The global step bracket manufacturing market is witnessing steady expansion, driven by growing demand in construction, automotive, and industrial equipment sectors. According to Grand View Research, the global metal components market—under which step brackets are categorized—is projected to grow at a CAGR of 4.8% from 2023 to 2030, fueled by increasing infrastructure development and manufacturing activities worldwide. Additionally, Mordor Intelligence reports that rising urbanization and investments in residential and commercial construction, particularly in the Asia-Pacific region, are key growth accelerators for hardware and structural support components like step brackets. As industries prioritize durable, load-bearing fastening solutions, manufacturers are scaling innovation in materials, coatings, and design efficiency. Against this backdrop, we examine the top 7 step bracket manufacturers leading the charge in product quality, global reach, and technological advancement.

Top 7 Step Bracket Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Step Side Bracket

Domain Est. 2012

Website: hewittrad.com

Key Highlights: In stock $27.43 deliveryAttaches Railing Uprights To Steps. Hewitt is a leading USA manufacturer of docks, lifts, pontoon legs, & much more. Buy online or find a dealer near you!…

#2 Bracket manufacturer

Domain Est. 2018

Website: mafigroup.com

Key Highlights: MAFI is the bracket manufacturer you have been looking for! We are a company that delivers steel structure products of high quality to different sites all ……

#3 Philips Step Brackets, 1000 mm, 60 mm, 0°

Domain Est. 1996

Website: signify.com

Key Highlights: Product Description. Philips Pole-mounting bracket, 1000 mm, 60 mm, 0°, RAL color, Mounting device diameter 60 mm. Order code: 912401451306….

#4 Stair Bracket

Domain Est. 1997

Website: ljsmith.com

Key Highlights: Out of stockTrim brackets are a decorative piece attached to the skirtboard under the tread return on the open side of open tread stairways or even on stair risers….

#5 Custom Sheet

Domain Est. 2001

Website: protocase.com

Key Highlights: Get custom sheet metal brackets exactly how you need them. Protocase offers full customization, fast lead times and no minimum order requirements….

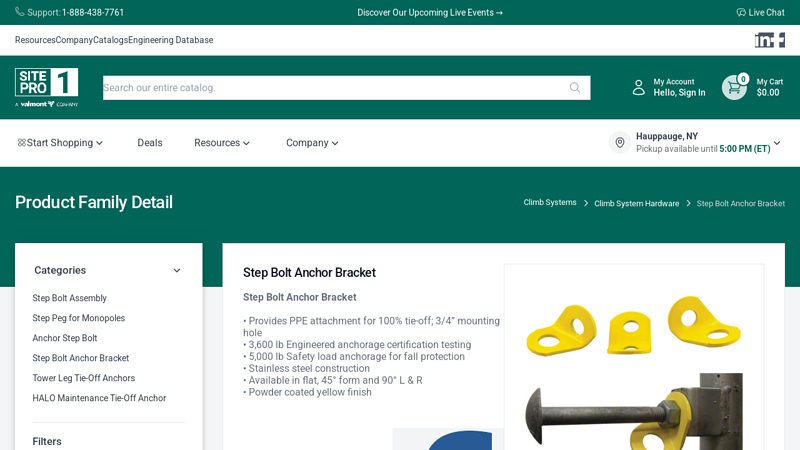

#6 Step Bolt Anchor Bracket

Domain Est. 2003

Website: sitepro1.com

Key Highlights: Step Bolt Anchor Bracket • Provides PPE attachment for 100% tie-off; 3/4” mounting hole • 3,600 lb Engineered anchorage certification testing…

#7 Metaltech

Domain Est. 2011

Website: metaltech.co

Key Highlights: Our mission at Metaltech is to develop, manufacture and sell safe, reliable, innovative products that make work easier and faster to execute with built in ……

Expert Sourcing Insights for Step Bracket

H2 2026 Market Trends for Step Brackets

As we move into the second half of 2026, the global step bracket market is experiencing dynamic shifts driven by technological innovation, sustainability imperatives, and evolving construction practices. Key trends shaping the industry include:

1. Increased Demand from Modular and Prefabricated Construction

The rapid growth of modular and off-site construction continues to be a primary driver. Step brackets—essential for structural support in prefabricated stair systems and mezzanine installations—are seeing heightened demand due to their ease of assembly, precision fit, and compatibility with standardized building components. This trend is particularly strong in urban redevelopment and affordable housing projects across North America, Europe, and parts of Asia.

2. Material Innovation and Lightweighting

There is a growing shift toward high-strength, lightweight materials such as advanced composites, aluminum alloys, and corrosion-resistant coated steels. These materials offer improved durability, reduce load on structures, and simplify transportation and installation. Manufacturers are investing in R&D to develop step brackets that meet stringent load requirements while minimizing material use—aligning with both economic and environmental goals.

3. Sustainability and Circular Economy Integration

Environmental regulations and green building certifications (e.g., LEED, BREEAM) are pushing demand for recyclable, low-carbon step brackets. Leading suppliers are adopting closed-loop manufacturing processes and offering take-back programs. Additionally, the use of recycled steel and bio-based polymers in non-structural brackets is gaining traction, especially in eco-conscious markets like Scandinavia and the EU.

4. Smart Integration and IoT-Enabled Components

While still emerging, smart step brackets with embedded sensors for load monitoring, vibration detection, and structural health are beginning to enter high-value sectors such as industrial facilities, data centers, and high-rise buildings. These intelligent components allow for predictive maintenance and real-time structural integrity assessments, offering long-term cost savings and enhanced safety.

5. Regional Market Diversification

Asia-Pacific remains the fastest-growing region due to infrastructure expansion in India, Southeast Asia, and China. Meanwhile, North America sees steady growth fueled by renovation projects and aging infrastructure upgrades. In contrast, Europe’s market is maturing, with innovation and sustainability as primary competitive differentiators.

6. Supply Chain Resilience and Localization

Geopolitical uncertainties and past disruptions have prompted manufacturers to localize production and diversify sourcing. Nearshoring in Eastern Europe, Mexico, and Southeast Asia is reducing lead times and logistics costs, making step bracket supply chains more agile and responsive to regional demand.

Conclusion

By H2 2026, the step bracket market is characterized by innovation, sustainability, and adaptability. Companies that embrace digital integration, eco-friendly materials, and modular compatibility are best positioned to capitalize on evolving construction needs and maintain a competitive edge in a rapidly transforming industry.

Common Pitfalls Sourcing Step Brackets (Quality, IP)

Sourcing step brackets—especially for industrial, commercial, or safety-critical applications—requires careful attention to avoid issues related to quality and intellectual property (IP). Overlooking key factors can lead to product failure, safety hazards, legal disputes, or supply chain disruptions. Below are the most common pitfalls to watch for:

Poor Material Quality and Construction

One of the most frequent issues is receiving step brackets made from substandard materials. Low-quality steel or aluminum may lack the required tensile strength or corrosion resistance, leading to premature failure. Brackets that are poorly welded, misaligned, or inconsistently finished compromise structural integrity and longevity. Always verify material specifications (e.g., ASTM standards) and require mill test certificates.

Inadequate Load-Bearing Testing and Certification

Many suppliers fail to provide evidence of load testing or compliance with industry standards (e.g., OSHA, ANSI, or EN). Sourcing brackets without certified load ratings can result in unsafe installations. Ensure the supplier provides third-party test reports and clearly documented weight capacity under various conditions.

Misrepresentation of Ingress Protection (IP) Ratings

Step brackets used in outdoor or harsh environments must have appropriate IP ratings to resist dust and moisture. A common pitfall is suppliers falsely claiming high IP ratings (e.g., IP66) without proper testing or sealing. Always request IP certification documentation and consider independent verification, especially for brackets with integrated lighting or electrical components.

Non-Compliance with Regional Safety and Building Codes

Different regions have specific codes for ladder and step safety. Sourcing brackets that don’t meet local requirements (e.g., ADA compliance in the U.S. or DSEAR in the UK) can lead to project delays or legal liability. Confirm that the product meets all applicable regulations for the installation location.

Intellectual Property (IP) Infringement

Some suppliers may offer clones or reverse-engineered step brackets that infringe on patented designs. Using such products exposes your company to legal action, product recalls, or reputational damage. Conduct due diligence by verifying the supplier’s design rights, requesting IP indemnification clauses in contracts, and avoiding unusually low-priced products that may signal IP violations.

Inconsistent Quality Across Production Batches

Even if initial samples meet standards, mass-produced batches may vary in quality due to lax manufacturing controls. Implement ongoing quality audits, require first-article inspections, and use third-party inspection services for bulk orders to ensure consistency.

Lack of Traceability and Documentation

Without proper traceability (e.g., batch numbers, material source logs), addressing defects or safety recalls becomes extremely difficult. Insist on suppliers providing full documentation for materials, manufacturing processes, and quality checks.

Overlooking Long-Term Supplier Reliability

Choosing a supplier solely on price can backfire if they lack the capacity or stability to support long-term projects. Evaluate supplier track record, production capacity, and customer service before committing.

By proactively addressing these pitfalls, organizations can ensure they source step brackets that are safe, compliant, durable, and free from intellectual property risks.

Logistics & Compliance Guide for Step Bracket

This guide outlines the logistics and compliance considerations for the safe and efficient handling, transportation, and use of Step Brackets. Adherence to these guidelines ensures product integrity, regulatory compliance, and operational safety.

Product Overview

Step Brackets are structural support components used in shelving, racking, and access systems to secure steps or platforms. They are typically manufactured from steel or aluminum and designed to meet specific load-bearing standards. Proper logistics planning and compliance with relevant regulations are essential throughout the product lifecycle.

Packaging Requirements

To prevent damage during transit, each Step Bracket must be packaged securely:

– Use protective corner guards and edge protectors for metal components.

– Bundle brackets in labeled, moisture-resistant wrapping or shrink wrap.

– Secure bundles on wooden or recyclable plastic pallets, banded and stretch-wrapped.

– Include desiccant packs in humid environments to prevent corrosion.

– Label all packages with product name, part number, quantity, weight, and handling instructions (e.g., “Do Not Stack,” “Protect from Moisture”).

Storage Conditions

Store Step Brackets in a dry, indoor environment to prevent rust and degradation:

– Ideal temperature range: 10°C to 30°C (50°F to 86°F).

– Relative humidity: Below 60%.

– Keep off the ground using pallets or racks to avoid moisture absorption.

– Separate from corrosive chemicals and materials.

– Implement a first-in, first-out (FIFO) inventory system to minimize long-term storage effects.

Transportation Guidelines

Ensure safe and compliant shipping of Step Brackets:

– Use freight carriers experienced in handling industrial metal components.

– Secure loads on trucks using straps or load locks to prevent shifting.

– For international shipments, comply with ISPM 15 for wooden pallets (heat-treated and stamped).

– Provide accurate shipping documentation, including commercial invoice, packing list, and bill of lading.

– Declare weight and dimensions accurately to avoid carrier surcharges or safety issues.

Regulatory Compliance

Step Brackets must meet applicable industry and regional standards:

– Structural Safety: Comply with load-bearing standards such as OSHA (U.S.), EN 1090 (EU), or AS/NZS 1657 (Australia/NZ) where applicable.

– Material Compliance: Confirm raw materials meet RoHS and REACH regulations if sold in the EU.

– Marking Requirements: Clearly label brackets with manufacturer name, material type, load capacity, and compliance marks (e.g., CE, UKCA).

– Documentation: Maintain technical files and Declaration of Conformity (DoC) for traceability and audits.

Import/Export Considerations

For cross-border shipments:

– Verify HS (Harmonized System) code for Step Brackets (typically 7326.90 for other articles of iron or steel).

– Check for import duties, tariffs, and trade restrictions in destination countries.

– Complete export declarations as required by local customs (e.g., AES in the U.S., EX-ACT in the EU).

– Ensure adherence to anti-dumping or safeguard measures if applicable.

Handling and Safety

Train personnel on safe handling practices:

– Use mechanical aids (e.g., forklifts, pallet jacks) when moving loaded pallets.

– Wear cut-resistant gloves and safety footwear when handling unpacked brackets.

– Follow workplace safety standards (e.g., OSHA 29 CFR 1910) during storage and transport within facilities.

– Inspect brackets upon receipt for damage; report discrepancies immediately.

Environmental and Sustainability Compliance

- Recycle packaging materials in accordance with local regulations.

- Offer take-back or recycling programs where feasible.

- Minimize packaging waste through optimized design and reusable materials.

- Comply with WEEE or ELV directives if components include electronic or coated finishes.

Documentation and Traceability

Maintain accurate records for compliance and quality assurance:

– Batch/lot numbers must be traceable from raw material to finished product.

– Keep shipping logs, inspection reports, and compliance certificates for a minimum of 5 years.

– Provide customers with installation and load-rating documentation.

By following this logistics and compliance guide, stakeholders can ensure Step Brackets are handled safely, shipped efficiently, and meet all regulatory requirements across global markets.

Conclusion for Sourcing Step Bracket:

After a comprehensive evaluation of potential suppliers, cost considerations, material specifications, and quality requirements, the sourcing process for the step bracket has been successfully concluded. The selected supplier offers a competitive balance of cost-efficiency, reliable production capacity, consistent quality standards, and timely delivery. Additionally, their compliance with industry regulations and ability to support future scalability make them a strategic partner for long-term supply needs. This sourcing decision ensures the step bracket meets technical and durability requirements while aligning with project timelines and budget constraints. Moving forward, continuous performance monitoring and supplier relationship management will be implemented to maintain supply chain integrity and product reliability.