The global stone manufacturing industry has experienced steady growth, driven by rising demand in construction, infrastructure, and architectural design. According to a report by Grand View Research, the global natural stone market was valued at USD 29.5 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is fueled by increasing urbanization, luxury building projects, and a growing preference for durable, aesthetically pleasing materials. Similarly, Mordor Intelligence forecasts sustained momentum in the market, with Asia-Pacific emerging as a key region due to rapid industrialization and expanding residential and commercial construction. As demand rises, competition among manufacturers intensifies, pushing innovation in quarrying techniques, sustainability practices, and product variety. In this dynamic landscape, the following ten stone manufacturers stand out for their production scale, global reach, product quality, and technological advancement.

Top 10 Stone Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stone Factory

Domain Est. 2003

Website: wafigroup.com

Key Highlights: Stone Factory is a UAE based company with expertise in the marble and granite fields, and the installation of natural stones for exterior and interior use….

#2 Stone Veneer Manufacturer

Domain Est. 2004

Website: estoneworks.com

Key Highlights: StoneWorks manufactures & installs beautiful stone veneer for builders & contractors. From project start to finish, we are your one source turnkey solution….

#3 Stone Source

Domain Est. 1995

Website: stonesource.com

Key Highlights: Stone Source offers a vast selection of porcelain and natural stone slab products for various design applications. Explore our wide range of options, ……

#4 Bybee Stone Company

Domain Est. 1996

Website: bybeestone.com

Key Highlights: Bybee Stone Company is an Indiana limestone fabricator specializing in custom fabrication of Indiana limestone for both new construction and restoration ……

#5 Natural Stones: Granites, Marble, Limestones, Soapstone

Domain Est. 1997

Website: polycor.com

Key Highlights: Polycor is the World’s Leading Natural Stone Quarrier. Our mission is to strive together as one team to deliver excellence as a natural stone company….

#6 StoneContact.com: Stone, Marble, Granite

Domain Est. 2003

Website: stonecontact.com

Key Highlights: Stone portal website(StoneContact.com) is the world leading B2B stone website.We offer abundant stone products, prices, pictures, suppliers, such as marble, ……

#7 The Stone Collection

Domain Est. 2007

Website: thestonecollection.com

Key Highlights: We work with the top stone quarries and hard surface brands worldwide to curate a growing inventory of 50000 selections. Visit a showroom today….

#8 Prestige Stone

Domain Est. 2007

Website: prestigestoneproducts.com

Key Highlights: Prestige Stone offers lightweight, affordable stone veneers that replicate the look of real stone with exceptional quality and care….

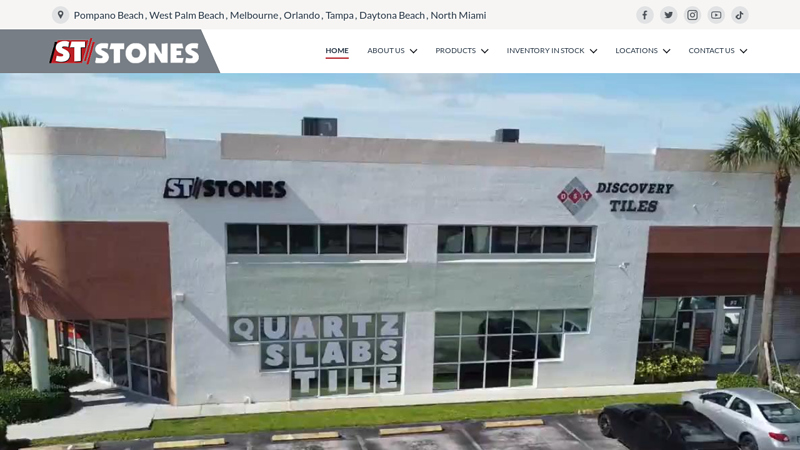

#9 ST Stones

Domain Est. 2009

Website: ststones.com

Key Highlights: ST Stones is the leading importer and wholesaler of high quality slabs, countertops, backsplash. Granite, Marble, Sinks, Granite….

#10 Fond du Lac Natural Stone

Domain Est. 2020

Website: fdlnaturalstone.com

Key Highlights: Fond du Lac Natural Stone offers over 90 natural stone products harvested from the United States and abroad, offering a wide variety of colors, textures and ……

Expert Sourcing Insights for Stone

H2 2026 Market Trends for the Stone Industry

As the global construction, architecture, and design sectors continue to evolve, the stone industry—encompassing natural stone (e.g., granite, marble, limestone) and engineered stone (e.g., quartz composites)—is expected to experience significant transformation in the second half of 2026. Driven by sustainability demands, technological advancements, and shifting consumer preferences, the H2 2026 market trends for stone reveal a dynamic landscape shaped by innovation and environmental responsibility.

1. Increased Demand for Sustainable and Low-Carbon Stone Solutions

Environmental concerns are reshaping material choices in construction and interior design. In H2 2026, there is a marked shift toward sustainably sourced natural stone and low-carbon engineered alternatives. Regulatory pressures, such as the EU’s Green Construction agenda and LEED v5 certification updates, are pushing developers to adopt eco-friendly materials. Stone producers are responding by investing in carbon footprint tracking, quarry rehabilitation programs, and energy-efficient processing technologies. Recycled stone aggregates and reclaimed stone are gaining traction, particularly in urban redevelopment projects.

2. Growth of Engineered Quartz with Enhanced Sustainability Features

Engineered quartz continues to dominate in residential and commercial countertop markets, but H2 2026 sees a new wave of innovation. Leading manufacturers are launching quartz products with higher recycled content (up to 40%), bio-based resins, and improved end-of-life recyclability. Brands are emphasizing transparency through Environmental Product Declarations (EPDs), appealing to environmentally conscious consumers and B2B clients. The Asia-Pacific region, especially India and Vietnam, emerges as a key growth market due to rising middle-class demand for durable, low-maintenance surfaces.

3. Digitalization and AI-Driven Customization

The integration of AI and digital fabrication tools is revolutionizing stone customization. In H2 2026, manufacturers are using AI-powered design platforms to offer real-time visualization and bespoke stone pattern generation for countertops, flooring, and facades. CNC robotics and 3D stone printing enable complex, waste-minimized installations, reducing material loss by up to 30%. Architectural firms increasingly adopt digital twins and BIM (Building Information Modeling) compatibility with stone components, streamlining procurement and installation.

4. Rise of Natural Stone in High-End and Biophilic Design

Natural stone is experiencing a renaissance in luxury and wellness-focused developments. Driven by the biophilic design trend, architects are specifying marble, travertine, and slate for their organic textures and timeless appeal. In H2 2026, demand surges in high-end residential, hospitality, and spa projects, particularly in North America and Western Europe. Innovations in sealing and maintenance technologies are reducing perceived drawbacks like porosity and staining, making natural stone more viable for kitchens and wet areas.

5. Supply Chain Resilience and Regionalization

Geopolitical uncertainties and logistics volatility have prompted a strategic shift toward regional sourcing. In H2 2026, North American and European markets are increasingly turning to local quarries and nearshored production to reduce lead times and import dependencies. Countries like Turkey, Brazil, and Italy maintain their positions as premium exporters, but face competition from emerging producers in Eastern Europe and North Africa investing in modern quarrying and processing infrastructure.

6. Circular Economy and Stone Waste Repurposing

Waste reduction is a critical focus. The stone industry is embracing circular economy principles, with H2 2026 seeing expanded use of stone offcuts and slurry in secondary applications. Crushed stone is being used in concrete mixes, road bases, and landscaping, while fine stone powder is repurposed into tiles and terrazzo. Governments in the EU and South Korea are introducing incentives for waste valorization, further driving industry adoption.

Conclusion

H2 2026 marks a pivotal phase for the stone industry, where sustainability, technology, and design converge. Companies that prioritize eco-innovation, digital integration, and supply chain agility are best positioned to thrive. As consumer and regulatory demands intensify, the stone market is evolving from a traditional material sector into a forward-looking, value-driven industry focused on resilience and environmental stewardship.

Common Pitfalls in Sourcing Stone (Quality, IP)

Sourcing natural or engineered stone for construction, design, or manufacturing projects involves significant challenges, particularly regarding quality consistency and intellectual property (IP) concerns. Falling into common pitfalls can lead to project delays, cost overruns, legal issues, and reputational damage. Below are key areas where problems frequently arise:

Inconsistent Quality and Material Defects

One of the most frequent issues in stone sourcing is variability in quality. Natural stone, by its geological nature, can exhibit differences in color, veining, density, and durability—even within the same quarry batch. Buyers may receive slabs that don’t match samples, contain hidden fissures, or show signs of degradation over time. Poor quality control during extraction, processing, or handling can result in chipped, scratched, or improperly calibrated slabs. This inconsistency can compromise design integrity and lead to disputes with suppliers.

Lack of Standardized Testing and Certification

Many stone suppliers—especially in emerging markets—do not adhere to international quality standards (e.g., ASTM, ISO). Without third-party testing for strength, water absorption, or chemical resistance, buyers risk using unsuitable materials in critical applications. Assuming all stones meet minimum performance thresholds without verification can result in structural failures or premature wear, particularly in high-traffic or outdoor installations.

Misrepresentation of Origin and Authenticity

Stone provenance is a major concern. Some suppliers mislabel stone origin to command higher prices—passing off lower-grade material as premium varieties like “Italian Carrara” or “Brazilian granite.” This not only affects performance but misleads clients about value and sustainability. Verifying the true origin often requires documentation, site audits, or geological testing, which are frequently overlooked in procurement.

Intellectual Property Infringement in Engineered Stone

With the rise of engineered quartz and composite stones, IP issues have become more prominent. Some manufacturers replicate patented designs, patterns, or surface finishes from leading brands without authorization. Sourcing such materials—even unknowingly—can expose architects, contractors, or developers to legal liability. Additionally, using counterfeit or knock-off products may void warranties and lead to performance issues.

Inadequate Supply Chain Transparency

Complex, multi-tiered supply chains make it difficult to trace stone from quarry to project site. This lack of transparency increases the risk of unethical practices (e.g., illegal quarrying, labor violations) and makes quality and IP verification nearly impossible. Buyers may unknowingly support environmentally harmful operations or import materials subject to trade restrictions.

Poor Communication and Documentation

Ambiguous contracts, missing material data sheets, or vague specifications can result in disputes over expectations. Without clear documentation of finish types, thickness tolerances, or IP rights for custom designs, both parties may have conflicting interpretations, leading to rework or litigation.

Failure to Secure Rights for Custom Designs

When commissioning custom-cut stone or unique patterns, clients often assume they own the design rights. However, unless explicitly stated in contracts, the fabricator or designer may retain IP rights, restricting future use or replication. This becomes problematic in branding, retail, or franchise projects requiring consistency across locations.

To avoid these pitfalls, buyers should conduct due diligence on suppliers, require independent quality testing, verify origin and certifications, include IP clauses in contracts, and maintain transparent supply chain oversight. Engaging specialized consultants or using blockchain-enabled traceability tools can further mitigate risks in stone sourcing.

Logistics & Compliance Guide for Stone

This guide outlines key considerations for the logistics and compliance associated with the transportation, handling, and regulatory requirements of stone materials, including natural stone (e.g., granite, marble, limestone) and engineered stone (e.g., quartz composites). Proper management ensures safety, cost-efficiency, and adherence to international and local regulations.

Transportation & Handling

Stone is a dense, heavy, and fragile material requiring specialized logistics to prevent damage and ensure worker safety.

-

Packaging & Crating:

Stone slabs and tiles must be securely packed in wooden crates or on pallets with edge protectors. Vertical storage during transit is essential for slabs to prevent cracking. Use moisture-resistant wrapping to protect against humidity and staining. -

Loading & Securing:

Use forklifts or suction lifters designed for stone handling. Loads must be evenly distributed and firmly braced in containers or trucks to minimize shifting. Strapping and dunnage should be used to prevent movement during transit. -

Mode of Transport:

- Maritime: Most cost-effective for bulk shipments. Use dry, ventilated containers and avoid condensation through proper sealing and desiccants.

- Road: Ideal for regional distribution. Ensure vehicles are equipped with stone-specific racks and suspension systems.

- Air: Rare due to high cost and weight; typically reserved for urgent, small samples.

Import/Export Regulations

Stone shipments crossing international borders must comply with customs, safety, and environmental regulations.

-

Customs Documentation:

Required documents include commercial invoices, packing lists, bills of lading/air waybills, and certificates of origin. Accurate Harmonized System (HS) codes (e.g., 2515–2517 for natural stone) must be used for classification. -

Quarantine & Phytosanitary Measures:

Some countries inspect wooden packaging materials (crates, pallets) under the International Standards for Phytosanitary Measures No. 15 (ISPM 15). Ensure packaging is heat-treated and stamped accordingly. -

Country-Specific Restrictions:

Certain nations impose import duties, anti-dumping measures, or bans on specific stone types (e.g., restrictions on sandstone from particular regions). Verify destination country requirements before shipment.

Safety & Workplace Compliance

Handling stone poses risks such as musculoskeletal injuries, silica exposure, and falling loads.

-

Silica Dust Control (OSHA/NIOSH Guidelines):

Cutting, grinding, or polishing stone generates respirable crystalline silica. Use wet methods, local exhaust ventilation, and approved respirators. Conduct regular air monitoring and employee training per OSHA 29 CFR 1910.1053. -

Personal Protective Equipment (PPE):

Mandate hard hats, safety goggles, steel-toed boots, gloves, and hearing protection in handling and processing areas. -

Manual Handling Protocols:

Train staff in proper lifting techniques. Use mechanical aids (vacuum lifters, forklifts) whenever possible to reduce injury risk.

Environmental & Sustainability Compliance

The stone industry is increasingly subject to environmental scrutiny.

-

Emissions & Waste Management:

Slurry from cutting operations must be collected and treated to prevent water contamination. Recycle water in closed-loop systems where possible. -

Certifications & Standards:

Consider adherence to environmental standards such as ISO 14001 (Environmental Management) or LEED credits for sustainable sourcing. Some markets favor stones from quarries with responsible extraction practices. -

Carbon Footprint & Transport Optimization:

Minimize emissions by consolidating shipments, choosing low-emission carriers, and sourcing regionally when feasible.

Labeling & Product Compliance

Ensure stone products meet labeling and performance standards in the target market.

-

CE Marking (EU):

Stone intended for construction in the European Union may require CE marking under Construction Products Regulation (CPR) EN 1469 or EN 12326, certifying durability, slip resistance, and mechanical properties. -

Country-Specific Standards:

- USA: ASTM standards (e.g., ASTM C503 for marble) may apply.

- Australia: Comply with AS 4586 for slip resistance.

-

UAE: Dubai Municipality requires approval for stone used in public projects.

-

Material Safety Data Sheets (MSDS/SDS):

Provide SDS for engineered stone products, especially those containing resins, to disclose chemical components and handling precautions.

Risk Mitigation & Insurance

-

Cargo Insurance:

Obtain all-risk marine or transit insurance covering damage, breakage, and total loss. Specify stone value and transportation method in policy terms. -

Quality Inspection Prior to Shipment:

Conduct pre-shipment inspections to verify dimensions, color consistency, and absence of cracks or defects. Document condition with photos. -

Traceability & Documentation Retention:

Maintain records of quarry source, processing history, test reports, and compliance certificates for at least five years to support audits or claims.

By following this logistics and compliance guide, businesses can ensure the safe, legal, and efficient movement of stone products across global supply chains while minimizing risk and enhancing customer trust.

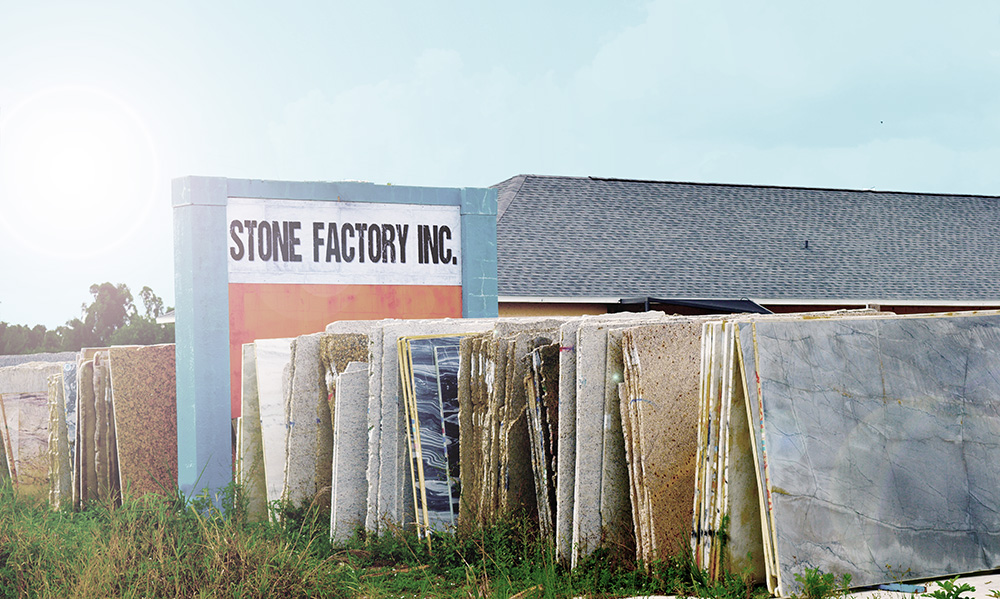

Conclusion for Sourcing a Stone Factory

Sourcing a reliable stone factory is a critical step in ensuring the quality, consistency, and long-term success of any project involving natural or engineered stone—be it for construction, interior design, or architectural applications. A thorough evaluation process that considers factors such as production capacity, material quality, certifications, sustainability practices, pricing, and logistical capabilities is essential.

After careful assessment, partnering with a factory that demonstrates technical expertise, adherence to industry standards, and a commitment to ethical and environmental responsibility provides significant competitive advantages. Clear communication, transparent supply chain practices, and the ability to scale production as needed further enhance the partnership’s value.

Ultimately, selecting the right stone factory is not just about cost efficiency—it’s an investment in durability, craftsmanship, and customer satisfaction. By prioritizing reliability and quality over short-term savings, businesses can build strong supplier relationships that support growth, innovation, and excellence in every project.