The global steel market continues to expand, driven by rising demand across construction, infrastructure, and manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global steel market was valued at USD 1.2 trillion in 2022 and is projected to grow at a CAGR of over 4.5% through 2028. This sustained growth underscores the critical role of specialized steel products—such as steel square stock—in industrial applications requiring high strength, durability, and precision. With increasing urbanization and infrastructure development, particularly in Asia-Pacific and North America, the demand for high-quality square steel sections has surged. As industries prioritize material efficiency and structural integrity, sourcing from reliable manufacturers becomes a strategic imperative. In this competitive landscape, identifying top-tier steel square stock producers is essential for businesses aiming to maintain supply chain resilience and product quality. Based on production capacity, global reach, certifications, and industry reputation, the following list highlights the leading manufacturers shaping the square steel segment.

Top 10 Steel Square Stock Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Structural Steel Tubes & Steel Pipes Manufacturer in India

Domain Est. 2010

Website: aplapollo.com

Key Highlights: APL Apollo Tubes Limited is the largest producer of Structural Steel Tubes in India. We have an extended distribution network of warehouses and branch offices ……

#2 Atlas Tube

Domain Est. 1995

Website: atlastube.com

Key Highlights: As the leading manufacturer of structural steel tube, we’re here to help you. From conceptual design through project completion, our engineering team, design ……

#3 Stainless Steel Tubing Manufacturing

Domain Est. 1995

Website: plymouth.com

Key Highlights: Plymouth Tube Company is a global specialty manufacturer of carbon alloy, nickel alloy, and stainless precision steel tubing….

#4 TW Metals: Specialty Metals Suppliers

Domain Est. 1997

Website: twmetals.com

Key Highlights: TW Metals stocks and processes Tube, Pipe, Bar, Extrusions, Sheet, and Plate in stainless, aluminum, nickel, titanium, and carbon alloy….

#5 Metals Supplier & Service Center

Domain Est. 1997

Website: sss-steel.com

Key Highlights: Triple-S Steel® and its subsidiaries are a leading distributor and service center of steel products and processing services. Learn more!…

#6 Tubular Steel

Domain Est. 1996

Website: tubularsteel.com

Key Highlights: Tubular Steel provides innovative tube and pipe solutions to help our customers reduce fabrication and manufacturing costs in a timely manner….

#7 Siskin Steel

Domain Est. 1997

Website: siskin.com

Key Highlights: Siskin Steel & Supply co stocks and processes Carbon, Stainless, Aluminum, & Alloy in thousands of shapes, sizes, and grades….

#8 Chicago Tube & Iron

Domain Est. 1997 | Founded: 1914

Website: chicagotube.com

Key Highlights: Founded in 1914, CTI is one of the largest specialty steel service centers in the United States, with nine locations throughout the Midwest and in Monterrey, ……

#9 Structural Steel Tubing

Domain Est. 1999

Website: eaglesteel.com

Key Highlights: We stock welded structural-grade steel square tubing in a wide variety of sizes and wall thicknesses. Made of the highest-strength steel, our square tubing can ……

#10 Square Steel Tubing Supplier

Domain Est. 2000

Website: tottentubes.com

Key Highlights: Totten Tubes is your best resource for square steel tubing. We aim to meet the needs of clients in every industry by offering many configurations and grades….

Expert Sourcing Insights for Steel Square Stock

H2: 2026 Market Trends for Steel Square Stock

As we move into the second half of 2026, the global market for steel square stock—solid or hollow structural steel bars with a square cross-section widely used in construction, manufacturing, and infrastructure—is experiencing a transformation driven by macroeconomic shifts, technological advancements, and evolving industrial demands. This analysis examines the key trends shaping the steel square stock sector during this period.

1. Resilient Demand from Construction and Infrastructure Sectors

Global infrastructure development remains a primary driver of demand for steel square stock in H2 2026. Government-led initiatives in North America, Europe, and parts of Asia—especially India and Southeast Asia—are accelerating public works projects, including urban transit systems, green buildings, and smart city developments. The U.S. Infrastructure Investment and Jobs Act and the European Green Deal continue to stimulate construction activity, where steel square stock is favored for its strength, versatility, and ease of fabrication. Additionally, the rise in modular and prefabricated construction methods further boosts demand due to the material’s compatibility with standardized building components.

2. Shift Toward Low-Carbon and Green Steel

Environmental regulations and corporate sustainability goals are pushing steel producers to adopt cleaner production technologies. In H2 2026, over 40% of new steel square stock in Europe and North America is produced using electric arc furnaces (EAF) powered by renewable energy or low-carbon hydrogen-based direct reduced iron (DRI) methods. Buyers, particularly in the commercial construction and renewable energy sectors, are increasingly specifying “green steel” with verified carbon footprints. This trend is reshaping supply chains and influencing pricing, with a 10–15% premium observed for certified low-carbon square stock.

3. Price Stabilization After Volatility

After experiencing price fluctuations in 2024–2025 due to raw material supply constraints and geopolitical tensions, steel square stock prices have stabilized in H2 2026. The normalization of iron ore and scrap metal markets, combined with improved global logistics and inventory rebalancing, has led to more predictable pricing. Average global prices are hovering around $780–$820 per metric ton, depending on grade and region. However, regional disparities persist, with Asia benefiting from overcapacity and lower prices, while North America and Europe face tighter margins due to higher regulatory and energy costs.

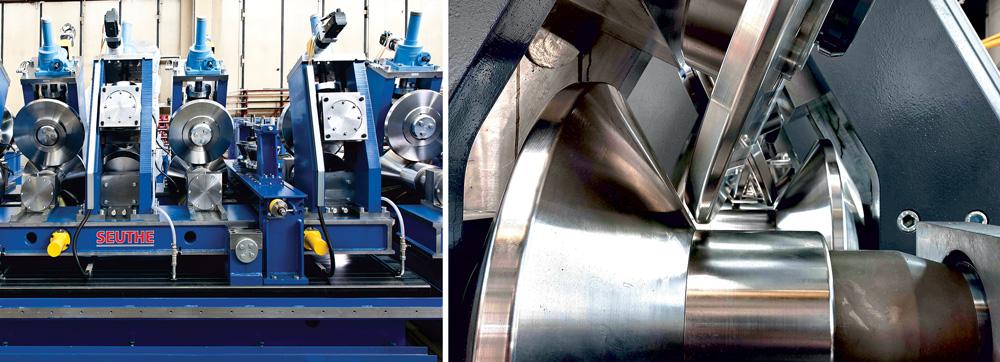

4. Technological Integration in Manufacturing and Distribution

Digitalization is transforming the steel square stock value chain. Major producers have adopted AI-driven production optimization, predictive maintenance, and real-time quality monitoring systems, improving yield rates and reducing waste. In distribution, blockchain-enabled traceability platforms are being used to verify material origin, quality, and sustainability credentials—especially important for large infrastructure contracts. Additionally, B2B e-commerce platforms are streamlining procurement, allowing buyers to compare grades, certifications, and delivery timelines with greater transparency.

5. Rising Competition from Alternative Materials

Despite strong demand, steel square stock faces increasing competition from composite materials, aluminum alloys, and engineered wood products—particularly in lightweight construction and non-load-bearing applications. However, steel maintains a dominant position in structural applications due to its unmatched strength-to-cost ratio. Innovations in high-strength, lightweight steel grades are helping manufacturers retain market share by offering improved performance without sacrificing durability.

6. Regional Market Dynamics

– Asia-Pacific: China remains the largest producer and consumer, but domestic demand growth is moderating due to a slowing real estate sector. India emerges as the fastest-growing market, driven by urbanization and industrialization.

– North America: Steady demand supported by infrastructure investment and reshoring of manufacturing. Trade policies continue to favor domestic production.

– Europe: Demand is strong but tempered by high energy costs and stringent environmental regulations. Recycling rates exceed 90%, reinforcing circular economy models.

– Middle East & Africa: Increasing investment in industrial parks and housing projects fuels demand, with Gulf Cooperation Council (GCC) countries leading regional growth.

Conclusion

In H2 2026, the steel square stock market is characterized by stabilization, sustainability, and strategic adaptation. While challenges such as material substitution and energy costs persist, the industry is responding with innovation, digital integration, and a strong focus on decarbonization. Producers and suppliers who prioritize quality, traceability, and environmental performance are best positioned to capitalize on long-term growth opportunities across global markets.

Common Pitfalls When Sourcing Steel Square Stock (Quality, IP)

Sourcing steel square stock involves navigating several potential challenges that can impact product quality, compliance, and overall project success. Being aware of these pitfalls—particularly those related to material quality and intellectual property (IP)—is essential for making informed procurement decisions.

Inadequate Verification of Material Specifications

One of the most frequent issues is assuming that all steel square stock meets required standards without proper verification. Buyers may accept mill certificates at face value without confirming chemical composition, mechanical properties (such as tensile strength and yield), or dimensional tolerances. This can lead to receiving substandard material unsuitable for critical applications, especially in industries like aerospace, automotive, or structural engineering.

Lack of Traceability and Certification

Proper traceability is crucial for quality assurance and regulatory compliance. Failing to source steel with full material traceability (e.g., heat numbers, mill test reports per ASTM, ISO, or EN standards) can result in rejected shipments, production delays, or safety risks. Without certified documentation, verifying the origin and processing history of the steel becomes impossible, increasing the risk of counterfeit or non-compliant materials.

Overlooking Surface and Dimensional Quality

Steel square stock may appear acceptable at first glance but can suffer from surface defects such as scale, cracks, pits, or uneven edges. Poor dimensional accuracy—such as out-of-tolerance sides or non-perpendicular corners—can compromise fit and function in machining or assembly processes. Relying on visual inspection alone without specified quality control checks often results in downstream manufacturing issues.

Misunderstanding Grade and Alloy Designations

Confusion between similar-sounding steel grades (e.g., 1018 vs. 1045, or A36 vs. 4140) can lead to incorrect material selection. Each grade has distinct properties affecting machinability, weldability, and strength. Sourcing the wrong grade due to miscommunication or lack of technical understanding can jeopardize product performance and safety.

Intellectual Property (IP) Risks in Custom or Proprietary Shapes

When sourcing custom-forged or specially processed square stock based on proprietary designs, there’s a risk of IP infringement if the supplier uses unauthorized tooling or replicates patented processes. Additionally, failure to secure IP rights in contracts may allow suppliers to reuse designs for competing customers, undermining competitive advantage and innovation.

Inadequate Supplier Vetting and Quality Management Systems

Partnering with suppliers lacking certified quality management systems (e.g., ISO 9001) increases the risk of inconsistent quality. Unaudited or offshore suppliers may cut corners in production or testing, especially when under cost pressure. Without on-site audits or third-party inspections, hidden quality issues may go undetected until after delivery.

Failure to Address Coatings and Corrosion Protection

For applications requiring corrosion resistance, assuming that all “stainless” or coated steel performs equally is a common mistake. Different grades (e.g., 304 vs. 316 stainless) offer varying resistance to environments. Inadequate specification of surface treatments—such as galvanizing, passivation, or oil coatings—can lead to premature failure in service.

Ignoring Supply Chain Transparency and Ethical Sourcing

Modern procurement must consider environmental, social, and governance (ESG) factors. Sourcing steel from suppliers with opaque supply chains may inadvertently involve materials from unethical sources or those violating environmental regulations. This not only poses reputational risks but may also conflict with corporate sustainability goals or regulatory requirements.

By proactively addressing these pitfalls—through rigorous specifications, supplier due diligence, proper documentation, and IP protection—buyers can ensure reliable, compliant, and high-quality steel square stock procurement.

Logistics & Compliance Guide for Steel Square Stock

Steel square stock is a widely used material in construction, manufacturing, and fabrication industries. Proper logistics planning and regulatory compliance are essential to ensure safe, efficient, and legally sound transportation and handling. This guide outlines key considerations for managing the logistics and compliance aspects of steel square stock shipments.

Classification and Specifications

Steel square stock is typically categorized by dimensions (side length and length), grade (e.g., ASTM A36, AISI 1018), finish (hot-rolled, cold-finished), and packaging (bundles, pallets, or loose). Accurate documentation of these specifications is critical for compliance with industry standards and international trade regulations.

Packaging and Handling Requirements

Proper packaging helps prevent damage during transit. Steel square stock should be:

– Bundled securely with metal strapping or banding

– Protected with edge guards or corner protectors to prevent deformation

– Separated with dunnage to avoid surface damage

– Labeled clearly with product details, batch numbers, and handling instructions

Ensure handling equipment (forklifts, cranes) are rated for the weight and dimensions of the bundles. Workers must follow OSHA safety guidelines when loading/unloading.

Domestic Transportation (U.S.)

When shipping steel square stock domestically:

– Use flatbed trailers or step-deck trailers depending on load height

– Comply with Federal Motor Carrier Safety Administration (FMCSA) tie-down and securement rules (49 CFR Part 393, Subpart I)

– Adhere to weight limits per axle and gross vehicle weight (typically 80,000 lbs on interstate highways)

– Ensure load overhang does not exceed legal limits (usually 3–4 feet beyond rear of vehicle; over 4 feet requires a flag or marker)

Carriers must have appropriate commercial driver’s licenses (CDL) and cargo insurance.

International Shipping and Export Compliance

For international shipments:

– Classify steel square stock under the correct Harmonized System (HS) code (e.g., 7216.40 for hot-rolled square bars)

– Comply with export regulations from the U.S. Department of Commerce, Bureau of Industry and Security (BIS), especially if dual-use or subject to EAR

– Obtain necessary export licenses if required

– Provide accurate commercial invoices, packing lists, and certificates of origin

– Be aware of anti-dumping and countervailing duties (AD/CVD) that may apply depending on the country of destination (e.g., imports from certain countries may be subject to U.S. trade remedies)

Import Regulations (U.S.)

Importers must:

– Declare steel square stock through U.S. Customs and Border Protection (CBP) using an Automated Broker Interface (ABI)

– Pay applicable duties based on origin and classification

– Comply with Section 232 tariffs if applicable (e.g., 25% tariff on steel imports under Section 232 of the Trade Expansion Act of 1962)

– Ensure conformity with ASTM, ASME, or other relevant standards

– Maintain records for at least five years for audit purposes

Hazardous Materials & Environmental Compliance

Steel square stock is generally not classified as hazardous. However, if coated with oils, paints, or other chemicals, it may require safety data sheets (SDS) under OSHA’s Hazard Communication Standard (HazCom). Ensure waste oils or packaging materials are disposed of in accordance with EPA regulations.

Quality and Certification Standards

Provide documentation such as:

– Mill test reports (MTRs) or certs of compliance

– Material traceability documentation

– Conformance to ASTM, ISO, or customer-specific standards

These documents support quality assurance and may be required for project acceptance or regulatory audits.

Storage and Inventory Management

Store steel square stock in a dry, level area to prevent corrosion and warping. Use racks or raised platforms to avoid ground moisture. Implement a first-in, first-out (FIFO) system to minimize long-term exposure and potential rust development.

Recordkeeping and Traceability

Maintain detailed records of:

– Shipment manifests

– Inspection reports

– Certifications

– Customs filings

– Customer delivery confirmations

Robust traceability ensures compliance during audits and facilitates recalls or investigations if necessary.

Conclusion

Efficient logistics and strict compliance are vital for the safe and legal movement of steel square stock. By adhering to transportation regulations, export/import requirements, and industry standards, businesses can minimize delays, avoid penalties, and ensure product integrity throughout the supply chain. Regular training for staff and engagement with certified freight partners further strengthen compliance efforts.

Conclusion for Sourcing Steel Square Stock:

Sourcing steel square stock requires careful consideration of material specifications, supplier reliability, cost-efficiency, and delivery timelines. By evaluating key factors such as grade, dimensions, tolerance, surface finish, and intended application, organizations can ensure they acquire material that meets both performance and regulatory standards. Additionally, building relationships with reputable suppliers, comparing quotes, and considering long-term supply agreements can enhance supply chain stability and reduce costs. Sustainable sourcing practices and adherence to quality certifications further support responsible procurement. Ultimately, a well-structured sourcing strategy for steel square stock contributes to improved production efficiency, product quality, and overall operational success in industries ranging from construction to manufacturing.