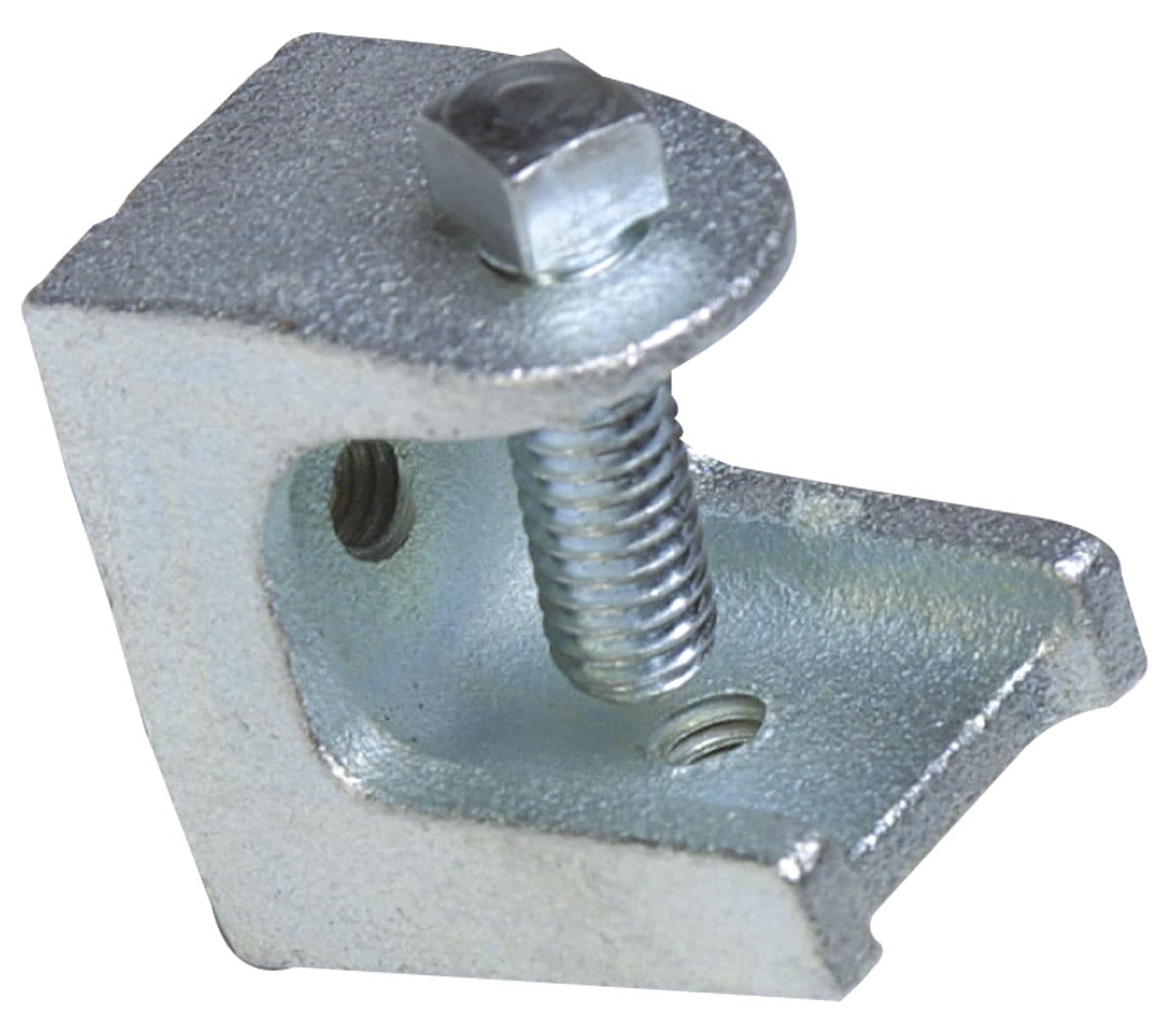

#4 Beam Clamps

Domain Est. 1996

Website: minerallac.com

Key Highlights: 4 Ways to Order. Toll-free Fax: (800) 824-8942. [email protected]. 100 Gast Rd. Hampshire, IL 60140….

#5 Beam Clamps and Accessories

Domain Est. 2001

Website: nvent.com

Key Highlights: BC26 Universal Beam Clamp with Tapped Hole. Reversible beam clamp for use with standard flange widths….

#6 • BEAMCLAMP

Domain Est. 2003

Website: beamclamp.com

Key Highlights: An extensive range of fixing designed to secure secondary steel work and building services equipment, such as cable trays, pipework, strengthening steel ……

#7 Chicago Clamp Systems

Domain Est. 2006

Website: chicagoclampcompany.com

Key Highlights: Chicago Clamp Systems: Chicago Clamp Company offers innovative solutions for efficient and safe steel-to-steel connections. Explore our systems today….

#8 Structural Steel BeamClamp Products

Domain Est. 2010

Website: lnasolutions.com

Key Highlights: Our BeamClamp products are structural clamps designed to secure steel to steel connections without the need for onsite drilling or welding….

#9 Beam Clamps

Domain Est. 2018

Website: unistrutstore.com

Key Highlights: Free delivery 30-day returnsShop I-beam clamps, window clamps, U-clamps & more at Unistrut Store. Available in stainless steel, green powder coat & other standard finishes….

#10 134 Heavy Duty Beam Clamp

Domain Est. 2020

Website: asc-es.com

Key Highlights: Size Range: 4″ through 12″. Material: Carbon steel. Finish: Plain or Hot-Dip Galvanized with Zinc Plated Fasteners. Service: Clamp centers the load on beam ……

Expert Sourcing Insights for Structural Beam Clamps

2026 Market Trends for Structural Beam Clamps

The global structural beam clamps market is poised for significant evolution by 2026, driven by advancements in construction methodologies, increasing demand for modular and temporary support systems, and a growing emphasis on worker safety and efficiency. These specialized clamps, used to securely attach scaffolding, formwork, and other temporary structures to steel beams without welding or drilling, are becoming increasingly integral to modern construction projects. The following key trends are expected to shape the market landscape in 2026.

Rising Demand from Sustainable and Modular Construction

The shift toward sustainable building practices and the adoption of modular and prefabricated construction techniques are major drivers for structural beam clamps. These clamps enable rapid assembly and disassembly, aligning perfectly with the principles of off-site construction and reusability. As governments and developers prioritize low-carbon construction and reduced on-site waste, reusable clamping systems are favored over permanent attachment methods. By 2026, the demand for beam clamps in modular high-rise buildings, data centers, and industrial facilities is expected to surge, particularly in North America and Europe where green building certifications are becoming standard.

Technological Innovation and Material Advancements

Innovation in materials and design is enhancing the performance and versatility of structural beam clamps. High-strength alloys and lightweight composites are being increasingly used to improve load-bearing capacity while reducing overall weight, making installations easier and safer. Smart clamps equipped with load sensors and digital monitoring capabilities are emerging, allowing real-time structural health assessments during construction. By 2026, these technologically advanced clamps are expected to gain traction in high-risk or complex infrastructure projects, such as bridges and stadiums, where safety and precision are paramount.

Focus on Safety and Regulatory Compliance

Stringent occupational health and safety regulations worldwide are pushing contractors to adopt safer temporary works solutions. Beam clamps eliminate the need for hot work (welding or cutting), reducing fire risks and structural damage. Regulatory bodies in regions like the EU and North America are increasingly mandating the use of certified, load-tested clamping systems. By 2026, compliance with international standards such as EN 795 and OSHA guidelines will be a critical market differentiator, driving demand for certified, third-party tested beam clamps and encouraging manufacturers to invest in product certification and traceability.

Expansion in Emerging Markets

Rapid urbanization and infrastructure development in Asia-Pacific, the Middle East, and Latin America are creating new growth opportunities. Countries like India, Indonesia, and Saudi Arabia are investing heavily in transportation networks, commercial buildings, and smart cities—all projects requiring efficient and safe temporary support systems. As construction practices in these regions modernize, the adoption of structural beam clamps is expected to grow significantly by 2026, supported by local manufacturing partnerships and increased awareness of safety best practices.

Competitive Market Dynamics and Supply Chain Optimization

The market is witnessing increased competition among global and regional manufacturers, leading to product differentiation through design innovation, rental models, and digital services. Rental and leasing models for beam clamps are gaining popularity, especially among smaller contractors, reducing upfront costs and promoting equipment reuse. Additionally, supply chain resilience has become a priority post-pandemic, prompting manufacturers to localize production and diversify sourcing. By 2026, companies with agile supply chains and strong digital integration (e.g., inventory tracking, e-commerce platforms) will have a competitive edge in meeting on-demand project needs.

Common Pitfalls Sourcing Structural Beam Clamps (Quality, IP)

Sourcing structural beam clamps requires careful attention to detail, as poor choices can lead to significant safety risks, project delays, and financial losses. Here are key pitfalls to avoid, particularly concerning quality and intellectual property (IP):

Inadequate Quality Verification

Many suppliers claim compliance with standards like ASME B30.20 or ISO 4309, but not all products are rigorously tested. Buyers often assume certifications are genuine without independent verification, leading to the use of substandard clamps that may fail under load. Always request certified test reports and material certifications, and consider third-party inspections, especially when sourcing from unfamiliar manufacturers.

Counterfeit or Non-Compliant Products

The market includes counterfeit beam clamps that mimic reputable brands but lack the required metallurgical properties and heat treatment. These clamps may look identical but fail catastrophically under stress. To avoid this, purchase only through authorized distributors and verify batch traceability. Beware of unusually low prices, which are often a red flag for non-compliant or fake products.

Ignoring Intellectual Property (IP) Risks

Some suppliers produce clamps that closely copy patented designs from leading manufacturers (e.g., specific jaw profiles, locking mechanisms). Using such IP-infringing products can expose your company to legal liability, especially in regulated industries or international projects. Always confirm that the supplier owns or has licensed the designs, and avoid products that appear to be unauthorized replicas.

Lack of Traceability and Documentation

High-quality beam clamps require full material and manufacturing traceability (e.g., heat numbers, test records). Many low-cost suppliers provide minimal documentation, making it impossible to verify quality or comply with project audits. Ensure suppliers offer complete documentation packages suitable for QA/QC processes and regulatory compliance.

Overlooking Environmental and Load-Specific Suitability

Not all beam clamps are suitable for extreme conditions (e.g., high humidity, corrosive environments, or dynamic loads). Sourcing generic clamps without considering environmental ratings or load dynamics can result in premature failure. Specify clamps with appropriate coatings (e.g., hot-dip galvanizing) and design features suited to the application.

Choosing Based Solely on Price

Prioritizing cost over quality and compliance can lead to higher lifecycle costs due to failures, replacements, or accidents. A slightly higher initial investment in certified, IP-compliant clamps from reputable sources ensures safety, reduces risk, and supports long-term project integrity.

By addressing these pitfalls proactively, buyers can ensure they source structural beam clamps that are safe, reliable, and legally sound.

Logistics & Compliance Guide for Structural Beam Clamps

Overview

Structural beam clamps are essential lifting and rigging devices used to secure loads to I-beams, H-beams, and other structural steel members. Proper logistics handling and strict compliance with safety and regulatory standards are critical to ensure operational safety, product integrity, and legal adherence.

Regulatory Standards and Compliance

Structural beam clamps must comply with recognized industry and international standards. Key compliance requirements include:

- ASME B30.20: Covers below-the-hook lifting devices, including design, testing, and marking requirements.

- OSHA 29 CFR 1910.184: U.S. regulation for slings and rigging hardware, applicable to beam clamp use in general industry.

- EN 13155: European standard for non-fixed load lifting attachments, relevant for CE-marked clamps used in the EU.

- ISO 16893: International standard for lifting devices used in overhead lifting.

- CE Marking: Required for sale and use within the European Economic Area, indicating conformity with health, safety, and environmental protection standards.

- UKCA Marking: Required for use in the United Kingdom post-Brexit, replacing CE in certain contexts.

Manufacturers and users must ensure all beam clamps are certified, tested, and marked per these standards.

Product Certification and Documentation

Each beam clamp must be supplied with the following documentation:

- Certificate of Conformity (CoC) stating compliance with relevant standards.

- Test and inspection reports, including proof load testing results.

- Manufacturer’s Declaration of Conformity (DoC) for CE/UKCA.

- User manual with installation instructions, load charts, and safety warnings.

- Traceability information (serial number, batch number, manufacturing date).

Maintain these documents throughout the product lifecycle for audit and compliance verification.

Storage and Handling Logistics

Proper storage and handling are vital to preserve clamp integrity and performance:

- Store in a dry, clean, and indoor environment to prevent corrosion.

- Avoid contact with chemicals, moisture, or extreme temperatures.

- Keep clamps organized on racks or in labeled containers to prevent physical damage.

- Handle with care during transportation—avoid dropping or impact.

- Protect threaded components and jaw surfaces from debris and damage.

Transportation Requirements

When shipping beam clamps:

- Use secure packaging (e.g., wooden crates or heavy-duty boxes) to prevent movement.

- Include cushioning materials to absorb shock and vibration.

- Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”).

- Ensure weight and dimensions comply with carrier regulations.

- Include shipping documentation: packing list, CoC, safety data sheet (if applicable), and commercial invoice.

Import/Export Compliance

For international shipments:

- Verify country-specific regulations (e.g., FDA, REACH, RoHS if applicable to materials).

- Provide accurate HS codes (e.g., 8431.31 for lifting appliances parts).

- Comply with customs documentation: bill of lading, commercial invoice, certificate of origin.

- Confirm destination country’s certification requirements (e.g., INMETRO for Brazil, GOST for Russia).

- Use licensed freight forwarders experienced in handling industrial hardware.

Inspection and Maintenance Compliance

Regular inspection is mandated by OSHA and ASME:

- Perform pre-use visual inspections for cracks, deformation, or worn threads.

- Conduct periodic inspections at intervals defined by usage (e.g., monthly or quarterly).

- Document all inspections and maintenance activities.

- Remove damaged or non-compliant clamps from service immediately.

- Follow manufacturer’s maintenance guidelines strictly.

Training and Operational Compliance

Personnel using beam clamps must be trained in:

- Proper selection based on beam size and load capacity.

- Correct installation and load engagement procedures.

- Recognizing signs of wear or failure.

- Adherence to load limits and working load limits (WLL).

- Emergency procedures and hazard identification.

Training records must be maintained as part of compliance documentation.

Disposal and End-of-Life Management

At end-of-life:

- Decommission damaged or expired clamps in accordance with company and regulatory policies.

- Recycle metal components where possible, following local environmental regulations.

- Document disposal to maintain traceability and compliance.

Summary

Adhering to logistics and compliance protocols ensures structural beam clamps are safely transported, stored, used, and maintained. Staying current with regulatory requirements protects workers, meets legal obligations, and supports operational reliability. Always consult manufacturer guidelines and jurisdiction-specific regulations when managing beam clamp operations.

Conclusion for Sourcing Structural Beam Clamps

In conclusion, sourcing structural beam clamps requires a careful evaluation of quality, safety standards, compatibility, and supplier reliability. These critical lifting and rigging components must meet recognized industry specifications—such as OSHA, ASME, or EN standards—to ensure safe and secure load handling in construction, industrial, and fabrication environments. Purchasing from reputable suppliers with verifiable certifications, traceable materials, and comprehensive product testing is essential to maintain worksite safety and regulatory compliance.

Moreover, understanding the specific application requirements—such as beam size, load capacity, clamp type (adjustable, fixed, or swivel), and environmental conditions—enables the selection of the most suitable clamp for optimal performance. Cost-effectiveness should not compromise safety or durability; therefore, a balanced approach that prioritizes long-term reliability over initial price savings is recommended.

By conducting thorough due diligence, comparing multiple suppliers, and consulting engineering or safety experts when necessary, organizations can ensure they procure high-quality structural beam clamps that enhance operational efficiency while safeguarding personnel and equipment.