The global personal protective equipment (PPE) market, driven by stringent workplace safety regulations and rising industrial accidents, has seen consistent growth in recent years. According to Mordor Intelligence, the global safety footwear market was valued at approximately USD 7.8 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A key contributor to this expansion is the rising demand for comfort-enhanced safety gear, particularly steel toe inserts used inside standard work boots. As industries ranging from construction to warehousing prioritize both protection and ergonomics, manufacturers are innovating with lightweight, heat-resistant, and fatigue-reducing insoles and toe caps. This growing niche has led to a surge in specialized producers offering high-performance steel toe inserts that meet ASTM and EN safety standards while improving wearer comfort throughout extended shifts. With North America and Europe leading in adoption due to rigorous OSHA and CE compliance requirements, and Asia Pacific emerging as a fast-growing region due to industrialization and labor safety reforms, the competition among insert manufacturers is intensifying. The following list highlights the top 8 manufacturers leading innovation, scalability, and product reliability in the steel toe insert space.

Top 8 Steel Toe Inserts For Inside Boots Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Toes2Go Steel Toe Cap

Domain Est. 2000

Website: impacto.ca

Key Highlights: Steel toe cap overshoes. Made of flexible, pliable PVC. Treads under sole to prevent slipping and help liquid ow away from the foot. Fully Adjustable.Missing: inside manufacturer…

#2 Steel Boots Official US Store

Domain Est. 2003

Website: us.steel-boots.com

Key Highlights: $83 delivery 30-day returnsSteel Boots at the best prices. We have everything in stock. Punk Rock and Metal Style. Original Steel accessories, winter models and sale for every day….

#3 Our Technologies

Domain Est. 1999

Website: hytest.com

Key Highlights: HYTEST® Steel Toe footwear meets ASTM standards for impact and compression. Designed with an anatomical shape for comfort and ample toe room. Detail shot of ……

#4 Steel Toe Safety Shoe Covers for Visitors and Employees

Domain Est. 2002

#5 Twisted X Boots

Domain Est. 2009

Website: twistedx.com

Key Highlights: The same comfort you know and love with an added flair to fit your style. Check out the new driving mocs today!…

#6 Our History

Domain Est. 2011

Website: customfit.me

Key Highlights: For 100 years, Lehigh has been an innovative supplier of safety footwear. We were at the forefront of steel toe development and pioneered the on-site shoe truck ……

#7 Steel Toe Inserts: What It Is and How It Works

Domain Est. 2022

Website: safusensafety.com

Key Highlights: Steel toe inserts, also known as steel toe caps or steel toe reinforcements, are protective components designed to enhance the safety of footwear….

#8 Foot protection

Website: deltaplus.eu

Key Highlights: Protect yourself from falling tools or materials with our safety footwear. Quality and reliability guaranteed with Delta Plus….

Expert Sourcing Insights for Steel Toe Inserts For Inside Boots

H2: 2026 Market Trends for Steel Toe Inserts for Inside Boots

The global market for steel toe inserts for inside boots is projected to experience notable shifts by 2026, driven by evolving workplace safety standards, advancements in materials science, and increasing demand across industrial sectors. Below are the key trends expected to shape this niche segment of the protective footwear industry:

1. Rising Demand in Construction and Manufacturing Sectors

By 2026, the construction, manufacturing, and logistics industries are expected to remain the primary drivers of demand for steel toe inserts. With ongoing infrastructure development projects in emerging economies and renewed investments in industrial automation, worker safety will continue to be a top priority. Steel toe inserts offer a cost-effective and modular solution for reinforcing standard work boots, making them increasingly popular among safety managers and procurement officers.

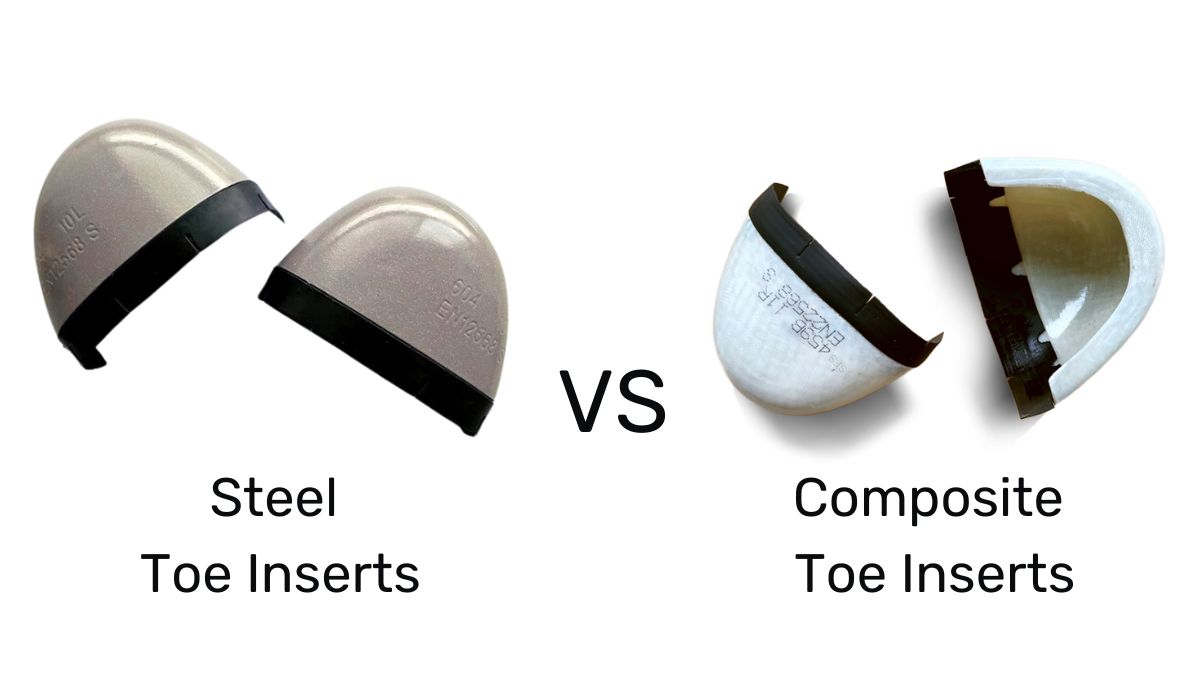

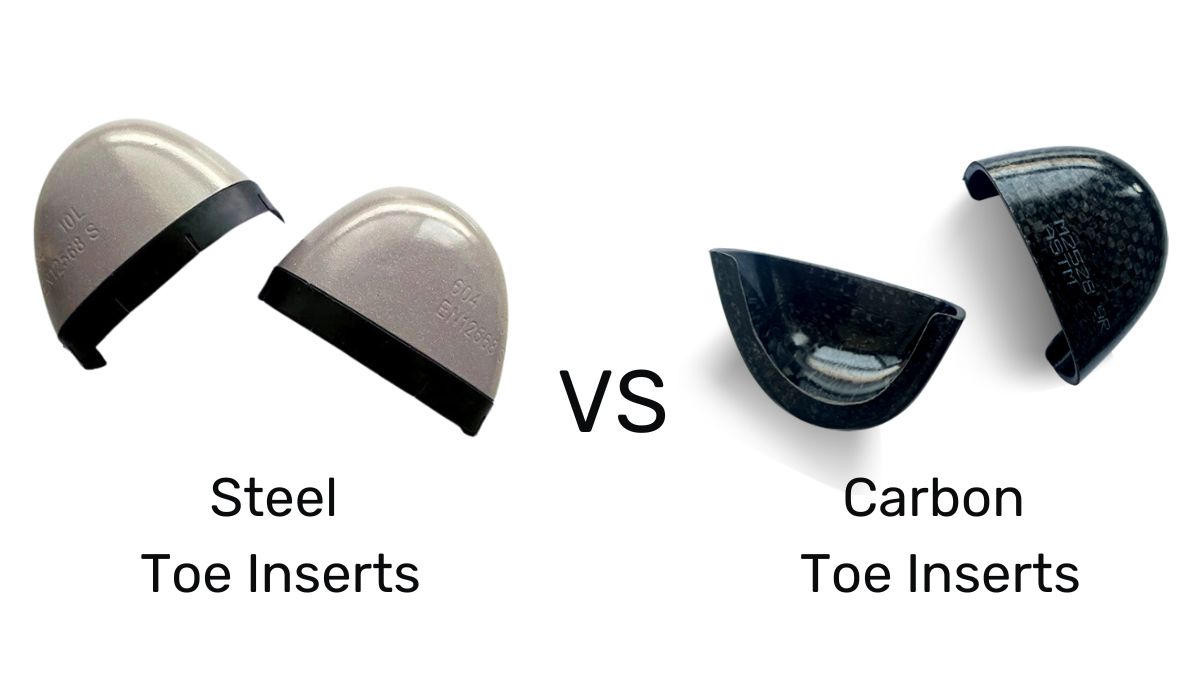

2. Shift Toward Lightweight and Composite Alternatives

Although steel remains a dominant material, market trends indicate growing competition from composite and aluminum toe inserts due to their lighter weight and non-metallic properties. However, steel toe inserts are expected to retain a strong foothold in high-impact environments where maximum protection is required. Innovations such as tempered or high-tensile steel may help steel inserts maintain relevance by improving strength-to-weight ratios.

3. Increased Focus on Comfort and Ergonomics

Consumer expectations are shifting toward comfort without compromising safety. By 2026, manufacturers of steel toe inserts are likely to emphasize ergonomic designs, improved fit, and heat-moldable materials that conform to the wearer’s foot. This trend is fueled by labor shortages in industrial fields, where employee retention depends on workplace comfort and reduced fatigue.

4. Growth in E-Commerce and Direct-to-Consumer Sales

The distribution landscape for safety gear, including steel toe inserts, is evolving. Online platforms and specialized e-commerce retailers are expected to play a larger role by 2026, enabling end-users to purchase inserts directly. Enhanced product descriptions, customer reviews, and virtual fit guides will support informed buying decisions, increasing market transparency and accessibility.

5. Regulatory Influence and Global Safety Standards

Stricter occupational health and safety regulations—especially in regions like North America, the EU, and parts of Asia-Pacific—are likely to mandate the use of certified protective gear. Compliance with standards such as ASTM F2413 (U.S.) and EN ISO 20345 (Europe) will remain critical for manufacturers. This regulatory push will support market growth and encourage innovation in tested and certified insert designs.

6. Expansion in Emerging Markets

Countries in Southeast Asia, India, and Africa are expected to experience rapid industrialization by 2026, leading to higher demand for affordable and durable safety solutions. Steel toe inserts, which can upgrade existing footwear rather than requiring full boot replacements, present a cost-effective alternative ideal for price-sensitive markets.

7. Sustainability and Recyclability Considerations

Environmental concerns are beginning to influence product development. The steel industry’s efforts to reduce carbon emissions and increase recycling rates may enhance the sustainability profile of steel toe inserts. Brands emphasizing recyclable materials and eco-conscious manufacturing processes are likely to gain competitive advantage.

Conclusion

By 2026, the market for steel toe inserts for inside boots will be shaped by a balance of safety requirements, comfort innovations, and economic factors. While facing competition from lighter alternatives, steel toe inserts are expected to maintain a strong presence—particularly in high-risk industries and cost-conscious markets. Manufacturers who invest in ergonomic design, compliance, and digital distribution will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Steel Toe Inserts for Inside Boots (Quality and Intellectual Property)

Sourcing steel toe inserts for integration inside boots involves several critical considerations, particularly regarding product quality and intellectual property (IP) rights. Falling into common traps can lead to compromised safety, legal disputes, and damage to brand reputation. Below are key pitfalls to avoid.

1. Prioritizing Cost Over Quality

One of the most frequent mistakes is selecting suppliers based solely on low pricing. Cheap steel toe inserts may use substandard materials or inadequate manufacturing processes, leading to reduced impact resistance and compression protection. These failures can violate safety standards such as ASTM F2413 or EN ISO 20345, putting end-users at risk and exposing the buyer to liability.

2. Inadequate Certification and Compliance Verification

Many suppliers claim compliance with international safety standards, but not all provide valid, third-party test reports. Relying on unverified certifications can result in non-compliant products entering the market. Always request up-to-date test reports from accredited laboratories and verify the scope of compliance.

3. Poor Material and Craftsmanship Standards

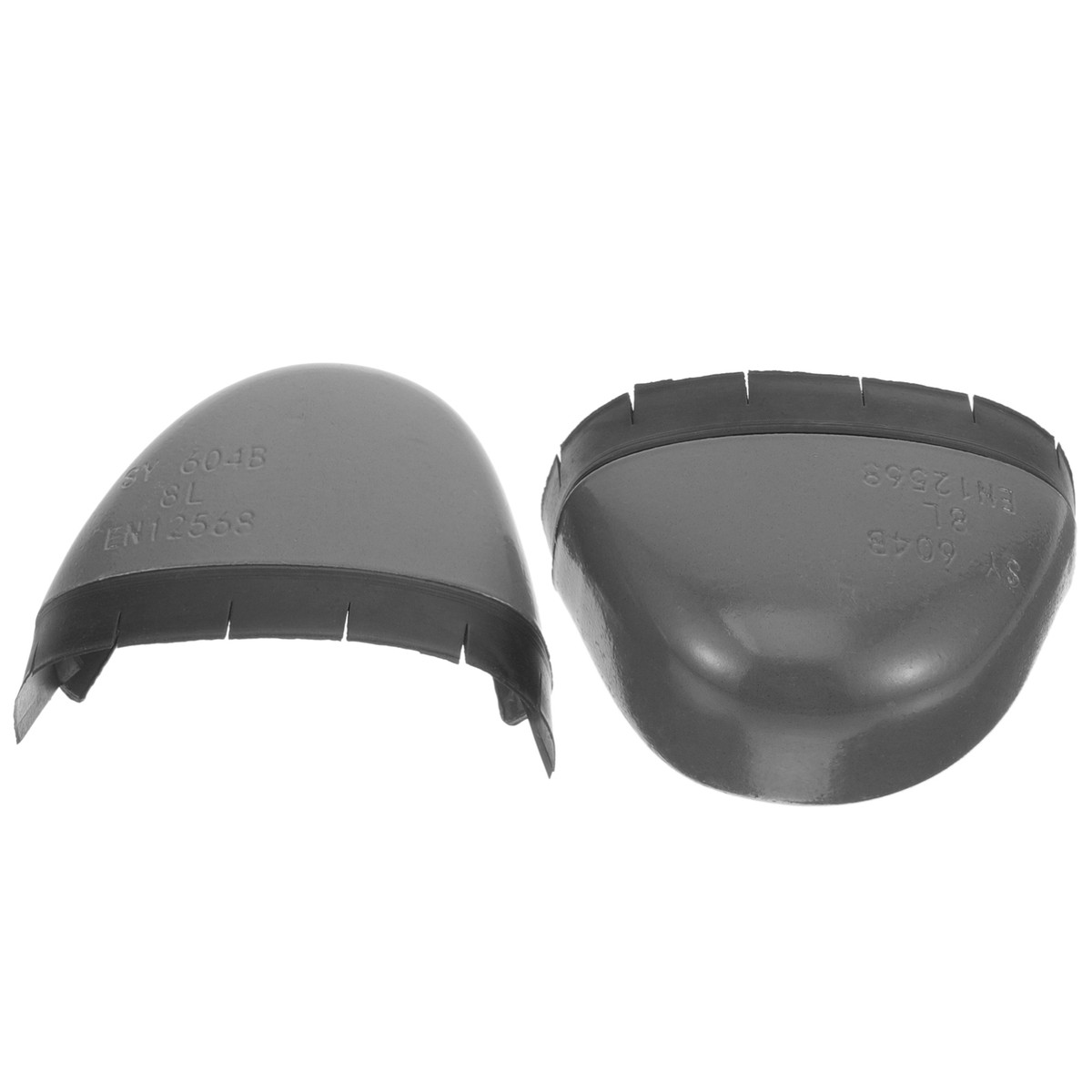

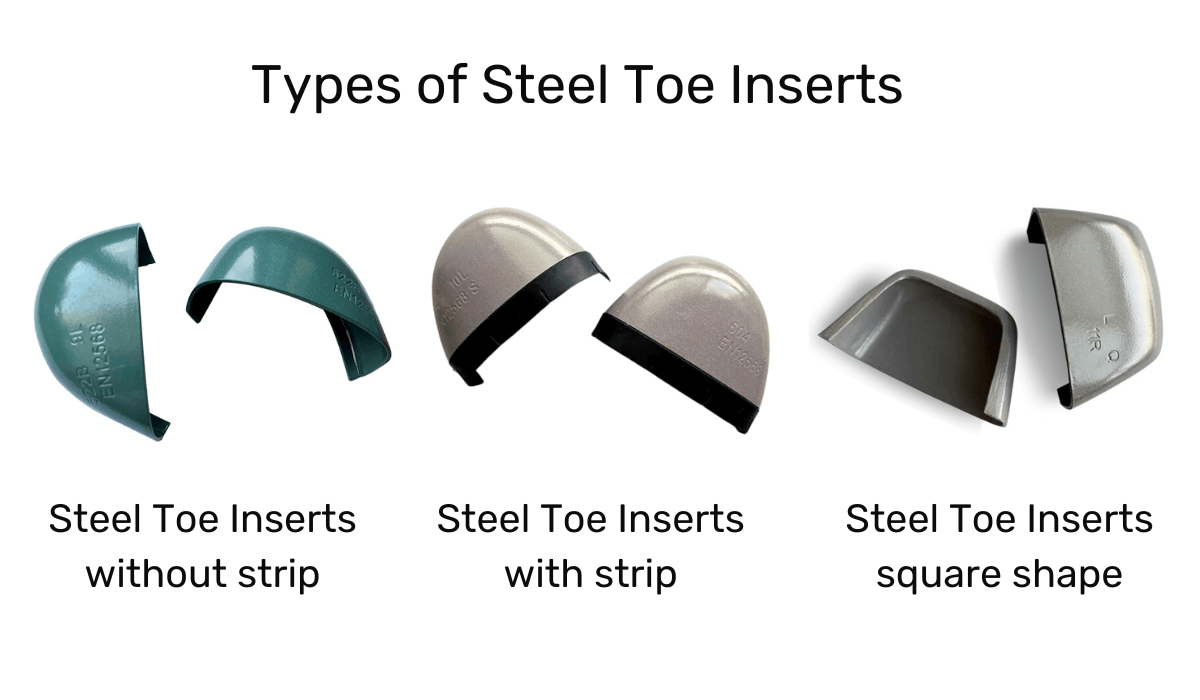

Low-quality steel toe caps may use thinner gauge steel, improper welding, or poor finishing, increasing the risk of cracking or deformation under stress. Additionally, sharp edges or irregular shapes can damage boot linings or cause discomfort. Insist on material specifications (e.g., steel grade, thickness) and conduct sample testing before bulk orders.

4. Ignoring Intellectual Property Rights

Using or sourcing steel toe insert designs that are patented or trademarked without authorization can lead to IP infringement. Some suppliers may copy proprietary designs from well-known brands, offering “compatible” or “OEM-style” inserts. Purchasing such products—even unknowingly—can expose your company to legal action, especially in regulated markets.

5. Lack of Design and Fit Customization Control

Off-the-shelf inserts may not fit precisely within your boot design, leading to discomfort or compromised protection. Failing to control the design specifications or tolerances can result in misalignment, pressure points, or reduced effectiveness. Ensure your supplier can provide custom tooling and maintains strict dimensional control.

6. Inconsistent Quality Control from Suppliers

Inconsistent batch quality is common with manufacturers lacking robust quality management systems (e.g., ISO 9001). Without regular audits and incoming inspection protocols, defects may go unnoticed until after production. Implement supplier qualification processes and regular quality checks.

7. Insufficient Documentation for Traceability

In regulated industries, traceability of components is essential. Suppliers who do not provide lot numbers, material certifications, or production records make it difficult to manage recalls or audits. Ensure documentation is comprehensive and retained for compliance purposes.

8. Overlooking Long-Term Supplier Reliability

Choosing a supplier based on a one-time quote without evaluating their financial stability, production capacity, or track record can lead to supply chain disruptions. Verify references, manufacturing capabilities, and scalability before committing.

Conclusion

Sourcing steel toe inserts requires a balance of cost-efficiency, quality assurance, and legal compliance. Avoiding these common pitfalls ensures that the final product meets safety standards, protects users, and safeguards your brand against liability and IP risks. Due diligence in supplier selection and ongoing quality management is essential for long-term success.

Logistics & Compliance Guide for Steel Toe Inserts for Inside Boots

Product Classification and HS Code

Steel toe inserts designed for inside boots typically fall under protective equipment or personal protective gear (PPE). The appropriate Harmonized System (HS) Code may vary by country, but common classifications include:

– 6307.90.99: Other made-up articles (textile-based components)

– 8302.50.00: Base metal mountings, fittings, and similar articles (for metal-based inserts)

– 9020.00.00: Other respiratory and safety appliances (in some jurisdictions, as part of PPE)

Always verify the correct HS code with local customs authorities or a certified customs broker, as misclassification can lead to delays or penalties.

Import/Export Regulations

Steel toe inserts may be subject to import/export controls depending on the destination country:

– United States: No export license required under EAR (Export Administration Regulations) for most destinations, provided the inserts are not intended for military use.

– European Union: Subject to general commercial regulations; no specific export restrictions unless part of a broader PPE system requiring CE marking.

– Canada, Australia, UK: Generally unrestricted, but compliance with local safety standards may be required upon entry.

Always check if dual-use or security-related regulations apply, especially when shipping in bulk.

Customs Documentation Requirements

Ensure the following documents accompany shipments:

– Commercial Invoice: Must include product description (“Steel Toe Inserts for Boot Insoles”), quantity, value, country of origin, and HS code.

– Packing List: Detail dimensions, weight per unit, and total shipment volume.

– Bill of Lading (BOL) or Air Waybill (AWB): Required for all international shipments.

– Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

Accurate documentation minimizes the risk of customs delays or inspections.

Compliance with Safety Standards

Although inserts are not always regulated independently, they may fall under broader PPE directives when marketed for safety use:

– United States (OSHA/ANSI): If marketed as protective, ensure compliance with ANSI/ISEA 126-2019 for protective footwear components.

– European Union (CE Marking): Falls under Regulation (EU) 2016/425 on PPE. If sold as part of or intended to upgrade safety footwear, certification by a Notified Body may be required.

– Canada (CSA Z195): Aligns with ANSI standards; inserts enhancing safety performance should meet applicable requirements.

Note: Inserts sold as comfort or orthotic products (not safety-rated) may avoid PPE regulations.

Labeling and Packaging Requirements

- Labeling: Include product name, size, material composition, care instructions, and country of manufacture. If safety-rated, include compliance markings (e.g., “Meets ANSI I/75” or “CE Certified”).

- Packaging: Use durable, moisture-resistant packaging to prevent deformation. Individual blister packs or polybags are recommended for retail.

- Language Requirements: Labels and instructions must be in the official language(s) of the destination country (e.g., French in Quebec, German in Germany).

Transportation and Handling

- Mode of Transport: Suitable for air, sea, or ground freight. Metal components may trigger additional screening in air cargo.

- Weight and Dimensions: Steel inserts add density; optimize packaging to reduce volumetric weight for air freight.

- Handling: Avoid stacking heavy loads on packaged inserts to prevent crushing. Use pallets for bulk shipments.

- Storage: Store in dry, temperature-controlled environments to prevent rust or material degradation.

Environmental and Disposal Regulations

- RoHS Compliance (EU): Ensure inserts are free from restricted substances (e.g., lead, cadmium) if sold in the EU.

- REACH (EU): Declare substances of very high concern (SVHC) if applicable.

- WEEE/Recycling: Not typically applicable unless integrated with electronic components. Standard metal recycling applies for end-of-life disposal.

Recordkeeping and Audit Readiness

Maintain records for at least 5–10 years, including:

– Product testing reports

– Supplier certifications

– Customs documentation

– Compliance declarations (e.g., EU Declaration of Conformity)

These records support audits and demonstrate due diligence in case of regulatory inquiries.

Summary

Steel toe inserts require careful attention to classification, safety compliance, and documentation. While not always regulated as standalone PPE, their intended use influences regulatory scope. Partner with experienced logistics providers and compliance consultants to ensure smooth global distribution.

In conclusion, sourcing steel toe inserts for inside boots requires careful consideration of safety standards, comfort, fit, material quality, and intended use. While traditional safety footwear with built-in steel toes remains the gold standard for foot protection, after-market steel toe inserts can offer a practical solution for workers needing added protection in non-safety boots. It is essential to ensure that any inserts sourced meet recognized safety certifications such as ASTM F2413 or EN ISO 20345 to guarantee adequate impact and compression resistance. Additionally, comfort, ease of insertion, and compatibility with the user’s footwear are critical for long-term wear and compliance. Sourcing from reputable suppliers with transparent product specifications and testing documentation is vital to ensure reliability and worker safety. Ultimately, while steel toe inserts can enhance protection, they should be evaluated on a case-by-case basis and used only when they do not compromise safety or ergonomics.