The global steel stair step manufacturing industry is experiencing steady growth, driven by rising infrastructure development, increasing demand in commercial and residential construction, and the material’s durability and cost-effectiveness. According to Grand View Research, the global steel construction market size was valued at USD 135.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth trajectory underscores the expanding need for high-quality steel components, including stair steps, across industrial, architectural, and urban development projects. As demand surges, a select group of manufacturers has emerged as leaders in innovation, scalability, and product reliability. Based on production capacity, geographic reach, technological integration, and market reputation, the following eight companies represent the top steel stair step manufacturers shaping the industry today.

Top 8 Steel Stair Step Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

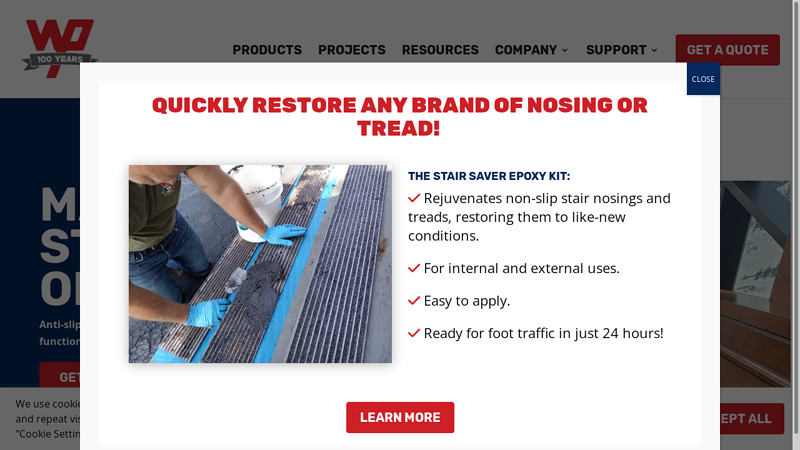

#1 Homepage

Domain Est. 2001

Website: woosterproducts.com

Key Highlights: Anti-slip stair treads & walkway products. Our stair safety products for new construction, renovation and OEM applications are built with proprietary compounds ……

#2 Lapeyre Stair

Domain Est. 1996

Website: lapeyrestair.com

Key Highlights: Compliant, prefabricated, and pre-engineered metal stairs designed to your exact specifications. The right systems for virtually any industrial application….

#3 Metal Stairs, Access & Work Platforms by ErectaStep

Domain Est. 2010

Website: erectastep.com

Key Highlights: Crafted from durable industrial-grade aluminum, our stair units, rolling steps, work platforms, and safety gates are proudly made in the USA, prefabricated, and ……

#4 L.J. Smith Stair Systems

Domain Est. 1997

Website: ljsmith.com

Key Highlights: LJ Smith is the largest stair parts manufacturing company in the country. Our continued growth over the past several decades is clearly a result of our ……

#5 American Stair

Domain Est. 1997

Website: americanstair.com

Key Highlights: Our products are fabricated by skilled craftsmen and we will put this experience and knowledge at your disposal to become your only steel stair supplier….

#6 Metal Staircase Co.

Domain Est. 2002

Website: metalstairs.com

Key Highlights: Our kit-form staircases are manufactured with complete accuracy and can be easily assembled with no need for complex skills….

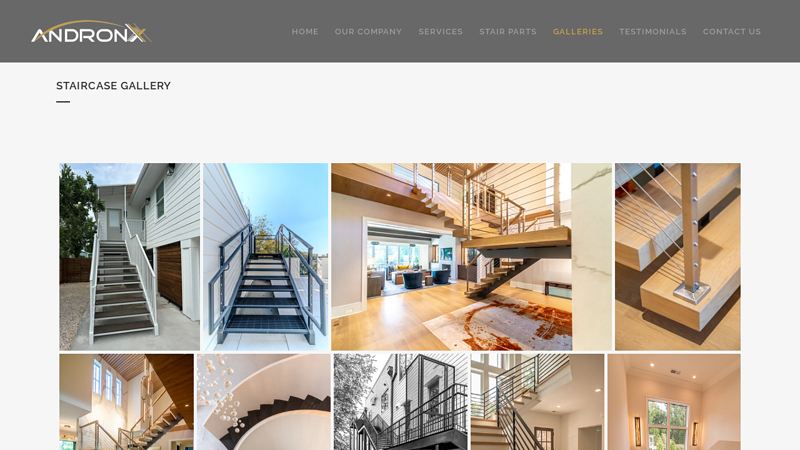

#7 Staircase Gallery

Domain Est. 2012

Website: andronx.com

Key Highlights: Ultra modern freestanding staircase, with open risers, glass railing and metal handrail by #andronxStairs in Charlotte NC….

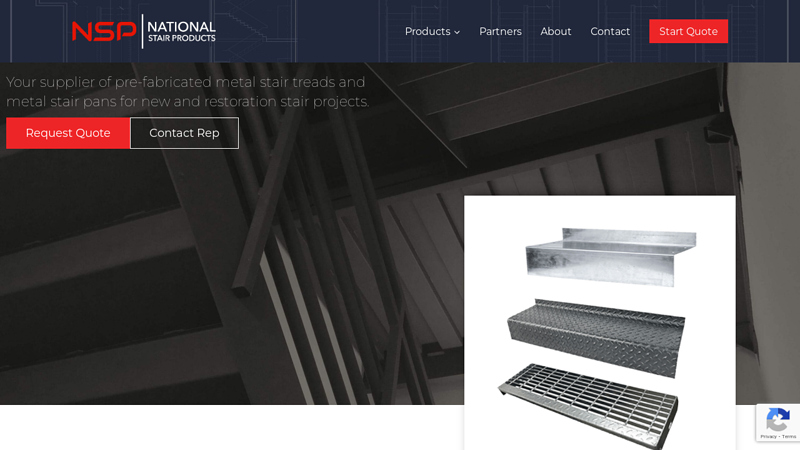

#8 Metal Stair Treads and Stair Pans

Domain Est. 2023

Website: nationalstair.com

Key Highlights: Find a wide selection of metal stair treads, stair pans as well. Many metal types to choose from. Slip resistant, bar grating options available as well….

Expert Sourcing Insights for Steel Stair Step

2026 Market Trends for Steel Stair Step

Global Demand and Market Growth

The global market for steel stair steps is projected to experience steady growth through 2026, driven by ongoing urbanization, infrastructure development, and advancements in construction technologies. According to industry forecasts, the construction sector—particularly commercial, industrial, and multi-residential projects—will remain a primary driver of demand. Emerging economies in Asia-Pacific, Latin America, and Africa are expected to account for a significant share of this growth due to rapid urban expansion and government-led infrastructure initiatives.

Steel stair steps, valued for their durability, fire resistance, and structural efficiency, are increasingly preferred over traditional materials like wood or concrete in both new builds and renovation projects. The global steel stair step market is anticipated to grow at a compound annual growth rate (CAGR) of approximately 4.5% from 2022 to 2026, reaching an estimated market value of USD 2.8 billion by the end of the forecast period.

Sustainability and Green Building Trends

A defining trend shaping the 2026 outlook for steel stair steps is the rising emphasis on sustainable construction. With green building certifications such as LEED, BREEAM, and WELL gaining global traction, architects and developers are favoring materials with high recyclability and low environmental impact. Steel, particularly recycled and low-carbon steel, aligns well with these sustainability goals.

Manufacturers are responding by integrating eco-friendly practices, such as using electric arc furnaces (EAF) for steel production and reducing embodied carbon in stair components. Additionally, modular and prefabricated steel stair systems are gaining popularity for their reduced construction waste and faster installation times—factors that contribute to more efficient, low-impact building processes.

Technological Advancements and Design Innovation

By 2026, digitalization and advanced manufacturing techniques will significantly influence steel stair step production. Building Information Modeling (BIM) is becoming standard in construction planning, allowing for precise design, customization, and integration of steel stair systems within complex architectural layouts. This enhances both aesthetic appeal and structural compatibility.

Furthermore, advancements in powder coating, anti-slip treatments, and corrosion-resistant alloys are improving the longevity and safety of steel stair steps. Design trends are also shifting toward minimalist, open-riser, and floating stair configurations, especially in modern commercial and high-end residential spaces. These designs not only offer visual lightness but also support open-plan layouts and improved spatial flow.

Regional Market Dynamics

The Asia-Pacific region is expected to dominate the steel stair step market by 2026, fueled by infrastructure investments in countries like China, India, and Indonesia. Government initiatives such as “Make in India” and China’s urban renewal programs are creating robust demand for industrial and commercial construction, where steel components are essential.

North America and Europe will maintain strong markets driven by renovation of aging infrastructure, stringent building codes, and a growing preference for modular construction. In Europe, regulatory support for circular economy principles is encouraging the use of reusable and recyclable steel elements, including stair systems.

Supply Chain and Raw Material Outlook

Steel stair step manufacturers face ongoing challenges related to steel price volatility and supply chain disruptions. However, by 2026, increased localization of production and strategic sourcing are expected to mitigate some of these risks. The adoption of just-in-time manufacturing and digital inventory systems will enhance supply chain resilience.

Additionally, the transition toward greener steel production—supported by government incentives and carbon pricing mechanisms—may influence long-term input costs. Producers investing in decarbonized steel will likely gain competitive advantage and align better with environmentally conscious clients.

Conclusion

By 2026, the steel stair step market will be shaped by converging forces of urban development, sustainability mandates, and technological innovation. Manufacturers that embrace modular solutions, eco-efficient materials, and digital design integration will be best positioned to capture market share. As construction evolves to meet environmental and efficiency demands, steel stair steps will continue to offer a durable, versatile, and future-ready solution across global building sectors.

Common Pitfalls When Sourcing Steel Stair Steps (Quality and Intellectual Property)

Sourcing steel stair steps involves more than just finding a low-cost supplier. Poor decisions can lead to compromised safety, legal issues, and long-term project delays. Below are some common pitfalls related to quality and intellectual property (IP) that buyers should be aware of.

1. Compromised Material Quality

One of the most frequent issues is receiving steel stair steps made from substandard materials. Some suppliers may use lower-grade steel that does not meet required tensile strength, corrosion resistance, or dimensional tolerances. This can result in premature wear, structural failure, or non-compliance with building codes.

Mitigation: Always verify material certifications (e.g., mill test certificates), request samples, and conduct third-party inspections when possible.

2. Inconsistent Welding and Fabrication Standards

Poor welding practices—such as incomplete welds, inconsistent bead quality, or lack of post-weld finishing—can significantly reduce the durability and safety of steel stair steps. Inconsistent fabrication also leads to fitment issues during installation.

Mitigation: Require proof of certified welders (e.g., AWS or ISO 3834), and include detailed welding specifications in your procurement documents.

3. Lack of Compliance with International Standards

Suppliers, especially in low-cost regions, may not adhere to internationally recognized standards such as ISO, ASTM, or EN. Non-compliant products can fail inspection, delay projects, or pose liability risks.

Mitigation: Clearly specify required standards in contracts and confirm compliance through documentation and independent testing.

4. Inadequate Surface Protection and Coating

Improper or thin galvanization, paint, or powder coating can lead to rapid corrosion, especially in outdoor or high-moisture environments. Some suppliers may cut corners by skipping surface prep steps like sandblasting.

Mitigation: Define coating thickness (e.g., microns for galvanizing) and require adhesion and salt spray test reports.

5. Intellectual Property Infringement

Using stair step designs that are patented or trademarked without authorization can lead to legal disputes, shipment seizures, or forced redesigns. This is particularly risky when sourcing from manufacturers that replicate branded or proprietary designs.

Mitigation: Conduct IP due diligence, obtain design authorization if needed, and include IP indemnity clauses in supplier contracts.

6. Copying Proprietary Designs Without Permission

Some suppliers may offer “compatible” or “equivalent” versions of branded stair systems, which may infringe on patents or design rights. Buyers can be held liable even if they were unaware of the infringement.

Mitigation: Avoid suppliers who advertise cloned or replica products. Work with original equipment manufacturers (OEMs) or licensed producers.

7. Poor Documentation and Traceability

Lack of proper documentation—such as drawings, material traceability records, or quality control reports—can hinder project approvals and audits. It also complicates root cause analysis if failures occur.

Mitigation: Require comprehensive documentation packages and ensure components are marked for traceability (e.g., heat numbers, batch IDs).

8. Overlooking Long-Term Supplier Reliability

Choosing a supplier based solely on initial pricing without assessing their long-term reliability, production capacity, or quality management systems can lead to inconsistent supply and quality drift over time.

Mitigation: Conduct supplier audits, review quality management certifications (e.g., ISO 9001), and establish performance metrics.

By proactively addressing these pitfalls, buyers can ensure they source steel stair steps that are safe, compliant, and free from intellectual property risks.

Logistics & Compliance Guide for Steel Stair Steps

Product Overview

Steel stair steps are structural components used in industrial, commercial, and residential applications to provide safe and durable access between levels. Typically fabricated from carbon steel, stainless steel, or aluminum, they must comply with regional building codes and safety standards. Proper logistics planning and regulatory compliance are essential to ensure timely delivery and legal use.

Material Specifications and Handling

Steel stair steps are often manufactured to order and vary in size, weight, and finish. They may be coated (e.g., galvanized, powder-coated) or left unfinished. Due to their weight and rigidity, appropriate handling equipment (e.g., forklifts, cranes) is required. Steps should be stored flat and protected from moisture to prevent corrosion during transit and storage.

Packaging and Unit Load Design

Each stair step should be securely bundled using steel strapping or wooden skids to prevent shifting. Protective corner guards and plastic wrapping help prevent surface damage. For international shipping, packaging must meet ISPM-15 standards if wood is used. Unit loads should be designed to optimize container or truck space while ensuring safe stacking and transport.

Transportation Requirements

Steel stair steps are typically shipped via flatbed trucks, dry van trailers, or sea containers. Oversized or heavy loads may require special permits and route planning. Proper load securing using tie-downs and dunnage is critical to prevent movement during transit. Temperature and humidity controls are generally not required, but exposure to rain or saltwater should be minimized.

Import/Export Documentation

For international shipments, essential documents include the commercial invoice, packing list, bill of lading, and certificate of origin. A material test report (MTR) may be required to verify steel composition and mechanical properties. Exporters should classify products under the correct HS code—typically 7308.90 (parts of structures of iron or steel).

Regulatory Compliance

Steel stair steps must comply with safety and construction standards such as:

– OSHA 1910.24–29 (U.S. workplace walking-working surfaces)

– IBC (International Building Code) for load capacity and dimensions

– EN 14122 (European standard for safe access to machinery)

– Local fire and accessibility codes (e.g., ADA in the U.S.)

Fabricators should provide certified drawings and load test reports when required.

Customs Clearance and Duties

Customs authorities may inspect shipments for conformity with declared specifications. Duties and tariffs vary by destination and material type (e.g., carbon vs. stainless steel). Importers should verify any anti-dumping or countervailing duties applicable to steel products from specific countries.

Quality Assurance and Inspection

Pre-shipment inspections should verify dimensions, weld quality, surface finish, and compliance with specifications. Third-party inspection services may be used for large orders or regulated environments. Documentation of inspections should be retained for traceability.

Environmental and Safety Considerations

Used oil, coatings, or cutting fluids from fabrication must be disposed of in compliance with environmental regulations (e.g., EPA in the U.S.). Workers handling steel steps must wear PPE (gloves, safety footwear) due to sharp edges and heavy weight.

Final Installation and Certification

Upon delivery, site supervisors should inspect for shipping damage. Installation must follow approved engineering drawings and be performed by qualified personnel. A final inspection and sign-off by a certified inspector may be required before use, especially in commercial or public buildings.

Conclusion for Sourcing Steel Stair Steps

In conclusion, sourcing steel stair steps requires a comprehensive approach that balances quality, cost, durability, and compliance with industry standards. Selecting the right supplier involves evaluating material specifications, manufacturing capabilities, lead times, and adherence to safety regulations such as OSHA or local building codes. Sustainable sourcing practices and long-term supplier relationships can further enhance value and reliability. By prioritizing these factors, organizations can ensure the acquisition of high-performance steel stair steps that meet structural requirements, contribute to safety, and support the overall efficiency and longevity of construction or industrial projects.