The global steel roof gutters market is experiencing steady growth, driven by rising construction activities, increased demand for durable building materials, and a shift toward sustainable infrastructure. According to Grand View Research, the global metal gutters market size was valued at USD 5.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is further supported by urbanization, especially in emerging economies, and growing preference for corrosion-resistant, long-lasting gutter systems like those made from galvanized and stainless steel. With North America and Europe leading in renovation projects and new residential construction, demand for high-performance steel gutters continues to rise. As a result, several manufacturers have emerged as key players, combining advanced production technologies, extensive product portfolios, and global distribution networks to capture market share. Based on performance, innovation, and industry presence, here are the top 9 steel roof gutters manufacturers shaping the future of rainwater management systems.

Top 9 Steel Roof Gutters Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Berridge Manufacturing Co.

Domain Est. 1996

Website: berridge.com

Key Highlights: For over 50 years Berridge has worked to set the standard by designing, developing and manufacturing superior architectural metal products and technology….

#2 Metal Roofing Manufacturer

Domain Est. 1998

Website: englertinc.com

Key Highlights: Englert Inc. is the gold standard and leading manufacturer of Metal Roofing and Gutter solutions, providing innovative and top quality metal products….

#3 GAF Roofing

Domain Est. 1996

Website: gaf.com

Key Highlights: As North America’s largest roofing manufacturer, GAF is an industry leader that produces quality, innovative roofing materials.Missing: steel gutters…

#4 McElroy Metal

Domain Est. 1996

Website: mcelroymetal.com

Key Highlights: McElroy Metal is the leading manufacturer of metal roofing, metal siding, and substructural components with locations across the United States. Learn more….

#5

Website: metalsales.us.com

Key Highlights: Metal Sales is the nation’s largest manufacturer of metal roofing, wall, and building systems. We are the most awarded and highly recognized provider of metal ……

#6 ABC Seamless

Domain Est. 1996

Website: abcseamless.com

Key Highlights: ABC Seamless offers roofing, gutters, and siding for your home. Call today to request your free estimate!…

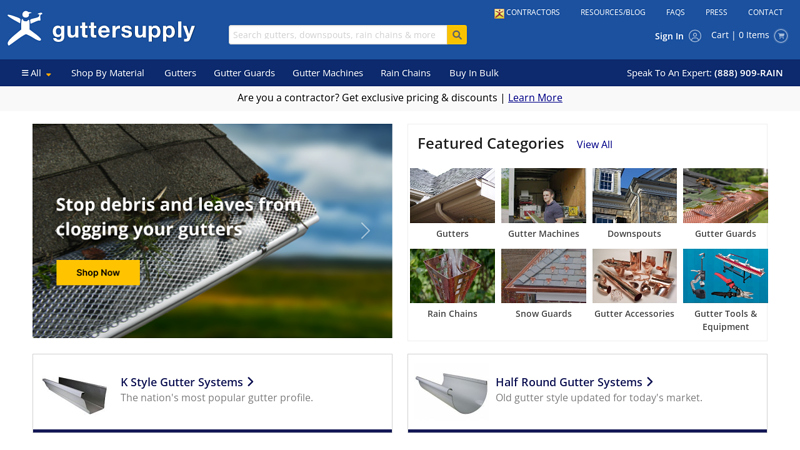

#7 Gutter Supply: Gutters

Domain Est. 2000

Website: guttersupply.com

Key Highlights: Welcome to Gutter Supply, your online reference for gutters, gutter machines, gutter guards and accessories. Come visit our selection of quality products….

#8 Berger

Domain Est. 2005

Website: bergerbp.com

Key Highlights: Find reliable guttering supply and essential roofing accessories with advanced roofing solutions to meet all your construction needs….

#9 Central States

Domain Est. 2020

Website: centralstatesco.com

Key Highlights: Central States is a 100% employee owned company who manufactures high quality metal roof, siding, and packages for buildings of all kinds….

Expert Sourcing Insights for Steel Roof Gutters

2026 Market Trends for Steel Roof Gutters

The steel roof gutters market is poised for notable transformation by 2026, driven by evolving construction practices, material innovations, and shifting consumer preferences. As sustainability and durability become paramount, steel—particularly coated and stainless variants—is gaining increased traction over traditional materials like aluminum and vinyl. Key trends shaping the market include:

Growing Demand for Premium, Long-Lasting Materials

Homeowners and commercial developers are increasingly prioritizing longevity and reduced maintenance. Steel gutters, especially those made from galvanized or stainless steel with advanced protective coatings, offer superior resistance to impact, high winds, and corrosion compared to aluminum or plastic alternatives. This durability appeals to markets in regions prone to extreme weather, supporting steady demand growth through 2026.

Advancements in Coating Technologies

Technological improvements in protective coatings—such as zinc-aluminum alloys (e.g., Galvalume®) and polymer-based finishes—are enhancing steel gutters’ resistance to rust and weathering. These innovations extend product lifespan and expand color and aesthetic options, making steel gutters more appealing for high-end residential and architectural projects. By 2026, coated steel is expected to dominate new installations in both retrofit and new-build segments.

Sustainability and Recyclability Driving Consumer Choice

With rising environmental awareness, the construction industry is favoring materials with lower lifecycle impacts. Steel is highly recyclable, often containing significant recycled content, aligning with green building standards like LEED and BREEAM. As building codes and consumer preferences emphasize eco-friendly materials, steel gutters are likely to gain market share over less sustainable options.

Expansion in Retrofit and Renovation Markets

Aging infrastructure in North America and Europe is fueling demand for roof gutter replacements. Homeowners upgrading older homes are opting for steel due to its strength and compatibility with historic or heavy roofing materials like slate or tile. The retrofit segment is projected to be a major growth driver for steel gutters by 2026.

Regional Divergence in Market Adoption

Growth will vary by region. North America and Western Europe are expected to lead in adoption due to higher disposable income and strict building codes. Meanwhile, emerging markets in Asia-Pacific may see slower uptake due to cost sensitivity, though urbanization and infrastructure development could spur future demand.

Increased Competition and Product Differentiation

Manufacturers are responding to market demands with value-added features such as seamless gutter systems, integrated leaf protection, and customizable profiles. This competition is driving innovation and improving cost-efficiency, making steel gutters more accessible and appealing across broader market segments.

In summary, by 2026, the steel roof gutters market will be characterized by technological innovation, sustainability focus, and strong demand in premium and renovation sectors, positioning steel as a leading material in modern gutter systems.

Common Pitfalls When Sourcing Steel Roof Gutters: Quality and Intellectual Property Risks

Sourcing steel roof gutters—especially from international or cost-driven suppliers—can expose buyers to significant quality and intellectual property (IP) pitfalls. Overlooking these issues may lead to product failure, safety hazards, legal disputes, and reputational damage. Below are key risks to consider.

Poor Material Quality and Specifications

One of the most frequent issues is receiving gutters made from substandard steel. Suppliers may use lower-grade materials than specified, such as thinner gauge steel or uncoated carbon steel instead of galvanized or aluzinc-coated variants. This compromises durability, leading to rust, warping, and premature failure—especially in harsh climates.

Inconsistent Coating and Corrosion Resistance

Steel gutters rely heavily on protective coatings (e.g., zinc, aluminum-zinc alloy) to resist corrosion. A common pitfall is inadequate or uneven coating application, which may not meet industry standards like ASTM A792 or EN 10346. Buyers may later discover premature rusting due to poor coating adhesion or insufficient thickness (microns), shortening the product lifespan.

Non-Compliance with Industry Standards

Many suppliers claim compliance with international standards but fail to provide verifiable test reports or certifications. Gutters that don’t meet structural load, wind uplift, or dimensional accuracy standards can fail under real-world conditions, posing safety risks and potential liability.

Lack of Quality Control and Testing

Inadequate in-process and final quality inspections can result in dimensional inaccuracies, poor weld integrity, and inconsistent finishes. Without third-party testing or factory audits, buyers risk receiving inconsistent batches that don’t fit or perform as expected.

Counterfeit or IP-Infringing Products

Some suppliers replicate patented gutter profiles, hidden hangers, or snap-together systems without authorization. Sourcing such products exposes buyers to intellectual property infringement claims, especially when importing into markets like the U.S. or EU. Legal actions can result in seized shipments, fines, or forced product recalls.

Misrepresentation of Manufacturing Origin

Suppliers may falsely claim that products are manufactured in countries known for high-quality steel production (e.g., Germany, Japan) when they are actually sourced from lower-cost regions with looser quality controls. This misrepresentation undermines brand trust and can breach labeling or procurement regulations.

Inadequate Documentation and Traceability

Lack of material test reports (MTRs), mill certifications, or batch traceability makes it difficult to verify steel composition and coating quality. Without proper documentation, resolving disputes or proving compliance during audits becomes challenging.

Hidden Costs from Rework and Warranty Claims

Initially low prices may be offset by high downstream costs due to defective installations, customer complaints, and warranty claims. Poor-quality gutters often require frequent maintenance or replacement, eroding profit margins and damaging customer relationships.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough supplier vetting, require independent quality inspections, verify IP rights, and insist on full documentation. Investing in reliable suppliers and due diligence upfront can prevent costly failures and legal issues down the line.

Logistics & Compliance Guide for Steel Roof Gutters

Product Overview and Specifications

Steel roof gutters are essential components of modern roofing systems, designed to channel rainwater away from building foundations. Typically made from galvanized steel, aluminum-coated steel, or stainless steel, they offer durability, resistance to corrosion, and long-term performance. Key specifications include gauge (thickness), length, profile type (e.g., K-style, half-round), and protective coatings. Accurate dimensions and material certifications must be maintained for compliance and quality assurance.

International and National Regulatory Standards

Steel roof gutters must comply with regional and international building codes and material standards. Key regulations include:

– ASTM A653/A653M (Standard Specification for Steel Sheet, Zinc-Coated) in the United States

– EN 14620 (European Standard for Site-Built Steel Refrigerated Cryogenic Vessels) for material strength and corrosion resistance

– AS/NZS 1365 (Tolerances for Flat-rolled Steel Products) in Australia and New Zealand

– Local building codes (e.g., International Building Code – IBC) governing load capacity, wind uplift resistance, and installation practices

Manufacturers and suppliers must ensure product conformity through third-party testing and certification where required.

Packaging and Handling Requirements

Proper packaging is critical to prevent damage during transit. Steel gutters should be:

– Bundled securely with protective end caps to prevent deformation

– Wrapped in moisture-resistant materials to avoid corrosion

– Labeled clearly with product type, length, coating type, and handling instructions

– Stored horizontally on flat, dry surfaces with adequate support to prevent bending

Use of edge protectors and shrink-wrapping is recommended for long-distance shipping.

Transportation and Freight Logistics

Steel gutters are typically transported via flatbed trucks, container freight, or specialized carriers. Key considerations:

– Maximize load efficiency by nesting or stacking without exceeding safe weight limits

– Secure loads with straps and edge guards to prevent shifting

– Comply with road transport regulations (e.g., load overhang restrictions, hazardous material classifications if coated with specific chemicals)

– For international shipments, ensure adherence to Incoterms (e.g., FOB, CIF) and customs documentation

Temperature and humidity controls may be necessary for coated steel products in extreme climates.

Import and Export Compliance

When shipping across borders, ensure compliance with:

– Harmonized System (HS) Codes: Typically 7308.90 (Other structural elements of iron or steel) or 7326.90 (Other articles of steel)

– Import duties, tariffs, and anti-dumping regulations (e.g., U.S. Section 232 tariffs on steel products)

– Documentation: Commercial invoice, packing list, certificate of origin, and material test reports (MTRs)

– Environmental and chemical regulations (e.g., REACH in the EU for coatings)

Engage customs brokers to streamline clearance and avoid delays.

Environmental and Sustainability Compliance

Steel gutter production and disposal must align with environmental standards:

– Use of recyclable materials (steel is 100% recyclable)

– Compliance with RoHS (Restriction of Hazardous Substances) if applicable to coatings

– Adherence to ISO 14001 for environmental management systems in manufacturing

– Reporting carbon footprint and energy use under local sustainability mandates (e.g., EPDs – Environmental Product Declarations)

Installation and On-Site Compliance

Installers must follow:

– Manufacturer’s technical guidelines for slope, hanger spacing, and expansion joints

– Local plumbing and building codes for drainage capacity and downspout placement

– Safety standards (e.g., OSHA in the U.S.) for working at heights and handling materials

– Inspection requirements by municipal or third-party authorities for code compliance

Proper installation ensures long-term performance and avoids liability issues.

Quality Assurance and Documentation

Maintain a traceable quality management system including:

– Mill test certificates for raw steel

– Coating thickness and adhesion test reports

– Dimensional inspection records

– Batch tracking and serial numbering for traceability

– Compliance with ISO 9001 standards for manufacturing and logistics processes

Conclusion

Effective logistics and compliance for steel roof gutters require coordinated attention to material standards, transportation safety, customs regulations, and environmental responsibilities. By adhering to this guide, manufacturers, distributors, and contractors can ensure product integrity, regulatory compliance, and customer satisfaction across global markets.

Conclusion for Sourcing Steel Roof Gutters

After a thorough evaluation of available materials, suppliers, and project requirements, sourcing steel roof gutters proves to be a durable, cost-effective, and aesthetically pleasing solution for long-term building performance. Steel gutters—particularly those made from galvanized or Colorbond®-coated steel—offer superior strength, resistance to environmental elements, and minimal maintenance needs compared to alternative materials like aluminum or vinyl.

The selection of a reliable supplier is critical to ensuring product quality, consistent availability, and compliance with industry standards. Factors such as lead times, pricing, customization options (e.g., color finishes, profiles), and after-sales support also significantly influence the decision-making process.

In conclusion, steel roof gutters present a reliable and sustainable choice for both residential and commercial applications. By partnering with reputable suppliers and selecting high-quality coated steel products, stakeholders can enhance the longevity and functionality of a building’s drainage system while maintaining architectural integrity. Proper installation and regular maintenance will further maximize the return on investment, making steel gutters a sound long-term solution in roof water management systems.