The global steel stair stringer market is experiencing steady growth, driven by rising construction activity and increased demand for durable, fire-resistant structural components in commercial, industrial, and residential buildings. According to Mordor Intelligence, the global steel structure market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, with stair stringers representing a critical component in modular and prefabricated steel frameworks. This growth is further fueled by urbanization, stringent building codes favoring steel in multi-story constructions, and advancements in manufacturing precision. As demand for engineered steel solutions rises, manufacturers specializing in high-quality steel stair stringer details are gaining prominence for their ability to deliver consistency, load-bearing reliability, and design flexibility. Based on market reach, production capabilities, and technical expertise, the following nine manufacturers have emerged as leaders in the supply of precision-engineered steel stair stringer components worldwide.

Top 9 Steel Stair Stringer Details Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Pre

Domain Est. 1998

Website: amezz.com

Key Highlights: Our industrial metal stairs can be designed to IBC or OSHA standards with many stair landing, tread and finish options available….

#2 American Stair

Domain Est. 1997

Website: americanstair.com

Key Highlights: Our products are fabricated by skilled craftsmen and we will put this experience and knowledge at your disposal to become your only steel stair supplier….

#3 Steel Profiles for Stair Applications

Domain Est. 2005

Website: stainless-structurals.com

Key Highlights: Our sharp cornered profiles in both carbon and stainless steel provide architects with a clean, modern look for stair applications….

#4 Formed Steel Stair Stringer

Domain Est. 2006

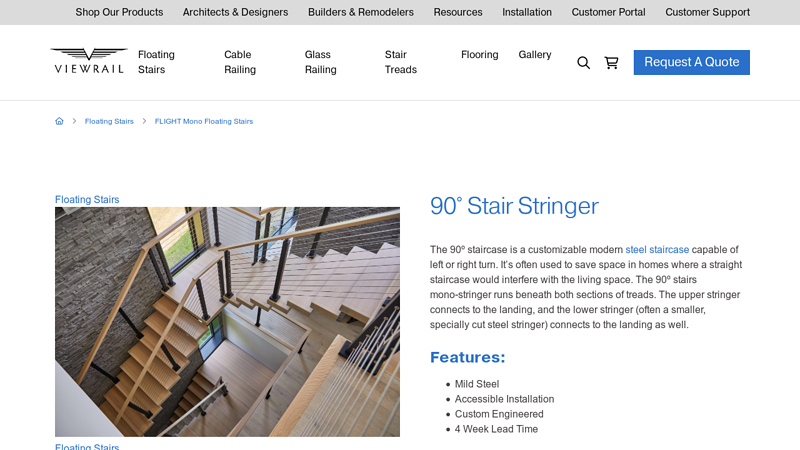

#5 Custom Mono & 90° Prefab Steel Stair Stringers

Domain Est. 2014

Website: viewrail.com

Key Highlights: 90 degree stair stringers are the perfect prefabricated stairs for your modern home. Contact an expert today for more information. Learn more….

#6 Metal Stair Treads and Stair Pans

Domain Est. 2023

Website: nationalstair.com

Key Highlights: Find a wide selection of metal stair treads, stair pans as well. Many metal types to choose from. Slip resistant, bar grating options available as well….

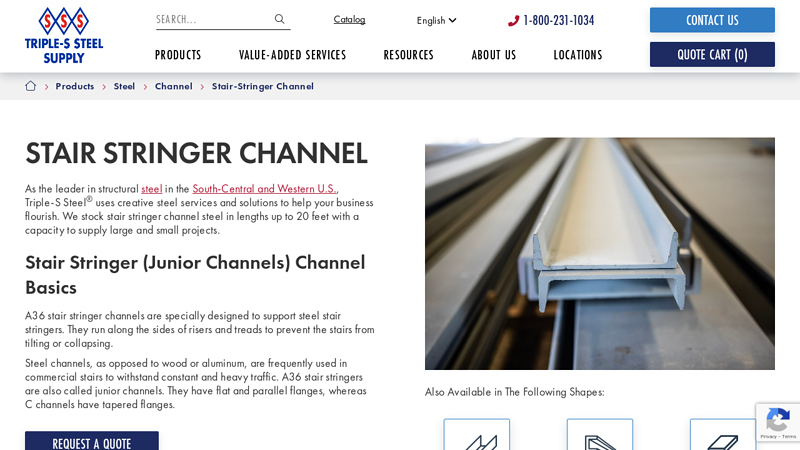

#7 A36 Stair Stringer Channel

Domain Est. 2024

Website: triple-s-steel.com

Key Highlights: We stock stair stringer channel steel in lengths up to 20 feet with a capacity to supply large and small projects to help your business flourish….

#8 Metal Stairs

Website: fast-stairs.com

Key Highlights: $70 deliveryFast-Stairs® are modular adjustable steel stair stringers for easy stair building in basements, lofts, attics, decks, garages and job sites….

#9 Buying Guide – Steel Stringers

Domain Est. 1999

Website: prestigemetal.com

Key Highlights: Prestige Metal is proud to offer you this steel stair stringers buying guide, which will tell you about the many facets and advantages of steel stringers….

Expert Sourcing Insights for Steel Stair Stringer Details

2026 Market Trends for Steel Stair Stringer Details

As we approach 2026, the construction and architectural engineering sectors are witnessing a significant evolution in the design, fabrication, and application of steel stair stringer details. Driven by advancements in materials science, digital design tools, sustainability demands, and regulatory changes, steel stair stringers are becoming more efficient, aesthetically refined, and adaptable to a wide range of structural needs. This analysis explores the key market trends shaping the future of steel stair stringer details in 2026.

Growing Demand for Prefabricated and Modular Solutions

One of the most prominent trends in 2026 is the rising adoption of prefabricated steel stair stringers. Off-site manufacturing allows for greater precision, reduced on-site labor, and faster project timelines—factors that align with the industry’s push toward modular construction. Steel stair stringers are increasingly being designed using Building Information Modeling (BIM), enabling seamless integration with other building systems and minimizing errors during installation. This shift is particularly evident in commercial, industrial, and multi-family residential developments where speed-to-completion is critical.

Emphasis on Sustainability and Low-Carbon Steel

Environmental regulations and green building certifications (such as LEED and BREEAM) are reshaping material choices in construction. In 2026, there is a growing preference for recycled and low-carbon steel in stair stringer fabrication. Manufacturers are investing in green steel technologies—such as hydrogen-based steel production—to reduce the carbon footprint of structural components. Designers are also optimizing stringer profiles to use less material without compromising strength, contributing to overall material efficiency and sustainability.

Integration of Advanced Design and Fabrication Technologies

Digital innovation continues to transform steel stair stringer detailing. By 2026, AI-assisted design tools and generative algorithms are being used to create highly optimized stringer geometries that reduce weight and material costs while maintaining structural integrity. CNC cutting, robotic welding, and laser templating have become standard in fabrication facilities, enabling complex, custom stringer configurations—including helical, cantilevered, and open-riser designs—that were previously difficult or costly to produce.

Aesthetic Customization and Architectural Expression

Steel stair stringers are no longer purely functional elements; they are increasingly treated as architectural features. In 2026, demand is rising for stringers with sculptural forms, exposed finishes (such as weathering steel or powder-coated surfaces), and integration with glass, wood, or composite treads. Architects and designers are leveraging the versatility of steel to create visually striking staircases in high-end residential, hospitality, and cultural buildings. This trend is supported by improved surface treatment technologies and greater collaboration between structural engineers and design professionals.

Regulatory and Safety Standards Evolution

Building codes and safety standards are becoming more stringent, especially regarding fire resistance, seismic performance, and fall protection. In 2026, steel stair stringers are being designed with enhanced fireproofing coatings and improved connection methodologies to meet higher resilience requirements. Additionally, there is a greater focus on universal design principles, with stringer configurations accommodating accessibility standards and inclusive mobility solutions.

Regional Market Variations

While global trends are converging, regional differences persist. In North America and Western Europe, the market is driven by renovation projects, sustainability mandates, and high labor costs—favoring prefabricated and automated solutions. In contrast, fast-growing markets in Asia-Pacific and the Middle East are seeing increased demand for steel stair stringers in high-rise developments and infrastructure projects, where structural efficiency and rapid construction are priorities.

Conclusion

By 2026, steel stair stringer details are at the intersection of technological innovation, environmental responsibility, and architectural creativity. The market is shifting toward smarter, leaner, and more sustainable solutions, supported by digital workflows and advanced manufacturing. As construction practices continue to evolve, steel stair stringers will play a pivotal role in shaping the future of safe, efficient, and visually compelling built environments.

Common Pitfalls When Sourcing Steel Stair Stringer Details (Quality, IP)

When sourcing steel stair stringer details—whether for architectural projects, industrial builds, or infrastructure developments—there are several recurring pitfalls related to quality control and intellectual property (IP) that can lead to project delays, cost overruns, or legal complications. Being aware of these risks helps ensure compliance, safety, and design integrity.

Poor Material Quality and Fabrication Standards

One of the most frequent issues is receiving steel stringers made from substandard materials or fabricated with poor workmanship. Low-quality steel may not meet required load-bearing specifications or corrosion resistance standards, compromising structural safety. Inadequate welding, incorrect hole placements, or dimensional inaccuracies can result in misalignment during installation, requiring costly rework.

To mitigate this, always verify that suppliers adhere to recognized standards such as ASTM, AISC, or EN specifications. Request material test reports (MTRs) and conduct third-party inspections when necessary.

Lack of Certified Engineering Documentation

Steel stair stringers must be designed to support specific loads and comply with building codes. A common pitfall is sourcing components without certified engineering drawings or structural calculations. Using unverified designs may violate local regulations and pose safety hazards.

Ensure that stringer details are stamped or signed by a licensed professional engineer, especially in jurisdictions requiring stamped drawings for permitting.

Inadequate Attention to Intellectual Property Rights

Architectural and structural designs, including customized steel stair stringer details, may be protected by copyright or design patents. Copying or reproducing detailed drawings from online sources, competitor products, or previous projects without permission can lead to IP infringement claims.

Always confirm the ownership of design files before manufacturing or installation. When working with design firms or fabricators, clarify licensing terms and ensure written agreements cover permitted use and redistribution rights.

Miscommunication in Design Specifications

Ambiguities in design documentation—such as unclear dimensions, finish requirements, or connection details—can result in incorrect fabrication. This often stems from using incomplete or outdated drawings, especially when sourcing from overseas suppliers unfamiliar with regional building practices.

Provide comprehensive, dimensionally accurate shop drawings and use standardized notation. Conduct pre-fabrication design reviews with all stakeholders to catch discrepancies early.

Failure to Verify Compliance with Building Codes

Different regions have specific requirements for stair geometry, guardrails, fire resistance, and seismic performance. Sourcing stringers designed for one region and using them in another without code adaptation can result in failed inspections or unsafe installations.

Always validate that the stringer design complies with local building codes (e.g., IBC, OSHA, or local municipal regulations) and accessibility standards like ADA.

Overlooking Surface Finish and Corrosion Protection

Steel stringers exposed to moisture or outdoor environments require proper surface treatment—such as galvanization, powder coating, or primer application. Skipping or skimping on protective finishes leads to premature rust and degradation.

Specify the required corrosion protection method and inspect delivered components for coating integrity before installation.

Conclusion

Sourcing steel stair stringer details involves more than just finding a low-cost supplier. Prioritizing quality assurance, regulatory compliance, and IP protection from the outset prevents costly setbacks and ensures long-term structural integrity and legal safety. Always vet suppliers thoroughly, demand proper documentation, and protect original design rights appropriately.

Logistics & Compliance Guide for Steel Stair Stringer Details

Material Specifications and Standards

Ensure steel stair stringers are fabricated in accordance with recognized industry standards such as ASTM A36 or ASTM A572 for structural steel. Materials must meet specified yield and tensile strength requirements. All steel must be accompanied by mill test reports (MTRs) certifying compliance with applicable specifications.

Design and Engineering Compliance

Steel stair stringer designs must be stamped and certified by a licensed professional engineer (PE). Designs shall comply with the International Building Code (IBC), American Institute of Steel Construction (AISC) 360, and Occupational Safety and Health Administration (OSHA) standards, particularly OSHA 1910.25 for stairways. Load calculations must include live loads (typically 100 psf), dead loads, and any dynamic or seismic considerations.

Fabrication Requirements

Stringers must be cut, welded, and assembled per approved shop drawings. All welds shall comply with AWS D1.1 Structural Welding Code – Steel. Welders must be certified, and welding procedures qualified. Fabrication tolerances should not exceed ±1/8 inch for overall dimensions and alignment.

Quality Control and Inspection

Implement a documented quality control plan including pre-fabrication reviews, in-process inspections, and final pre-shipment checks. Third-party inspections may be required for critical applications. Non-destructive testing (NDT), such as ultrasonic or magnetic particle testing, should be performed on major welds as specified in the project requirements.

Surface Preparation and Coating

Prior to coating, steel surfaces must be cleaned to SSP-SP6 (commercial blast cleaning) or better. Protective coatings shall be applied per project specifications—typically a primer (e.g., zinc-rich epoxy) with intermediate and finish coats as needed. Coating thickness must be verified using a DFT (Dry Film Thickness) gauge and recorded.

Marking and Traceability

Each steel stair stringer must be clearly marked with project ID, stringer designation, batch/heat number, and orientation (left/right, top/bottom). Markings should be paint-stenciled or tagged and remain legible throughout transport and installation.

Packaging and Handling

Stringers should be bundled securely using steel strapping or cradles to prevent deformation during handling. Contact points must be padded to avoid coating damage. Load-bearing edges and connection points should be protected with corner guards. Store horizontally on level supports to prevent warping.

Transportation and Shipping

Use flatbed trucks or enclosed trailers with adequate tie-down points. Secure loads with rated chains or straps and include dunnage to prevent shifting. Provide a detailed packing list and bill of lading with shipment. Comply with Department of Transportation (DOT) regulations for load securement and hazardous materials (if applicable).

Site Delivery and Receiving

Coordinate delivery schedules with the construction manager to avoid site congestion. Upon receipt, inspect stringers for transit damage, verify quantities, and confirm compliance with delivery documentation. Report discrepancies or damages immediately to the supplier and project team.

Regulatory and Safety Compliance

All operations—from fabrication to installation—must adhere to OSHA workplace safety standards. Fall protection, proper lifting equipment, and personal protective equipment (PPE) are mandatory during handling and installation. Maintain compliance records, including safety data sheets (SDS) for coatings and welding materials.

Documentation and Submittals

Submit the following prior to fabrication and shipment:

– Approved shop drawings

– Material test reports (MTRs)

– Welding procedure specifications (WPS) and PQRs

– Coating specifications and application records

– Inspection and test plans (ITP)

– As-built drawings upon completion

Ensure all documentation is archived for audit and certification purposes.

Conclusion for Sourcing Steel Stair Stringer Details:

Sourcing steel stair stringers requires careful consideration of structural requirements, material specifications, manufacturing standards, and project-specific design criteria. It is essential to collaborate with reputable suppliers or fabricators who adhere to industry standards such as AISC (American Institute of Steel Construction) or equivalent regional codes to ensure safety, durability, and compliance. Accurate detailing—including dimensions, connection methods, finish requirements, and load-bearing capacity—must be clearly communicated to avoid delays or fabrication errors. Additionally, factors such as lead times, cost, and logistics should be evaluated during the sourcing process to support timely project delivery. By thoroughly assessing technical, quality, and supply chain aspects, stakeholders can secure high-performing steel stair stringers that meet both design intent and regulatory requirements.