The global lithium-ion battery storage market is experiencing rapid expansion, driven by rising demand for renewable energy integration, electric vehicles, and grid-level energy storage solutions. According to Grand View Research, the global energy storage systems market size was valued at USD 43.6 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 18.4% from 2023 to 2030. Similarly, Mordor Intelligence projects the lithium-ion battery market to register a CAGR of over 12.5% during the forecast period of 2023–2028, fueled by advancements in battery technology and supportive government policies worldwide. As demand surges, a select group of manufacturers have emerged as leaders in producing high-performance, reliable storage lithium-ion batteries. These companies are not only scaling production but also driving innovation in energy density, lifespan, and safety. Here are the top 10 storage lithium-ion battery manufacturers shaping the future of energy storage.

Top 10 Storage Lipo Battery Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 MaxAmps Lithium Batteries: LiPo Batteries

Domain Est. 2004

Website: maxamps.com

Key Highlights: Every MaxAmps lithium cell is grade A rated from the factory. This ensures performance and reliability for our LiPos, Li-ion, and LiFePO4 batteries….

#2 Rechargeable Lithium Polymer Battery Manufacturing

Domain Est. 2010

Website: m.lipolbattery.com

Key Highlights: LiPol Battery is known as the battery industrial over for quality, safety, price, and lead time. Our 18650 lithium battery shows real rated capacity….

#3 Lithium polymer battery manufacturer and Li

Domain Est. 2014

Website: pdbattery.com

Key Highlights: Padre Electronics is asian important lithium polymer battery manufacturer, we produce rechargeable Lithium-ion and polymer batteries,cells and packs for ……

#4 American Battery Factory

Domain Est. 2021

Website: americanbatteryfactory.com

Key Highlights: American Battery Factory (ABF) focuses exclusively on manufacturing and enhancing high-performance prismatic Lithium Iron Phosphate (LFP) batteries….

#5 Everything about Storing Lithium Polymer (LiPo) Batteries

Domain Est. 1999

Website: grepow.com

Key Highlights: Today’s topic will be focusing on maintaining your lithium battery; specifically, storing your lithium polymer batteries….

#6 Rcbattery.com : Lipo Battery

Domain Est. 2000

Website: rcbattery.com

Key Highlights: Free delivery over $99 · 90-day returnsAt RCBattery.com we believe that everyone deserves to have the best lipo battery for the most affordable price, we are providing the best qu…

#7 CNHL LiPo Batteries for RC Cars, FPV Drones & Planes …

Domain Est. 2010

#8 LiPo Battery

Domain Est. 2017

Website: sunpadow.com

Key Highlights: In addition to traditional batteries, the Company focuses on developing laminated high-rate model series lithium batteries and UAV series lithium batteries. Now ……

#9 Zeee RC Lipo Battery Official Store

Domain Est. 2020

Website: zeeebattery.com

Key Highlights: zeeebattery.com provides one-stop service to find high-performance lipo batteries for RC cars, boats, FPV, and airplane. Has US/CA/UK/AU/EU local warehouse….

#10

Domain Est. 2020

Website: lithionbattery.com

Key Highlights: Reliable replacements for lead-acid with longer life, faster charging, and built-in safety. Our lineup of scalable modular battery solutions power projects ……

Expert Sourcing Insights for Storage Lipo Battery

H2: 2026 Market Trends for Storage Lithium-Ion (Lipo) Batteries

As the global energy landscape evolves toward decarbonization and electrification, the market for storage lithium-ion (LiPo) batteries is poised for significant transformation by 2026. These advanced energy storage systems—known for their high energy density, lightweight construction, and rechargeability—are increasingly critical across consumer electronics, electric vehicles (EVs), and renewable energy integration. The following analysis outlines key trends expected to shape the LiPo battery storage market in 2026.

-

Accelerated Demand from Renewable Energy Integration

By 2026, the deployment of solar and wind energy is projected to grow exponentially, particularly in North America, Europe, and Asia-Pacific. This expansion will heighten the need for efficient energy storage to manage intermittency and stabilize grids. LiPo batteries, with their rapid response times and scalability, are becoming the preferred solution for residential, commercial, and utility-scale energy storage systems (ESS). Government incentives and renewable energy targets will further drive adoption. -

Electric Vehicle (EV) Market Expansion

The EV sector will remain the primary demand driver for LiPo battery technology. As major automakers commit to electrification and governments enforce stricter emissions regulations, the global EV fleet is expected to surpass 100 million units by 2026. This will increase demand for high-capacity, long-cycle-life LiPo batteries. Battery pack costs are anticipated to fall below $80/kWh by 2026 (from ~$130/kWh in 2023), enabling broader affordability and accelerating EV adoption. -

Advancements in Battery Chemistry and Solid-State Hybrids

While traditional LiPo batteries dominate the market, research into next-generation technologies—such as lithium-sulfur, lithium-air, and solid-state batteries—will influence LiPo development. By 2026, hybrid systems incorporating solid-state electrolytes with LiPo designs are expected to enter commercialization, offering improved safety, energy density, and thermal stability. These innovations will expand use cases in aerospace, medical devices, and high-performance EVs. -

Supply Chain Resilience and Raw Material Sourcing

Geopolitical tensions and supply constraints for critical materials—especially lithium, cobalt, and nickel—are prompting manufacturers to diversify sourcing and invest in recycling. By 2026, circular economy models will gain traction, with battery recycling rates expected to exceed 50% in developed markets. Additionally, regulatory frameworks such as the EU Battery Regulation will mandate recycled content and carbon footprint declarations, pushing companies toward sustainable sourcing and localized production. -

Rise of Second-Life and Repurposed Battery Applications

As first-life EV batteries reach end-of-service (typically after 8–10 years), the volume of used LiPo batteries will surge. By 2026, second-life applications—such as stationary storage for microgrids and backup power—will become a structured segment of the market. Standardized testing, grading, and modular repurposing platforms will enhance economic viability and reduce waste. -

Regional Market Dynamics

Asia-Pacific, led by China, South Korea, and Japan, will continue to dominate LiPo battery production and innovation. However, North America and Europe are rapidly scaling domestic manufacturing due to policy support (e.g., U.S. Inflation Reduction Act, EU Green Deal). By 2026, localized gigafactories will reduce import reliance and shorten supply chains, fostering regional self-sufficiency. -

Digitalization and Smart Battery Management

Integration of AI and IoT into battery management systems (BMS) will become standard by 2026. Smart LiPo systems will enable real-time health monitoring, predictive maintenance, and optimized charge-discharge cycles, improving longevity and safety. Cloud-based energy platforms will allow aggregated control of distributed storage assets, enhancing grid flexibility.

In summary, the 2026 market for storage LiPo batteries will be shaped by sustained demand from clean energy and transportation sectors, technological innovation, sustainability imperatives, and evolving regulatory landscapes. Companies that invest in R&D, circular supply chains, and intelligent battery ecosystems will be best positioned to lead in this dynamic and high-growth market.

Common Pitfalls When Sourcing Storage Lipo Batteries (Quality & IP)

Sourcing lithium polymer (LiPo) batteries for storage applications involves navigating several critical challenges related to quality and intellectual property (IP). Overlooking these pitfalls can lead to performance failures, safety hazards, legal issues, and reputational damage. Below are the most common risks to avoid:

Quality-Related Pitfalls

Using Substandard Cell Materials

Many low-cost suppliers cut corners by using inferior-grade electrode materials, separators, or electrolytes. These compromises reduce cycle life, increase internal resistance, and raise the risk of thermal runaway. Always verify material specifications and request third-party test reports (e.g., cycle life, capacity retention).

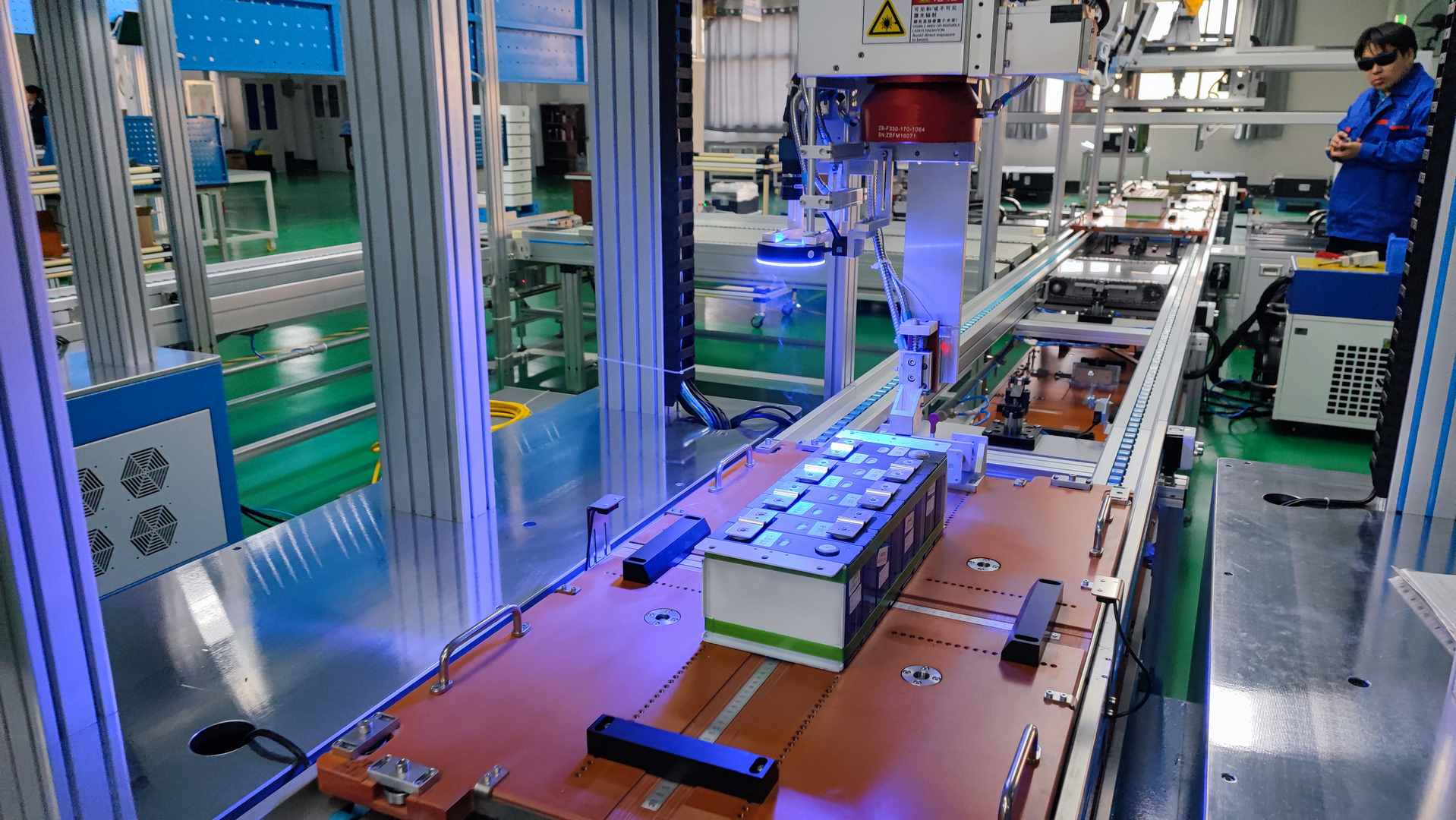

Inconsistent Manufacturing Processes

Poor quality control during cell production—such as uneven electrode coating, inadequate sealing, or improper formation—leads to cell-to-cell variability. This inconsistency is especially problematic in battery packs, where mismatched cells degrade faster and pose safety risks. Audit supplier facilities or work with manufacturers certified under ISO 9001 and IATF 16949.

Overstated Capacity and Performance Claims

Suppliers may advertise inflated capacity (e.g., labeling a 3,000mAh cell as 5,000mAh) or exaggerated cycle life. Verify performance claims through independent lab testing under standard conditions (e.g., 0.2C discharge, 25°C). Request full discharge curves and datasheets with test protocols.

Lack of Safety Certifications

Reputable LiPo batteries should comply with international safety standards such as UL 1642, IEC 62133, UN 38.3, and CE. Sourcing cells without valid certifications increases the risk of fire, explosion, or regulatory rejection. Demand up-to-date compliance documentation.

Poor Battery Management System (BMS) Integration

For storage systems, the BMS is as critical as the cells themselves. Low-quality or incompatible BMS units fail to provide overcharge, over-discharge, short-circuit, and temperature protection. Ensure the BMS is specifically designed for your cell chemistry and application.

Intellectual Property (IP)-Related Pitfalls

Procuring Counterfeit or Clone Batteries

Some suppliers offer “branded” LiPo cells (e.g., mimicking LG, Samsung, or Panasonic) that are unauthorized replicas. These clones often infringe on patents and trademarks and lack reliability. Source only from authorized distributors or directly from original manufacturers.

Unlicensed Use of Proprietary Cell Designs

Certain LiPo cell formats, chemistries, or manufacturing techniques are protected by patents. Using batteries that incorporate such IP without licensing can expose your company to litigation. Conduct IP due diligence and require suppliers to warrant freedom to operate.

Lack of Traceability and Documentation

Without proper batch tracking, material disclosures, and chain-of-custody records, proving IP compliance during audits or legal disputes becomes impossible. Insist on detailed documentation, including cell origin, bill of materials (BOM), and compliance statements.

Ambiguous Supply Agreements

Contracts that fail to address IP ownership, liability for infringement, or warranty terms leave buyers vulnerable. Ensure sourcing agreements clearly define IP responsibilities, indemnification clauses, and quality assurance protocols.

Conclusion

To mitigate these pitfalls, conduct thorough supplier vetting, perform independent quality testing, and engage legal counsel for IP review. Prioritize transparency, certifications, and traceability over initial cost savings to ensure long-term reliability and compliance in your storage LiPo battery supply chain.

Logistics & Compliance Guide for Storing Lithium-Ion (LiPo) Batteries

Regulatory Framework and Classification

Lithium-ion polymer (LiPo) batteries are classified as dangerous goods under international and national transportation and storage regulations due to their potential fire hazard. Key regulatory bodies include:

– UN Recommendations on the Transport of Dangerous Goods (UN 38.3): Mandates testing standards for lithium batteries.

– IATA Dangerous Goods Regulations (DGR): Governs air transport; LiPo batteries are generally classified under UN 3480 (lithium-ion batteries alone) or UN 3091 (when packed with equipment).

– IMDG Code: Regulates maritime transport.

– 49 CFR (U.S. Department of Transportation): Applies to domestic U.S. transport.

– ADR/RID: European agreements for road and rail transport.

Compliance with these regulations is mandatory for legal storage and transportation.

Storage Facility Requirements

Storage areas for LiPo batteries must be designed to minimize fire risks and ensure safety:

– Fire-Resistant Construction: Use non-combustible materials and fire-rated cabinets or rooms.

– Ventilation: Maintain adequate airflow to prevent gas accumulation (e.g., from thermal runaway).

– Temperature Control: Store in a cool, dry environment (ideally 15–25°C / 59–77°F); avoid exposure to direct sunlight or heat sources.

– Humidity Control: Maintain relative humidity below 65% to prevent condensation and corrosion.

– Separation from Flammables: Keep batteries at least 10 feet (3 meters) away from flammable materials and ignition sources.

Charge State and Packaging

- State of Charge (SoC): Store LiPo batteries at approximately 30–50% charge. Fully charged batteries pose a higher thermal runaway risk.

- Original Packaging: Store in original or UN-certified packaging to prevent short circuits.

- Terminal Protection: Ensure terminals are insulated (e.g., using caps, tape, or individual pouches) to prevent contact with conductive materials.

- Palletizing: Use non-conductive pallets and segregate stacks appropriately to avoid physical damage.

Handling and Personnel Safety

- Trained Personnel: Only trained staff should handle or store LiPo batteries. Training must include emergency response and hazard awareness.

- Personal Protective Equipment (PPE): Gloves, safety goggles, and flame-resistant clothing should be worn during handling.

- No Metal Tools: Avoid using conductive tools near exposed terminals.

- Inspection Routine: Regularly inspect batteries for swelling, leakage, or damage. Remove compromised units immediately.

Fire Prevention and Emergency Response

- Fire Suppression Systems: Install Class D fire extinguishers (metal fires) or specialized lithium battery fire suppression systems. Water mist systems may be effective but require specialized planning.

- Smoke and Heat Detectors: Deploy early warning systems compatible with battery fire signatures.

- Spill Containment: Prepare secondary containment trays or berms for leaks.

- Emergency Plan: Establish and practice procedures for thermal runaway incidents, including evacuation and isolation protocols.

Documentation and Compliance Records

- Safety Data Sheets (SDS): Maintain accessible SDS for all battery types.

- Inventory Logs: Record battery type, quantity, storage date, and charge level.

- Inspection Reports: Document routine checks and maintenance.

- Training Records: Keep up-to-date records of staff safety training.

- Regulatory Permits: Obtain required local fire department or environmental permits for hazardous material storage.

Transportation Preparation

Prior to shipping:

– State of Charge: Confirm batteries are stored and shipped at ≤30% SoC for air transport (per IATA).

– Packaging Marking: Clearly label packages with “LITHIUM ION BATTERIES—FORBIDDEN FOR TRANSPORT ABOARD AIRCRAFT IF DAMAGED OR RECALL” (when applicable) and proper UN markings.

– Shipper’s Declaration: Complete dangerous goods declaration forms when required.

– Carrier Notification: Inform carriers in advance about lithium battery shipments.

Environmental and Disposal Considerations

- Recycling Program: Partner with certified recyclers (e.g., UL 1185 or R2 certified) for end-of-life batteries.

- Hazardous Waste Handling: Follow EPA (U.S.) or equivalent environmental regulations for disposal.

- Spill Response Kit: Keep kits with non-conductive absorbents and neutralizing agents on-site.

Regular Audits and Continuous Improvement

- Conduct periodic audits of storage practices against IATA, OSHA, or local fire codes.

- Review incident reports and update procedures accordingly.

- Stay updated on regulatory changes through industry associations (e.g., NAATBatt, NFPA).

Adhering to this guide ensures safe, compliant storage of lithium-ion polymer batteries and mitigates risks to personnel, property, and the environment.

Conclusion for Sourcing Lithium Polymer (LiPo) Batteries for Storage Applications

Sourcing lithium polymer (LiPo) batteries for storage applications requires a careful evaluation of multiple factors including performance, safety, cost, supplier reliability, and long-term sustainability. LiPo batteries offer significant advantages such as high energy density, lightweight construction, and flexible form factors, making them suitable for various energy storage needs, especially in portable and space-constrained systems.

However, their sensitivity to overcharging, temperature extremes, and physical damage necessitates rigorous quality control and adherence to safety standards when selecting suppliers. It is essential to partner with reputable manufacturers that comply with international certifications (e.g., UN38.3, CE, RoHS) and offer strong technical support and warranty terms.

Additionally, considering total cost of ownership—factoring in lifespan, cycle performance, and maintenance—rather than just upfront price will lead to more sustainable and economical decisions. Exploring local versus overseas suppliers, evaluating logistics and import regulations, and assessing scalability of supply are also critical for long-term reliability.

In conclusion, successful sourcing of LiPo batteries for storage demands a balanced approach that prioritizes safety, quality, and supplier credibility while aligning with the specific technical and operational requirements of the application. A strategic, well-vetted supply chain will ensure optimal performance, regulatory compliance, and return on investment over the battery’s lifecycle.