The global steel stairs market is experiencing steady growth, driven by rising construction activities in commercial, industrial, and infrastructure sectors. According to a report by Mordor Intelligence, the Steel Stairs Market was valued at USD 5.87 billion in 2023 and is projected to reach USD 7.73 billion by 2029, growing at a CAGR of 4.8% during the forecast period. This expansion is fueled by the increasing demand for durable, modular, and fire-resistant stair solutions, particularly in multi-story buildings and industrial facilities. Steel stringer stairs, known for their structural strength and design flexibility, are a preferred choice in modern construction. As the industry evolves, a select group of manufacturers are leading innovation through advanced fabrication techniques, sustainability initiatives, and global supply chain integration. Based on market presence, production capacity, and engineering expertise, the following are the top 10 steel stringer stairs manufacturers shaping the future of architectural and industrial access solutions.

Top 10 Steel Stringer Stairs Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pre

Domain Est. 1998

Website: amezz.com

Key Highlights: Our industrial metal stairs can be designed to IBC or OSHA standards with many stair landing, tread and finish options available….

#2 Curved Stair Stringers for Spiral Staircases

Domain Est. 1996

Website: cmrp.com

Key Highlights: Chicago Metal Rolled Products makes circular metal custom stair stringers that are big, true, and plumb. After we manufacture your curved custom stair stringer ……

#3 American Stair

Domain Est. 1997

Website: americanstair.com

Key Highlights: Our products are fabricated by skilled craftsmen and we will put this experience and knowledge at your disposal to become your only steel stair supplier….

#4 Stair steel stringers

Domain Est. 1999

Website: prestigemetal.com

Key Highlights: Check out our exceptional selection of high-quality single and double steel stair stringers! Made in Canada. Shipping everywhere in Canada ……

#5 Paragon Stairs

Domain Est. 2005

Website: paragonstairs.com

Key Highlights: Metal Floating Stairs. Make a statement in your home with a one-of-kind Paragon floating staircase built in Pennsylvania with premium hand-forged steel….

#6 Formed Steel Stair Stringer

Domain Est. 2006

Website: tsdistributors.com

Key Highlights: In stockRoll formed from sturdy 12 gauge plate; Stocked in 20′ lengths. HOUSTON · TS DISTRIBUTORS 832-467-5400. Mon-Fri | 7:30 AM – 4:30 PM (CDT) 4404 Windfern Rd….

#7 Metal Stairs

Domain Est. 2007

Website: fast-stairs.com

Key Highlights: $70 deliveryFast-Stairs® are modular adjustable steel stair stringers for easy stair building in basements, lofts, attics, decks, garages and job sites….

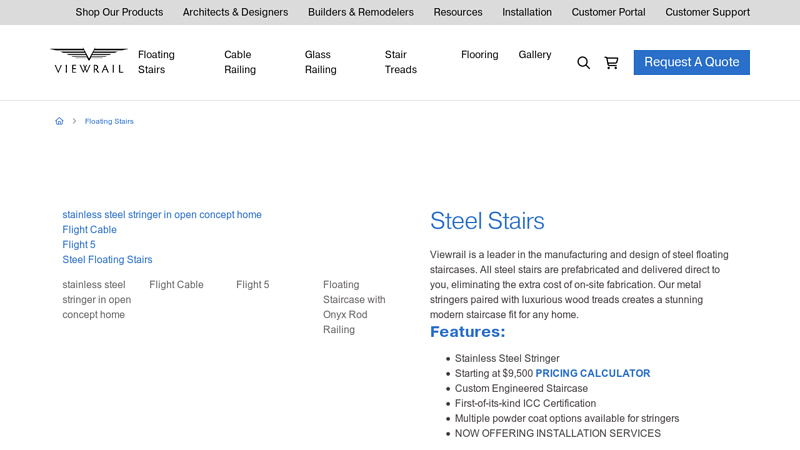

#8 Steel Floating Stairs

Domain Est. 2014

Website: viewrail.com

Key Highlights: $350 delivery 180-day returnsViewrail is a leader in the manufacturing and design of steel floating staircases. All steel stairs are prefabricated and delivered direct to you….

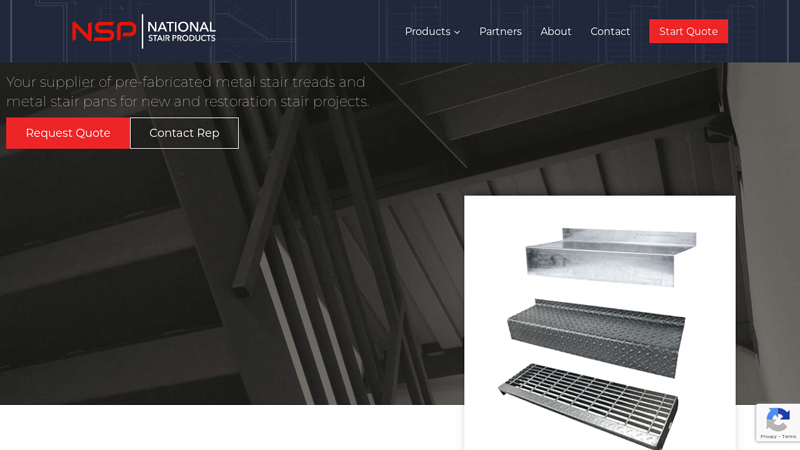

#9 Metal Stair Treads and Stair Pans

Domain Est. 2023

Website: nationalstair.com

Key Highlights: Find a wide selection of metal stair treads, stair pans as well. Many metal types to choose from. Slip resistant, bar grating options available as well….

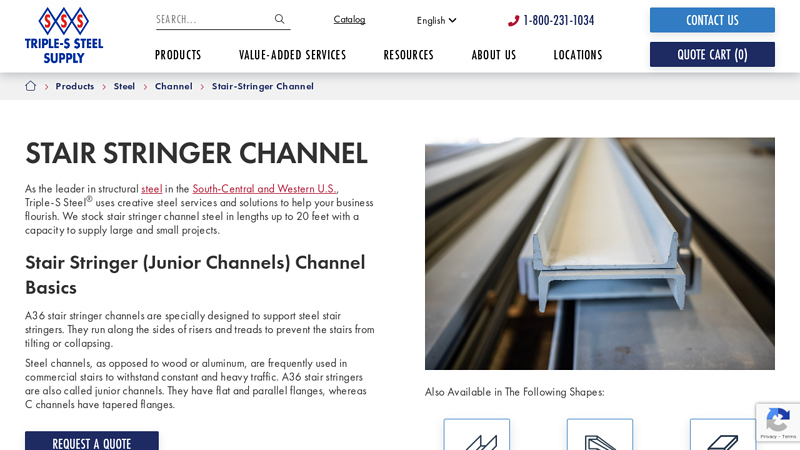

#10 A36 Stair Stringer Channel

Domain Est. 2024

Website: triple-s-steel.com

Key Highlights: We stock stair stringer channel steel in lengths up to 20 feet with a capacity to supply large and small projects to help your business flourish….

Expert Sourcing Insights for Steel Stringer Stairs

H2: 2026 Market Trends for Steel Stringer Stairs

The global market for steel stringer stairs is poised for steady growth through 2026, driven by evolving construction practices, increasing demand for durable and space-efficient architectural solutions, and the expansion of commercial and industrial infrastructure. This analysis explores key trends shaping the steel stringer stairs market in 2026 across technological, regional, and sector-specific dimensions.

-

Growth in Commercial and Industrial Construction

The expansion of commercial real estate, including office complexes, retail spaces, and mixed-use developments, is a primary driver for steel stringer stairs. Their structural strength, fire resistance, and design flexibility make them ideal for high-traffic and safety-critical environments. Additionally, the rise in industrial automation and warehouse development—especially with the growth of e-commerce logistics hubs—favors modular steel stair systems that support mezzanine levels and multi-tier storage. These applications are expected to account for over 50% of steel stringer stair demand by 2026. -

Adoption of Prefabricated and Modular Designs

Prefabrication continues to gain traction in construction due to its time and cost efficiency. Steel stringer stairs, often manufactured off-site with precision welding and CNC cutting, align well with modular construction trends. In 2026, the market will see increased integration of Building Information Modeling (BIM) and digital fabrication tools, enabling faster installation and reduced on-site labor. This shift supports green building initiatives by minimizing construction waste. -

Emphasis on Aesthetic and Architectural Integration

Beyond functionality, steel stringer stairs are increasingly valued for their sleek, modern appearance. Architects and designers are incorporating exposed steel structures into open-plan interiors, particularly in adaptive reuse projects and urban lofts. Powder-coated finishes, stainless steel variants, and custom geometries allow for greater design flexibility. The trend toward industrial-chic aesthetics in offices and hospitality spaces is expected to boost demand for architecturally expressive steel stair solutions. -

Regional Market Expansion

North America and Europe remain dominant markets due to stringent building codes and high construction standards. However, the Asia-Pacific region—especially China, India, and Southeast Asia—is projected to register the highest compound annual growth rate (CAGR) through 2026. Rapid urbanization, infrastructure development, and government investments in smart cities are key catalysts. In contrast, mature markets will focus on renovation and retrofitting projects, where steel stringer stairs offer space-saving and seismic resilience benefits. -

Sustainability and Regulatory Influence

Environmental regulations and sustainability certifications (e.g., LEED, BREEAM) are influencing material selection. Steel, as a recyclable and long-lasting material, aligns with green building goals. Innovations in low-carbon steel production and the use of recycled content are expected to enhance the environmental profile of steel stringer systems. By 2026, compliance with fire safety, load-bearing, and accessibility standards will remain central to product development. -

Technological Integration and Smart Features

While still niche, the integration of smart technologies into stair systems is emerging. In high-end commercial and institutional applications, steel stringer stairs may incorporate integrated lighting, anti-slip sensors, or IoT-enabled monitoring for structural health. Though not yet widespread, these innovations represent a potential growth vector in premium segments.

Conclusion

By 2026, the steel stringer stairs market will be shaped by a convergence of structural performance, design innovation, and sustainable construction practices. Demand will be strongest in industrial, commercial, and urban residential sectors, with significant regional variation. Manufacturers and suppliers who invest in modular solutions, digital design tools, and eco-friendly materials will be best positioned to capture market share in this evolving landscape.

Common Pitfalls When Sourcing Steel Stringer Stairs: Quality and Intellectual Property Concerns

Sourcing steel stringer stairs involves more than just obtaining a quote—it requires careful attention to quality standards and intellectual property (IP) rights. Overlooking these aspects can lead to safety risks, project delays, legal disputes, and reputational damage. Below are key pitfalls to avoid.

Poor Material Quality and Non-Compliance

One of the most frequent issues is receiving steel stringers made from substandard materials. Suppliers may use under-spec steel alloys, incorrect thicknesses, or poor-quality welds to cut costs. This compromises structural integrity and fails to meet building codes such as OSHA, IBC, or local regulations. Always verify material certifications (e.g., mill test reports) and require third-party inspections when possible.

Inadequate Welding and Fabrication Standards

Weld quality directly impacts stair safety and longevity. Poor workmanship—such as incomplete welds, excessive spatter, or lack of penetration—can lead to premature failure. Ensure suppliers adhere to AWS D1.1 Structural Welding Code and provide welding procedure specifications (WPS). Request sample inspections or site audits of fabrication facilities.

Lack of Design Verification and Engineering Approval

Some suppliers offer “standard” stair designs without certified engineering stamps. Using unapproved designs risks non-compliance and liability. Always require stamped structural calculations and drawings from a licensed professional engineer, especially for custom or high-load applications.

Copying Proprietary Designs (IP Infringement)

A significant but often overlooked risk is unintentionally sourcing stairs that infringe on patented or copyrighted designs. Some manufacturers replicate patented stringer configurations, tread layouts, or connection details without authorization. Purchasers may face legal action even if unaware of the infringement. Conduct due diligence by asking suppliers to confirm design ownership or provide IP indemnification clauses in contracts.

Insufficient Documentation and Traceability

Missing or incomplete documentation—including as-built drawings, material test reports, and inspection records—complicates quality assurance and regulatory compliance. Ensure contracts require full traceability from raw materials to finished product, which is critical for audits and liability protection.

Hidden Costs from Rework and Delays

Low initial bids can mask future expenses. Inferior quality often leads to rejected shipments, on-site modifications, or complete re-fabrication. These delays disrupt project timelines and increase labor costs. Prioritize suppliers with proven quality management systems (e.g., ISO 9001 certification) to minimize such risks.

Failure to Secure Usage Rights for Custom Designs

If you commission a custom stair design, ensure your contract explicitly transfers IP rights or grants you perpetual usage rights. Otherwise, the fabricator may retain ownership, preventing replication or future modifications without permission or additional fees.

By proactively addressing these pitfalls, buyers can ensure they receive safe, compliant, and legally sound steel stringer stairs that meet both performance and regulatory requirements.

Logistics & Compliance Guide for Steel Stringer Stairs

Overview

Steel stringer stairs are critical structural components used in commercial, industrial, and residential construction. Proper logistics planning and adherence to compliance standards are essential to ensure safety, structural integrity, and regulatory approval. This guide outlines key considerations for the transportation, handling, installation, and regulatory compliance of steel stringer stairs.

Material Specifications and Standards

Steel stringer stairs must be fabricated in accordance with recognized standards to ensure structural reliability and safety. Key specifications include:

– ASTM A36/A36M: Standard specification for carbon structural steel.

– AISC 360: Specifications for structural steel buildings by the American Institute of Steel Construction.

– OSHA 1910.25: Standards for fixed industrial stairs, including dimensional requirements and load capacity.

– IBC (International Building Code): Governs stair dimensions, rise/run ratios, handrail requirements, and fire safety considerations.

– ANSI/ASC A117.1: Accessibility standards for stairs in public and commercial buildings.

Fabricators must provide mill test reports and certifications confirming compliance with applicable material standards.

Fabrication and Quality Control

- Fabrication must follow approved shop drawings and engineering designs.

- Welding procedures must comply with AWS D1.1 (Structural Welding Code – Steel).

- All welds should be inspected visually and, where required, via non-destructive testing (NDT).

- Dimensional accuracy must be verified prior to shipment to ensure compatibility with on-site connections.

- Galvanizing or protective coatings should meet ASTM A123 for corrosion resistance, especially in outdoor or corrosive environments.

Packaging and Handling

- Stairs should be bundled and secured to prevent movement during transit.

- Protective padding must be used on edges and connections to avoid damage to coatings or structural integrity.

- Marking: Each stair assembly should be clearly labeled with project name, item number, and handling instructions (e.g., “This End Up”).

- Lifting points must be designed into the stringer or indicated on drawings to ensure safe rigging during loading and installation.

- Avoid dragging or dropping; use cranes, forklifts, or spreader bars for movement.

Transportation Logistics

- Vehicle Selection: Use flatbed trucks or lowboys appropriate for the length and weight of the stairs. Oversize loads may require permits.

- Securement: Use rated chains, straps, and dunnage to prevent shifting. Comply with FMCSA (Federal Motor Carrier Safety Administration) tie-down regulations.

- Route Planning: Assess bridge weight limits, overheight clearances, and access roads to the jobsite.

- Lead Time: Coordinate delivery with site readiness to avoid on-site storage, which can lead to damage or theft.

On-Site Receiving and Storage

- Inspect stairs upon delivery for transport damage; document any issues with photos and reports.

- Store on level, dry ground with adequate support to prevent bending or warping.

- Elevate off the ground using timber dunnage to prevent moisture accumulation.

- Protect from weather and construction debris; use tarps if exposed to elements.

- Maintain clear access paths for crane or hoist operations during installation.

Installation Requirements

- Installation must be performed by qualified personnel following engineered erection plans.

- Verify alignment, level, and plumb before final bolting or welding.

- Anchor connections must meet design specifications (e.g., base plates, embedded bolts, or welded connections).

- Temporary bracing may be necessary during installation to ensure stability.

- Coordinate with other trades (e.g., concrete, framing) to avoid conflicts.

Safety and Compliance During Installation

- Follow OSHA fall protection standards (1926.501) when working at heights.

- Use proper PPE, including hard hats, gloves, safety glasses, and harnesses.

- Ensure stair treads and landings are installed promptly to provide safe access.

- Confirm that handrails and guardrails are installed per OSHA 1910.29 and IBC requirements.

- Conduct a pre-use safety inspection before the stairs are put into service.

Inspection and Certification

- Final inspection by a qualified structural engineer or building inspector may be required.

- Verify compliance with local building codes and permit conditions.

- Maintain as-built drawings, inspection reports, and material certifications for project documentation.

- Obtain a certificate of occupancy or approval where applicable.

Environmental and Disposal Considerations

- Recycle steel packaging materials and scrap metal in accordance with local regulations.

- Manage paint or coating waste per EPA or regional environmental guidelines.

- Control dust and fumes during field welding or cutting operations.

Conclusion

Proper logistics and strict compliance with industry standards are essential for the safe and effective use of steel stringer stairs. By adhering to this guide, project stakeholders can ensure structural performance, regulatory approval, and worker safety throughout the lifecycle of the stairs—from fabrication to final installation.

In conclusion, sourcing steel stringer stairs requires careful consideration of design specifications, material quality, fabrication standards, and compliance with relevant building codes. It is essential to partner with reputable suppliers or manufacturers who demonstrate expertise in structural steel fabrication and can provide certified materials and welds. Factors such as load requirements, environmental conditions, finish options, and lead times should be evaluated to ensure the stairs meet both functional and aesthetic needs. Proper coordination between design, engineering, and installation teams will help streamline the procurement process and ensure timely delivery and safe installation. Ultimately, a well-sourced steel stringer staircase offers durability, safety, and long-term value for commercial, industrial, or residential applications.