The global personal protective equipment (PPE) market, driven by stringent safety regulations and rising industrialization, is witnessing robust growth—with particular expansion in demand for high-performance footwear such as steel toe boots. According to Grand View Research, the global safety footwear market was valued at USD 7.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2023 to 2030. This growth is fueled by increasing defense spending, expanding military operations, and heightened focus on soldier safety across armed forces worldwide. As militaries continue to modernize gear and prioritize durability, comfort, and protection in extreme environments, manufacturers of tactical steel toe boots are playing a pivotal role. The following list highlights the top nine steel toe boot manufacturers trusted by military units globally—companies combining advanced materials, ergonomic design, and rigorous compliance with military-grade standards to meet the evolving demands of defense forces.

Top 9 Steel Toe Boots Military Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Corcoran Boots

Domain Est. 1999

Website: carolinashoe.com

Key Highlights: Free deliveryOur Men’s 10″ Original Jump Boot carries the legacy of WWII paratroopers and is proudly handcrafted in the USA by skilled workers in our Pennsylvania factory….

#2 Fire Fighter Boots

Domain Est. 2006

Website: haixusa.com

Key Highlights: HAIX is a leading manufacturer of high quality, functional footwear to thousands of firefighters, EMTs, paramedics, law enforcement officers, loggers, ……

#3 https://rockyboots.com/

Domain Est. 1996

Website: rockyboots.com

Key Highlights: Shop Rocky’s vast collection of rugged & dependable outdoor, work, wester, and commercial military boots … Rocky Blizzard Stalker Steel Toe Waterproof 1200G ……

#4 Bates Boots – Tactical, Military & Security

Domain Est. 1997

Website: wolverine.com

Key Highlights: Free delivery over $99Official Bates Footwear Site – Shop military boots, tactical boots, security & uniform shoes and more. Find high quality boots designed to protect and ……

#5 Shop Military Combat Boots (Army Boots)

Domain Est. 1999

Website: propper.com

Key Highlights: Free delivery over $99 · 30-day returnsMilitary Boots built for the demands of the US Army and US Air Force. Get free memory foam inserts & free shipping on Army Boots & Military …

#6 HYTEST Safety Footwear for Work

Domain Est. 1999

Website: hytest.com

Key Highlights: Free deliveryShop Steel Toe HYTEST® Steel Toe footwear is designed with sturdy steel for ultimate protection from falling objects and workplace hazards. · Shop Composite Toe….

#7 Military Boots

Domain Est. 2005

Website: bellevilleboot.com

Key Highlights: Free deliveryFrom Army boots to Navy combat boots, discover why Belleville military boots are more than your basic boot. Shop the best military boots now!…

#8 Tactical Boots: Military and Police Footwear

Domain Est. 2006

Website: garmonttactical.com

Key Highlights: Honor service with Garmont Tactical Boots: Shop Garmont’s professional tactical boots for military and police. Commitment to quality for those who serve….

#9 Tactical Boots & Shoes

Domain Est. 2015

Expert Sourcing Insights for Steel Toe Boots Military

H2: 2026 Market Trends for Steel Toe Boots in the Military Sector

The global market for steel toe boots in the military sector is poised for significant evolution by 2026, driven by technological advancements, evolving operational requirements, and increasing emphasis on soldier safety and performance. This analysis explores key trends shaping the demand, design, and supply chain dynamics of military-grade steel toe boots over the coming years.

Rising Demand for Enhanced Protection and Comfort

Military operations continue to shift toward asymmetric warfare, urban combat, and prolonged deployments in diverse terrains. As a result, armed forces are prioritizing footwear that combines robust protection with long-term wearability. By 2026, steel toe boots are expected to integrate advanced composite materials that meet or exceed ASTM F2413 safety standards while reducing overall boot weight. This trend is driven by soldier feedback indicating fatigue reduction and improved mobility with lighter, yet equally protective, footwear.

Integration of Smart Technology

A defining trend by 2026 is the integration of smart technology into military steel toe boots. Defense contractors and footwear manufacturers are increasingly embedding sensors to monitor soldier health metrics such as foot temperature, pressure distribution, and fatigue levels. These data points can be transmitted in real-time to command centers, enabling proactive medical interventions and mission adjustments. Additionally, GPS-enabled insoles and motion-tracking systems are being tested for logistics and battlefield awareness, making boots a part of the broader network-centric warfare ecosystem.

Emphasis on Multi-Climate and Multi-Terrain Performance

Modern military operations span extreme environments—from Arctic conditions to desert heat. The 2026 market will see a surge in all-terrain steel toe boots engineered for climate adaptability. Features such as moisture-wicking linings, breathable yet waterproof membranes (e.g., Gore-Tex), and removable thermal insoles will become standard. Manufacturers are also focusing on sole compounds that maintain flexibility in sub-zero temperatures and resist melting in high-heat scenarios.

Sustainability and Ethical Sourcing

With increasing scrutiny on military supply chains, sustainability is emerging as a key consideration. By 2026, defense procurement agencies are expected to favor suppliers that use eco-friendly materials, reduce carbon footprints in manufacturing, and ensure ethical labor practices. Recyclable components, bio-based leather alternatives, and waterless dyeing techniques are being adopted by leading military boot producers to meet these demands.

Growth in Emerging Markets and Defense Modernization

Countries in Asia-Pacific, the Middle East, and Eastern Europe are modernizing their armed forces, leading to increased procurement of high-performance military gear, including steel toe boots. Nations such as India, South Korea, and Poland are investing in domestic defense manufacturing, creating opportunities for local production partnerships. This regional expansion is expected to drive double-digit growth in the military boot market by 2026.

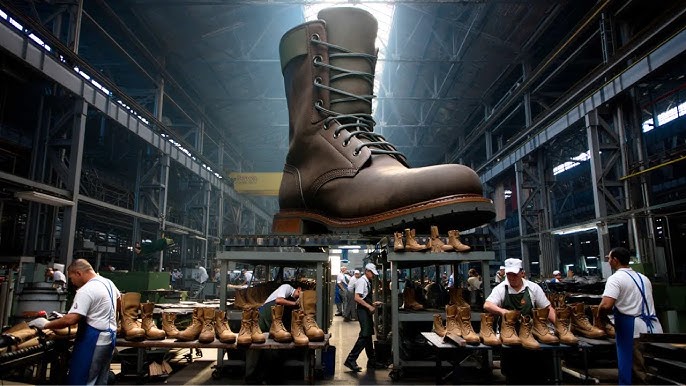

Supply Chain Resilience and Localization

Global disruptions have underscored the need for resilient supply chains. Militaries are shifting toward localized production of critical gear, including footwear, to reduce dependency on single-source suppliers. By 2026, we anticipate more defense ministries entering long-term contracts with regional manufacturers capable of rapid scaling and customization, ensuring continuity during geopolitical tensions or emergencies.

Conclusion

The 2026 market for military steel toe boots will be defined by innovation, adaptability, and integration. As armed forces seek to enhance soldier effectiveness and survivability, steel toe boots are transitioning from basic protective gear to intelligent, multi-functional equipment. Manufacturers that embrace advanced materials, digital integration, and sustainable practices will lead the market, meeting the evolving needs of modern militaries worldwide.

Common Pitfalls When Sourcing Steel Toe Boots for Military Use

Sourcing steel toe boots for military applications requires careful attention to quality, safety standards, and intellectual property (IP) considerations. Failure to address these aspects can lead to procurement of substandard equipment, legal complications, or compromised operational safety. Below are key pitfalls to avoid.

1. Compromising on Quality Standards

One of the most significant risks in sourcing military-grade steel toe boots is selecting products that fail to meet rigorous performance requirements. Military operations demand durability, protection, and comfort under extreme conditions.

- Inadequate Compliance with Safety Standards: Ensure boots meet international standards such as ASTM F2413 (USA), ISO 20345 (international), or MIL-PRF-24376 (military-specific). Boots lacking proper certification may offer insufficient protection against impact, compression, or punctures.

- Poor Material Selection: Low-quality leather, substandard rubber soles, or weak stitching can lead to premature failure. Boots must resist abrasion, water, and extreme temperatures.

- Lack of Testing and Validation: Avoid suppliers who cannot provide test reports or third-party certifications. Boots should undergo rigorous field or lab testing for slip resistance, electrical hazard protection, and thermal performance.

2. Ignoring Intellectual Property (IP) Risks

Military-spec footwear often involves proprietary designs, trademarks, or patented technologies. Sourcing from unauthorized manufacturers can lead to IP infringement.

- Counterfeit or Knockoff Products: Some suppliers offer “military-style” boots that mimic official designs but infringe on registered trademarks or patents. This can expose procurement agencies or contractors to legal liability.

- Unauthorized Use of Branding or Logos: Using military insignias, official emblems, or branded names (e.g., “Army Combat Boot”) without permission violates IP laws and regulations.

- Patented Technologies: Features like advanced suspension systems, moisture-wicking linings, or composite safety toes may be protected by patents. Sourcing boots that incorporate these without licensing can lead to disputes.

3. Overlooking Supply Chain Transparency

Lack of visibility into the manufacturing process increases the risk of receiving inconsistent or non-compliant products.

- Unverified Suppliers: Working with intermediaries or brokers without direct access to manufacturing facilities can result in misrepresentation of product quality.

- Inconsistent Batch Quality: Without strict quality control and traceability, different production batches may vary in materials or construction, compromising performance.

- Ethical and Compliance Concerns: Ensure suppliers adhere to labor laws and environmental regulations. Use of forced labor or unsafe working conditions can damage organizational reputation and lead to supply chain disruptions.

4. Failing to Align with Operational Requirements

Military boots must be fit-for-purpose across diverse environments—jungle, desert, arctic, or urban combat zones.

- One-Size-Fits-All Approach: Not all military roles require the same boot specifications. Tactical boots differ from load-bearing or cold-weather variants. Misalignment reduces effectiveness and increases injury risk.

- Neglecting Ergonomics and Comfort: Poorly designed boots lead to blisters, fatigue, and reduced mobility. Soldier feedback and biomechanical testing should inform sourcing decisions.

- Inadequate After-Sales Support: Lack of warranty, repair options, or spare parts availability can hinder long-term usability.

5. Underestimating Total Cost of Ownership

Focusing solely on upfront price can lead to higher long-term costs due to frequent replacements or medical incidents.

- Higher Replacement Rates: Cheap boots wear out faster, increasing procurement frequency and logistical burden.

- Impact on Personnel Readiness: Foot injuries from poor footwear reduce operational effectiveness and increase medical costs.

- Logistical Complexity: Sourcing from unreliable vendors may result in delays, customs issues, or non-compliance with defense procurement regulations.

Conclusion

Sourcing steel toe boots for military use demands a strategic approach that balances quality, compliance, and legal diligence. Avoiding these common pitfalls ensures that personnel are equipped with reliable, safe, and legally compliant footwear essential for mission success.

Logistics & Compliance Guide for Steel Toe Boots (Military)

Overview

Steel toe boots are critical personal protective equipment (PPE) in military operations, providing essential foot protection in hazardous environments. Proper logistics and compliance management ensures operational readiness, personnel safety, and adherence to military and regulatory standards. This guide outlines key logistics procedures and compliance requirements for the procurement, distribution, maintenance, and disposal of military-grade steel toe boots.

Procurement & Specification Compliance

Military steel toe boots must meet strict technical and performance standards. Procurement must align with:

- MIL-STD and NATO STANAG Requirements: Boots must comply with applicable military standards for durability, thermal resistance, electrical hazard protection, and puncture resistance.

- ASTM F2413 Compliance: In the U.S. military, boots must meet ASTM F2413 for impact and compression resistance (I/75 C/75 ratings minimum).

- Authorized Manufacturers and Contracts: Procurement should only occur through approved vendors listed in Defense Logistics Agency (DLA) catalogs or relevant procurement contracts.

- Size and Climate Variants: Include variants for different environments (e.g., temperate, arid, cold weather) and ensure availability across all required sizes, including wide and narrow fittings.

Inventory Management & Distribution

Effective logistics ensures boots are available where and when needed:

- Centralized and Forward Stocking: Maintain strategic reserves at central depots (e.g., DLA Troop Support) and forward operating bases for rapid deployment.

- Automated Tracking Systems: Use RFID tags or barcode systems integrated with logistics platforms like GCSS-Army or GCSS-MC for real-time inventory visibility.

- Unit-Level Issue Procedures: Implement controlled issue processes through unit supply rooms, requiring documentation (e.g., DA Form 2062 or equivalent) to track accountability.

- Pre-Deployment Kits: Include steel toe boots in individual deployment readiness kits; verify fit and compliance during pre-mobility processing.

Maintenance & Inspection

Regular upkeep extends boot lifespan and ensures continued protection:

- Routine Inspections: Soldiers must inspect boots monthly for sole separation, cracked toe caps, worn treads, and upper material damage.

- Field Repairs: Issue repair kits (e.g., seam sealers, temporary sole patches); major repairs should be conducted by authorized maintenance units.

- Cleaning and Drying Protocols: Provide guidance on proper cleaning (avoiding harsh chemicals) and air-drying procedures to prevent mold and material degradation.

- Service Life Monitoring: Track boot usage; replace after 12–18 months of active service or earlier if damage compromises safety.

Compliance & Safety Standards

Ensure boots remain compliant throughout their lifecycle:

- PPE Certification: Verify that all boots bear certification marks (e.g., ASTM, CE, or MIL-PRF-32412) and are on the current Authorized Protective Footwear List (APFL).

- Hazard-Specific Requirements: Confirm suitability for operational hazards (e.g., static-dissipative boots in explosive environments).

- Medical and Ergonomic Compliance: Coordinate with medical and safety officers to ensure boots meet orthopedic and comfort standards, reducing injury risk.

- Environmental Regulations: Comply with DoD environmental policies for disposal of non-repairable boots, especially those containing hazardous materials.

Training & Personnel Accountability

Effective use depends on proper training and accountability:

- Issuance Training: Conduct boot fitting sessions to ensure proper sizing and prevent injury (e.g., blisters, foot strain).

- Wear and Care Instruction: Include boot maintenance in basic and ongoing training (e.g., Soldier Readiness Program).

- Accountability Records: Log issued boots in individual equipment records; track through systems like ERB or eMILPO for audits and redeployment.

- Turn-In and Replacement: Establish clear procedures for turning in worn boots and issuing replacements, minimizing gaps in protection.

Disposal & Sustainability

Manage end-of-life boots responsibly:

- Reuse and Redistribution: Recondition serviceable boots for training use or transfer to allied forces via Foreign Military Sales (FMS).

- Recycling Programs: Partner with vendors offering boot recycling for rubber, leather, and metal components.

- Hazardous Waste Disposal: Follow EPA and DoD guidelines for disposing of boots treated with flame retardants or other regulated substances.

Conclusion

Effective logistics and compliance for military steel toe boots are essential to force protection and mission readiness. By standardizing procurement, maintaining rigorous inventory control, enforcing compliance, and promoting proper use and disposal, military units can ensure that personnel are equipped with safe, durable, and regulation-compliant footwear at all times.

In conclusion, sourcing steel toe boots for military use requires careful consideration of durability, safety standards, comfort, and compliance with military specifications. High-quality materials, such as full-grain leather and puncture-resistant soles, combined with features like slip-resistance, waterproofing, and ergonomic design, are essential to meet the demanding environments faced by military personnel. Engaging with reputable suppliers, verifying certifications (such as ASTM or MIL-SPEC compliance), and conducting thorough quality assessments ensure that the boots provide optimal protection and performance. Ultimately, investing in reliable, combat-tested steel toe boots enhances soldier safety, operational effectiveness, and long-term cost-efficiency for military organizations.