The commercial foodservice equipment market is experiencing steady expansion, driven by increasing demand from restaurants, catering services, and institutional kitchens. According to a report by Mordor Intelligence, the global commercial kitchen equipment market size was valued at USD 67.3 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. A key component within this ecosystem is steam table pans, which standardize food portioning and temperature maintenance across operations. With rising emphasis on efficiency, hygiene, and kitchen workflow optimization, the demand for standardized, high-quality steam table pans has intensified. This growth has catalyzed innovation and competition among manufacturers focusing on durability, material quality (primarily 18/8 and 18/0 stainless steel), and compatibility with NSF-certified equipment. As the market evolves, nine key manufacturers have emerged as leaders in producing a full range of steam table pan sizes—from full, half, and third pans to specialty depths—meeting the exacting needs of modern foodservice operations worldwide.

Top 9 Steam Table Pan Sizes Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Steam Table Pans

Domain Est. 1996

#2 Hotel Pans – Stainless Steam Table Pans

Domain Est. 1997

#3 Winco SPTT2 14 Inch Steam Table Pan 2/3 Size 25 Gauge Stainless …

Domain Est. 1998

Website: restaurantsupply.com

Key Highlights: This 2/3 size pan measures 14 inches by 12-7/8 inches with a depth of 2-1/2 inches, constructed from 18/8 stainless steel with a 25 gauge standard weight, ……

#4 Hotel Pan Sizes & Dimensions (with Chart)

Domain Est. 2003

Website: webstaurantstore.com

Key Highlights: Full size food pans are the standard in the foodservice industry, measuring approximately 20 3/4″ x 12 3/4″. All other sizes of food pans are simply a ……

#5 Winco SPH2 1/2 Size Steam Table Pan

Domain Est. 2014

Website: kitchenrestock.com

Key Highlights: In stock Rating 5.0 7 The Winco SPH2 Steam Table Pan 1/2 Size 10-3/8″ X 12-3/4″ X 2-1/2″ Deep is a versatile piece of equipment designed for the food service industry, particular…

#6 Steam Table Pans & Accessories

Domain Est. 2017

Website: vollrathfoodservice.com

Key Highlights: Our steam table pans (or hotel pans) and accessories are designed to look elegant and impress your customers while enduring the toughest of kitchens….

#7 Half-Size Deep Aluminum Steam Table

Domain Est. 2020

#8 Half Size Steam Table Pan Racks

Domain Est. 2020

Website: pvimanufacturing.com

Key Highlights: All Welded Aluminum Slides. 1″ H x 1 1/2″ W. Holds Following Pan Sizes by the Lip. Full Size 20 3/4″ x 12 3/4″; Half Size 10 3/8″ x 12 3/4″; Two-Third Size ……

#9 What are Hotel Pans?

Domain Est. 1996

Website: wasserstrom.com

Key Highlights: Shop for half size hotel steam table pans. Half Pan. 12″ x 10″. 2 ½” – 4.3qt; 4″ – 6.6qt; 6″ – 9.4qt; 8″ – 11qt. Shop for half size long hotel ……

Expert Sourcing Insights for Steam Table Pan Sizes

2026 Market Trends for Steam Table Pan Sizes

The commercial foodservice industry is evolving rapidly, and steam table pan sizes are adapting to meet emerging demands. As we approach 2026, several key trends are shaping the market for steam table pan sizes, driven by operational efficiency, sustainability goals, menu innovation, and labor challenges.

Standardization with Flexibility Remains Core

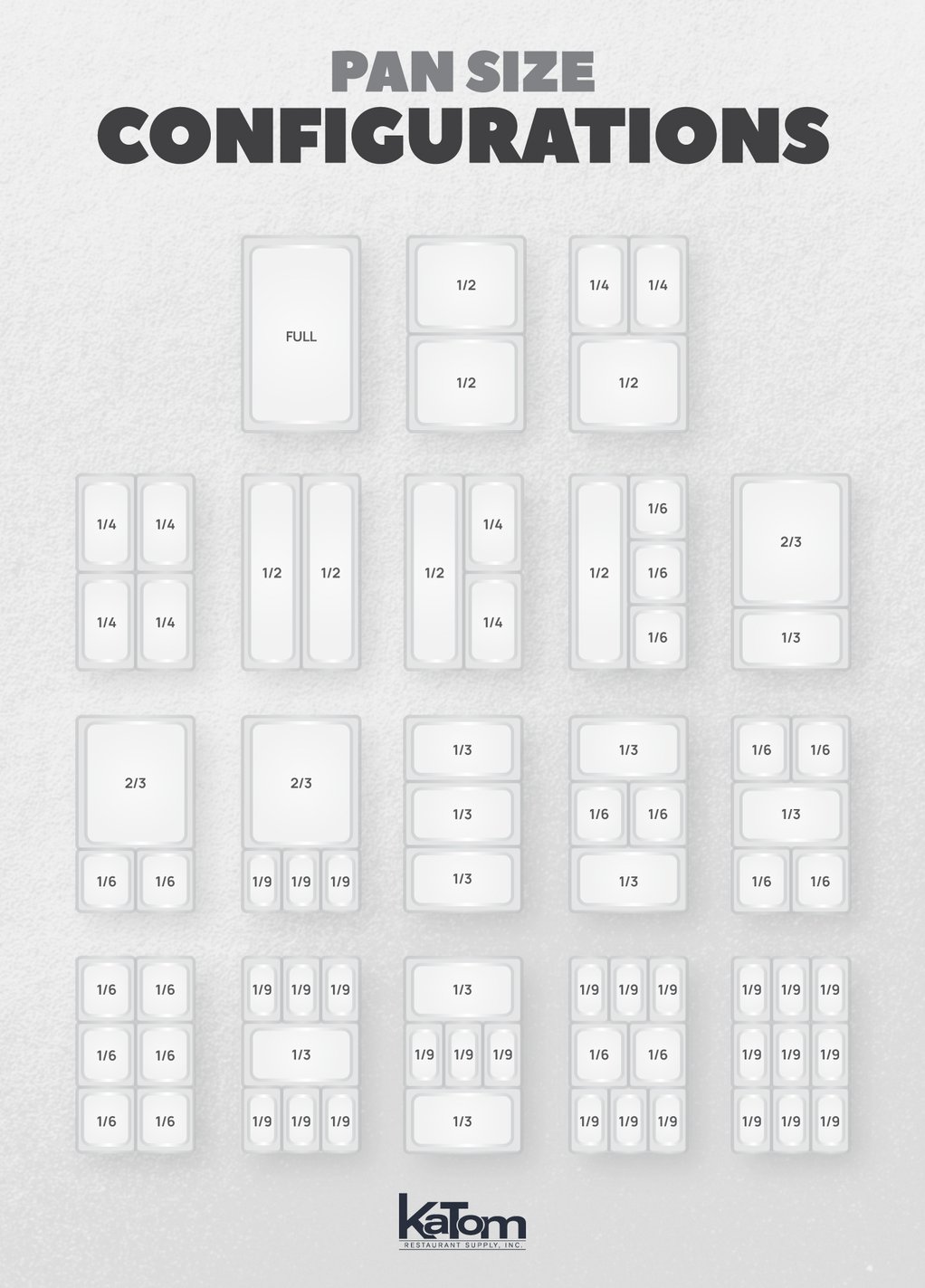

While the NSF/ANSI 2 standard (including full-size 12″ x 20″, and fractional sizes like 1/2, 1/3, 1/4, 1/6, and 1/9 pans) continues to dominate, there is growing demand for modular compatibility. Operators increasingly prioritize pans that can be mixed and matched across brands and equipment. In 2026, expect enhanced interoperability, with manufacturers focusing on tighter tolerance controls to ensure seamless fit across steam tables, refrigerated bases, and prep stations—reducing waste and simplifying inventory.

Rise of Deep and Fractional Sizing for Menu Diversification

As menus expand to include globally inspired dishes, bulk ingredients, and customizable offerings, deeper pan options (e.g., 6″ deep “hotel pans”) are gaining traction. These accommodate items like braised meats, large-volume sauces, and prepped vegetables. Simultaneously, smaller fractional sizes—especially 1/6 and 1/9 pans—are seeing increased use in fast-casual and grab-and-go setups, enabling portion control and reducing food waste. This reflects a broader shift toward precision and customization in food presentation.

Sustainability and Material Innovation

Environmental concerns are influencing material choices. While stainless steel remains the gold standard for durability, lightweight aluminum and recyclable composite materials are emerging as alternatives to reduce energy consumption during heating and transportation. In 2026, expect more brands to offer eco-certified pans and emphasize lifecycle sustainability, including recyclability and reduced carbon footprint in manufacturing.

Integration with Smart Kitchen Systems

As commercial kitchens adopt smart technology, pans are being designed to integrate with inventory and temperature monitoring systems. While not yet widespread, pans with embedded RFID tags or compatible with smart steam table sensors are beginning to enter the market. These innovations allow for real-time tracking of food levels, temperature consistency, and even automated replenishment alerts—improving food safety and reducing labor costs.

Labor Efficiency Driving Design Changes

With persistent labor shortages, ergonomics and ease of use are paramount. Pans with improved handle designs, non-slip bases, and nesting features for storage are becoming standard. Additionally, compatible lids—especially clear, vented, and microwave-safe options—are being prioritized to streamline service and reduce cross-contamination.

In conclusion, the 2026 steam table pan market is defined by intelligent adaptation: maintaining core standards while innovating in depth, material, and functionality. Operators will increasingly seek pans that support efficiency, reduce waste, and integrate seamlessly into modern, tech-enabled kitchens.

Common Pitfalls When Sourcing Steam Table Pan Sizes (Quality, IP)

Sourcing steam table pan sizes involves more than just matching dimensions—it requires attention to quality and intellectual property (IP) considerations to avoid operational inefficiencies and legal risks. Below are key pitfalls to watch for:

Inconsistent Quality Standards

One major pitfall is assuming all pans of the same nominal size (e.g., 1/3, 1/2, full-size) are interchangeable. Low-quality pans may use thinner gauge stainless steel, leading to warping under high heat, reduced durability, and poor heat distribution. This impacts food safety and service consistency. Always verify material specifications (e.g., 18/8 stainless steel, 20- or 18-gauge thickness) and prioritize reputable manufacturers to ensure longevity and compliance with health standards.

Non-Standardized Dimensions (Lack of IP Compliance)

Many suppliers produce pans that deviate slightly from industry-standard dimensions defined by organizations like NSF or ISO. These variations can result in improper fits in steam tables, refrigeration units, or combi ovens, reducing efficiency and creating safety hazards. Avoid generic or unbranded pans that don’t adhere to established sizing protocols. Using pans that align with recognized IP (such as standardized Gastronorm GN sizes) ensures compatibility across equipment and simplifies inventory management.

Intellectual Property Infringement Risks

Some manufacturers produce pans designed to mimic proprietary profiles from major brands (e.g., specific corner radius, rim design, or labeling). While these may appear compatible, they could infringe on design patents or trademarks. Sourcing such products exposes businesses to legal liability and supply chain disruption. Always purchase from authorized distributors or brands with clear IP compliance and avoid vendors offering “universal fit” pans that closely replicate branded designs without licensing.

Overlooking Equipment Compatibility

Even with standard sizing, differences in pan depth (common depths: 2.5″, 4″, 6″) or rim configuration can affect performance. Using a pan that’s too deep may impede steam flow; one that’s too shallow increases spill risk. Confirm pan dimensions against your specific equipment requirements and avoid assuming interchangeability across brands without testing.

Cost-Driven Substitutions

Opting for the cheapest available pans often leads to higher long-term costs due to frequent replacement, energy inefficiency, and downtime. Prioritize total cost of ownership over initial price, and verify certifications (e.g., NSF, ISO) to ensure the product meets foodservice industry benchmarks for safety and performance.

By addressing these pitfalls—emphasizing quality materials, adherence to IP-protected standards, and equipment compatibility—foodservice operators can ensure reliable, safe, and legally compliant steam table pan procurement.

Logistics & Compliance Guide for Steam Table Pan Sizes

Understanding steam table pan sizes is essential for foodservice operations to ensure compatibility, efficiency, and regulatory compliance. This guide outlines standard dimensions, logistics considerations, and compliance requirements related to steam table pan usage in commercial kitchens.

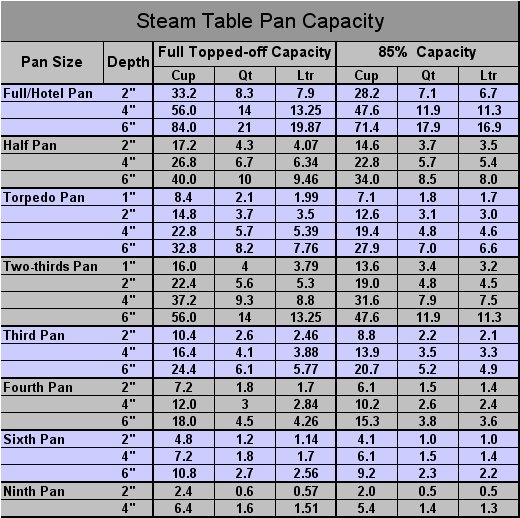

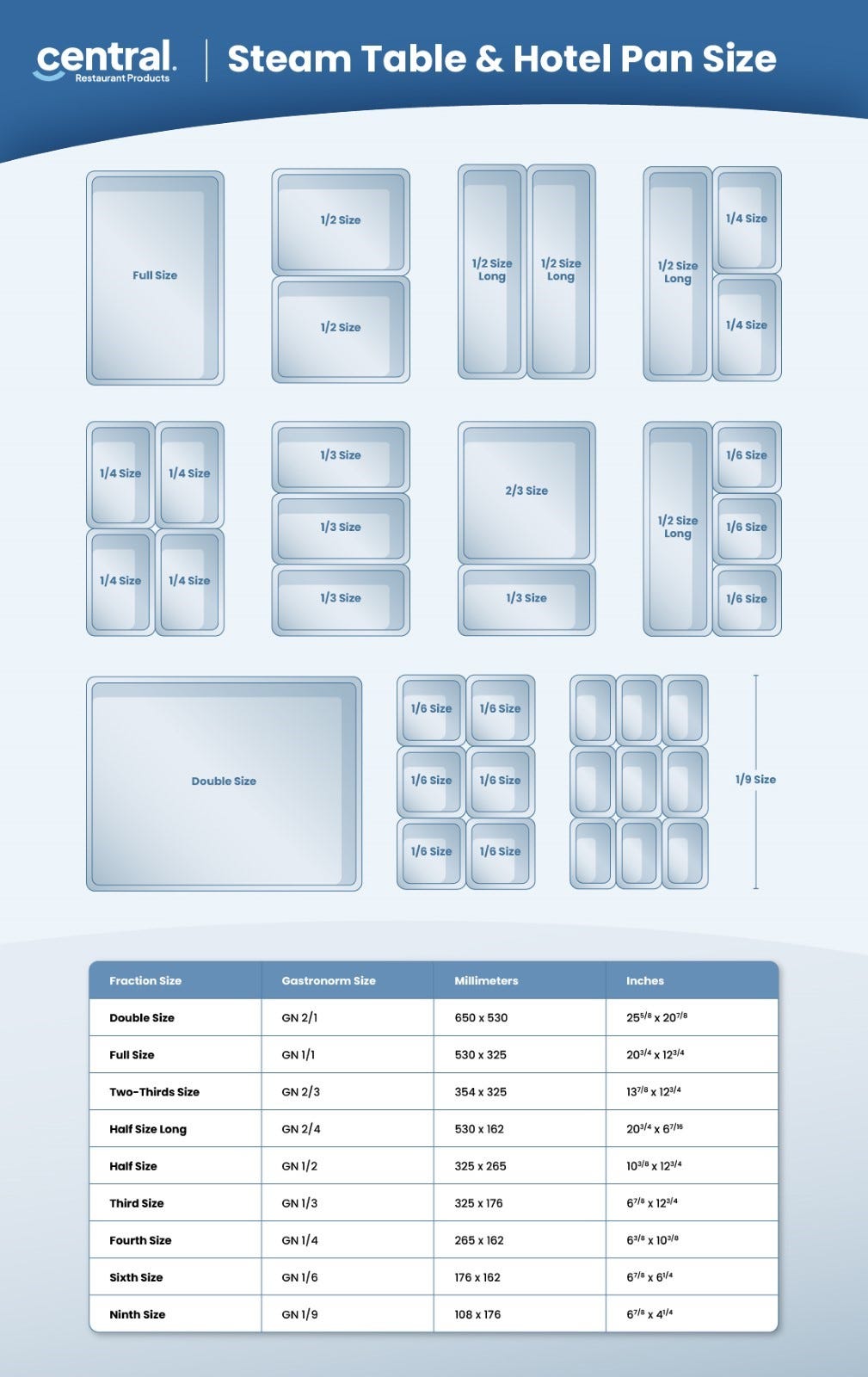

Standard Pan Sizes and Dimensions

Steam table pans—also known as food pan, service pan, or hotel pans—are manufactured to standardized sizes to ensure interchangeability across equipment. The most common standard is based on the U.S. National Sanitation Foundation (NSF) and National Kitchen & Bath Association (NKBA) guidelines.

- Full-Size Pan: 12″ × 20″ (nominal dimensions)

- Half-Size Pan: 12″ × 10″

- Third-Size Pan: 12″ × 6⅔”

- Quarter-Size Pan: 12″ × 5″

- Sixth-Size Pan: 6⅔” × 4″

- Ninth-Size Pan: 4″ × 6⅔”

Note: Actual measurements may vary slightly by manufacturer but must conform within tolerance limits for equipment compatibility.

Depth Variations

Pans are available in multiple depths to accommodate different food types and storage needs:

- 2.5 inches (63.5 mm) – Shallow

- 4 inches (102 mm) – Standard

- 6 inches (152 mm) – Deep

Deeper pans may impact heat transfer efficiency in steam tables and must be used with compatible equipment.

Material and Construction Standards

To comply with food safety regulations, steam table pans must be constructed from food-grade materials:

- Material: Minimum 22-gauge stainless steel (AISI 304 preferred)

- Finish: Smooth, non-porous, corrosion-resistant

- Edges: Rolled or hemmed to prevent cuts and facilitate cleaning

Pans must meet NSF/ANSI Standard 8 for commercial food equipment, ensuring they are safe for food contact and easy to clean.

Compatibility with Equipment

Logistical planning must ensure pan sizes match steam tables, refrigerated bases, and prep tables:

- Verify pan compatibility with steam table wells (e.g., 12″ × 20″ full-size wells)

- Use pan retainers or inserts for smaller sizes to prevent shifting

- Confirm temperature uniformity when stacking or nesting pans

Inconsistent sizing can lead to gaps, heat loss, and potential cross-contamination.

Temperature Control and Food Safety Compliance

Steam table pans are used in time/temperature control for safety (TCS) food handling. Compliance with FDA Food Code requirements includes:

- Maintaining hot-held foods at or above 135°F (57°C)

- Using well-fitting lids to reduce evaporation and contamination

- Avoiding overfilling pans to ensure proper heat circulation

- Limiting pan depth to 4 inches for optimal heat penetration

Use of deeper pans (e.g., 6″) without proper temperature monitoring can result in unsafe temperature zones.

Storage and Transportation Logistics

For warehouse and kitchen logistics:

- Stack pans by size and depth to maximize space

- Use racks or carts designed for standard pan dimensions

- Label pans for specific uses (e.g., raw meat, allergens) to prevent cross-contact

- Transport covered to reduce contamination risk during service

Ensure delivery vehicles and storage areas accommodate full-size pans (12″ × 20″) for efficient handling.

Cleaning and Sanitation Protocols

To meet health department standards:

- Clean and sanitize pans after each use per HACCP plans

- Use non-abrasive cleaners to preserve surface integrity

- Inspect for dents, warping, or corrosion that could harbor bacteria

- Replace damaged pans promptly

Pans should be dishwasher-safe and compatible with commercial warewashing temperatures (minimum 160°F rinse).

Regulatory and Certification Compliance

Ensure purchased pans carry proper certification:

- NSF International Certification: Verify listing on NSF website

- FDA-Compliant Materials: Must not leach harmful substances

- Country-Specific Standards: For international operations (e.g., CE marking in EU)

Procurement teams should request documentation from suppliers to validate compliance.

Conclusion

Adhering to standardized steam table pan sizes and compliance guidelines ensures operational efficiency, food safety, and regulatory adherence. By selecting NSF-certified, properly sized pans and integrating them into safe handling and storage systems, foodservice operators can maintain quality and avoid violations during health inspections.

Conclusion: Sourcing Steam Table Pan Sizes

When sourcing steam table pan sizes, it is essential to recognize the importance of standardization, compatibility, and operational efficiency in commercial food service environments. The most widely accepted standard in North America is the NSF/ANSI 4 specification, which ensures uniform dimensions—such as the common 12″ x 20″ full-size pan and its fractional counterparts (½, ⅓, ⅙, etc.)—allowing for interchangeability across steam tables, refrigeration units, ovens, and serving lines.

Successful sourcing requires verifying compatibility with existing equipment, including steam tables, gastronorm inserts, and storage systems, especially when mixing brands or international products. While the U.S. primarily uses the “hotel pan” sizing system, awareness of the GN (Gastronorm) system used internationally is beneficial for global operations or specialty equipment.

Additionally, material quality—typically 18/8 stainless steel—and pan depth (ranging from 2.5″ to 6″) should be selected based on food type, holding duration, and portion control needs. Investing in durable, well-sized pans reduces waste, improves food presentation, and enhances workflow efficiency.

In summary, carefully selecting steam table pan sizes based on standard dimensions, equipment compatibility, and operational demands ensures seamless integration into food service operations, supporting consistency, safety, and cost-effectiveness in high-volume environments.