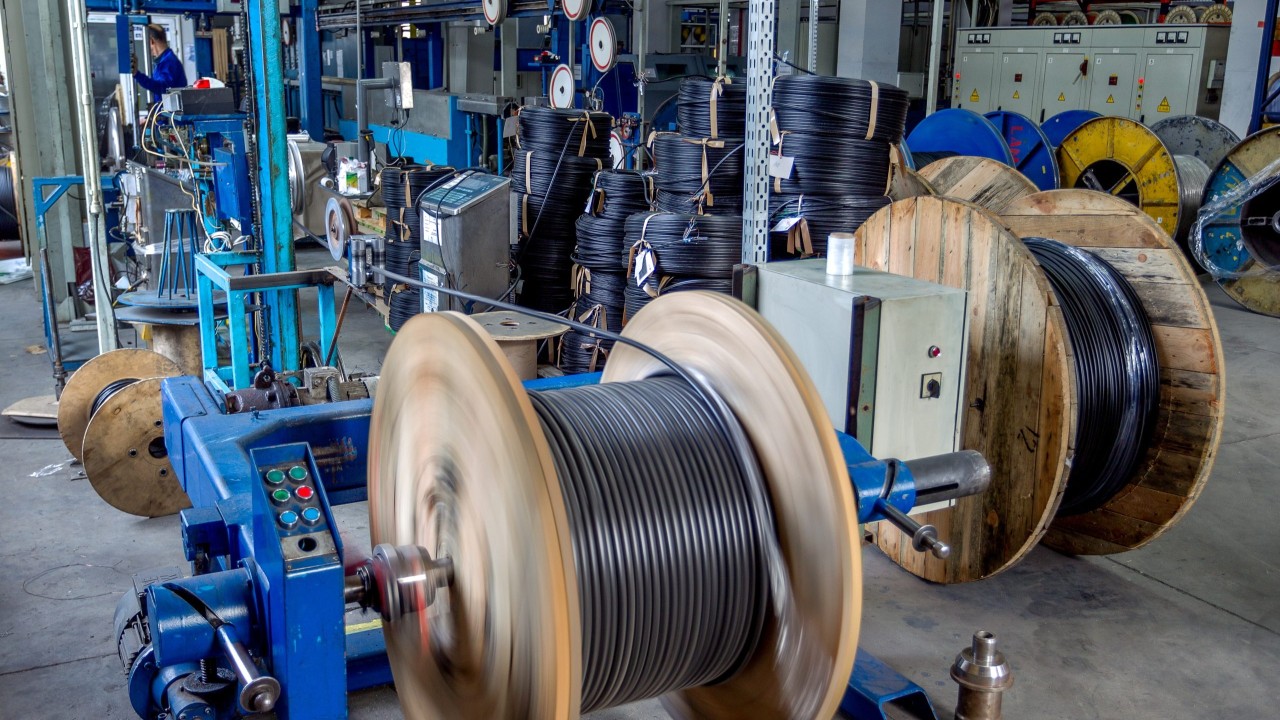

The global demand for high-performance networking infrastructure continues to surge, driven by the rapid expansion of data centers, enterprise networks, and smart building technologies. According to Grand View Research, the global Ethernet cable market was valued at USD 7.8 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 7.3% from 2023 to 2030. This growth is fueled by increased data transmission needs, rising adoption of IoT devices, and the rollout of next-generation networking standards such as Cat6A and Cat8. As a result, straight-through cables—essential for seamless connectivity between dissimilar networking devices—have become a cornerstone of modern IT infrastructure. In this competitive and expanding market, a select group of manufacturers have distinguished themselves through innovation, scalability, and consistent quality. The following list highlights the top 10 straight-through cable manufacturers shaping the future of reliable, high-speed network connectivity.

Top 10 Straight-Through Cable Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Wire and Cable Manufacturers

Domain Est. 1996

Website: encorewire.com

Key Highlights: Encore Wire is the leading manufacturer of copper and aluminum for residential, commercial and industrial wire needs. We’re unlike any other wire company….

#2 Service Wire Company

Domain Est. 1996 | Founded: 1968

Website: servicewire.com

Key Highlights: Since 1968, we’ve built a reputation for safely manufacturing high-quality wire and cable, delivering industry-leading service levels….

#3 Belden

Domain Est. 1997

Website: belden.com

Key Highlights: We design, manufacture and market networking, connectivity, cable products and solutions for industrial automation, smart buildings and broadcast markets….

#4 Cables

Domain Est. 1998

Website: cables.com

Key Highlights: Datacomm Cables (Cables.com) is one of New York’s Premiere Cable Suppliers. We are a distributor and manufacturer of fiber optic cables, networking cables, ……

#5 Lexco Cable

Domain Est. 2002

Website: lexcocable.com

Key Highlights: Lexco Cable is a wire rope and cable manufacturer that provides custom solutions for a variety of industries including aircraft and ……

#6 Wire and Cable Manufacturer

Domain Est. 2005

Website: na.prysmian.com

Key Highlights: Prysmian North America is a global leader in cable manufacturing, energy solutions, and telecommunications cables and systems. Learn more!…

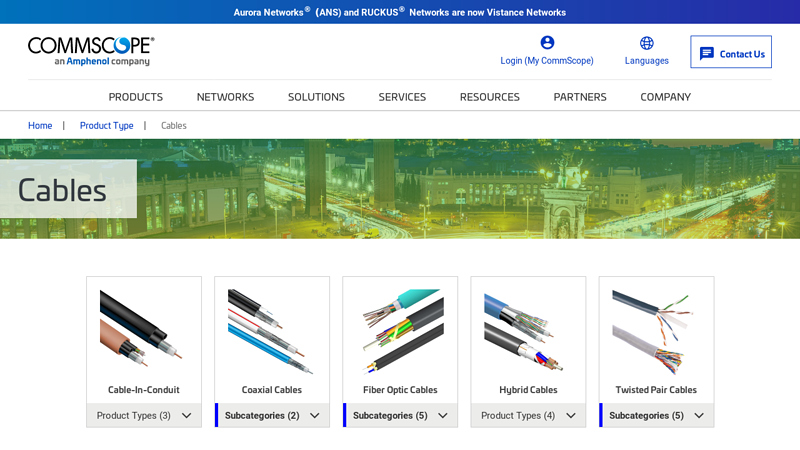

#7 Cables

Domain Est. 1994

Website: commscope.com

Key Highlights: CommScope Cables for Superior Connectivity. CommScope offers an extensive range of high-performance cables to meet your connectivity needs….

#8 AUDIO INTERCONNECTS: Audio cables, video …

Domain Est. 1997

Website: straightwire.com

Key Highlights: Straight Wire manufactures, produces and distributes audio cable and wire for home theater, HDMI, Audio, Video cable, PC, dvi, component, toslink, coaxial, ……

#9 US Wire & Cable

Domain Est. 1997 | Founded: 1985

Website: uswireandcable.com

Key Highlights: Since 1985 US Wire & Cable Corporation has produced cable and extension cords right here on American soil….

#10 Major Custom Cable

Domain Est. 1998

Website: majorcustomcable.com

Key Highlights: We specialize in designing and manufacturing performance-driven custom cable solutions for the most demanding industries. From simple assemblies to complex ……

Expert Sourcing Insights for Straight-Through Cable

H2: 2026 Market Trends for Straight-Through Cables

By 2026, the market for straight-through Ethernet cables—primarily Cat 5e, Cat 6, Cat 6a, and increasingly Cat 8—will be shaped by a convergence of technological advancement, infrastructure modernization, and evolving connectivity demands. While often viewed as a mature technology, the straight-through cable market is experiencing steady, targeted growth driven by several key trends:

1. Accelerated Adoption of Higher-Performance Categories

The shift toward bandwidth-intensive applications will continue to fuel demand for advanced cable types. By 2026, Cat 6a and Cat 8 cables are expected to capture a larger market share, particularly in enterprise environments, data centers, and smart buildings. This transition is driven by the need to support 10 Gbps and 25/40 Gbps speeds over short distances, future-proofing installations amid the rollout of Wi-Fi 6E/7 and 5G-enabled services.

2. Expansion of Smart Infrastructure and IoT Ecosystems

The proliferation of Internet of Things (IoT) devices, building automation systems, and edge computing nodes will significantly increase structured cabling requirements. Straight-through cables remain the backbone of reliable, low-latency connectivity in smart offices, industrial IoT (IIoT), and smart cities. As more devices require stable wired connections, demand for standardized patch cables will grow, especially in hybrid network architectures.

3. Growth in Data Center Modernization and Hyperscale Investments

Hyperscale data centers and cloud service providers are upgrading infrastructure to handle AI/ML workloads and real-time analytics. Although fiber dominates long-haul and backbone connections, straight-through copper cables are still essential for server-to-switch connections and top-of-rack (ToR) deployments. The push for energy efficiency and reduced latency will maintain copper’s relevance, particularly with shielded Cat 6a and Cat 8 variants offering improved performance and EMI resistance.

4. Resilience of Copper in Enterprise and SMB Networks

Despite fiber’s advantages, copper-based straight-through cables remain cost-effective and easy to install, making them the preferred choice for small and medium businesses (SMBs) and enterprise LANs. By 2026, the plug-and-play simplicity, backward compatibility, and lower equipment costs associated with copper will sustain robust demand, especially in retrofit and office deployment scenarios.

5. Emphasis on Sustainability and Compliance

Environmental regulations and corporate ESG (Environmental, Social, Governance) goals will influence cable manufacturing. Producers are increasingly offering low-smoke zero-halogen (LSZH) and RoHS-compliant cables, with recyclable materials and energy-efficient production processes. By 2026, sustainable sourcing and end-of-life recyclability will become key differentiators in the market.

6. Supply Chain Optimization and Regional Manufacturing Shifts

Post-pandemic supply chain resilience will drive localization of production. North America and Europe are expected to see increased regional manufacturing to reduce reliance on Asian imports, improving delivery times and customs agility. This shift will support faster deployment in government, healthcare, and education sectors prioritizing secure and reliable infrastructure.

Conclusion

While not subject to explosive growth, the straight-through cable market in 2026 will be characterized by steady, quality-driven expansion. The demand will be anchored in reliability, compatibility, and cost-efficiency, with innovation focused on performance enhancements and sustainability. As hybrid networks and digital transformation initiatives continue, straight-through cables will remain a foundational component of global connectivity ecosystems.

Common Pitfalls When Sourcing Straight-Through Cables (Quality and IP Considerations)

Sourcing straight-through Ethernet cables may seem straightforward, but overlooking key quality and intellectual property (IP) aspects can lead to network performance issues, security vulnerabilities, and legal risks. Below are common pitfalls to avoid:

Poor Cable Quality and Performance

Low-quality straight-through cables often use substandard materials—such as copper-clad aluminum (CCA) instead of pure copper—leading to higher resistance, signal attenuation, and reduced transmission speeds. These cables may fail to meet required category standards (e.g., Cat5e, Cat6), resulting in intermittent connectivity, slower data rates, and increased packet loss. Always verify compliance with industry standards (e.g., TIA/EIA-568) and request test reports or certification documentation from suppliers.

Lack of Shielding in Noisy Environments

In industrial or high-interference environments, unshielded cables (UTP) are prone to electromagnetic interference (EMI). Sourcing unshielded cables without assessing the deployment environment can degrade signal integrity. Ensure cables are appropriately shielded (e.g., STP or FTP) when needed, and confirm compatibility with grounding requirements to maintain performance.

Inconsistent or Non-Compliant Connector Termination

Poor crimping or miswired RJ45 connectors can cause intermittent connections or complete failure. Cables may appear functional during testing but fail under real-world load. Verify that cables follow the T568B or T568A wiring standard consistently and that terminations are professionally done. Consider pre-terminated, factory-tested cables for mission-critical applications.

Counterfeit or Non-Genuine Products

The market is flooded with counterfeit cables that mimic reputable brands but lack performance and safety certifications. These may pose fire hazards or fail prematurely. To avoid counterfeits, purchase from authorized distributors, verify batch numbers, and inspect packaging and labeling for inconsistencies.

Ignoring IP and Branding Risks

Sourcing cables with unauthorized branding or patented designs can lead to intellectual property infringement. Some manufacturers hold patents on specific connector designs, shielding technologies, or cable constructions. Using cloned or reverse-engineered products—even unintentionally—can expose organizations to legal liability. Conduct due diligence on suppliers and ensure products are legally licensed or generic alternatives without IP conflicts.

Overlooking Environmental and Safety Certifications

Cables used in plenum spaces, outdoor installations, or industrial settings require specific safety ratings (e.g., CMP, CMR, UV resistance, waterproofing). Sourcing standard cables without these ratings can violate building codes and create safety hazards. Always match cable specifications to the installation environment and confirm relevant certifications (e.g., UL, RoHS, REACH).

Failure to Verify Length and Gauge Specifications

Longer cables or those with inadequate wire gauge (e.g., 28 AWG instead of 24 AWG) suffer greater signal loss, especially at higher speeds (e.g., 10 Gbps). Suppliers may misrepresent maximum usable length. Always cross-check gauge, length, and supported bandwidth to ensure compatibility with network requirements.

By proactively addressing these pitfalls, organizations can ensure reliable, secure, and compliant network infrastructure when sourcing straight-through Ethernet cables.

Logistics & Compliance Guide for Straight-Through Cable

Overview

A straight-through cable, also known as a patch cable, is a type of Ethernet cable used to connect different types of networking devices—such as a computer to a switch or router. Ensuring proper logistics and compliance during the manufacturing, shipping, and deployment of straight-through cables is essential for performance, safety, and regulatory adherence.

Cable Specifications

- Standard: Compliant with IEEE 802.3 for Ethernet networking

- Connector Type: RJ45 male to RJ45 male

- Wiring Standard: T568B on both ends (standard for straight-through configuration)

- Cable Category: Typically Cat5e, Cat6, or Cat6a

- Length Options: Common lengths include 0.5m, 1m, 3m, 5m, and 10m

- Shielding: UTP (Unshielded Twisted Pair) or STP (Shielded Twisted Pair), depending on environment

Manufacturing & Quality Compliance

- RoHS Compliance: Must meet Restriction of Hazardous Substances (RoHS) directives (EU Directive 2011/65/EU), restricting the use of lead, mercury, cadmium, and other hazardous materials.

- REACH Compliance: Ensure no restricted substances under EU REACH regulations (Registration, Evaluation, Authorisation and Restriction of Chemicals).

- Flame Ratings: Cables must meet flammability standards such as:

- CM (Communications Multipurpose) – General use

- CMR (Riser-rated) – Vertical shafts between floors

- CMP (Plenum-rated) – Air handling spaces (HVAC)

- UL/ETL Certification: Must be certified by recognized testing laboratories (e.g., UL, ETL) for safety and performance.

Packaging & Labeling

- Labeling Requirements:

- Cable type (e.g., Cat6 UTP)

- Length

- Manufacturer name and part number

- Compliance marks (e.g., RoHS, CE, UL)

- Date of manufacture and batch/lot number

- Packaging:

- Individually wrapped or boxed to prevent tangling

- Use recyclable or eco-friendly materials where possible

- Barcodes or QR codes for traceability in inventory systems

Shipping & Logistics

- Storage Conditions:

- Store in dry, temperature-controlled environments (5°C to 35°C recommended)

- Avoid direct sunlight and exposure to moisture

- Keep away from electromagnetic interference sources

- Shipping:

- Use sturdy packaging to prevent crushing or bending

- Label packages with handling instructions (e.g., “Fragile,” “Do Not Bend”)

- Maintain chain of custody documentation for enterprise or government shipments

- Export Compliance:

- Ensure adherence to international shipping regulations (e.g., ITAR, EAR if applicable)

- Provide commercial invoice, packing list, and certificate of origin for cross-border shipments

Environmental & Disposal Compliance

- WEEE Directive (EU): Comply with Waste Electrical and Electronic Equipment regulations—provide take-back or recycling options.

- Eco-Labeling: Consider energy-efficient and sustainable production practices.

- End-of-Life Management: Encourage proper disposal and recycling through certified e-waste handlers.

Regulatory Standards by Region

- North America:

- FCC Part 15 – Electromagnetic interference (EMI) compliance

- NFPA 70 (NEC) – Fire safety and cable installation standards

- European Union:

- CE Marking – Indicates conformity with health, safety, and environmental protection standards

- CPR (Construction Products Regulation) – For cables installed in buildings (EU No 305/2011)

- Asia-Pacific:

- PSE Mark (Japan) – Required for electrical safety

- CCC Mark (China) – Compulsory certification for certain cable types

Testing & Certification Documentation

- Maintain records of:

- Electrical performance tests (insertion loss, crosstalk, etc.)

- Flammability and safety certifications

- Material compliance (RoHS, REACH test reports)

- Third-party lab certifications (e.g., UL, TÜV)

Best Practices for Deployment

- Inspection: Verify cable integrity before installation—check for kinks, damaged connectors, or insulation wear.

- Documentation: Keep logs of cable runs, lengths, and installation locations for network management.

- Training: Ensure technicians follow TIA/EIA-568 standards for proper termination and handling.

Summary

Adhering to logistics and compliance standards ensures that straight-through cables perform reliably and meet legal and environmental requirements across global markets. Manufacturers and distributors must maintain strict quality control, proper documentation, and regulatory alignment throughout the product lifecycle.

Conclusion for Sourcing Straight-Through Cable:

Sourcing straight-through Ethernet cables is a straightforward and cost-effective solution for connecting dissimilar networking devices, such as switches to computers, routers to PCs, or switches to routers. These cables, typically wired to T568A or T568B standards on both ends, ensure reliable and consistent data transmission across standard network infrastructures. When sourcing, it is important to consider cable category (e.g., Cat5e, Cat6, or Cat6a) based on speed and bandwidth requirements, as well as length, shielding, and environmental conditions (e.g., plenum-rated for indoor use). Procuring from reputable suppliers ensures compliance with industry standards and guarantees performance, durability, and compatibility with existing network equipment. Overall, straight-through cables remain a fundamental component in modern networking, and careful sourcing supports a stable, high-performing network environment.