The global market for static charge removal equipment is experiencing steady growth, driven by increasing demand across industries such as electronics, packaging, printing, and plastics, where electrostatic discharge (ESD) can compromise product quality and operational safety. According to a report by Grand View Research, the global electrostatic control equipment market size was valued at USD 1.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030. This growth is fueled by the rising adoption of automation, stricter quality control standards in manufacturing, and the proliferation of sensitive electronic components. As industries seek reliable solutions to mitigate static-related defects and improve production efficiency, manufacturers of static eliminators—ranging from ionizers and static bars to grounding systems—are innovating to deliver high-performance, energy-efficient, and smart ESD control technologies. In this evolving landscape, the top nine static charge removal manufacturers have emerged as key players, combining robust R&D, global reach, and advanced product portfolios to meet the escalating demands of modern industrial applications.

Top 9 Static Charge Removal Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Specialist Manufacturer of Static Control Technology

Domain Est. 2010

Website: fraser-antistatic.com

Key Highlights: Fraser Anti-Static are world leading specialist manufacturers of equipment and solutions used to control static electricity throughout industry worldwide….

#2 Electrostatics the experts in controlling static electricity and cleaning

Domain Est. 1996

Website: electrostatics.com

Key Highlights: ElectroStatics Incorporated is a leading designer and manufacturer of systems to control reduce static electricity and remove contamination related to static ……

#3 Static Eliminator Manufacturers

Domain Est. 2001

Website: static-eliminators.com

Key Highlights: Find static eliminator suppliers whose high speed, low maintenance products help to reduce the chance for malfunction in your organization’s applications….

#4 Static Elimination

Domain Est. 1995

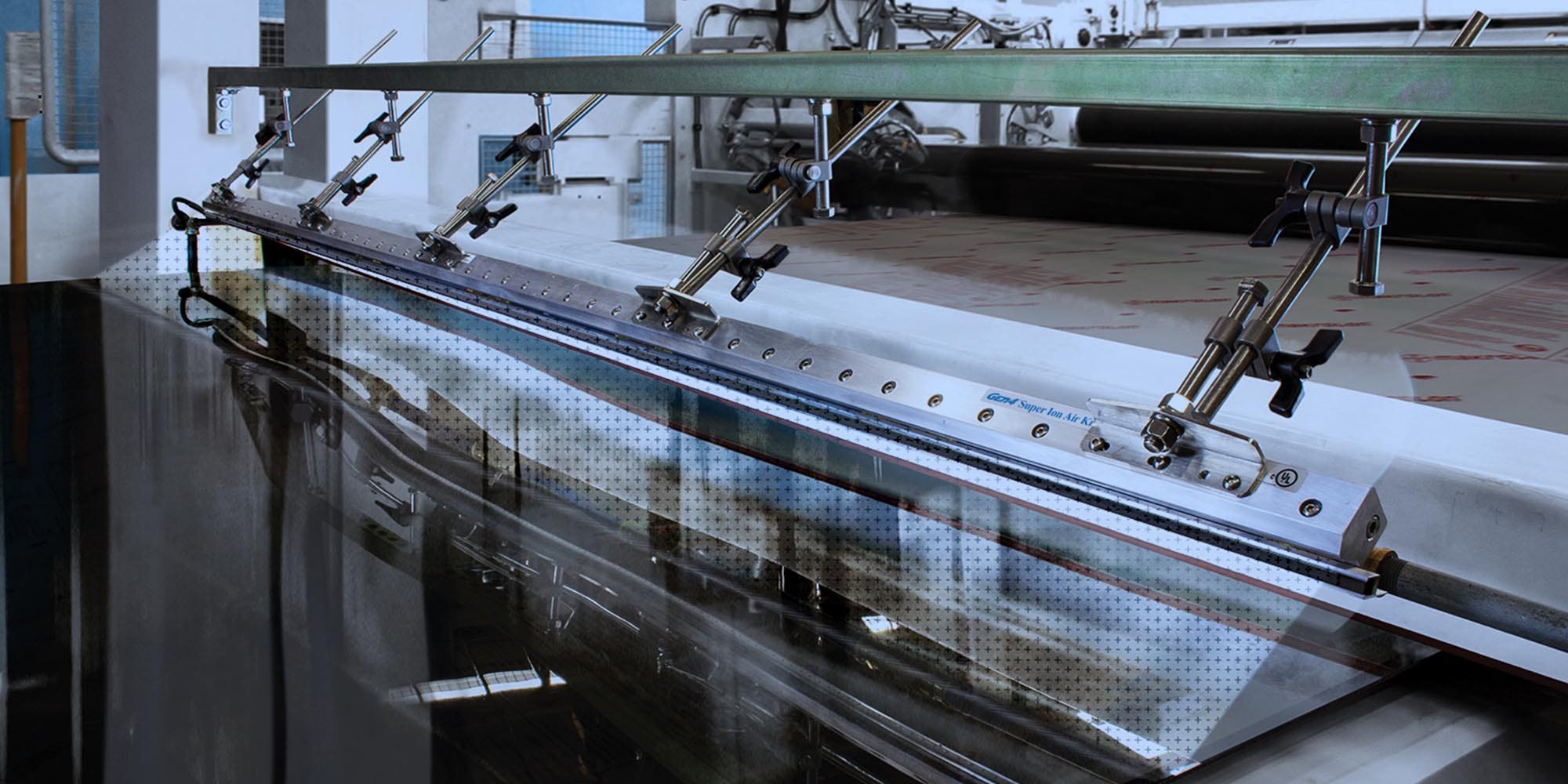

Website: exair.com

Key Highlights: A wide, laminar sheet of static eliminating airflow to remove static charge on plastics, webs, sheet stock, and other conductive material….

#5 our products

Domain Est. 1996

Website: meech.com

Key Highlights: OUR PRODUCTS. At Meech, we deliver a comprehensive range of advanced static control devices that optimise production across a wide range of industries….

#6 Static Control

Domain Est. 1996

Website: keyence.com

Key Highlights: A static electricity elimination gun with impressive dust removal performance and a robust design. Adding ions to air delivered at supersonic speeds….

#7 Stop Static.com™

Domain Est. 1999

Website: stopstatic.com

Key Highlights: Forget about grounding the machine. You cannot ground plastic sheets or winding plastic. · You need to carefully ground the person with our ionTape. See: Wide ……

#8 Static Management Static control solutions

Domain Est. 2005

Website: staticclean.com

Key Highlights: Neutralize unwanted static charge that causes defects, contamination, and handling issues. Solutions include ionizing bars, blowers, guns, nozzles, air knives, ……

#9 TRINC static electricity removal (ionizer)

Domain Est. 2022

Website: artiencegroup.com

Key Highlights: TRINC is a specialist in foreign matter and static electricity countermeasures. We will create a manufacturing environment that is free from foreign matter….

Expert Sourcing Insights for Static Charge Removal

2026 Market Trends for Static Charge Removal

The Static Charge Removal market is poised for significant transformation by 2026, driven by evolving industrial automation, stringent quality requirements, and technological advancements. Here are the key trends shaping the landscape:

H2: Accelerated Adoption in Advanced Manufacturing and Electronics

By 2026, the demand for static charge removal solutions will surge in high-precision sectors, particularly semiconductor manufacturing, advanced electronics assembly, and photonics. As device miniaturization continues and feature sizes shrink into nanometer ranges, even minute levels of static electricity can cause catastrophic damage to sensitive components (ESD events) or disrupt nanoscale processes. Manufacturers will increasingly deploy sophisticated ionization systems—such as pulsed DC and AC ionizers with real-time monitoring and feedback loops—to ensure electrostatic-safe environments. The rise of AI-driven production lines will further integrate static control systems directly into process control architectures, enabling predictive maintenance and dynamic adjustment of ion output based on environmental conditions.

H2: Growth in Sustainable and Energy-Efficient Solutions

Environmental regulations and corporate sustainability goals will push the industry toward low-energy, eco-friendly static elimination technologies. By 2026, there will be a marked shift away from traditional high-energy consumption AC ionizers toward advanced pulsed DC and steady-state DC systems that offer superior balance and lower power usage. Additionally, manufacturers will prioritize products with longer lifespans, reduced material waste, and recyclable components. Non-nuclear static elimination methods—already dominant—will see further innovation, especially in compact, maintenance-free designs suitable for cleanroom environments where emissions and particulate generation are tightly controlled.

H2: Integration with Industry 4.0 and IoT Platforms

Static control systems will become integral nodes in the Industrial Internet of Things (IIoT) ecosystem. By 2026, smart ionizers equipped with embedded sensors and wireless connectivity will be commonplace, enabling remote monitoring of performance metrics such as balance, offset voltage, and contamination levels. Cloud-based dashboards will allow facility managers to visualize static risk across production lines, receive real-time alerts for out-of-spec conditions, and perform predictive analytics to prevent downtime. This integration will enhance traceability and compliance, particularly in regulated industries such as pharmaceuticals and medical devices, where documentation of environmental controls is mandatory.

H2: Expansion in Emerging Applications and Geographies

Beyond traditional industrial and electronics sectors, static charge removal will gain traction in emerging fields such as additive manufacturing (3D printing), electric vehicle (EV) battery production, and flexible hybrid electronics. In EV manufacturing, static control is critical during electrode handling and cell assembly to prevent defects and safety hazards. Regionally, Asia-Pacific—led by China, South Korea, and India—will remain the fastest-growing market due to expanding high-tech manufacturing capacity and government initiatives promoting domestic semiconductor and electronics production. North America and Europe will see steady growth driven by automation upgrades and reshoring efforts.

H2: Innovation in Non-Contact and Miniaturized Technologies

The trend toward compact, high-performance equipment will drive innovation in miniaturized static eliminators suitable for confined spaces and robotic applications. By 2026, expect to see wider adoption of micro-ionizers, air-based static bars with integrated nozzles, and modular designs that can be easily reconfigured. Non-contact technologies using targeted ionized airflow or advanced emitter materials will gain favor over contact-based methods, reducing maintenance and contamination risks. These innovations will support agile manufacturing practices and the growing deployment of collaborative robots (cobots) in sensitive production environments.

Common Pitfalls When Sourcing Static Charge Removal Equipment (Quality, IP)

Sourcing static charge removal equipment—such as ionizers, static bars, and grounding systems—requires careful evaluation to ensure performance, safety, and compatibility. Two critical areas where buyers often encounter pitfalls are quality and Ingress Protection (IP) rating. Overlooking these aspects can lead to system failures, safety hazards, and reduced product life.

Poor Quality Components and Construction

One of the most frequent pitfalls is selecting low-quality static removal devices based solely on upfront cost. Cheaply made ionizers may use substandard emitters, unstable power supplies, or inferior housing materials. These components degrade quickly, leading to inconsistent ion output, frequent maintenance, or complete failure. For example, poorly manufactured emitter pins can corrode or become contaminated, reducing neutralization efficiency and causing static-related defects in sensitive manufacturing processes like printing, packaging, or electronics assembly. Additionally, unreliable quality control from certain suppliers may result in non-compliance with industry standards (e.g., ANSI/ESD S20.20), undermining ESD protection programs.

Incorrect or Misunderstood IP Ratings

Ingress Protection (IP) ratings define a device’s resistance to dust and moisture—critical in industrial environments. A common sourcing mistake is selecting static control equipment with an IP rating that doesn’t match the operating environment. For instance, using an IP20-rated ionizer (protected only against solid objects >12mm, no moisture protection) in a washdown or high-humidity area can lead to electrical shorts, corrosion, or safety risks. Conversely, over-specifying with unnecessarily high IP ratings (e.g., IP68 in a dry environment) increases cost without added benefit. Buyers must assess environmental conditions carefully and verify that the IP rating applies to the entire unit—not just the housing—and that it has been independently tested and certified.

Logistics & Compliance Guide for Static Charge Removal

Static charge accumulation in industrial and manufacturing environments presents significant risks, including fire hazards, product damage, and operational inefficiencies. Effective static charge removal is essential not only for safety and quality but also for compliance with logistics and regulatory standards. This guide outlines key considerations for the logistics and compliance aspects of static charge removal systems.

Understanding Static Charge Hazards

Static electricity can generate sparks capable of igniting flammable vapors, dust, or solvents commonly found in warehouses, production lines, and packaging areas. In logistics operations involving sensitive electronics or pharmaceuticals, electrostatic discharge (ESD) can damage components or compromise product integrity. Identifying high-risk areas—such as conveyor lines, filling stations, and packaging zones—is the first step in mitigating these hazards.

Regulatory and Compliance Requirements

Compliance with industry standards and regulations is essential when implementing static charge removal systems. Key standards include:

- OSHA (Occupational Safety and Health Administration) – Requires employers to provide a safe working environment, including protection from fire and explosion risks associated with static discharge.

- NFPA 77: Recommended Practice on Static Electricity – Provides guidelines for identifying, evaluating, and controlling static electricity hazards in industrial settings.

- ATEX Directive (EU) – Applies to equipment and protective systems used in potentially explosive atmospheres, requiring static control measures in designated zones.

- IEC 61340 (Electrostatics) – International standard covering ESD protection, particularly relevant for electronics manufacturing and handling.

Facilities must conduct risk assessments and implement appropriate static control solutions to meet these requirements.

Selecting Appropriate Static Removal Equipment

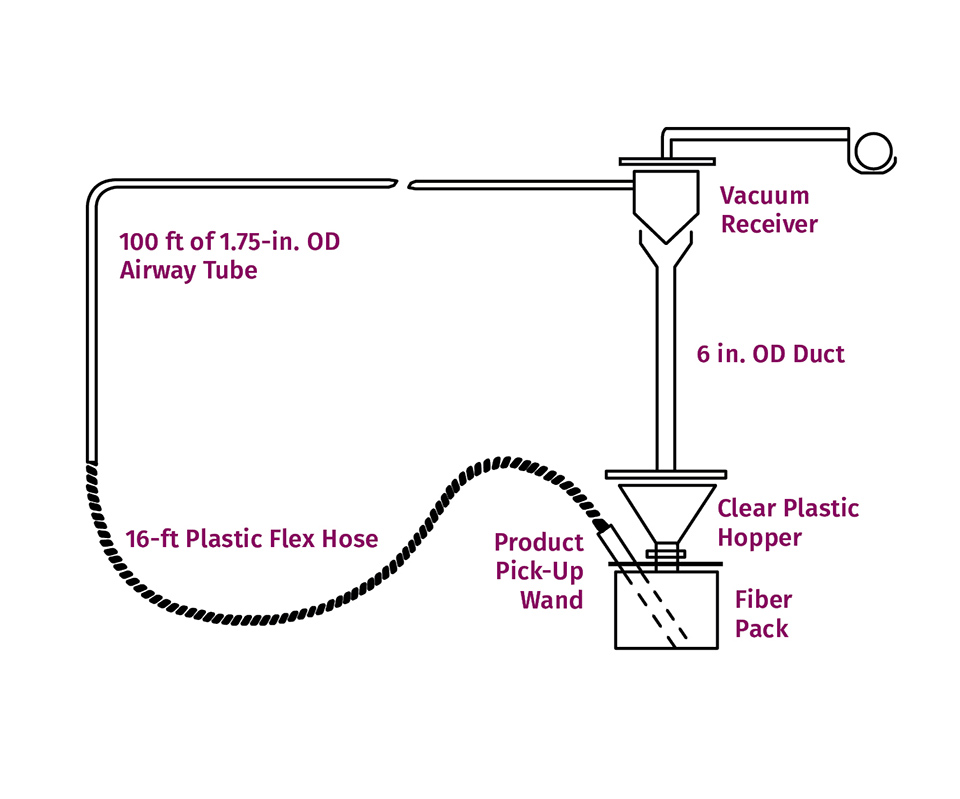

Common static charge removal devices include:

- Ionizing Bars – Installed along production lines to neutralize static on surfaces.

- Static Brushes (Tinsel or Conductive Fiber) – Passive devices that dissipate charge through grounding.

- Ionizing Air Guns and Nozzles – Used for targeted static removal during maintenance or manual operations.

- Conductive Flooring and Workstations – Essential in ESD-sensitive areas to safely ground personnel and equipment.

Selection should consider the environment (e.g., explosive, cleanroom, high-humidity), material types, and throughput requirements.

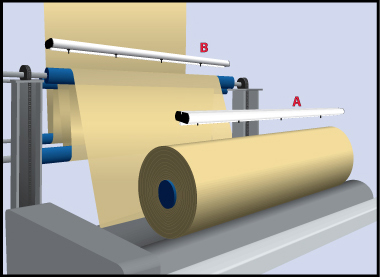

Logistics Planning and Installation

Proper logistics planning ensures effective deployment and maintenance of static control systems:

- Site Assessment – Evaluate material flow, equipment layout, and grounding infrastructure.

- Power and Air Supply – Confirm availability of electrical power or compressed air for active ionization systems.

- Installation Location – Position ionizers close to points of static generation (e.g., unwinding rolls, conveyors).

- Integration with Existing Systems – Coordinate with automation and control systems for monitoring and alerts.

Maintenance and Compliance Documentation

Regular maintenance is critical to ensure ongoing effectiveness and compliance:

- Scheduled Inspections – Check for dust buildup, damaged emitters, or grounding failures.

- Performance Testing – Use field meters to verify ion balance and decay time per IEC 61340-5-1.

- Calibration Records – Maintain logs for audit purposes.

- Training – Ensure personnel understand static risks and equipment operation.

Document all procedures, inspections, and corrective actions to demonstrate due diligence during audits.

Training and Operational Procedures

Implement clear protocols for:

- Equipment use and handling

- Response to static-related incidents

- Routine checks and reporting

Train all relevant staff, including logistics, warehouse, and production personnel, to recognize static hazards and respond appropriately.

Conclusion

Effective static charge removal is a critical component of safe and compliant logistics and manufacturing operations. By aligning equipment selection, installation, maintenance, and training with recognized standards, organizations can mitigate risks, protect assets, and ensure regulatory compliance. Regular review of static control measures ensures continued effectiveness in dynamic operational environments.

Conclusion for Sourcing Static Charge Removal:

Effective static charge removal is essential in various industrial and manufacturing processes to ensure product quality, operational safety, and equipment longevity. After evaluating different sourcing options—such as ionizing bars, air blowers, static brushes, and conductive materials—it is evident that selecting the right static elimination solution depends on specific application requirements, environmental conditions, and budget considerations.

Sourcing high-quality static control equipment from reputable suppliers ensures reliability, compliance with safety standards, and long-term cost savings through reduced downtime and product defects. Additionally, partnering with vendors who offer technical support and maintenance services enhances system performance and adaptability to evolving production needs.

In conclusion, a strategic approach to sourcing static charge removal solutions—balancing technology, cost, and support—enables organizations to mitigate static-related risks, improve production efficiency, and maintain a safe working environment. Investing in the right static control measures is not just a technical necessity but a critical component of operational excellence.