The global outdoor power equipment market is experiencing steady growth, driven by increasing demand for efficient landscaping and lawn care solutions. According to Grand View Research, the global lawn and garden equipment market size was valued at USD 35.7 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by rising urban green spaces, residential landscaping trends, and advancements in equipment technology—factors that have also amplified demand for reliable replacement parts compatible with popular models like the STIHL FS 45. As one of the most widely used trimmer platforms, the FS 45 has created a robust aftermarket ecosystem. In response, a select group of manufacturers have distinguished themselves through precision engineering, material quality, and adherence to OEM specifications. Below is an in-depth look at the top six STIHL FS 45 parts manufacturers shaping this expanding market segment.

Top 6 Stihl Fs45 Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Buy accessories and spare parts online

Domain Est. 1997

Website: stihl.co.za

Key Highlights: Looking for STIHL product accessories? Our online shop has a wide range of compatible accessories ➤ Find out more now!…

#2 STIHL Trimmer Service Kit for FS45, FS46, FS55, KM55

Domain Est. 1997

Website: farmandfleet.com

Key Highlights: Rating 5.0 (3) · $5.99 deliveryDesigned for optimal maintenance, this STIHL Trimmer Service Kit provides essential replacement components for FS45, FS46, FS55, and KM55 trimmer…

#3 FS45 Brushcutter Parts

Domain Est. 2008

Website: gardenhirespares.co.uk

Key Highlights: GHS supplies genuine spare parts for all major garden and forestry brands including Stihl, Honda, Hayter, Husqvarna, Belle and Allet….

#4 Non

Domain Est. 2011

Website: hlsproparts.com

Key Highlights: Quality aftermarket piston and rings assembly. 34mm. Fits: Stihl BG45, BG46, FS38, FS45, FS55, HS45, HS81 blowers, trimmers and brushcutters….

#5 Stihl (FS45

Domain Est. 2012

Website: diyspareparts.com

Key Highlights: Select a page from the Stihl FS 45 Brushcutter diagram to view the parts list and exploded view diagram. View all parts for the Stihl FS 45 Brushcutter….

#6 Trimmer Heads & Blades Replacement

Domain Est. 1996

Website: stihlusa.com

Key Highlights: Learn how to properly and safely replace replace your trimmer heads and blades with STIHL’s helpful guide that includes, tips, safety precautions, ……

Expert Sourcing Insights for Stihl Fs45 Parts

H2: 2026 Market Trends for Stihl FS45 Parts

The market for Stihl FS45 replacement parts is expected to evolve significantly by 2026, driven by shifts in consumer behavior, technological advancements, and growing emphasis on equipment sustainability. As the Stihl FS45 — a lightweight, entry-level string trimmer — remains popular among homeowners and small landscaping businesses, the demand for its parts will be shaped by several key trends.

-

Increased Demand for Aftermarket and Compatible Parts

By 2026, the aftermarket for Stihl FS45 components is projected to grow as cost-conscious consumers seek affordable, high-quality alternatives to OEM (Original Equipment Manufacturer) parts. Third-party manufacturers are investing in precision engineering to produce compatible trimmer heads, bump knobs, drive shafts, and fuel lines that meet or exceed OEM standards. This trend is supported by the rising popularity of e-commerce platforms like Amazon, eBay, and specialized outdoor power equipment sites, which enhance accessibility and price transparency. -

Sustainability and Equipment Longevity

Environmental awareness and circular economy principles will drive demand for repair and reuse over replacement. Consumers and small businesses are increasingly opting to repair their existing Stihl FS45 units rather than purchasing new models. This shift supports a robust market for parts such as air filters, spark plugs, carburetor kits, and starter assemblies. Original Stihl parts will continue to be preferred for reliability, but eco-conscious buyers may also favor recyclable packaging and suppliers with sustainable practices. -

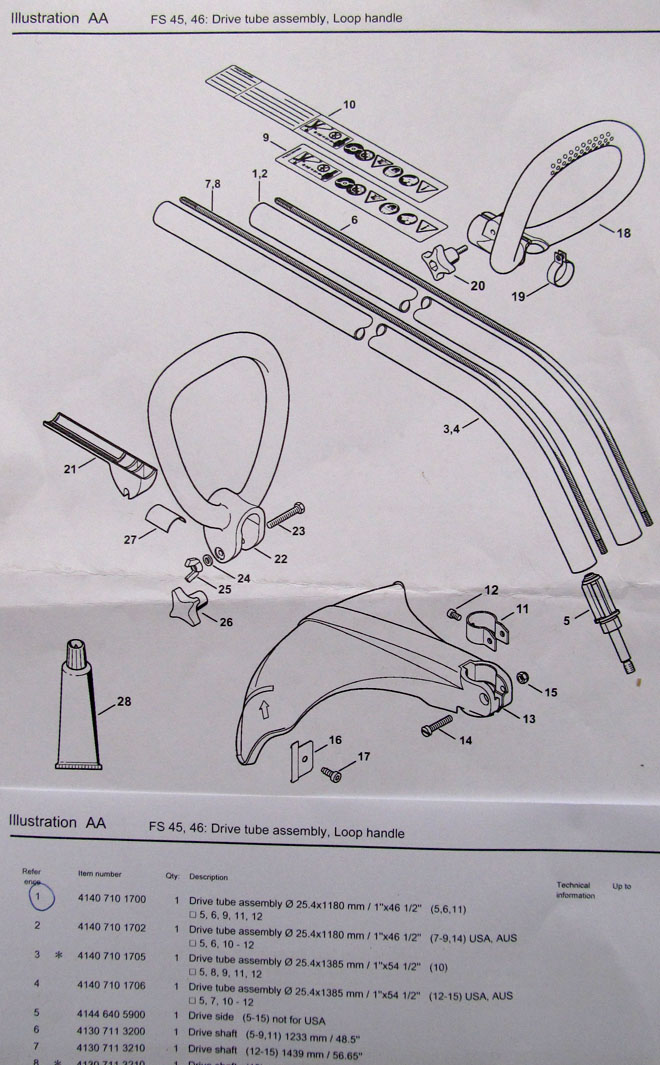

Digital Integration and Enhanced Customer Support

By 2026, digital tools will play a larger role in parts identification and purchasing. Augmented reality (AR) apps and AI-powered diagnostic tools may assist users in identifying worn components and sourcing exact replacements. Stihl’s official website and authorized dealers are likely to expand interactive part diagrams and mobile support, improving customer experience and reducing purchase errors. This digital transformation will also facilitate inventory management for retailers and reduce lead times. -

Consolidation of Authorized Dealer Networks

Stihl’s exclusive distribution model will continue to influence parts availability. As of 2026, the brand is expected to strengthen its network of authorized dealers, potentially integrating online ordering with local pickup or same-day delivery options. This hybrid model ensures authenticity and warranty compliance while meeting the convenience expectations of modern consumers. -

Impact of Regulatory and Emissions Standards

With tightening emissions regulations, especially in regions like the EU and California, there may be a gradual phase-out of older two-stroke engines like the one in the FS45. While the FS45 itself may become legacy equipment, this will paradoxically boost demand for repair parts as owners extend the life of compliant units. Retrofit kits and emission-reducing components may also emerge as niche offerings. -

Rise of Educational Content and DIY Culture

Online tutorials, YouTube repair guides, and forums will continue to empower users to perform their own maintenance. This DIY trend will drive demand for individual components such as trimmer line, clutch shoes, and gaskets. Brands offering clear instructions and compatible parts bundles will capture market share by aligning with this self-reliant consumer base.

In conclusion, the 2026 market for Stihl FS45 parts will be characterized by a blend of enduring OEM loyalty, growth in the aftermarket sector, digital innovation, and sustainability-driven repair culture. While newer models may surpass the FS45 in efficiency, its widespread use ensures a resilient parts ecosystem for years to come.

Common Pitfalls When Sourcing Stihl FS45 Parts: Quality and Intellectual Property Concerns

Logistics & Compliance Guide for STIHL FS 45 Parts

Overview

This guide outlines the logistics and compliance requirements for handling, shipping, storing, and distributing replacement parts for the STIHL FS 45 string trimmer. Adherence to these guidelines ensures operational efficiency, regulatory compliance, and product integrity across the supply chain.

Regulatory Compliance

International Trade Regulations

All STIHL FS 45 parts shipped across international borders must comply with relevant export and import regulations, including:

– Export Control Classification Numbers (ECCN): Verify ECCN for applicable parts (e.g., engines, electronic components) under the U.S. Commerce Control List (CCL) or equivalent in other jurisdictions.

– Customs Documentation: Accurate commercial invoices, packing lists, and certificates of origin must accompany all shipments. Harmonized System (HS) codes must be correctly applied (e.g., 8448.20 for parts of lawn mowers).

– Restricted Parties Screening: Ensure no transactions involve entities on OFAC, BIS, or EU sanctions lists.

Environmental & Safety Standards

- RoHS (Restriction of Hazardous Substances): Electrical and electronic components must comply with RoHS directives in the EU and similar standards in other regions.

- REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals): Ensure no restricted substances are present in plastics, coatings, or adhesives used in parts.

- Battery Regulations: If shipping parts containing lithium-ion batteries (e.g., for electric start models), compliance with IATA Dangerous Goods Regulations (DGR) is mandatory.

Packaging & Labeling Requirements

Packaging Standards

- Use STIHL-approved packaging materials to prevent damage during transit.

- Include anti-corrosion protection for metal components (e.g., shafts, blades).

- Segregate sharp or heavy parts to avoid punctures or crushing of other items.

Labeling

- Each package must display:

- Part number and description

- Quantity

- STIHL logo and “Genuine STIHL Part” designation

- Batch/lot number and manufacturing date

- Country of origin

- Handling symbols (e.g., “Fragile,” “Do Not Stack”)

- For hazardous components (e.g., fuel lines with residual fuel), apply GHS-compliant hazard labels.

Storage & Inventory Management

Warehouse Conditions

- Store parts in a dry, climate-controlled environment (10–25°C, 30–60% humidity).

- Maintain separation between incompatible materials (e.g., fuels, solvents).

- Implement FIFO (First-In, First-Out) inventory rotation to minimize obsolescence.

Inventory Tracking

- Use barcode or RFID systems to track part movement.

- Integrate with STIHL’s authorized dealer management system for real-time stock visibility.

- Conduct regular cycle counts to ensure accuracy and detect discrepancies.

Transportation & Shipping

Domestic Shipments

- Use carriers certified for automotive or industrial parts logistics.

- Ensure proper securing of loads to prevent shifting.

- Maintain proof of delivery (POD) for all shipments.

International Shipments

- Partner with freight forwarders experienced in machinery parts logistics.

- Comply with Incoterms® 2020 (e.g., FCA, DAP) as defined in contracts.

- Provide bilingual documentation where required (e.g., English/French for Canada).

Quality Assurance & Traceability

Incoming Inspection

- Verify part numbers, quantities, and condition upon receipt.

- Inspect for damage, counterfeit indicators, or non-compliance.

- Reject non-conforming parts and report to STIHL Quality Assurance.

Traceability

- Maintain records of supplier, batch number, and shipment date for a minimum of 7 years.

- Support STIHL’s product recall procedures through full traceability.

Returns & Reverse Logistics

Return Authorization

- All returns require a valid Return Material Authorization (RMA) number issued by STIHL.

- Returns must include reason code (e.g., defective, incorrect part).

Handling Returned Parts

- Quarantine returned items pending inspection.

- Recondition or dispose of parts per STIHL environmental guidelines.

- Update inventory and financial records accordingly.

Training & Compliance Monitoring

Staff Training

- Train warehouse, logistics, and sales staff annually on:

- STIHL part authenticity verification

- Hazardous materials handling

- Export control awareness

- Data privacy (GDPR, CCPA) when handling customer information

Audits & Reporting

- Conduct internal compliance audits at least annually.

- Report violations or near-misses to STIHL Compliance Office within 48 hours.

- Maintain audit logs and corrective action records.

Conclusion

Strict adherence to this logistics and compliance guide ensures that STIHL FS 45 parts are handled safely, legally, and efficiently throughout the supply chain. Authorized distributors and service partners must follow these protocols to maintain STIHL certification and uphold brand integrity.

In conclusion, sourcing STIHL FS 45 replacement parts requires careful attention to compatibility, authenticity, and supplier reliability. Due to the age and discontinuation of the FS 45 model, parts may be limited or no longer manufactured, making it essential to consult official STIHL parts diagrams or contact authorized dealers for accurate identification. Reputable online retailers, salvage yards, and specialty small engine repair shops may offer viable alternatives, including used or aftermarket components. Always prioritize OEM (original equipment manufacturer) parts when possible to ensure proper fit, performance, and longevity. Maintaining detailed records of part numbers and verifying compatibility before purchase will help streamline repairs and extend the usable life of your equipment.