The global market for static changeover switches, a critical component in uninterrupted power supply systems, is experiencing steady expansion driven by rising demand for reliable power management solutions across industrial, commercial, and healthcare sectors. According to Mordor Intelligence, the Static Transfer Switch Market was valued at USD 1.47 billion in 2024 and is projected to grow at a CAGR of over 6.8% from 2025 to 2030. This growth is fueled by increasing investments in data centers, the modernization of aging electrical infrastructure, and the proliferation of mission-critical applications requiring zero-transfer-time power switching. As reliability and energy efficiency become paramount, procurement teams and engineering firms are prioritizing manufacturers that offer high-performance, scalable, and smart-ready static transfer switch solutions. Against this backdrop, identifying the leading players with proven innovation, global reach, and technical excellence is essential for stakeholders navigating an increasingly competitive landscape.

Top 9 Static Changeover Switch Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Static Transfer Switching

Domain Est. 1995

Website: powersmiths.com

Key Highlights: The STATYS PS is designed to protect critical and sensitive appliances in IT, telecom and industrial applications….

#2 Static Transfer Switches

Domain Est. 1990

Website: electrification.us.abb.com

Key Highlights: The enhanced 1600A Cyberex® SuperSwitch®4 design is an industry benchmark in power quality detection and transfer performance for higher power density ……

#3 Static Transfer Switches

Domain Est. 1997

Website: se.com

Key Highlights: Schneider Electric USA. Browse our products and documents for Static Transfer Switches – True redundancy and exceptional high reliability for automatic ……

#4 TwinSource – Rack Mounted Static Transfer Switches

Domain Est. 2002

Website: twinsource.net

Key Highlights: TwinSource manufactures rack-mount automatic transfer switches in both solid state (single phase and three phase) and electromechanical (single phase) versions….

#5 Static Transfer Switches (STS) for Data Centers

Domain Est. 2003

#6 Static Transfer Solutions

Domain Est. 2004

Website: socomec.us

Key Highlights: Static switches in UPS systems are smart and easy-to-integrate devices that operate automatically when a power outage occurs to ensure permanent power ……

#7 Static Switch Transfer

Domain Est. 2017

Website: eolapower.com

Key Highlights: With a Static Transfer Switch, it eliminates the chance of a loss of power to critical loads by properly coordinating with the electrical distribution system….

#8 Static Power

Founded: 2002

Website: staticpower.com.au

Key Highlights: STATIC POWER is an Australian company, based since 2002 in Melbourne where we develop, design and manufacture solid-state power switching solutions….

#9 Static Transfer Switch

Website: deltapowersolutions.com

Key Highlights: The Delta Static Transfer Switch (STS) ensures continuous operation for sensitive equipment and mission-critical application….

Expert Sourcing Insights for Static Changeover Switch

H2: 2026 Market Trends for Static Transfer Switches

The global market for Static Transfer Switches (STS) is poised for significant evolution by 2026, driven by rising demands for uninterrupted power supply, advancements in critical infrastructure, and the proliferation of digital technologies. A Static Transfer Switch, which enables seamless power source switching without mechanical interruption, plays a crucial role in data centers, healthcare facilities, industrial automation, and telecommunications. The following are key trends shaping the STS market through 2026:

-

Growth in Data Center Expansion

The surge in cloud computing, artificial intelligence, and edge data centers is a primary driver for STS adoption. As hyperscale and edge facilities require higher power reliability, STS systems offer millisecond-level transfer times to prevent downtime. This trend is particularly strong in North America, Europe, and parts of Asia-Pacific, where digital infrastructure investments are accelerating. -

Increased Focus on Energy Efficiency and Sustainability

With global emphasis on reducing carbon emissions, STS manufacturers are integrating energy-efficient designs and smart monitoring features. The trend toward green data centers and LEED-certified buildings supports demand for STS units that minimize energy loss during transfer and support integration with renewable energy sources. -

Adoption of Smart and IoT-Enabled STS Systems

By 2026, a growing number of STS units are expected to feature IoT connectivity, remote monitoring, predictive maintenance, and real-time diagnostics. These intelligent systems allow facility managers to optimize power usage, anticipate failures, and reduce operational costs—key selling points in mission-critical environments. -

Rising Demand in Healthcare and Industrial Sectors

Hospitals and medical facilities require uninterrupted power for life-support systems and diagnostic equipment, making STS adoption essential. Similarly, in industrial automation and process manufacturing, STS units help maintain continuous operations, especially in smart factories adopting Industry 4.0 principles. -

Regional Market Shifts and Emerging Economies

While North America and Western Europe remain dominant markets, regions such as India, Southeast Asia, and the Middle East are witnessing rapid infrastructure development. Governments and private enterprises in these regions are investing in resilient power systems, creating new opportunities for STS vendors. -

Technological Advancements and Product Innovation

Manufacturers are focusing on developing compact, modular STS solutions with higher current ratings and improved fault tolerance. Integration with UPS systems, dual-bus architectures, and paralleling switchgear is enhancing system reliability. Additionally, advancements in semiconductor technology (e.g., IGBTs) are improving transfer speed and reducing waveform distortion. -

Stringent Regulatory and Compliance Standards

Global standards such as UL 1008, IEC 60947-6-2, and TIA-942 are influencing STS design and deployment. Compliance with these standards ensures safety, reliability, and interoperability—factors increasingly prioritized by end-users and regulatory bodies.

In conclusion, the 2026 market for Static Transfer Switches is characterized by technological innovation, expanding applications, and heightened demand for power continuity across sectors. As digitalization and electrification continue to accelerate worldwide, STS systems will remain a cornerstone of resilient power infrastructure, positioning the market for sustained growth and transformation.

Common Pitfalls When Sourcing Static Changeover Switches (Quality, IP Rating)

When sourcing Static Changeover Switches (SCOS), overlooking critical quality and Ingress Protection (IP) rating factors can lead to system failures, safety hazards, and costly downtime. Below are common pitfalls to avoid:

1. Prioritizing Low Cost Over Quality and Certification

One of the most frequent mistakes is selecting a low-cost Static Changeover Switch without verifying its compliance with international standards such as IEC 62310 or UL 1008. Cheap units may use inferior components (e.g., lower-grade semiconductors or relays), leading to reduced lifespan, higher failure rates, and unreliable switching performance during critical power transitions.

Best Practice: Always request certification documentation and test reports, and consider total cost of ownership rather than initial purchase price.

2. Ignoring IP Rating Requirements for the Installation Environment

Selecting a switch with an inappropriate IP rating for the environment—such as deploying an IP20-rated unit in a dusty or humid industrial setting—exposes internal electronics to contaminants, increasing the risk of short circuits, corrosion, and failure.

Best Practice: Match the IP rating to the environment—e.g., use IP54 or higher for outdoor or harsh indoor environments with dust and moisture.

3. Overlooking Thermal Management and Cooling Design

Poor thermal design in low-quality switches can cause overheating, especially under continuous load. This degrades semiconductor performance and can trigger premature failure. Units without adequate heat dissipation or forced cooling may not sustain rated capacity.

Best Practice: Verify thermal performance data and ensure proper ventilation or forced cooling mechanisms are in place, especially in high-ambient-temperature environments.

4. Inadequate Surge and Transient Protection

Some budget SCOS units lack proper transient voltage suppression (TVS) or surge protection. This leaves connected loads vulnerable to voltage spikes during switching or from external sources like lightning.

Best Practice: Confirm the presence of built-in surge protection (e.g., MOVs or TVS diodes) and compatibility with the site’s surge protection strategy.

5. Assumptions About Switching Speed and Bypass Reliability

Not all SCOS units provide true seamless transfer. Lower-quality models may have longer transfer times or unreliable mechanical bypass mechanisms, which can disrupt sensitive equipment.

Best Practice: Validate switching speed (typically <4ms) and ensure the bypass mechanism undergoes regular maintenance cycles without degradation.

6. Poor Sealing and Enclosure Integrity

Even with a stated IP rating, poor manufacturing—such as inadequate gasketing, misaligned covers, or substandard materials—can compromise ingress protection over time.

Best Practice: Inspect sample units for build quality and request third-party verification of IP compliance, especially for critical installations.

7. Lack of Remote Monitoring and Diagnostic Features

Lower-tier units often lack communication interfaces (e.g., Modbus, SNMP), making remote monitoring and predictive maintenance difficult. This increases response time during failures.

Best Practice: Choose switches with digital communication options and diagnostic capabilities to enhance system reliability and reduce downtime.

Avoiding these pitfalls ensures reliable, safe, and long-term performance of Static Changeover Switches in mission-critical applications such as data centers, healthcare, and industrial facilities.

Logistics & Compliance Guide for Static Changeover Switch

This guide outlines the key logistics and compliance considerations for the handling, transportation, installation, and operation of Static Changeover Switch (SCOS) units. Adherence to these guidelines ensures safety, regulatory compliance, and optimal performance.

Product Overview and Specifications

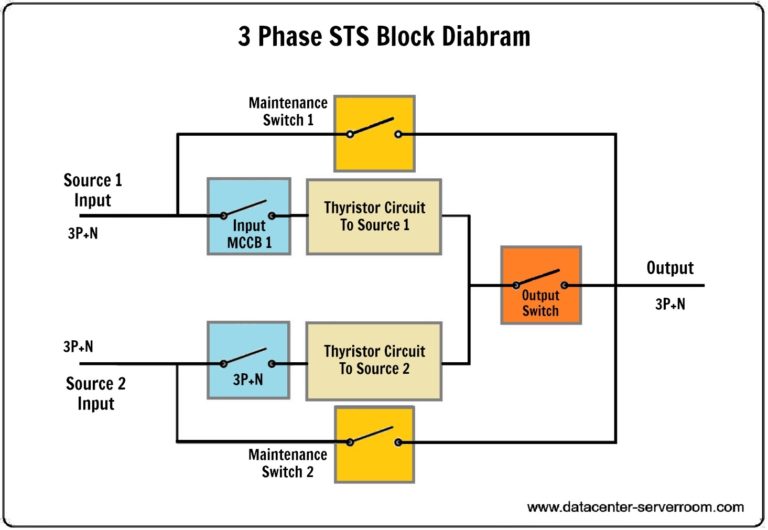

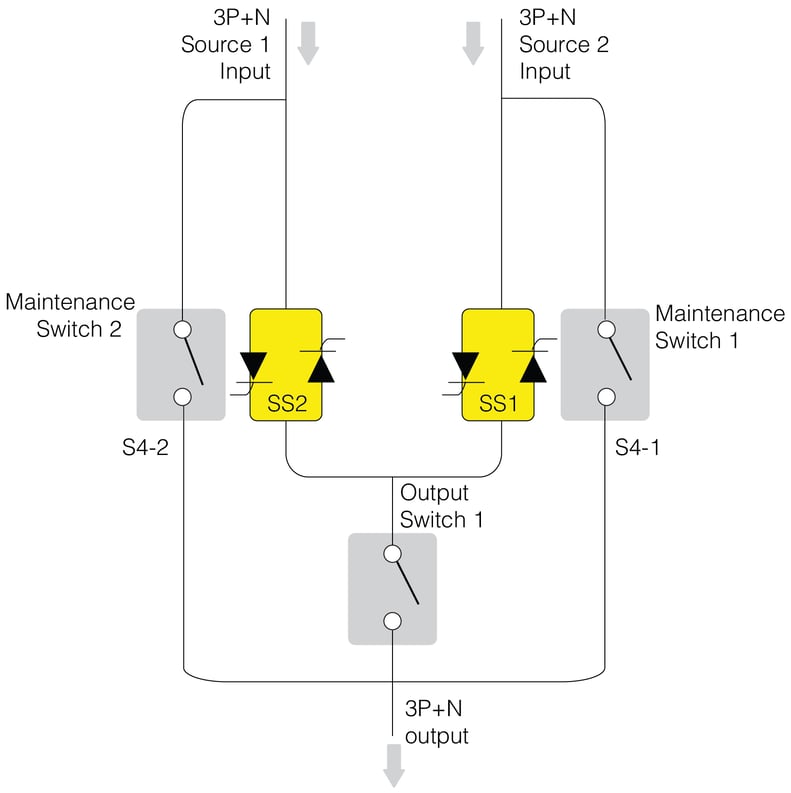

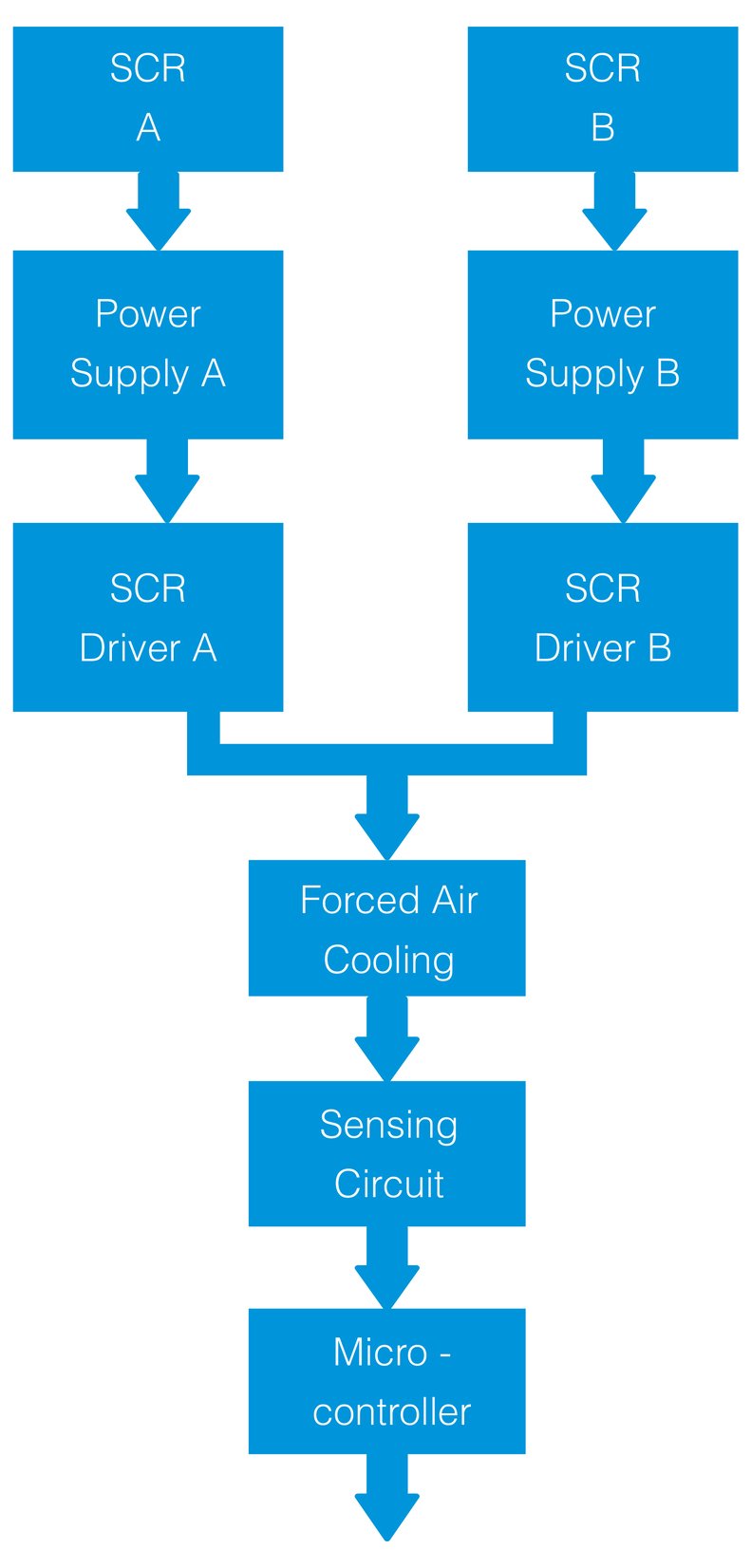

Static Changeover Switches are solid-state electrical devices used to transfer power supply between two independent sources—typically main utility and backup generator—without interrupting power to critical loads. These switches utilize semiconductor-based technology (such as SCRs or IGBTs) for seamless, ultra-fast transfer (typically within ¼ cycle), making them ideal for sensitive applications in healthcare, data centers, and industrial facilities.

Key specifications typically include:

– Voltage rating: 120V to 600V AC

– Frequency: 50/60 Hz

– Power rating: 20A to 2000A

– Transfer time: < 5 ms

– IP rating: IP20 (indoor), IP54 or higher (outdoor/rugged environments)

– Compliance standards: UL 1008, IEC 60947-6-1, IEEE 446

Packaging and Handling Requirements

Proper packaging and handling are essential to prevent physical damage during transit and storage.

- Packaging: Units must be shipped in manufacturer-approved, crush-resistant corrugated boxes with internal foam or molded inserts to secure components.

- Labeling: Packages must include:

- Product name and model number

- “Fragile” and “This Side Up” indicators

- Handling instructions (e.g., “Do not stack above 2 boxes”)

- Electrostatic discharge (ESD) sensitive symbol if applicable

- Handling: Use mechanical lifting equipment (e.g., forklifts, pallet jacks) for units over 25 kg. Never drag or drop. Avoid tilting beyond ±10° unless specified.

Transportation Guidelines

Ensure compliance with national and international shipping regulations during transportation.

- Domestic Transport (e.g., US, EU): Follow DOT (Department of Transportation) or ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road) regulations where applicable. Although SCOS units are generally non-hazardous, batteries or capacitors in integrated control modules may require special handling.

- International Shipping: Comply with IATA (air), IMDG (sea), or UNECE standards as needed. Provide Material Safety Data Sheets (MSDS) or Safety Data Sheets (SDS) for any hazardous subcomponents.

- Environmental Conditions: Maintain storage and transport temperatures between -25°C to +70°C. Avoid exposure to moisture, direct sunlight, or corrosive atmospheres.

Import and Export Compliance

Ensure adherence to trade regulations when shipping across borders.

- Export Controls: Verify if the SCOS unit contains technology subject to export control regulations such as EAR (Export Administration Regulations) or ITAR. Most commercial SCOS units are EAR99, but confirm with manufacturer documentation.

- Customs Documentation: Provide accurate commercial invoices, packing lists, and certificates of origin. Include HS Code 8537.10 (boards, panels for electrical control).

- Import Regulations: Comply with local electrical safety and conformity standards (e.g., CE marking for EU, CCC for China, RCM for Australia). Obtain necessary import permits or certifications prior to shipment.

Installation and Site Preparation

Proper site preparation and installation ensure compliance with electrical codes and safety standards.

- Location Requirements:

- Indoor, dry, well-ventilated area

- Clearance: Minimum 1 meter front, 0.5 meters sides and rear for maintenance

- Ambient temperature: 0°C to 40°C

- Altitude: Up to 2000 meters above sea level (derating required above)

- Electrical Compliance:

- Install per NEC Article 700 (Emergency Systems), NEC 701 (Legally Required Standby), or local equivalent

- Grounding: Comply with IEEE 142 (Green Book) and local grounding standards

- Conduit and wiring: Use appropriately sized, UL-listed conductors with proper insulation

- Testing and Commissioning:

- Perform insulation resistance and continuity tests

- Validate transfer sequence and bypass functionality

- Document results in a commissioning report per NFPA 110

Regulatory and Safety Certifications

Ensure the SCOS unit carries required certifications for the target market.

- North America:

- UL 1008 Listed (Transfer Switch Equipment)

- CSA C22.2 No. 178.1

- FCC Part 15 (EMI compliance)

- European Union:

- CE Marking (LVD Directive 2014/35/EU, EMC Directive 2014/30/EU)

- EN 60947-6-1 (Control and monitoring switchgear)

- Other Regions:

- UKCA (UK)

- CCC (China)

- RCM (Australia/New Zealand)

- EAC (Eurasian Conformity)

Maintain access to test reports, declarations of conformity, and certification marks.

Maintenance and Decommissioning

Follow lifecycle management practices to ensure long-term reliability and environmental compliance.

- Maintenance:

- Schedule annual inspections and thermographic scanning

- Clean ventilation grilles and check for component wear

- Update firmware per manufacturer recommendations

- Decommissioning and Disposal:

- Disconnect and lockout/tagout (LOTO) per OSHA 29 CFR 1910.147

- Recycle components in accordance with WEEE (EU) or state-level e-waste regulations (e.g., California SB 20)

- Do not dispose of in regular landfill; use certified electronic waste handlers

Documentation and Recordkeeping

Maintain comprehensive records to support compliance audits and warranty claims.

Required documentation includes:

– Manufacturer’s operation and maintenance manual

– UL/CE test reports and certification documents

– Commissioning and periodic test reports

– Shipping manifests and customs clearance records

– Maintenance logs and repair history

Store records for a minimum of 10 years or as required by local regulations.

Contact and Support

For compliance inquiries, technical support, or documentation requests, contact:

[Manufacturer Name] Technical SupportPhone: [Support Number] Email: [email protected]

Website: www.manufacturer.com/compliance

Always refer to the latest product-specific documentation provided by the manufacturer for model-accurate details.

Conclusion for Sourcing Static Changeover Switch:

After a thorough evaluation of technical requirements, operational reliability, and cost-efficiency, sourcing a static changeover switch (also known as a static transfer switch – STS) is a critical decision for ensuring uninterrupted power supply in sensitive environments such as data centers, healthcare facilities, and industrial infrastructure. The static changeover switch offers seamless, ultra-fast transfer between dual power sources—typically under 4 milliseconds—preventing downtime and protecting critical loads from power disturbances.

Key factors in the sourcing process include selecting a switch with appropriate voltage and current ratings, compatibility with existing power systems (such as UPS and generators), built-in diagnostic and monitoring features, and compliance with international standards (e.g., IEC 60947, UL 1008). Additionally, supplier reliability, service support, and scalability should be considered to ensure long-term performance and ease of integration.

In conclusion, investing in a high-quality static changeover switch from a reputable supplier not only enhances system resilience and power continuity but also contributes to overall operational efficiency and risk mitigation. Proper sourcing, based on technical suitability and lifecycle value, ensures optimal protection of critical equipment and minimizes the impact of power source failures.