The global static mixing market is experiencing steady expansion, driven by increasing demand across industries such as chemical processing, oil and gas, water treatment, pharmaceuticals, and food and beverage. According to a 2023 report by Mordor Intelligence, the static mixer market was valued at USD 3.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2028. This growth is fueled by the rising need for energy-efficient mixing solutions, stringent environmental regulations requiring precise chemical dosing, and advancements in mixer design that enhance performance in continuous processes.

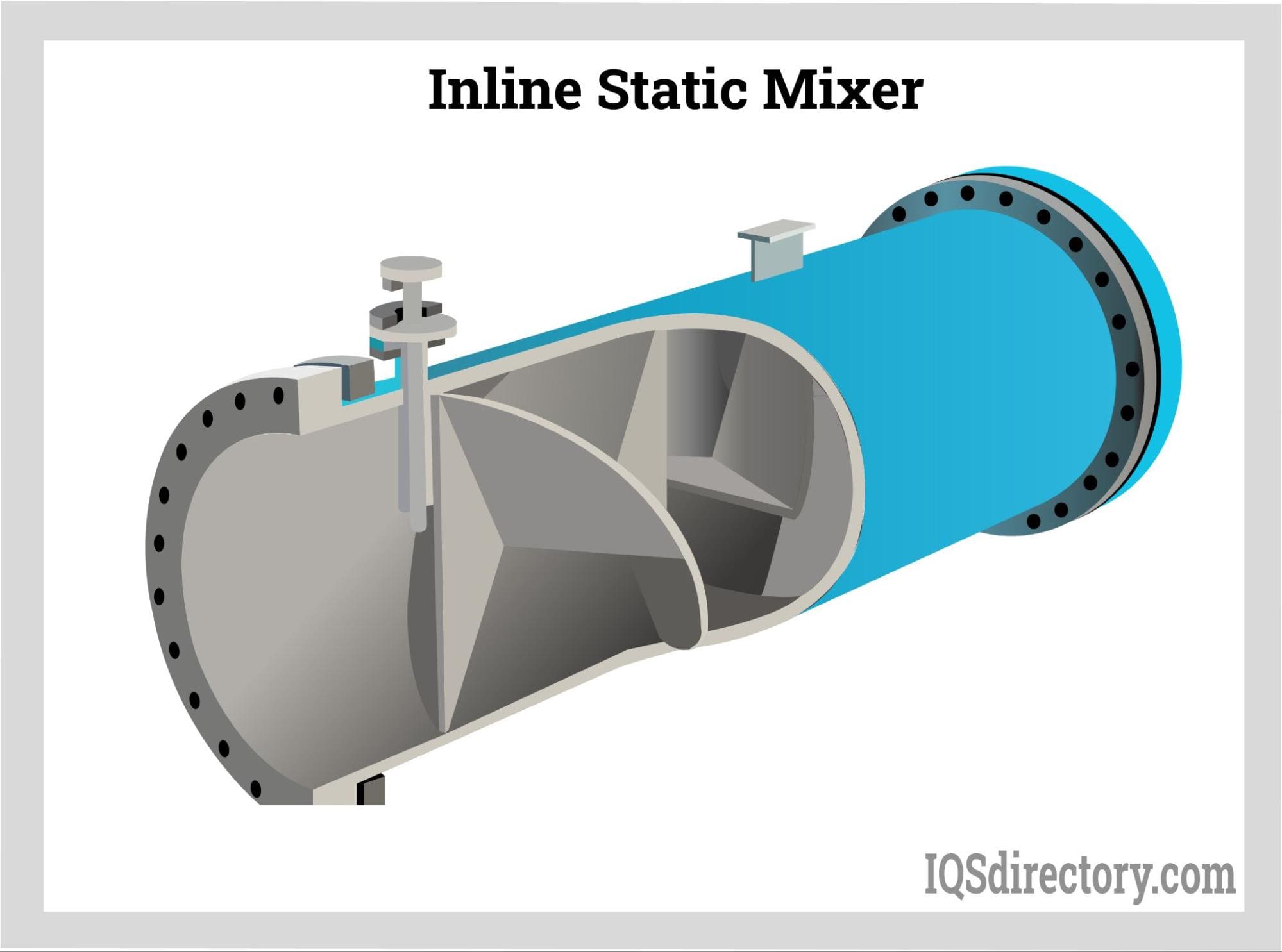

Static mixers—maintenance-free, inline devices that promote efficient blending without moving parts—are increasingly preferred over dynamic mixers due to their reliability, low operational costs, and compact footprint. Grand View Research further corroborates this trend, noting that the surge in automation and process optimization across industrial sectors is accelerating adoption, particularly in emerging economies. With key players investing in innovative materials and modular designs, the competitive landscape is evolving rapidly. In this dynamic environment, selecting the right manufacturer is critical for ensuring process efficiency, product consistency, and long-term cost savings. Here’s a data-driven look at the top 10 static mixing manufacturers shaping the industry today.

Top 10 Static Mixing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Komax Systems

Domain Est. 1996 | Founded: 1973

Website: komax.com

Key Highlights: We have been a manufacturer of static inline mixers, steam heaters, and heat exchangers since 1973 with our technologies being applied to projects worldwide….

#2 Stirrers : Static mixers

Domain Est. 1999

Website: agitec.com

Key Highlights: AGITEC manufacturer of static mixer, liquid mixing, liquid mixer, gas mixer for static and dynamical industrial stirrers, static mixers….

#3 Kenics

Domain Est. 1995

Website: nov.com

Key Highlights: Kenics static mixers have set the standard for inline mixing and heat transfer performance. We incorporate advanced technology into every static mixer….

#4 Koflo Corporation

Domain Est. 2000

Website: koflo.com

Key Highlights: Koflo designs and manufactures custom static mixers of all sizes for every industry and application. Let us design a mixer to meet your needs….

#5 Page

Domain Est. 2004

Website: stamixco-usa.com

Key Highlights: StaMixCo designs and manufactures a wide variety of static mixers (motionless mixers with no moving parts) for the continuous processing of polymers, liquids, ……

#6 Statiflo

Domain Est. 1996

Website: statiflo.com

Key Highlights: Statiflo is a world leader in the development and application of static pipe mixers, inline static mixers, channel mixers, duct mixers, gas dispersion systems….

#7 Static mixers

Domain Est. 1996

Website: sulzer.com

Key Highlights: With Sulzer’s static mixers you can produce small volumes with an excellent mixing reliability. They can be easily installed, cleaned and maintained….

#8 Static Mixers for Process Industry Applications

Domain Est. 1999

Website: staticmixers.com

Key Highlights: Our Static Mixers are well proven for wide ranging uses in turbulent and laminar flow applications, supplied as complete plug-in modules or as mixer inserts….

#9 High Performance Static Mixers Custom Made By Westfall

Domain Est. 2016

Website: westfallstaticmixers.com

Key Highlights: High performance drop-in Static Mixers are engineered to order for the water, wastewater, oil, gas, chemical, aerospace and insulation industries….

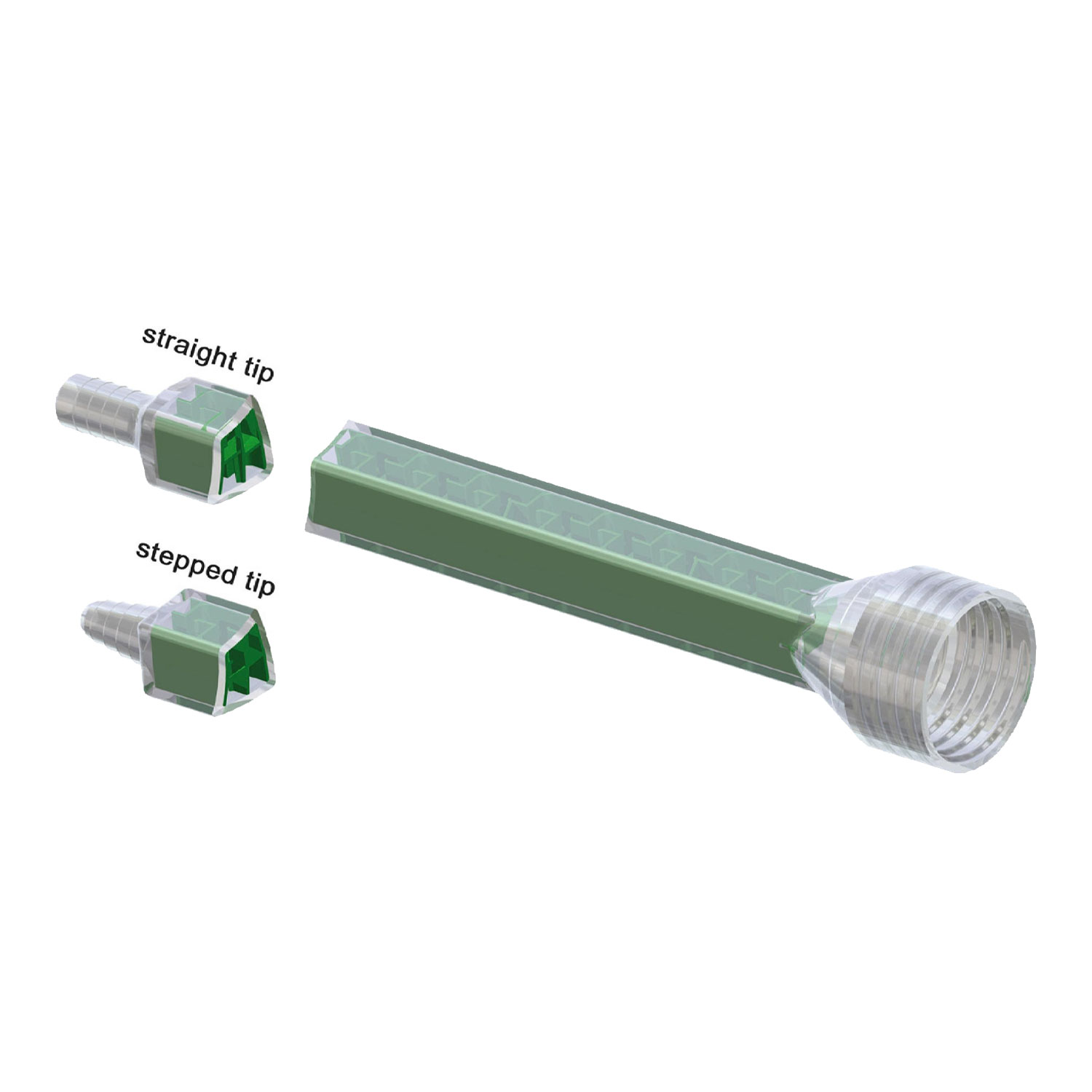

#10 Mixpac static mixers for 2

Domain Est. 2021

Website: medmix.swiss

Key Highlights: We offer a fantastic range of static and dynamic mixers compatible with most cartridge-based systems and other meter-mix-dispense equipment….

Expert Sourcing Insights for Static Mixing

H2: Market Trends in Static Mixing Technology Forecast for 2026

The static mixing market is poised for significant transformation by 2026, driven by advancements in materials science, rising demand for process efficiency, and growing adoption across key industries such as chemicals, pharmaceuticals, food and beverage, and water treatment. Several key trends are expected to shape the static mixing landscape in the coming years.

-

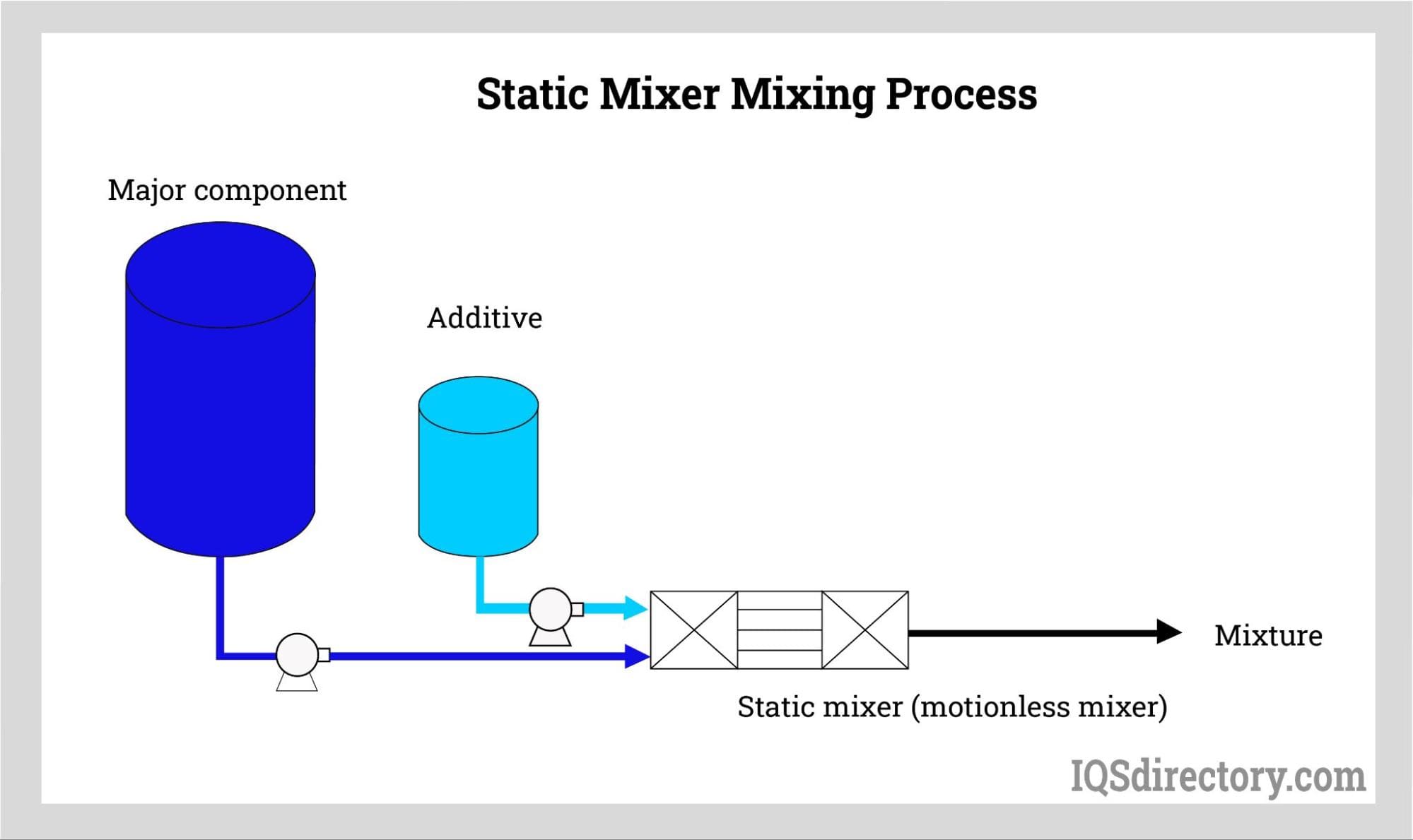

Increased Demand for Energy Efficiency and Process Optimization

Manufacturers are increasingly prioritizing energy-efficient solutions to reduce operational costs and meet sustainability targets. Static mixers, known for their ability to enhance mixing efficiency without moving parts, are gaining traction as low-maintenance, energy-saving alternatives to dynamic mixers. By 2026, demand is projected to grow significantly in industries seeking to streamline processes and minimize downtime. -

Expansion in Pharmaceutical and Biotechnology Applications

The pharmaceutical sector is adopting static mixers for precise blending in drug formulation, sterile processing, and bioreactor applications. As regulatory standards tighten and the need for contamination-free, reproducible mixing grows, static mixers offer a reliable solution. Innovations in sanitary designs and compliance with FDA and GMP standards are expected to drive adoption further by 2026. -

Growth in Environmental and Water Treatment Sectors

With global focus on clean water and wastewater management, static mixers are being widely deployed in chemical dosing, flocculation, and pH adjustment processes. Their ability to uniformly mix reagents with minimal energy input makes them ideal for municipal and industrial water treatment plants. The rollout of stricter environmental regulations is expected to boost market demand, particularly in emerging economies. -

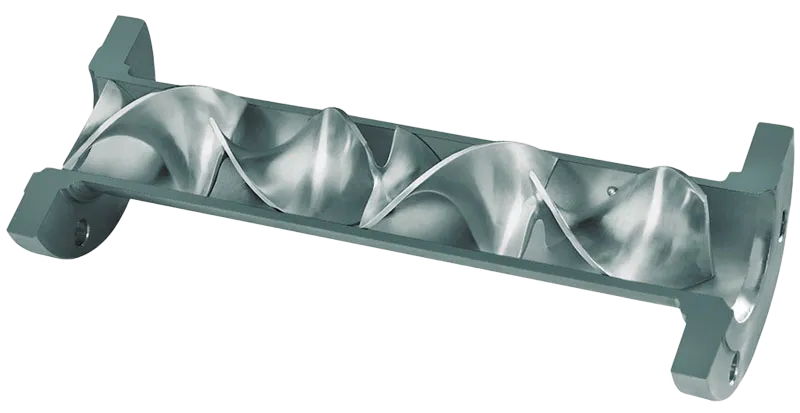

Technological Advancements in Mixer Design and Materials

Developments in computational fluid dynamics (CFD) and 3D printing are enabling the design of more efficient and application-specific static mixer elements. High-performance materials such as PTFE, PVDF, and specialty alloys are being used to enhance chemical resistance and durability. By 2026, customized static mixers tailored to specific flow rates, viscosities, and media types are expected to dominate premium market segments. -

Integration with Industry 4.0 and Smart Manufacturing

The integration of static mixers into smart processing systems is emerging as a key trend. While static mixers themselves have no moving parts, their performance can be monitored using inline sensors and IoT-enabled platforms that provide real-time data on flow, pressure drop, and mixing efficiency. This trend supports predictive maintenance and quality control, aligning with broader Industry 4.0 initiatives. -

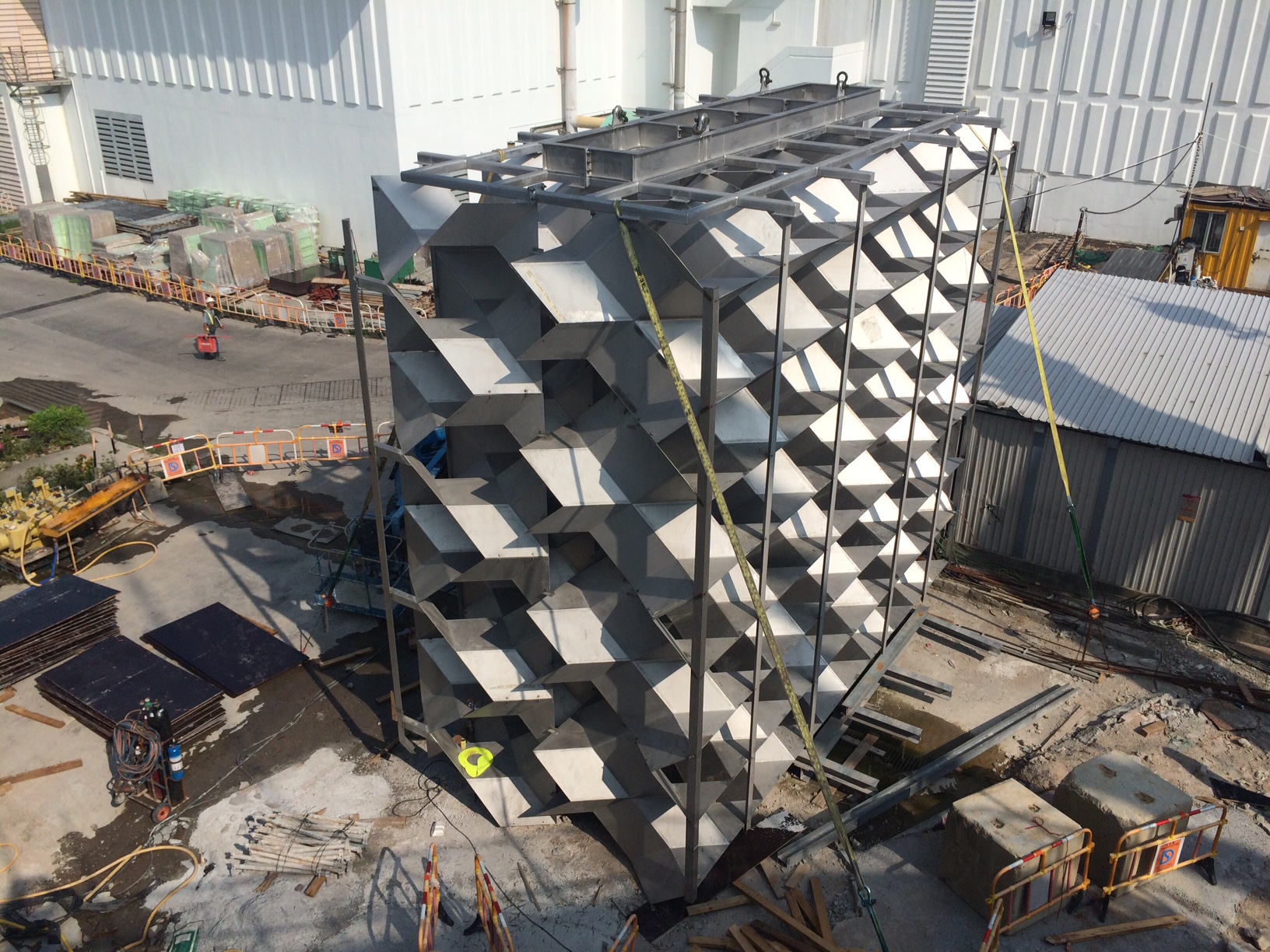

Geographic Shifts and Emerging Markets

While North America and Europe remain strong markets due to mature industrial infrastructure, Asia-Pacific—particularly China, India, and Southeast Asia—is expected to witness the highest growth rate by 2026. Rapid industrialization, increasing investments in infrastructure, and expanding chemical and food processing sectors are key growth drivers in the region.

In conclusion, the static mixing market in 2026 will be characterized by innovation, sustainability, and digital integration. As industries continue to seek efficient, reliable, and scalable mixing solutions, static mixers are well-positioned to meet evolving demands across diverse applications.

Common Pitfalls in Sourcing Static Mixers (Quality, IP)

When sourcing static mixers—critical components in process industries like chemicals, pharmaceuticals, and food processing—organizations often encounter significant challenges related to quality assurance and intellectual property (IP) protection. Overlooking these aspects can lead to operational inefficiencies, compliance risks, and legal exposure. Below are the most common pitfalls to avoid:

1. Inadequate Supplier Qualification and Quality Assurance

Many buyers focus solely on cost and delivery timelines, neglecting rigorous supplier vetting. This can result in receiving mixers made from substandard materials or with inconsistent geometries, leading to poor mixing performance, contamination risks, or premature failure. Without proper certifications (e.g., ISO 9001, ASME BPE), material traceability, or documented quality control procedures, ensuring consistent product quality becomes difficult.

2. Lack of Design Verification and Performance Testing

Static mixer effectiveness depends heavily on precise internal element design. Sourcing from suppliers who do not provide performance data, CFD (Computational Fluid Dynamics) validation, or test reports risks acquiring inefficient mixers. Buyers often assume standardized designs perform uniformly, but minor dimensional deviations can drastically affect mixing efficiency, pressure drop, and scalability.

3. Overlooking Material Compatibility and Regulatory Compliance

Using mixers made from non-compliant or incompatible materials (e.g., incorrect stainless steel grades, unsuitable elastomers) can lead to corrosion, product contamination, or failure in regulated environments (e.g., FDA, EHEDG, 3A). Sourcing without verifying material certifications (e.g., material test reports, RoHS, REACH) exposes companies to safety and compliance liabilities.

4. Intellectual Property Infringement Risks

Static mixer designs—especially proprietary helical or segmented configurations—are often protected by patents. Sourcing from unauthorized or copycat manufacturers may result in IP violations, leading to legal disputes, shipment seizures, or forced redesigns. Buyers must confirm that the mixer design does not infringe on existing patents, particularly when replicating a competitor’s solution.

5. Insufficient Documentation and Traceability

Lack of detailed design drawings, CAD files, or manufacturing records hinders troubleshooting, maintenance, and replacement part sourcing. It also complicates audit readiness in regulated industries. Without proper documentation, reproducing or validating the mixer’s performance becomes challenging.

6. Failure to Secure IP Rights in Custom Designs

When working with suppliers on custom mixer development, companies often neglect to formalize IP ownership in contracts. This can result in the supplier retaining rights to the design, limiting exclusivity or enabling them to sell the same solution to competitors. Clear contractual terms assigning IP to the buyer are essential.

7. Geographic and Supply Chain Vulnerabilities

Relying on offshore suppliers without on-site audits increases the risk of quality deviations and IP theft. Weak supply chain oversight can lead to unauthorized subcontracting or reverse engineering of designs, especially in regions with less stringent IP enforcement.

To mitigate these pitfalls, organizations should implement a structured sourcing strategy that includes supplier audits, design validation, material certification checks, patent landscape reviews, and robust contractual IP clauses.

Logistics & Compliance Guide for Static Mixing

Overview of Static Mixing Technology

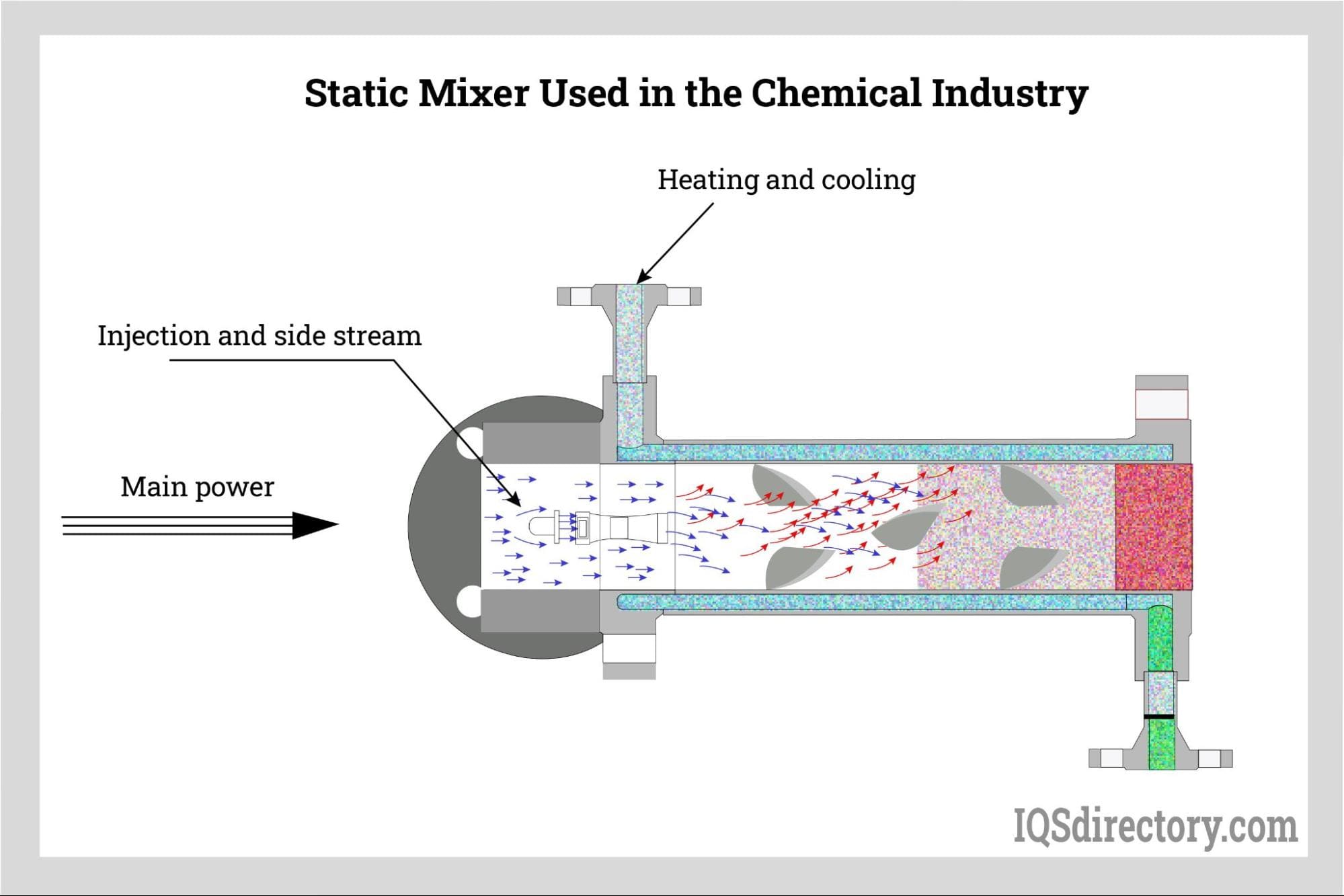

Static mixing refers to the process of combining two or more fluid streams using a stationary (non-moving) internal element within a pipeline. These mixers enhance homogeneity without requiring external power, making them energy-efficient and low-maintenance. Proper logistics and compliance are critical to ensure safe, efficient, and legally compliant operations.

Regulatory Compliance Requirements

Static mixing systems must adhere to applicable industry standards and safety regulations. Key compliance areas include:

– Pressure Equipment Directive (PED) 2014/68/EU: Required for static mixers used in pressurized systems within the European Union.

– ASME B31.3 Process Piping Code: Governs design, materials, and fabrication in the U.S. chemical and process industries.

– ATEX/IECEx: Mandatory for mixers used in explosive atmospheres to prevent ignition risks.

– FDA & EU 1935/2004: Applicable when handling food, beverage, or pharmaceutical products; materials must be food-grade and non-leaching.

– REACH & RoHS: Ensure chemical substances used in mixer construction comply with environmental and health regulations.

Material Handling and Transportation Logistics

Proper handling and transportation are vital to prevent damage and maintain performance:

– Packaging: Secure mixers in protective crates or padded containers to avoid impact damage. Include moisture barriers for corrosion-sensitive materials.

– Labeling: Clearly mark packages with handling instructions (e.g., “Fragile,” “This Side Up”) and compliance certifications.

– Transport Mode: Use climate-controlled transport for temperature-sensitive components; avoid extreme conditions during transit.

– Inventory Management: Store mixers in dry, clean environments, off the ground, and away from corrosive chemicals or vibrations.

Installation and Operational Compliance

Ensure safe and compliant installation and operation:

– Pre-Installation Inspection: Verify mixer dimensions, material certifications (e.g., material test reports), and compatibility with process fluids.

– Alignment and Support: Install with proper pipe support to prevent stress on the mixer body. Misalignment can cause leaks or premature failure.

– Flow Conditions: Operate within specified flow rates and pressure drops to ensure efficient mixing and avoid cavitation or erosion.

– Documentation: Maintain records of installation procedures, pressure tests, and compliance checks for audits.

Maintenance and Inspection Protocols

Regular maintenance supports longevity and regulatory adherence:

– Scheduled Inspections: Check for corrosion, erosion, or clogging, especially in abrasive or viscous media.

– Cleaning Procedures: Follow CIP (Clean-in-Place) protocols where applicable. Use only approved cleaning agents compatible with mixer materials.

– Replacement Records: Track component lifespan and replace worn elements per manufacturer guidelines.

– Calibration and Validation: For critical applications (e.g., pharmaceuticals), validate mixing performance periodically.

Environmental and Safety Considerations

Minimize environmental impact and ensure workplace safety:

– Leak Prevention: Use proper gaskets and seals rated for operating conditions. Monitor for fugitive emissions.

– Waste Disposal: Dispose of used mixers or cleaning residues in accordance with local environmental regulations (e.g., hazardous waste protocols).

– Personnel Training: Train operators on safe handling, emergency shutdown procedures, and PPE requirements.

– Process Safety Management (PSM): Integrate static mixers into broader PSM programs when handling hazardous materials.

Documentation and Audit Readiness

Maintain comprehensive records to demonstrate compliance:

– Certificates: Keep copies of material certifications, pressure test reports, and conformity declarations (e.g., CE, ASME).

– SOPs: Document standard operating, maintenance, and emergency procedures.

– Audit Trail: Archive inspection logs, maintenance records, and regulatory correspondence for minimum retention periods (typically 5–10 years).

Conclusion

Effective logistics and compliance management for static mixing ensures operational safety, regulatory adherence, and process reliability. By following industry standards, maintaining proper documentation, and implementing robust handling and maintenance protocols, organizations can optimize performance while minimizing risk.

Conclusion for Sourcing Static Mixers

Sourcing static mixers requires a strategic approach that balances technical requirements, material compatibility, cost efficiency, and supplier reliability. These passive mixing devices play a critical role in various industries—including chemical processing, water treatment, food and beverage, and pharmaceuticals—by ensuring efficient, consistent mixing without the need for moving parts. When selecting a supplier, key factors such as mixer design (e.g., helical, axially symmetric), material construction (e.g., stainless steel, PVC, PTFE), pressure drop considerations, and flow rate compatibility must be carefully evaluated.

A successful sourcing strategy involves engaging with reputable suppliers who offer proven product performance, technical support, customization options, and compliance with industry standards. Additionally, lifecycle cost analysis—factoring in maintenance, energy savings, and longevity—can reveal long-term value beyond initial purchase price. By aligning technical specifications with operational needs and supplier capabilities, organizations can optimize mixing performance, enhance process efficiency, and achieve reliable, scalable solutions across their operations.