The global steel shelving rack market is experiencing steady growth, driven by rising demand across industrial, commercial, and retail sectors. According to a report by Mordor Intelligence, the global storage rack market was valued at USD 18.5 billion in 2023 and is projected to reach USD 25.3 billion by 2029, growing at a CAGR of 5.2% during the forecast period. This expansion is fueled by the rapid growth of e-commerce, increased warehouse automation, and the need for efficient space utilization in logistics and distribution centers. Additionally, rising construction activities and the expansion of cold storage infrastructure further bolster demand for durable and scalable steel shelving solutions. As the industry evolves, several manufacturers have emerged as leaders through innovation, global reach, and product reliability—shaping the competitive landscape of material handling equipment worldwide.

Top 10 Steel Shelving Rack Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 RMI

Domain Est. 1995

Website: mhi.org

Key Highlights: The Rack Manufacturers Institute, Inc. (RMI) members are the Industry’s leading suppliers of Industrial Steel Storage Racks and Related Structural Systems….

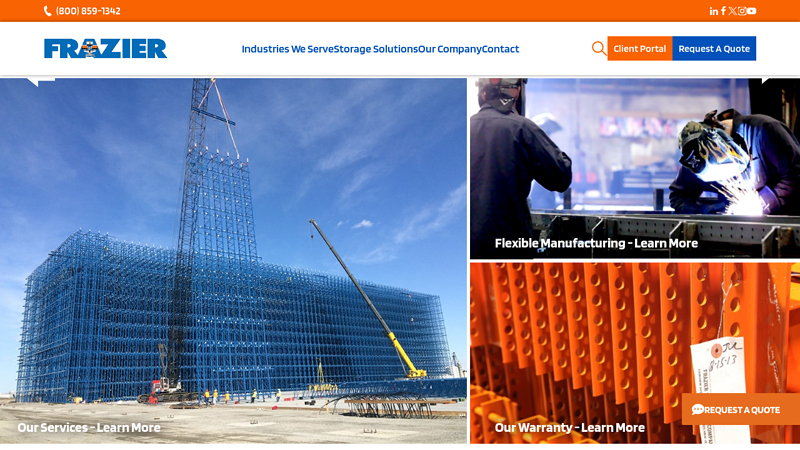

#2 Storage Racking System, Industrial Pallet Racks, Pallet Racking …

Domain Est. 1995

Website: frazier.com

Key Highlights: Frazier is the leading manufacturer of structural steel pallet racking storage systems for warehouses in the United States, Canada and Mexico….

#3 Steel King

Domain Est. 1998

Website: steelking.com

Key Highlights: Steel King is the nation’s single-source industrial rack manufacturer. We are a qualified industrial rack supplier that provides efficient material handling ……

#4 Republic Storage Products

Domain Est. 1999

Website: republicstorage.com

Key Highlights: Republic is a leading manufacturer of quality steel lockers! Available to be configured for a wide variety of locations and applications….

#5 Metro

Domain Est. 1997

Website: metro.com

Key Highlights: Metro is the global manufacturer for original Super Erecta wire shelving and a vast array of storage & productivity products….

#6 MuscleRack™ Heavy Duty Welded Steel Storage Racks

Domain Est. 1997

Website: edsal.com

Key Highlights: In stockIndustrial grade welded steel frames and beams · Easy to assemble in just minutes · Shelves can be easily adjusted in 1-1/2” increments to provide more ……

#7 North American Steel

Domain Est. 2000

Website: naseco.ca

Key Highlights: North American Steel provides customizable, high-performance steel storage and industrial racking systems for lasting facility improvements across industries….

#8 Shelving Direct

Domain Est. 2002

Website: shelvingdirect.com

Key Highlights: Shelving Direct provides heavy duty storage shelving solutions: including metal shelving, steel shelving, industrial shelving, warehouse shelving & more….

#9 Steel Storage Systems

Domain Est. 1996

Website: steelstorage.com

Key Highlights: Steel Storage Systems provides material handling and warehouse storage racking for steel products. Find the right steel storage racks for your needs!…

#10 Steel Shelving

Domain Est. 1997

Website: quantumstorage.com

Key Highlights: Here at Quantum Storage we offer a variety of heavy-duty steel shelving systems. Visit our website to see our inventory and place an order!…

Expert Sourcing Insights for Steel Shelving Rack

H2: 2026 Market Trends for Steel Shelving Racks

The global steel shelving rack market is poised for significant transformation by 2026, driven by evolving industrial demands, technological advancements, and shifting consumer behaviors. Key trends shaping the market include increased demand from e-commerce and logistics sectors, growing emphasis on sustainability, integration of smart warehouse technologies, and regional shifts in manufacturing and consumption.

One of the most prominent drivers is the exponential growth of e-commerce, which continues to fuel demand for efficient storage and warehouse solutions. Companies are investing heavily in automated and high-density steel shelving systems to optimize space and streamline order fulfillment. By 2026, modular and adjustable steel racks are expected to dominate due to their adaptability in dynamic warehouse environments.

Sustainability is another major trend influencing the steel shelving industry. As environmental regulations tighten and corporate sustainability goals become more stringent, manufacturers are shifting toward recycled steel and eco-friendly production processes. Consumers and businesses alike are favoring durable, recyclable storage solutions, positioning steel as a preferred material over plastic or wood alternatives.

Technological integration is also reshaping the market. Smart shelving systems—equipped with sensors, RFID tags, and IoT connectivity—are gaining traction, especially in automated distribution centers. These innovations allow for real-time inventory tracking, improved safety, and enhanced operational efficiency, making them a key focus area for leading manufacturers by 2026.

Regionally, Asia-Pacific is anticipated to lead market growth, supported by rapid industrialization, urbanization, and expansion of logistics infrastructure in countries like China, India, and Vietnam. Meanwhile, North America and Europe will see steady growth driven by warehouse automation and retrofitting of existing storage facilities.

In summary, the 2026 steel shelving rack market will be characterized by innovation, sustainability, and digital integration, with strong growth potential across both developed and emerging economies.

Common Pitfalls When Sourcing Steel Shelving Racks (Quality and Intellectual Property)

Poor Material Quality and Thickness

One of the most frequent issues when sourcing steel shelving racks is receiving products made from substandard materials. Suppliers may use thinner gauge steel than specified, which compromises load capacity and durability. This can lead to sagging shelves, structural failure, or safety hazards. Always verify material specifications (e.g., steel gauge and grade) and request mill certificates or material test reports.

Inconsistent Welding and Finish

Low-quality manufacturing often results in inconsistent or weak welds, which reduce the rack’s structural integrity. Additionally, poor surface finishing—such as uneven powder coating or rust spots—can indicate inadequate corrosion protection. Insist on factory audits or third-party inspections to assess welding quality and finish consistency.

Misrepresentation of Load Capacity

Some suppliers exaggerate the load rating of their shelving racks to win bids. Without proper engineering validation or third-party testing, these claims can be misleading. Ensure load capacities are backed by structural calculations or test certifications (e.g., from SGS or TÜV).

Lack of Compliance with International Standards

Steel shelving racks may fail to meet regional safety and quality standards such as ANSI/MH16.1 in the U.S. or EN standards in Europe. Non-compliant products can lead to regulatory issues or insurance complications. Confirm that the product adheres to relevant industry standards for your market.

Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers that copy patented designs—such as unique beam connections, upright frame profiles, or adjustability mechanisms—can expose buyers to IP litigation. Even if unintentional, importing infringing products may result in customs seizures or legal action. Conduct due diligence by checking patent databases and requiring suppliers to confirm original design or proper licensing.

Inadequate Design Documentation and Traceability

Many low-cost suppliers provide little or no technical documentation, such as assembly instructions, load charts, or CAD drawings. This lack of traceability complicates quality control, installation, and liability management. Always require comprehensive technical files before placing bulk orders.

Hidden Costs from Poor Packaging and Logistics

Poorly packed steel racks can suffer damage during transit, increasing replacement and labor costs. Some suppliers cut corners on packaging to reduce prices, but this leads to higher total cost of ownership. Clarify packaging standards upfront and include damage clauses in contracts.

Overlooking After-Sales Support and Spare Parts

If a supplier doesn’t offer spare parts or technical support, replacing damaged components becomes difficult. This can render entire systems obsolete after minor damage. Evaluate the supplier’s after-sales capabilities before finalizing procurement.

Logistics & Compliance Guide for Steel Shelving Racks

Product Classification and HS Code

Steel shelving racks are typically classified under the Harmonized System (HS) code 7308.90, which covers “structures and parts of structures, of iron or steel.” However, specific sub-classifications may vary by country. For example, in the United States, the HTS code might be 7308.90.99 for assembled or unassembled steel storage racks. Accurate classification ensures proper duty assessment and customs clearance.

Packaging and Handling Requirements

Steel shelving racks are commonly shipped in flat-packed, knock-down (KD) configurations to optimize space and reduce shipping costs. Packaging should include:

– Corrugated cardboard or wooden crates for uprights, beams, and accessories

– Protective corner guards and edge protectors to prevent damage

– Waterproof wrapping to prevent rust during transit

– Clearly labeled packages indicating contents, weight, and handling instructions (e.g., “This Side Up,” “Fragile”)

Ensure all shipments comply with carrier-specific stacking and weight limits.

Transportation and Shipping Modes

Steel shelving racks can be transported via:

– Ocean freight (FCL/LCL): Most cost-effective for bulk international shipments. Racks should be securely palletized and banded.

– Road freight: Ideal for regional or domestic delivery. Load distribution must comply with local weight and dimension regulations.

– Air freight: Rare due to high cost and weight, but used for urgent small-quantity shipments.

Use freight forwarders experienced in handling heavy industrial goods to ensure smooth transit.

Import/Export Documentation

Standard documentation includes:

– Commercial Invoice

– Packing List

– Bill of Lading (B/L) or Air Waybill (AWB)

– Certificate of Origin

– Import/Export Declaration (varies by country)

Ensure invoices include product descriptions, HS codes, country of origin, and total value to avoid customs delays.

Regulatory and Safety Compliance

Steel shelving racks must meet relevant safety and structural standards depending on the destination market:

– United States: Comply with standards from the Rack Manufacturers Institute (RMI) and OSHA regulations for workplace safety.

– European Union: Must meet EN 15512 (adjustable pallet racking systems) and EN 15635 (racking safety principles). CE marking may be required for certain components.

– Australia/New Zealand: Comply with AS 4084 for steel storage racking.

Provide technical documentation, load capacity charts, and installation manuals with each shipment.

Environmental and Sustainability Considerations

Steel shelving racks are 100% recyclable. Ensure manufacturing processes follow environmental standards such as ISO 14001. Some markets may require declarations on recyclability or use of recycled steel content under green building standards (e.g., LEED).

Installation and User Compliance

End-users must:

– Follow manufacturer installation guidelines

– Conduct regular inspections for damage or deformation

– Adhere to load capacity limits

– Comply with local fire safety regulations (e.g., sprinkler clearance requirements)

Include multilingual installation manuals and safety warnings where applicable.

Warranty and After-Sales Support

Clearly define warranty terms (typically 5–10 years for structural integrity) and provide accessible customer support. Offer spare parts logistics and technical assistance to ensure long-term compliance and safety.

Conclusion

Adhering to logistics best practices and regulatory requirements ensures safe, efficient delivery and legal compliance for steel shelving racks globally. Partner with certified suppliers and logistics providers to maintain quality and compliance across the supply chain.

Conclusion:

After a thorough evaluation of potential suppliers and market options, sourcing steel shelving racks from reputable manufacturers offers a reliable, cost-effective, and durable solution for storage needs. The selection process highlights the importance of considering factors such as material quality, load capacity, customization options, pricing, and supplier reliability. By partnering with suppliers that adhere to industry standards and offer strong after-sales support, businesses can ensure long-term value, operational efficiency, and scalability. Ultimately, investing in high-quality steel shelving racks not only optimizes space utilization but also contributes to improved inventory management and workplace safety. Strategic sourcing with a focus on total cost of ownership will lead to a sustainable and efficient storage infrastructure.