The global hand tool market, including specialized equipment such as strap wrenches, is experiencing steady growth driven by increasing demand from automotive, industrial maintenance, and plumbing sectors. According to Grand View Research, the global hand tools market was valued at USD 11.8 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. A key contributor to this expansion is the rising need for non-marring tools in precision applications, where rubber-strapped wrenches are favored for their ability to grip without damaging surfaces. As industries prioritize efficiency and equipment longevity, manufacturers of high-performance strap wrenches with durable rubber components are seeing heightened demand. This growing market landscape has spurred innovation and competition among leading suppliers, positioning the top 10 strap wrench rubber manufacturers as critical players in meeting evolving industry standards.

Top 10 Strap Wrench Rubber Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

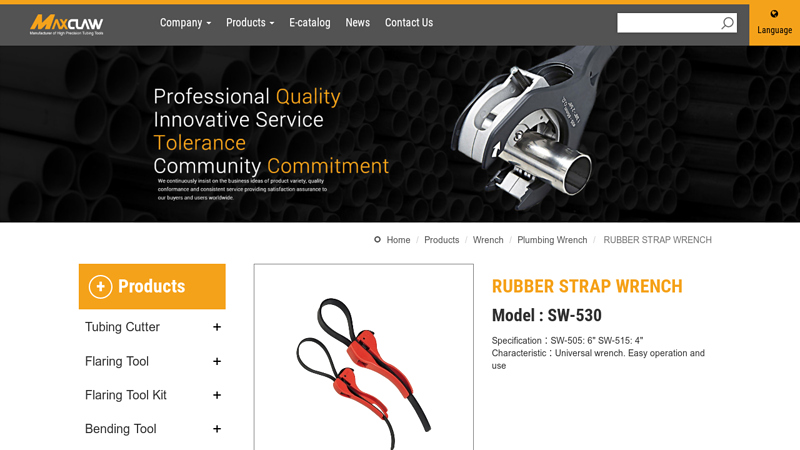

#1 Rubber Strap Wrench

Domain Est. 2015

Website: maxclawtools.com

Key Highlights: Seeking a universal wrench which is professional-quality and easy to operate? SW-530 rubber strap wrench is absolutely your best choice….

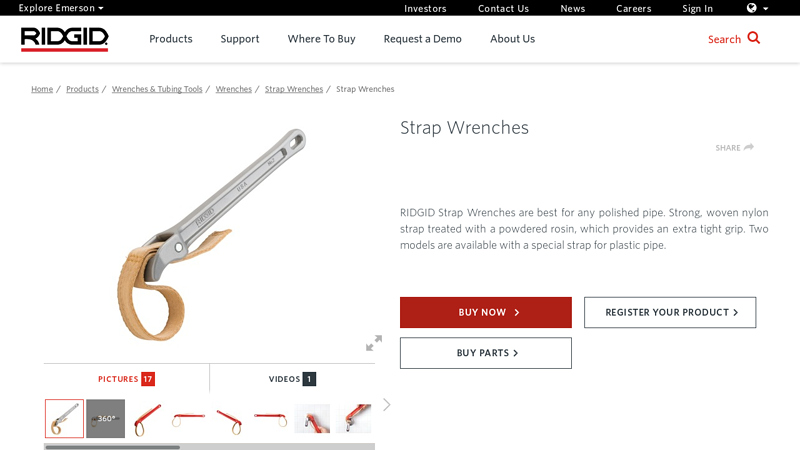

#2 Strap Wrenches

Domain Est. 1995

Website: ridgid.com

Key Highlights: Rating 4.9 (9) RIDGID Strap Wrenches are best for any polished pipe. Strong, woven nylon strap treated with a powdered rosin, which provides an extra tight grip….

#3 Strap Wrench to Remove Ports

Domain Est. 1995

Website: ikelite.com

Key Highlights: In stock Rating 4.5 4 Multi-use rubber strap wrench. Perfect for disassembly of the Modular Port System, or removing ports from compact digital housings….

#4 The hardest working strap wrenches

Domain Est. 1996

Website: wheelerrex.com

Key Highlights: Strap Wrenches provide quick gripping to plastic or chrome plated objects without scratching or damaging the surface….

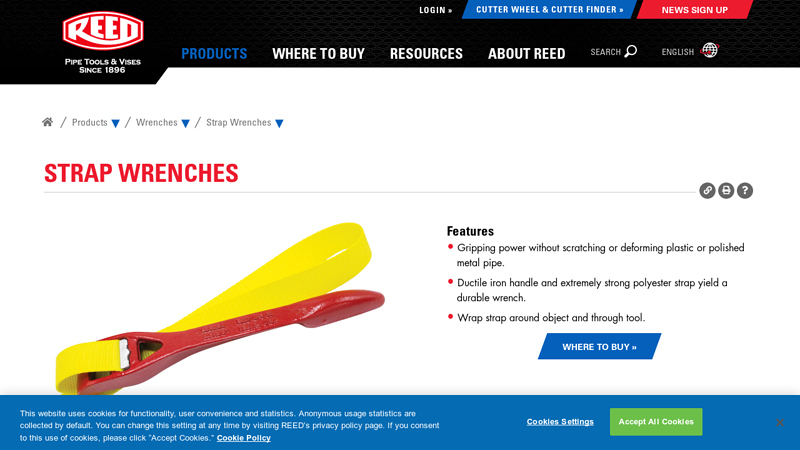

#5 Strap Wrenches

Domain Est. 1997

Website: reedmfgco.com

Key Highlights: REED strap wrenches provide gripping power without scratching or deforming plastic or polished metal pipe. Use on plastic pipe, filters, or any slick or smooth ……

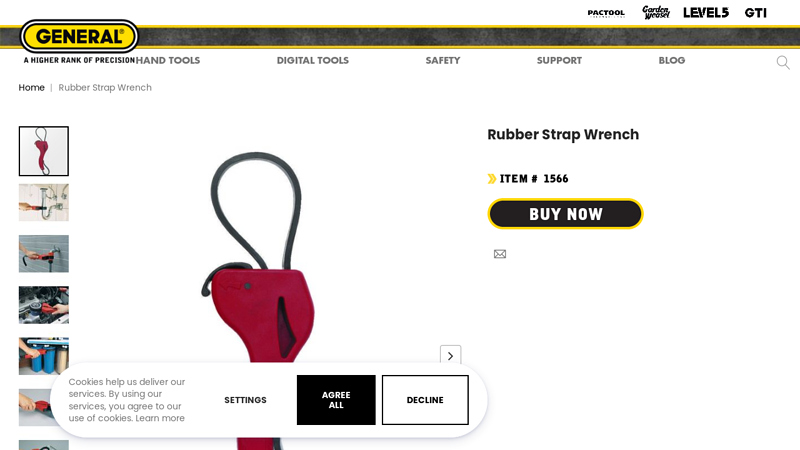

#6 Rubber Strap Wrench

Domain Est. 1997

Website: generaltools.com

Key Highlights: The #1566 Adjustable Rubber Strap Wrench is ideal for holding, tightening or loosening irregular shapes. It can be used to open or tighten jar lids, bottles, ……

#7 Strap wrench

Domain Est. 1998

Website: stahlwille.com

Key Highlights: Low-wear strap wrench for clamping, loosening and tightening sensitive and stiff bolted joints such as oil, sand or water filters….

#8 Strap Wrenches

Domain Est. 1998

Website: kleintools.com

Key Highlights: Klein Tools’ strap wrenches are completely adjustable for tight-quarters tasks on polished, PVS and glass pipes, fittings, filters, conduit and shafts….

#9 Strap Wrench

Domain Est. 2004

Website: toptul.com

Key Highlights: Rubber coated on the strong woven strap to prevent slipping. Perfect use for polished pipes, plastic pipes and fittings against with scratch damage or ……

#10 Adjustable Rubber Strap Wrench

Domain Est. 2017

Expert Sourcing Insights for Strap Wrench Rubber

H2: 2026 Market Trends for Strap Wrench Rubber

The global market for strap wrench rubber components is projected to experience steady growth and notable shifts by 2026, driven by advancements in materials science, rising demand in automotive and industrial maintenance sectors, and an increasing emphasis on tool durability and safety. The rubber element in strap wrenches—critical for providing grip without damaging surfaces—is undergoing transformation due to evolving consumer expectations and technological innovation.

One of the key trends shaping the 2026 landscape is the adoption of high-performance synthetic rubbers. Manufacturers are increasingly replacing conventional natural rubber with advanced elastomers such as silicone, nitrile, and thermoplastic polyurethane (TPU). These materials offer superior resistance to heat, oil, abrasion, and UV exposure, enhancing the lifespan and versatility of strap wrenches in challenging environments. This shift is particularly evident in the automotive repair and aerospace industries, where precision and non-marring performance are paramount.

Another emerging trend is the focus on sustainability and eco-friendly materials. By 2026, leading tool manufacturers are expected to integrate recyclable or bio-based rubber alternatives into their strap wrench designs. This aligns with broader environmental regulations and corporate sustainability goals, especially in Europe and North America. Companies investing in green supply chains are likely to gain a competitive edge in environmentally conscious markets.

Additionally, customization and modular design are gaining traction. Consumers and industrial users alike are demanding interchangeable rubber straps tailored to specific applications—such as plumbing, HVAC, or automotive work. This modularity allows for cost-effective maintenance and extends product usability, supporting a circular economy approach.

The e-commerce boom is also influencing market dynamics. Online platforms now offer detailed product comparisons, user reviews, and specialty strap wrench kits, increasing consumer access to high-quality rubber strap components. As a result, brand reputation and customer trust are becoming crucial differentiators.

In summary, the 2026 strap wrench rubber market will be defined by material innovation, sustainability, product customization, and digital market expansion. Companies that prioritize R&D in advanced elastomers and environmentally responsible manufacturing are poised to lead the next phase of growth in this niche yet essential segment of the hand tool industry.

Common Pitfalls When Sourcing Strap Wrench Rubber (Quality, IP)

Sourcing high-quality strap wrench rubber—especially when intellectual property (IP) considerations are involved—can present several challenges. Being aware of these pitfalls helps ensure you obtain reliable materials without legal or performance issues.

Poor Material Quality and Inconsistent Performance

One of the most frequent issues is receiving strap rubber made from substandard materials. Low-grade rubber may lack the necessary grip, durability, or resistance to oils and temperature extremes. This leads to premature wear, slippage during use, and reduced tool effectiveness. Inconsistent thickness or improper curing during manufacturing can also result in uneven tension and poor performance across batches.

Lack of IP Due Diligence and Risk of Infringement

When sourcing from third-party suppliers—particularly overseas—there’s a risk of inadvertently purchasing rubber components that infringe on patented designs or proprietary patterns. Some manufacturers replicate the tread pattern or composite formulation of branded strap wrenches without authorization. Using such components may expose your company to legal liability, product recalls, or customs seizures, especially in regions with strict IP enforcement.

Inadequate Testing and Certification Documentation

Many suppliers fail to provide comprehensive test reports or material certifications (e.g., ASTM, RoHS, REACH). Without proof of performance standards or compliance, it becomes difficult to verify the rubber’s grip strength, chemical resistance, or safety for intended applications. This lack of transparency increases the risk of product failure and regulatory non-compliance.

Supply Chain Opacity and Counterfeit Materials

Especially in global sourcing, the supply chain for rubber components can be opaque. Intermediaries may substitute specified materials without notice, or recycled/contaminated rubber may be used to cut costs. This not only affects quality but can also undermine your product’s reputation and safety credentials.

Overlooking Customization Rights and Design Ownership

If you’re developing a proprietary strap wrench design, failing to secure clear ownership of custom rubber formulations or tread patterns can lead to future IP disputes. Suppliers may claim rights to modified designs or reuse your specifications for competing products unless contracts explicitly assign IP to your company.

Avoiding these pitfalls requires thorough vetting of suppliers, clear contractual terms around quality and IP, and ongoing quality control measures such as batch testing and audit rights.

Logistics & Compliance Guide for Strap Wrench Rubber

Product Overview

Strap Wrench Rubber refers to the replaceable rubber strap or pad component used in strap wrenches—hand tools designed to grip and rotate smooth or delicate surfaces without causing damage. These rubber components are typically made from nitrile, silicone, or natural rubber and must meet specific performance and safety standards.

Packaging Requirements

- Individual Wrapping: Each rubber strap should be sealed in polyethylene bags to prevent contamination and moisture exposure.

- Box Labeling: Outer packaging must include product name, model number, batch/lot number, quantity, weight, and manufacturer details.

- Barcoding: Include UPC or SKU barcodes for inventory tracking.

- Inner Protection: Use foam inserts or dividers to prevent abrasion during transit.

Storage Conditions

- Temperature: Store between 10°C and 30°C (50°F to 86°F). Avoid extreme heat or freezing.

- Humidity: Maintain relative humidity below 65% to prevent mold or degradation.

- Light Exposure: Keep away from direct sunlight and UV radiation to avoid rubber aging.

- Ventilation: Store in a well-ventilated area to prevent accumulation of volatile organic compounds (VOCs).

Transportation Guidelines

- Mode of Transport: Suitable for road, air, and sea freight. Use enclosed containers to control environmental exposure.

- Stacking Limits: Do not exceed 5 layers of boxes to prevent compression damage.

- Moisture Protection: Use desiccants in containers for sea freight to counteract humidity.

- Hazard Classification: Non-hazardous under IATA, IMDG, and ADR when packaged correctly. No special handling required.

Regulatory Compliance

- REACH (EU): Ensure rubber compounds are registered and free from SVHCs (Substances of Very High Concern) above threshold limits.

- RoHS (EU): Compliant if used in tools within the scope; verify absence of restricted heavy metals (e.g., lead, cadmium).

- California Prop 65: Label if containing chemicals known to cause cancer or reproductive harm (e.g., certain phthalates or benzene derivatives).

- REACH SVHC Disclosure: Provide SCIP notification if applicable.

- FDA Compliance (if applicable): Only required if marketed for food-contact applications—standard industrial use does not require this.

Customs & Documentation

- HS Code: 4016.93.00 (Other articles of vulcanized rubber, non-hardened, mechanical appliances) – verify locally.

- Certificate of Origin: Required for preferential tariffs under trade agreements (e.g., USMCA, RCEP).

- Commercial Invoice & Packing List: Must detail product description, value, weight, and country of manufacture.

- Import Restrictions: No known bans, but verify destination-specific rubber import regulations (e.g., biosecurity in Australia).

Environmental & Disposal Compliance

- WEEE (EU): Not applicable—component is not electrical/electronic.

- End-of-Life Disposal: Dispose of as industrial rubber waste. Incineration must comply with local air emission standards.

- Recycling: Encourage recycling through rubber reprocessing programs where available.

Quality Assurance & Testing

- Tensile Strength: Minimum 8 MPa (ASTM D412)

- Elongation at Break: ≥ 250%

- Hardness: 50–70 Shore A (ASTM D2240)

- Aging Resistance: Pass 70°C for 72 hours (ASTM D573) with ≤30% tensile strength loss

- Batch Testing: Certify each production lot with a Certificate of Conformance (CoC)

Supplier & Manufacturer Responsibilities

- Maintain ISO 9001-certified quality management systems.

- Provide Safety Data Sheet (SDS) in accordance with GHS standards.

- Declare all raw material sources to ensure conflict mineral compliance (if applicable).

- Audit sub-suppliers for labor and environmental practices (SMETA or equivalent).

Customer Communication & Labeling

- Include multilingual handling and safety instructions on packaging (EN, FR, DE, ES, etc.).

- Clearly mark “Do not expose to oil or solvents” if material is oil-sensitive.

- Use GHS pictograms on SDS and packaging if classified as irritant (e.g., rubber dust).

For further compliance support, contact your regulatory affairs team or consult local authorities based on destination market requirements.

In conclusion, sourcing strap wrench rubber requires careful consideration of material quality, durability, compatibility with various surfaces, and adherence to industry standards. Selecting high-grade, heat- and oil-resistant rubber ensures long-lasting performance and reduces the risk of damage to sensitive components during use. It is essential to partner with reliable suppliers who offer consistent quality, competitive pricing, and scalability to meet production demands. Additionally, evaluating customization options—such as length, thickness, and elasticity—can enhance the functionality of the strap wrench for specific applications. Ultimately, a strategic sourcing approach focused on quality, reliability, and supplier reputation will ensure optimal performance and cost-efficiency in both manufacturing and end-user environments.