The U.S. steel manufacturing sector continues to demonstrate steady resilience, supported by rising infrastructure investments and strong demand from construction and industrial applications. According to Grand View Research, the global steel market was valued at USD 1.47 trillion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 4.9% from 2023 to 2030, driven by urbanization and industrialization trends. Within this landscape, Charleston, SC has emerged as a regional hub for steel production, leveraging its strategic port access, skilled labor force, and favorable business climate. The presence of both established producers and innovative manufacturers has positioned the Lowcountry as a key player in the Southeast’s evolving industrial economy. As demand for high-quality, domestically produced steel grows, these Charleston-based manufacturers are expanding capacity, adopting advanced fabrication technologies, and contributing significantly to local and national supply chains.

Top 10 Steel Charleston Sc Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Owen Steel Company Inc.

Domain Est. 2001

#2 Charleston Steel & Metal Co

Domain Est. 2003

Website: business.greatersummerville.org

Key Highlights: Regional leader in metals recycling since 1893. Purchase all types of ferrous and non-ferrous metals and perform demolition and sale of usable steel. 4 area ……

#3 Steel & Metal Supplier in Charleston

Domain Est. 1996

Website: metalsupermarkets.com

Key Highlights: Rating 5.0 (286) Need metal in Charleston? We have over 8000 metal types, no order minimums, and value-added services. Ask us about pickup or delivery….

#4 Charleston Steel

Domain Est. 1997

Website: charlestonsteel.com

Key Highlights: Charleston Steel is a Structural Steel Fabricator and we are an AISC Certified shop. We are subject to annual evaluation and review….

#5 SC Steel

Domain Est. 1998

Website: scsteel.com

Key Highlights: For decades our team at SC Steel has been fabricating structural steel to hundreds of clients across the country. You will find that we are a diverse group ……

#6 Charleston Steel & metal: Metal and Steel Services

Domain Est. 2002

Website: charlestonsteelandmetal.com

Key Highlights: We have a large selection of usable steel for sale in the region. Learn more on how Charleston Steel and Metal can handle all your scrap metal and recycling ……

#7 Charleston Steel Company

Domain Est. 2003

Website: knightscompanies.com

Key Highlights: Expert Steel services in Charleston offering rebar, prestressed concrete, piling, and bridge solutions by Knight’s Companies for major infrastructure ……

#8 Pegasus Steel

Domain Est. 2003

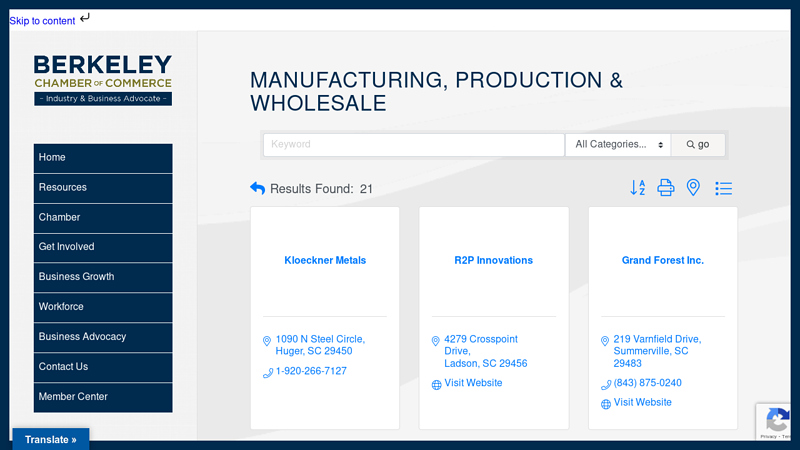

#9 Manufacturing, Production & Wholesale

Domain Est. 2004

Website: business.berkeleysc.org

Key Highlights: Charleston Steel and Metal Co. – Moncks Corner · 3038 Hwy 52. Moncks Corner SC 29461 · (843) 761-3161 · Visit Website….

#10 Metal Supplier Charleston

Domain Est. 2011

Website: kloecknermetals.com

Key Highlights: Charleston is a 120,000 sq. ft. facility. Products in Charleston include pattern size sheet and coil in hot rolled, floor plate, HRP&O, and cold rolled….

Expert Sourcing Insights for Steel Charleston Sc

H2: Projected 2026 Market Trends for Steel in Charleston, SC

As of 2026, the steel market in Charleston, South Carolina, is experiencing a period of strategic growth and transformation, driven by a combination of regional infrastructure development, port expansion, manufacturing resurgence, and evolving national trade policies. Charleston’s geographic and economic positioning as a major Southeastern logistics and industrial hub continues to amplify demand for structural and fabricated steel across multiple sectors.

-

Infrastructure and Construction Surge

Charleston is seeing increased public and private investment in infrastructure, including road expansions, bridge rehabilitation, and water system upgrades—many funded in part by the federal Infrastructure Investment and Jobs Act (IIJA). These projects are fueling demand for structural steel, particularly in bridge construction and large-scale public works. Additionally, Charleston County’s population growth is accelerating residential and commercial construction, with mid-rise developments and mixed-use complexes favoring steel framing for speed and durability. -

Port of Charleston Expansion

The ongoing $1.8 billion expansion of the Port of Charleston, including the development of the Hugh K. Leatherman Terminal and deeper harbor channels, is a major catalyst. The port’s growth increases demand for heavy steel in terminal infrastructure, cranes, and storage facilities. Moreover, as one of the busiest container ports on the East Coast, Charleston’s steel imports and exports are rising, positioning the region as a key node in domestic and international steel logistics chains. -

Advanced Manufacturing and Defense Sector Growth

Charleston’s manufacturing base—especially in aerospace (e.g., Boeing North Charleston), automotive (e.g., Volvo near Berkeley County), and shipbuilding—is expanding its use of high-strength and specialty steels. The Navy’s presence at Joint Base Charleston and ongoing ship repair activities at local shipyards further bolster demand for marine-grade steel. In 2026, local steel service centers report increased orders for precision-cut and pre-treated steel tailored to OEM specifications. -

Sustainability and Regulatory Influence

Environmental regulations and corporate sustainability goals are prompting steel buyers in Charleston to prioritize recycled-content steel and low-carbon production methods. Mills supplying the region are responding with increased transparency around Environmental Product Declarations (EPDs). Additionally, local building codes are gradually incorporating green construction standards, influencing material selection in favor of sustainable steel solutions. -

Supply Chain Resilience and Local Sourcing

After years of global supply chain disruptions, businesses in the Charleston area are emphasizing nearshoring and regional steel sourcing. This trend benefits regional producers and distributors in the Southeast, including those in the Carolinas and Georgia. Inventory management strategies now favor just-in-case over just-in-time models, leading to steadier steel order volumes even amid fluctuating prices. -

Labor and Workforce Development

A persistent challenge in 2026 remains the skilled labor shortage in steel fabrication and welding. However, partnerships between technical colleges (e.g., Trident Technical College) and industry groups are expanding apprenticeship programs, helping to close the gap and support continued growth in steel-dependent sectors.

In summary, the 2026 steel market in Charleston, SC, is characterized by strong demand from infrastructure, port-related projects, and advanced manufacturing, supported by strategic investments and regional economic momentum. While price volatility and workforce constraints remain concerns, the overall outlook for steel consumption and distribution in the Lowcountry is positive and poised for sustained growth through the mid-2020s.

Common Pitfalls When Sourcing Steel in Charleston, SC (Quality & Intellectual Property)

Sourcing steel in Charleston, SC—whether for construction, manufacturing, or industrial applications—offers logistical advantages due to the city’s port infrastructure and industrial base. However, buyers often encounter recurring challenges related to material quality and intellectual property (IP) protection. Being aware of these pitfalls can help mitigate risks and ensure a successful procurement process.

Inconsistent Material Quality Standards

One of the most common issues when sourcing steel in Charleston is variability in material quality. Suppliers may offer steel that meets basic ASTM standards on paper, but actual batches can deviate in chemical composition, tensile strength, or dimensional accuracy. This is particularly problematic when sourcing from secondary or smaller mills that may lack rigorous quality control systems. Buyers must verify certifications (e.g., Mill Test Reports) and consider third-party inspections to confirm compliance.

Lack of Traceability and Mill Certification

Without full traceability—such as heat numbers and certified mill test reports (MTRs)—it becomes difficult to verify the origin and properties of the steel. Some suppliers in the region may provide incomplete or falsified documentation, increasing the risk of receiving substandard or non-compliant material. Always insist on full documentation and validate it with the original mill when possible.

Counterfeit or Misrepresented Materials

The steel supply chain can be vulnerable to counterfeit products, especially for high-performance or specialty alloys. In Charleston’s competitive market, some suppliers may misrepresent lower-grade steel as higher-grade (e.g., passing off A36 as A572) to capture higher margins. This not only compromises structural integrity but also exposes the buyer to liability. Conducting independent material testing (e.g., PMI—Positive Material Identification) can help detect such fraud.

Intellectual Property Risks in Custom Fabrication

When sourcing custom-fabricated steel components, particularly for proprietary designs, there is a risk of intellectual property (IP) exposure. Some fabricators in the Charleston area may not have strong IP protection policies, potentially leading to unauthorized replication or sharing of design specifications. Always use clear contracts with non-disclosure agreements (NDAs) and IP ownership clauses before sharing sensitive blueprints or engineering files.

Inadequate Supplier Vetting

Many buyers fall into the trap of selecting suppliers based solely on price or proximity, without conducting thorough due diligence. This can result in partnerships with vendors who lack the certifications (e.g., ISO, AISC) or track record needed for consistent quality and IP protection. Conduct site audits, request client references, and verify supplier credentials before finalizing contracts.

Supply Chain Disruptions Affecting Quality

Charleston’s coastal location makes it susceptible to weather-related disruptions (e.g., hurricanes, flooding), which can impact storage and handling of steel. Poor storage practices during such events can lead to corrosion or physical damage, degrading material quality before delivery. Ensure suppliers have proper warehousing and contingency plans in place.

Failure to Define Specifications Clearly

Ambiguous purchase orders or vague specifications increase the risk of receiving steel that technically meets a standard but doesn’t fulfill functional requirements. Clearly define grades, tolerances, surface finish, coating requirements, and testing protocols in all procurement documents to avoid disputes and ensure quality alignment.

By proactively addressing these common pitfalls—through rigorous vetting, clear contracts, independent verification, and strong IP safeguards—buyers can confidently source high-quality steel in Charleston, SC while protecting their technical and commercial interests.

Logistics & Compliance Guide for Steel Operations in Charleston, SC

Overview of the Charleston, SC Steel Market

Charleston, South Carolina, is a strategic hub for steel logistics due to its deep-water port, robust transportation infrastructure, and proximity to key industrial and construction markets across the Southeast. The Port of Charleston, operated by the South Carolina Ports Authority (SCPA), is one of the busiest container terminals on the U.S. East Coast, facilitating efficient import and export of steel products such as coils, plates, beams, and rebar. Steel operations in the region support sectors including automotive manufacturing, shipbuilding, infrastructure development, and energy projects.

Port Infrastructure and Steel Handling Capabilities

The Port of Charleston features specialized facilities for handling steel cargo at terminals such as Columbus Street Terminal and North Charleston Terminal. These locations are equipped with heavy-lift cranes, steel racks, and secure storage yards designed to manage both inbound and outbound steel shipments. The port supports breakbulk, roll-on/roll-off (RoRo), and containerized steel products. Additionally, on-dock and near-dock rail services via CSX and short-line rail providers enable seamless intermodal transfers, reducing truck congestion and transit times.

Transportation and Distribution Networks

Charleston’s steel logistics benefit from a well-connected multimodal transportation network. Interstate 26 links the port to inland markets in Georgia, North Carolina, and beyond, while proximity to I-95 enhances north-south freight movement. Regional trucking companies and national carriers offer last-mile delivery services tailored to steel products, including flatbed and step-deck trailers. Rail access supports bulk movements to major manufacturing centers, reducing per-unit transportation costs. Efficient drayage operations between the port and regional distribution centers ensure timely delivery to end users.

Regulatory and Environmental Compliance

Steel operations in Charleston must comply with federal, state, and local regulations. Key compliance areas include:

- U.S. Customs and Border Protection (CBP): All imported steel is subject to entry filing, tariff classification, and potential anti-dumping (AD) or countervailing duty (CVD) investigations. Steel shipments must be accompanied by accurate Harmonized Tariff Schedule (HTS) codes and documentation such as commercial invoices and packing lists.

- Environmental Protection Agency (EPA) and SCDHEC: Facilities storing or processing steel must adhere to stormwater management regulations under the National Pollutant Discharge Elimination System (NPDES). Spill prevention, proper waste disposal, and air quality standards apply, especially for operations involving cutting, coating, or galvanizing.

- Occupational Safety and Health Administration (OSHA): Employers must follow safety protocols for handling heavy materials, operating cranes, and working in industrial environments. This includes fall protection, machine guarding, and hazard communication standards.

- SC Department of Transportation (SCDOT): Oversized or overweight steel loads require permits for road transport. Compliance with axle weight limits and routing restrictions is mandatory.

Trade Compliance and Steel-Specific Regulations

Importers and exporters of steel must navigate specific trade measures:

- Section 232 Tariffs: Under Section 232 of the Trade Expansion Act, certain steel articles from designated countries are subject to a 25% tariff. Proper country-of-origin documentation is essential for tariff assessment and potential exclusions.

- Buy American and Infrastructure Requirements: Public infrastructure projects funded by federal dollars often require the use of domestically produced steel, per Buy American provisions. Contractors must certify steel sourcing accordingly.

- Customs-Trade Partnership Against Terrorism (C-TPAT): Participation is encouraged for supply chain security. Members receive benefits such as reduced inspections and expedited processing at the border.

Best Practices for Efficient Steel Logistics

To optimize steel operations in Charleston:

- Partner with licensed freight forwarders and customs brokers experienced in steel commodities.

- Utilize port-based inventory management systems for real-time tracking of steel stock.

- Schedule off-peak deliveries to minimize port congestion and reduce demurrage/detention charges.

- Conduct regular compliance audits to ensure adherence to trade, safety, and environmental standards.

- Leverage Charleston’s Foreign Trade Zone (FTZ) status to defer, reduce, or eliminate duties on imported steel used in manufacturing or re-export.

Conclusion

Charleston, SC, offers a competitive advantage for steel logistics through its modern port infrastructure, multimodal connectivity, and favorable business climate. Success in this market requires a thorough understanding of compliance obligations and proactive supply chain management. By aligning with regulatory requirements and leveraging local resources, steel operators can achieve efficient, cost-effective, and compliant operations in the Charleston region.

In conclusion, sourcing steel in Charleston, SC offers numerous advantages due to the city’s strategic location, robust infrastructure, and proximity to major ports and transportation networks. Charleston’s growing industrial sector and strong presence of steel suppliers, fabricators, and distributors provide businesses with reliable access to high-quality materials for construction, manufacturing, and infrastructure projects. Additionally, the region’s skilled workforce and supportive business environment further enhance the efficiency and cost-effectiveness of steel procurement. Whether sourcing carbon steel, structural steel, or custom-fabricated components, companies can benefit from competitive pricing, timely delivery, and responsive service from local suppliers. By leveraging Charleston’s logistical strengths and established supply chain networks, businesses can ensure a steady and sustainable steel supply to meet their project demands.