The steel manufacturing industry in the United States continues to demonstrate resilience and steady growth, with regional hubs like Cleveland, Ohio playing a pivotal role in national production. According to Grand View Research, the U.S. steel market was valued at approximately $113 billion in 2023 and is projected to expand at a compound annual growth rate (CAGR) of 3.8% through 2030, driven by rising demand from construction, automotive, and infrastructure sectors. Reinforcing this trend, Mordor Intelligence forecasts similar momentum, citing increased domestic production and government investments in manufacturing revitalization as key growth enablers. As a historic center for industrial manufacturing, Cleveland remains home to a cluster of influential steel producers that contribute significantly to regional output and innovation. This list highlights the top 9 steel manufacturing companies in Cleveland, Ohio, selected based on production capacity, operational footprint, innovation, and industry reputation—reflecting the city’s ongoing impact on the evolving American steel landscape.

Top 9 Steel Companies In Cleveland Ohio Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cleveland

Domain Est. 2004

Website: clevelandcliffs.com

Key Highlights: Cleveland-Cliffs is North America’s largest flat-rolled steel producer and supplier of iron ore pellets serving various industries, mainly automotive….

#2 Worthington Steel

Domain Est. 1999

Website: worthingtonsteel.com

Key Highlights: Premier value-added steel processor, producer of electrical steel laminations and automotive lightweighting solutions in North America and beyond….

#3

Domain Est. 2009

Website: jswsteel.us

Key Highlights: We are the only American mill offering small lot deliveries and utilizing proven UOE production technology for superior field performance….

#4 ArcelorMittal Ohio

Domain Est. 2021

Website: arcelormittal-oh.com

Key Highlights: Delivering high-quality products and demonstrating industry leadership by fostering innovation, embracing change, and setting standards in the ……

#5 Cleveland, Ohio

Domain Est. 1996 | Founded: 1954

Website: olysteel.com

Key Highlights: Discover Olympic Steel’s Cleveland, OH location founded in 1954, multiple buildings serving the Midwest, PA, & KY with steel & metal products….

#6 Mill Steel

Domain Est. 1996

Website: millsteel.com

Key Highlights: Explore our online store for a wide selection of ready to ship steel and aluminum products, backed by expert support and dependable delivery….

#7 Charter Steel

Domain Est. 1997

Website: chartersteel.com

Key Highlights: Based out of our Cleveland, OH facility, our highly automated rolling mill uses precision controls to produce bar in diameters from 3/4 inches (19.0 mm) to 3-1/ ……

#8 Specialty Steel

Domain Est. 1998

Website: specialtysteel.com

Key Highlights: Discover top-quality alloy, carbon, and stainless steel products at Specialty Steel. Your steel distributor with decades of experience….

#9 Universal Steel Company

Domain Est. 1999 | Founded: 1926

Website: univsteel.com

Key Highlights: The Universal Steel Company is a privately held Flat Rolled steel service center located in Northeast Ohio and serving the US since 1926….

Expert Sourcing Insights for Steel Companies In Cleveland Ohio

H2: Projected 2026 Market Trends for Steel Companies in Cleveland, Ohio

As the U.S. industrial landscape evolves, steel companies in Cleveland, Ohio, are poised to experience significant shifts by 2026, driven by technological innovation, infrastructure investment, supply chain dynamics, and sustainability mandates. Cleveland, historically a cornerstone of American steel production, continues to adapt to modern market forces, positioning its steel sector for strategic growth and transformation.

-

Infrastructure-Led Demand Surge

The Biden administration’s Infrastructure Investment and Jobs Act (IIJA), enacted in 2021, will continue to fuel demand for domestic steel through 2026. With over $1.2 trillion allocated to roads, bridges, rail systems, and clean energy projects, Cleveland-based steel producers—such as Cleveland-Cliffs Inc.—are expected to benefit from increased orders for structural and sheet steel. The Great Lakes region’s proximity to major construction corridors (e.g., I-75, I-90) enhances logistical advantages, supporting just-in-time delivery and reducing transportation costs. -

Reshoring and Supply Chain Resilience

Global supply chain disruptions have accelerated the trend of reshoring manufacturing operations to the U.S. By 2026, domestic automakers and heavy equipment manufacturers are projected to increase reliance on locally produced steel. Cleveland’s integrated steel mills and access to iron ore via Great Lakes shipping routes provide a competitive edge. Additionally, trade policies protecting domestic steel (e.g., Section 232 tariffs) are expected to remain in place, bolstering local production against low-cost imports. -

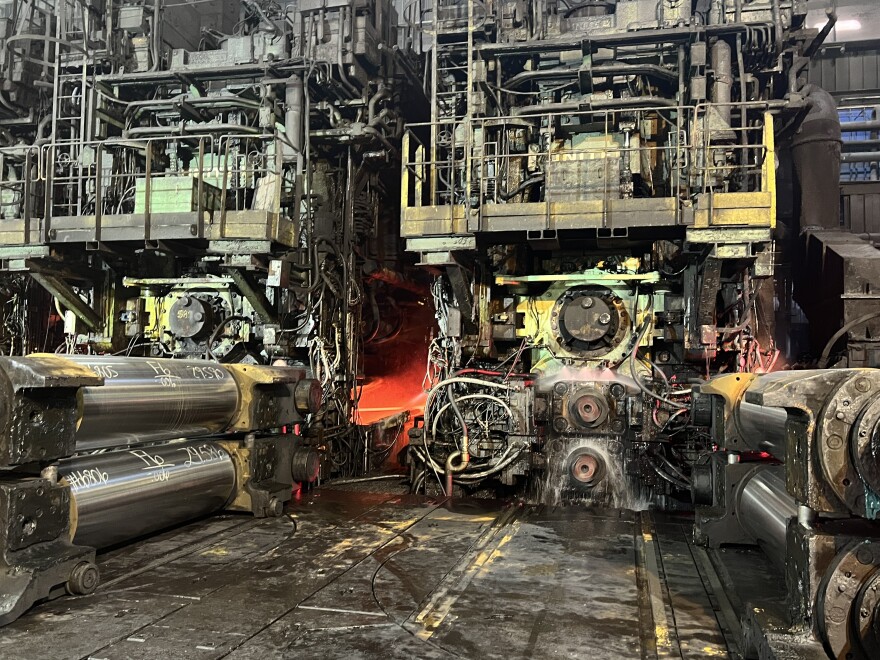

Technological Modernization and Automation

Steel companies in Cleveland are investing heavily in digital transformation. Predictive maintenance, AI-driven process optimization, and IoT-enabled monitoring systems are expected to be fully integrated into production lines by 2026. These advancements will improve energy efficiency, reduce downtime, and lower per-ton production costs. Cleveland-Cliffs’ ongoing modernization of its Cleveland Works facility exemplifies this shift, aiming to increase output while reducing emissions. -

Decarbonization and Sustainability Pressures

Environmental, Social, and Governance (ESG) criteria are reshaping the steel industry. By 2026, federal and state regulations are expected to tighten emissions standards, particularly around carbon intensity. Cleveland steelmakers are responding with initiatives to transition toward lower-carbon production methods, including increased use of electric arc furnaces (EAFs) and exploration of hydrogen-based direct reduced iron (DRI) technologies. Companies securing green financing or tax credits under the Inflation Reduction Act (IRA) will gain a competitive advantage. -

Workforce and Labor Market Dynamics

The aging workforce in traditional manufacturing remains a challenge. By 2026, Cleveland steel companies will likely face intensified competition for skilled labor, prompting partnerships with local community colleges (e.g., Cuyahoga Community College) and apprenticeship programs. Automation may offset some labor shortages, but upskilling will be critical to managing advanced production systems. -

Market Competition and Consolidation

Cleveland-Cliffs’ acquisition of AK Steel and ArcelorMittal USA has solidified its dominance in the Midwest. By 2026, further consolidation within the regional steel sector may occur as companies seek economies of scale and vertical integration. Smaller mills may face pressure to innovate or partner with larger entities to remain competitive.

Conclusion

By 2026, Cleveland’s steel industry is expected to emerge stronger, more efficient, and more sustainable, supported by federal investment, technological adoption, and regional economic resilience. While challenges around emissions, labor, and global competition persist, Cleveland’s strategic location, industrial heritage, and proactive corporate leadership position its steel sector for a pivotal role in America’s manufacturing renaissance.

Common Pitfalls When Sourcing Steel Companies in Cleveland, Ohio: Quality and Intellectual Property Concerns

Sourcing steel from companies in Cleveland, Ohio—historically a hub for steel manufacturing—can offer advantages in terms of industrial infrastructure and skilled labor. However, businesses must remain vigilant to avoid common pitfalls related to quality control and intellectual property (IP) risks. Understanding these challenges is essential for ensuring reliable supply chains and protecting proprietary interests.

1. Inconsistent Quality Standards

One of the primary concerns when sourcing steel is inconsistent product quality. While many Cleveland steel producers maintain high industry standards, some smaller or less-regulated suppliers may cut corners to reduce costs. This can result in variations in chemical composition, tensile strength, or surface finish, which may compromise the integrity of the final product. Buyers should verify certifications (such as ISO 9001 or ASTM compliance) and request material test reports (MTRs) for each batch.

2. Lack of Transparency in Manufacturing Processes

Some steel suppliers may not fully disclose their production methods, including whether the steel is produced from recycled materials or primary raw inputs. This lack of transparency can affect performance, especially in applications requiring specific metallurgical properties. It’s crucial to audit supplier operations or partner with third-party inspectors to confirm adherence to specified manufacturing protocols.

3. Substandard Coatings and Finishes

For applications requiring corrosion resistance or aesthetic precision, coatings and surface treatments are critical. Poor application or use of inferior coating materials can lead to premature degradation. Ensure suppliers follow industry standards (e.g., ASTM A123 for galvanizing) and conduct periodic quality checks on finished products.

4. Intellectual Property Risks in Custom Fabrication

When working with steel companies on custom-designed components or proprietary alloys, IP protection becomes a significant concern. Some suppliers may reuse design specifications, tooling, or formulations for other clients without consent. Always establish clear contractual terms, including non-disclosure agreements (NDAs) and clauses that define ownership of designs, molds, and technical data.

5. Unauthorized Reverse Engineering

In competitive markets, there is a risk that a supplier could reverse engineer a custom steel product to replicate or sell it to competitors. To mitigate this, limit the disclosure of sensitive information, use obfuscated designs where possible, and consider patenting unique innovations before engaging with third-party manufacturers.

6. Inadequate Documentation and Traceability

Poor record-keeping can hinder traceability in case of defects or compliance issues. Reliable steel suppliers should provide full material traceability—from raw material sourcing to finished product—including heat numbers and processing history. Lack of documentation may expose your business to regulatory or liability risks.

7. Overreliance on Verbal Agreements

Handshake deals are still common in regional manufacturing, but they leave room for misunderstandings, especially regarding quality expectations or IP rights. Always formalize agreements in writing, specifying tolerances, delivery timelines, inspection criteria, and IP ownership terms.

By proactively addressing these pitfalls—through due diligence, clear contracts, and ongoing supplier audits—businesses can leverage Cleveland’s strong steel industry while minimizing risks to quality and intellectual property.

Logistics & Compliance Guide for Steel Companies in Cleveland, Ohio

Overview of the Steel Industry in Cleveland

Cleveland, Ohio, has long been a hub for steel manufacturing and metal processing in the United States. With its strategic location along Lake Erie, access to major rail networks, and proximity to key industrial markets, Cleveland provides a strong logistical foundation for steel companies. However, operating in this sector requires strict adherence to federal, state, and local regulations, as well as efficient logistics planning to remain competitive.

Key Logistics Considerations

Transportation Infrastructure

Cleveland benefits from a robust multimodal transportation network, crucial for moving raw materials and finished steel products:

- Rail Access: Major freight railroads, including Norfolk Southern and CSX, serve the region, enabling cost-effective long-haul transport of bulk materials like iron ore, coal, and scrap metal.

- Port of Cleveland: As the only container port on Lake Erie, it facilitates Great Lakes shipping and connects to the St. Lawrence Seaway, allowing international and domestic waterborne freight.

- Highway Networks: I-71, I-90, and I-480 provide direct access to regional and national markets, supporting trucking operations for just-in-time deliveries.

- Intermodal Facilities: Facilities like the Cleveland Intermodal Terminal enhance efficiency by integrating rail and truck freight.

Supply Chain Management

Steel companies must maintain reliable supply chains for:

- Raw material procurement (scrap metal, iron ore, alloys)

- Timely delivery of finished products (coils, beams, plates)

- Inventory management of high-bulk, heavy goods

Adopting digital logistics platforms and real-time tracking systems helps optimize scheduling, reduce downtime, and improve customer service.

Regulatory Compliance Requirements

Environmental Regulations

Steel production is highly regulated due to environmental impacts. Key agencies and rules include:

- U.S. Environmental Protection Agency (EPA): Compliance with Clean Air Act (CAA) and Clean Water Act (CWA) standards is mandatory. Emissions from blast furnaces, coke ovens, and processing facilities must be monitored and controlled.

- Ohio Environmental Protection Agency (OEPA): State-level permits (e.g., air quality, wastewater discharge) must be obtained and renewed. OEPA conducts regular inspections.

- Stormwater and Spill Prevention: Facilities must implement Spill Prevention, Control, and Countermeasure (SPCC) plans and comply with stormwater discharge regulations under the National Pollutant Discharge Elimination System (NPDES).

Occupational Safety and Health

- OSHA Standards: Steel plants must comply with OSHA’s General Industry and Construction standards, including hazard communication, fall protection, lockout/tagout (LOTO), and machine guarding.

- Heat and Confined Space Protocols: Special attention is required for high-temperature operations and working in confined spaces like boilers and tanks.

- Cleveland-specific Enforcement: The Ohio Bureau of Workers’ Compensation (BWC) requires workplace safety programs and regular audits.

Hazardous Materials and DOT Compliance

- Department of Transportation (DOT) Regulations: Transporting hazardous materials (e.g., gases used in steelmaking) requires compliance with 49 CFR, including proper labeling, packaging, and driver training.

- Emergency Response Plans: Facilities must have plans in place for chemical spills or fires and coordinate with local emergency responders.

Permitting and Local Requirements

City of Cleveland Business Licensing

- All steel companies must register with the City of Cleveland and obtain appropriate business licenses.

- Zoning compliance is essential—industrial zones (e.g., M1, M2) govern where steel operations can be located.

Cuyahoga County and Regional Agencies

- Cuyahoga County Planning Commission: Monitors land use and development projects.

- Northeast Ohio Regional Sewer District (NEORSD): Regulates industrial wastewater discharges into the public sewer system.

Air Quality Permits

- Major sources of air pollution must obtain Title V operating permits under the EPA’s program, administered by OEPA.

- Routine emissions testing and reporting are required.

Best Practices for Compliance & Logistics Efficiency

Invest in Technology

- Implement ERP and supply chain management software to track compliance deadlines, shipments, and inventory.

- Use IoT sensors to monitor emissions, equipment performance, and safety conditions.

Employee Training

- Regular training on OSHA, DOT, and environmental compliance ensures that staff are aware of regulations and emergency procedures.

- Certifications in hazardous materials handling and forklift operation are recommended.

Partner with Local Authorities

- Engage with the Greater Cleveland Partnership and Enterprise Cleveland to stay informed on incentives and regulatory updates.

- Collaborate with the Port of Cleveland for export logistics and customs compliance.

Sustainability Initiatives

- Explore recycling scrap metal on-site and using electric arc furnaces to reduce carbon footprint.

- Participate in Ohio EPA’s Environmental Audit Privilege Program to proactively identify and correct compliance issues.

Conclusion

Steel companies in Cleveland, Ohio, operate in a dynamic environment with significant logistical advantages and complex compliance obligations. By leveraging the region’s transportation infrastructure and maintaining rigorous adherence to environmental, safety, and transportation regulations, steel manufacturers can achieve operational excellence and long-term sustainability. Staying informed, investing in training and technology, and building strong relationships with regulatory agencies are key to success in this vital industry.

In conclusion, sourcing steel companies in Cleveland, Ohio presents a strong strategic advantage due to the city’s rich industrial heritage, central location in the Midwest, and access to major transportation networks including rail, highway, and Great Lakes shipping routes. Cleveland is home to a mix of large-scale steel producers, specialized service centers, and distributors that offer a wide range of carbon, alloy, and stainless steel products. These suppliers often provide value-added services such as cutting, fabrication, and just-in-time delivery, which enhance supply chain efficiency for manufacturers and construction firms.

Additionally, many steel companies in the region are committed to sustainability and innovation, incorporating advanced manufacturing technologies and environmentally responsible practices. By partnering with local steel suppliers, businesses can benefit from reduced lead times, responsive customer service, and opportunities for long-term collaboration.

Overall, Cleveland’s established steel industry, skilled workforce, and robust infrastructure make it a reliable and competitive hub for sourcing high-quality steel products, supporting the needs of diverse sectors including automotive, construction, energy, and heavy equipment manufacturing.