The global drill bit market is experiencing robust expansion, driven by rising demand across construction, oil and gas, mining, and manufacturing sectors. According to a report by Mordor Intelligence, the market was valued at USD 4.8 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% through 2029. This growth is fueled by technological advancements in bit materials—such as polycrystalline diamond compact (PDC) and carbide-tipped designs—and the increasing need for high-performance drilling solutions in challenging environments. As infrastructure development accelerates worldwide and energy exploration activities intensify, particularly in emerging economies, the demand for durable, precision-engineered drill bits continues to rise. Against this backdrop, leading manufacturers are investing heavily in R&D and strategic partnerships to gain competitive advantage. Based on market presence, innovation, product range, and global reach, the following ten companies stand out as the strongest drill bit manufacturers shaping the future of industrial drilling.

Top 10 Strongest Drill Bit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Smith Bits

Domain Est. 1987

Website: slb.com

Key Highlights: Additionally, Smith Bits is continually recognized for advancement in bit technology, having earned the Hart Energy Special Meritorious Awards ……

#2 Rodman Drill: We Get the Job Done

Domain Est. 2017

Website: rodmandrill.com

Key Highlights: Free delivery over $100 30-day returnsThe Rodman Multipurpose bit will cut the hardest steel found, including Grade A bolts, broken taps, broken easy outs, stainless and spring….

#3 Greenfield Industries

Domain Est. 1996

Website: gfii.com

Key Highlights: Greenfield Industries’ tradition of excellence has stood the test of time. We provide the highest quality cutting tools at the greatest value possible….

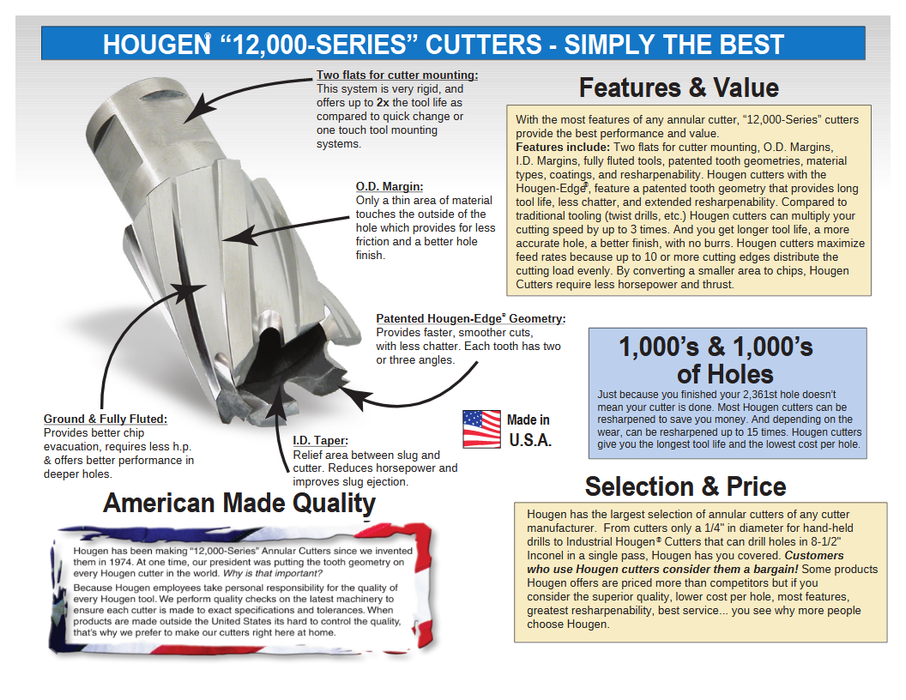

#4 HOUGEN MANUFACTURING

Domain Est. 1996

Website: hougen.com

Key Highlights: Built for the toughest jobs in the shop or on site, Hougen® tools cut faster, drill cleaner, & help you stay more productive. · Magnetic Drills · Annular Cutters….

#5 Rockmore International

Domain Est. 1997

Website: rockmore-intl.com

Key Highlights: Rockmore International manufactures the finest and most efficient DTH hammers and bits for the mining, construction and water well industries. More information ……

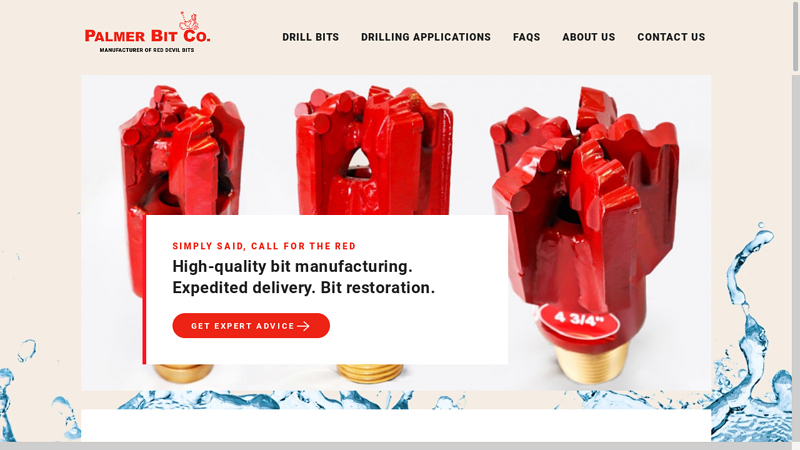

#6 PDC Drill Bits

Domain Est. 1999

Website: palmerbit.com

Key Highlights: We manufacture Diamond Devil PDCs and Red Devil bits. We sell a complete line of PDC bits, drag bits, rock bits and other drill bits….

#7 Norseman™ Drill & Tool

Domain Est. 2000

Website: norsemandrill.com

Key Highlights: Norseman™ Drill & Tool our cutting tools are designed, engineered and superbly crafted to provide long lasting durability….

#8 to DrillsandCutters.com

Domain Est. 2009

Website: drillsandcutters.com

Key Highlights: Free delivery over $99.99 30-day returns…

#9 Precision

Domain Est. 2014 | Founded: 1952

Website: dormerpramet.com

Key Highlights: You’ve known us as Precision Twist Drill (PTD) since 1952. Today, we’re simply Precision—carrying forward the same reliability you’ve always known….

#10 20+ Best Drill Bit Manufacturers in the World

Domain Est. 2004

Website: sinodrills.com

Key Highlights: This blog post explores over 20 of the world’s best drill bit manufacturers, offering insights into their expertise, technological advancements ……

Expert Sourcing Insights for Strongest Drill Bit

H2: Market Trends for the Strongest Drill Bit in 2026

As we approach 2026, the market for high-performance drill bits—particularly those positioned as the “strongest” in terms of durability, heat resistance, and material versatility—is undergoing significant transformation. Driven by advancements in industrial manufacturing, construction demands, and material science innovations, several key trends are shaping the future of the strongest drill bit market.

1. Rise of Advanced Composite Materials

Manufacturers are increasingly incorporating cutting-edge materials such as polycrystalline diamond (PCD), titanium aluminum nitride (TiAlN) coatings, and nano-structured carbide alloys. These materials significantly enhance drill bit strength, allowing penetration through hardened steel, composite laminates, and abrasive materials used in aerospace and automotive sectors. By 2026, drill bits with multi-layer nano-coatings are expected to dominate premium segments due to their extended tool life and resistance to wear.

2. Growth in Automation and Smart Tool Integration

The integration of IoT-enabled smart tools is reshaping industrial drilling. High-strength drill bits are now being designed with embedded sensors to monitor temperature, torque, and wear in real time. This trend is particularly strong in automated manufacturing and CNC machining environments. In 2026, the demand for “smart” ultra-strong drill bits capable of predictive maintenance and data feedback will surge, especially in smart factories and Industry 4.0 applications.

3. Expansion in Renewable Energy and EV Manufacturing

The booming electric vehicle (EV) and renewable energy sectors are creating new demands for precision drilling in battery enclosures, motor housings, and wind turbine components. These applications require drill bits that can handle high-tensile alloys and composite materials without chipping or dulling. As a result, manufacturers of the strongest drill bits are tailoring products for these niche but high-growth markets, driving innovation and market expansion.

4. Sustainability and Circular Economy Initiatives

Environmental regulations and corporate sustainability goals are pushing manufacturers to develop drill bits that are not only strong but also recyclable and longer-lasting. By 2026, there will be a noticeable shift toward modular, re-sharpenable, and re-coatable drill bit designs. Companies offering take-back programs and lifecycle extension services will gain competitive advantage, aligning with global circular economy trends.

5. Regional Market Shifts and Supply Chain Localization

Geopolitical dynamics and supply chain resilience concerns are prompting regionalization of production. In 2026, North America and Europe are expected to increase domestic manufacturing of high-performance drill bits, reducing reliance on imported tools. Meanwhile, Asia-Pacific—especially China and India—will remain key growth markets due to rapid infrastructure and industrial development, creating demand for durable, cost-effective strong drill bits.

6. Competitive Landscape and Innovation Race

Major tooling companies such as Bosch, DeWalt, Hilti, and Sandvik are investing heavily in R&D to claim leadership in the “strongest drill bit” category. Patents related to gradient-hardness substrates and adaptive geometry are on the rise. By 2026, brand positioning around strength, backed by independent lab testing and real-world performance data, will be a key differentiator in both professional and DIY markets.

Conclusion

The 2026 market for the strongest drill bit is being redefined by technological innovation, evolving industry needs, and sustainability imperatives. Companies that combine material science breakthroughs with smart functionality and eco-conscious design will lead the market, meeting the growing demand for tools that deliver unmatched strength and reliability across diverse applications.

Common Pitfalls When Sourcing the Strongest Drill Bit (Quality and Intellectual Property)

Logistics & Compliance Guide for Strongest Drill Bit

Product Classification & Documentation

Ensure accurate product classification under the appropriate Harmonized System (HS) code for drill bits, typically under Chapter 82 (Tools, cutlery, and general hardware). Maintain up-to-date technical specifications, safety data sheets (SDS), and product compliance certificates (e.g., ISO, RoHS, REACH) to support international shipments and customs clearance.

Packaging & Labeling Requirements

Package each Strongest Drill Bit in durable, anti-corrosion materials to prevent damage during transit. Clearly label all units with product name, model number, material composition, country of origin, and batch/lot number. Include required safety warnings and comply with local labeling regulations in destination markets (e.g., CE marking for the EU, ANSI standards for the U.S.).

Import/Export Regulations

Verify export control classifications (ECCN) to determine if the drill bits require export licenses, especially if used in aerospace, defense, or high-precision manufacturing applications. Comply with International Traffic in Arms Regulations (ITAR) if applicable, and ensure adherence to U.S. Department of Commerce and Bureau of Industry and Security (BIS) guidelines.

Transportation & Shipping

Ship via certified freight carriers experienced in handling industrial tools. Use temperature-controlled and shock-resistant transport methods where necessary. Maintain proper shipping manifests, commercial invoices, packing lists, and certificates of origin. For air freight, comply with IATA Dangerous Goods Regulations if packaging includes lubricants or other regulated substances.

Environmental & Safety Compliance

Confirm that the Strongest Drill Bit manufacturing process and materials comply with environmental regulations such as REACH (EU), RoHS (Restriction of Hazardous Substances), and EPA standards (U.S.). Implement proper waste disposal procedures for production byproducts and ensure workplace safety compliance with OSHA (U.S.) or equivalent standards abroad.

Customs Clearance & Duties

Prepare complete customs documentation for each shipment, including a detailed commercial invoice indicating value, quantity, and HTS code. Account for applicable tariffs, import VAT, and any preferential trade agreements (e.g., USMCA, EU-South Korea FTA) that may reduce duty rates. Utilize bonded warehouses or customs brokers to streamline clearance.

Quality Assurance & Traceability

Implement a traceability system to track each batch of Strongest Drill Bits from raw material sourcing through production and delivery. Conduct regular quality audits and maintain records for at least five years to support recalls, warranty claims, and regulatory inspections.

End-Use & End-User Compliance

Perform due diligence on end-users to prevent diversion to unauthorized or restricted applications. Maintain records of end-user declarations, particularly for shipments to sanctioned countries or regions. Adhere to anti-boycott and anti-corruption regulations such as the U.S. Foreign Corrupt Practices Act (FCPA) and UK Bribery Act.

In conclusion, sourcing the strongest drill bit requires careful consideration of material composition, coating technology, intended application, and brand reliability. High-performance options such as carbide-tipped, cobalt (especially M35 or M42 high-speed steel), or polycrystalline diamond (PCD) bits offer superior strength, heat resistance, and durability for demanding tasks. Matching the drill bit to the specific material (e.g., metal, masonry, or composites) ensures optimal performance and longevity. Additionally, purchasing from reputable manufacturers and suppliers guarantees quality control and consistency. Ultimately, investing in the strongest and most suitable drill bit enhances efficiency, accuracy, and tool life, making it a crucial decision for both professional and DIY applications.