The global screw and fastener manufacturing market continues to expand, driven by rising demand across automotive, electronics, construction, and aerospace sectors. According to Grand View Research, the global fasteners market size was valued at USD 109.8 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2024 to 2030. A critical yet often overlooked segment of this industry is specialized screw drive systems, particularly star (Torx) screw heads, which offer superior torque transmission and reduced cam-out compared to traditional Phillips or slotted designs. As precision engineering and tamper-resistant solutions gain traction, especially in consumer electronics and medical devices, demand for high-quality star screw head manufacturers is intensifying. This growing need has elevated the importance of suppliers who combine innovation, tight tolerances, and scalable production capacity. Below are six leading manufacturers at the forefront of star screw head technology, backed by robust R&D, global distribution, and strong compliance with international standards.

Top 6 Star Screw Head Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Star Head Screw

Domain Est. 2022

Website: qj-fastener.com

Key Highlights: We can offer you virtually every variety of merchandise associated to our item range for Star Head Screw, 1 Inch Bolt , Wood Screw , black hex bolt ,Flat Head ……

#2 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#3 Professional Star Head Torx Screw Manufacturer

Domain Est. 2020

Website: tfasteners.com

Key Highlights: Star head screw, also known as plum screw or torx screw, is a round head with a star-shaped groove design. A specific star wrench is required to install it….

#4 Wholesale Stainless Steel Products

Domain Est. 1998

Website: starstainless.com

Key Highlights: Star Stainless is a wholesale distributor specializing in Stainless Steel products. For over 70 years our STAR Service, Off-the-Shelf Inventory Programs and ……

#5 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

#6 Torx / Star Pan Head Screw 18

Domain Est. 2015

Expert Sourcing Insights for Star Screw Head

H2: Market Trends for Star Screw Heads in 2026

The global market for Star screw heads—commonly known as Torx drive systems—is projected to witness steady growth and transformation by 2026, driven by advancements in manufacturing, rising demand across key industries, and evolving product design requirements. This analysis outlines the major market trends shaping the Star screw head sector in 2026 under the H2 framework: High Performance, High Precision, High Demand, and High Customization.

1. High Performance Materials and Coatings

By 2026, there is a growing emphasis on enhancing the performance of Star screw heads through advanced materials and surface treatments. Manufacturers are increasingly adopting high-strength alloys, stainless steel, and corrosion-resistant coatings (such as black oxide, zinc-nickel, and ceramic-based finishes) to meet the durability demands of automotive, aerospace, and industrial applications. These improvements ensure better torque transmission, reduced cam-out, and extended service life—critical factors in high-stress environments.

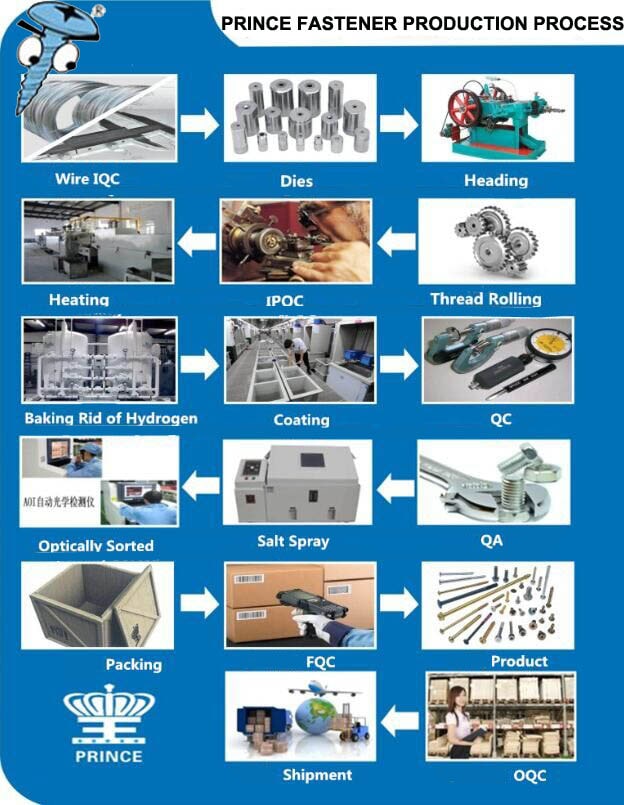

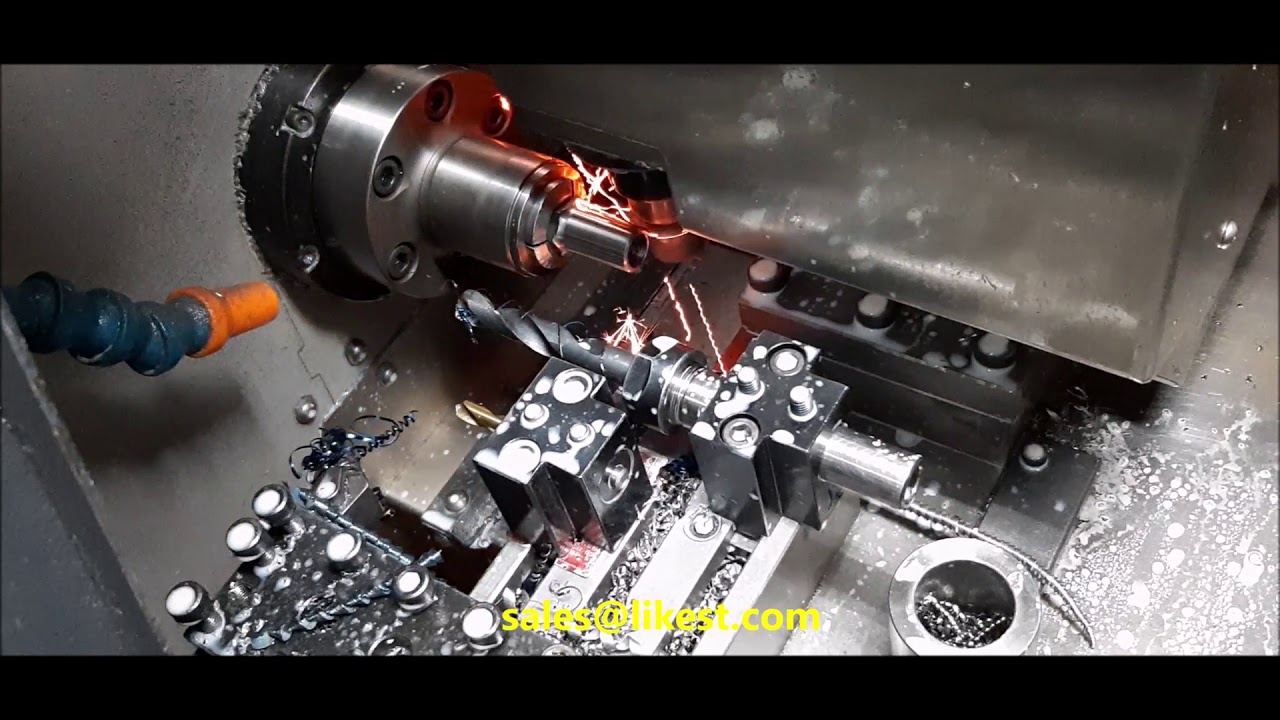

2. High Precision Manufacturing and Quality Control

With the proliferation of automation and smart manufacturing (Industry 4.0), the production of Star screw heads in 2026 is characterized by ultra-high precision. CNC machining, robotic assembly, and AI-powered quality inspection systems enable tighter tolerances and consistent geometries. This ensures compatibility across international standards (e.g., ISO 10664) and supports use in precision electronics and medical devices where even minor deviations can lead to failure.

3. High Demand from Electric Vehicles and Renewable Energy Sectors

The rapid expansion of the electric vehicle (EV) market and renewable energy infrastructure (such as solar panel mounting systems and wind turbines) is a key driver for Star screw head adoption. These industries favor Torx drives for their superior torque control and tamper-resistant variants, which enhance safety and reliability. By 2026, EV battery pack assemblies and powertrain components are expected to account for a significant share of Star screw head consumption, especially in North America and Asia-Pacific.

4. High Customization and Security Features

As product differentiation and anti-tampering needs grow, especially in consumer electronics, security equipment, and public infrastructure, manufacturers are offering highly customized Star screw head designs. This includes proprietary variants like Torx Plus, Torx TTAP, and tamper-proof versions (e.g., pin-in-center or one-way screws). In 2026, OEMs increasingly partner with fastener suppliers to co-develop bespoke drive systems that improve assembly efficiency while protecting intellectual property and preventing unauthorized access.

Conclusion

By 2026, the Star screw head market is evolving beyond a commodity component into a value-added, performance-critical element in advanced manufacturing ecosystems. Driven by High Performance materials, High Precision engineering, High Demand from emerging green technologies, and High Customization for security and integration, the sector is poised for innovation and sustained growth. Companies that invest in R&D, digital manufacturing, and strategic industry partnerships will be best positioned to lead in this dynamic landscape.

Common Pitfalls When Sourcing Star Screw Heads (Quality and Intellectual Property)

Sourcing star screw heads, such as those based on the widely recognized Torx® design, presents several challenges related to both product quality and intellectual property (IP) rights. Being aware of these pitfalls is crucial for manufacturers, distributors, and end-users to avoid legal issues, performance failures, and reputational damage.

Poor Material and Manufacturing Quality

One of the most frequent issues when sourcing star screw heads—especially from low-cost suppliers—is substandard material composition and inadequate manufacturing processes. Low-grade steel or incorrect heat treatment can lead to stripped drive sockets, reduced torque capacity, and premature failure during installation or service. Inconsistent tolerances and poor surface finishes also compromise the screw’s performance and durability, particularly in high-stress or precision applications.

Non-Compliance with Industry Standards

Many star screw designs are governed by international standards (e.g., ISO 10664 for Torx). Sourcing screws that do not conform to these specifications can result in incompatibility with standard driver bits, leading to operational inefficiencies and safety risks. Suppliers may claim compliance without proper certification or testing, especially in unregulated markets, making due diligence essential.

Intellectual Property Infringement

The Torx® drive system is a registered trademark and protected by patents (some now expired, others still active in certain jurisdictions). While generic “star” drive screws are widely available, unauthorized use of the Torx® name or misleading branding can constitute trademark infringement. Additionally, using designs that incorporate proprietary geometries covered by active patents may expose buyers to legal liability, especially in regions with strong IP enforcement.

Misrepresentation and Counterfeit Products

Some suppliers market substandard or non-compliant screws as “Torx-compatible” or use misleading packaging that implies official certification or endorsement. These counterfeit or misrepresented products may look similar but fail under load or wear quickly. This not only affects performance but can also damage the reputation of companies integrating these components into their products.

Lack of Traceability and Certification

Reputable sourcing requires traceability—knowing the manufacturer, material origin, and quality control processes. Many low-cost suppliers do not provide mill test certificates, RoHS/REACH compliance documentation, or batch traceability. This lack of transparency becomes a significant risk in regulated industries like automotive, aerospace, or medical devices, where component failure can have serious consequences.

Inadequate Due Diligence on Suppliers

Relying solely on price as a selection criterion often leads to overlooking red flags such as unverified manufacturing capabilities, lack of quality management systems (e.g., ISO 9001), or limited technical support. Conducting site audits, requesting samples, and verifying certifications are critical steps to avoid long-term supply chain disruptions and quality issues.

By recognizing these common pitfalls, organizations can implement more robust sourcing strategies that prioritize both compliance and performance, reducing risks associated with quality failures and IP violations.

Logistics & Compliance Guide for Star Screw Head

This guide outlines the essential logistics and compliance considerations for the handling, transportation, import/export, and regulatory adherence of Star Screw Head components used in manufacturing, assembly, and distribution operations.

Product Classification & Identification

Star Screw Heads, also known as Torx® or 6-point star drive screws, must be accurately classified for logistical and regulatory purposes. Key identifiers include:

- HS Code (Harmonized System Code): Typically 7318.15 or 7318.16 (for threaded steel screws, bolts, and similar articles). Confirm exact classification based on material, size, and finish.

- Product Specifications: Document diameter, length, material (e.g., stainless steel, carbon steel), thread type, head style (e.g., flat, pan, truss), drive size (e.g., T10, T25), coating/finish (e.g., zinc-plated, black oxide), and compliance certifications.

Packaging & Labeling Requirements

Proper packaging ensures product integrity during transit and supports regulatory compliance:

- Internal Packaging: Use anti-corrosion materials (VCI paper, desiccants) where applicable. Secure small parts in sealed bags or partitioned trays to prevent movement.

- Outer Packaging: Utilize sturdy corrugated boxes or reusable containers. Clearly label with:

- Part number and description

- Quantity per unit

- Net/gross weight

- Manufacturer and batch/lot number

- Handling symbols (e.g., “Fragile,” “This Way Up”)

- Barcoding: Implement standard barcode formats (e.g., UPC, Code 128) for inventory and customs tracking.

Transportation & Handling

Ensure safe and efficient movement across supply chain stages:

- Mode Selection: Choose appropriate transport (air, sea, or ground) based on lead time, cost, and volume. Small components like screws are typically shipped via ground or sea freight.

- Stacking & Palletization: Stack packages per weight limits. Use standard pallet sizes (e.g., 48” x 40”) and secure loads with stretch wrap or straps.

- Environmental Controls: Protect against moisture, extreme temperatures, and contaminants, especially for coated or corrosion-sensitive screws.

Import/Export Compliance

Adhere to international trade regulations when shipping across borders:

- Documentation: Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Customs Declarations: Provide correct HS codes, country of origin, and declared value. Comply with Incoterms® (e.g., FOB, EXW, DDP).

- Export Controls: Verify if the product is subject to export restrictions (e.g., dual-use items under EAR/ITAR). Star screws are generally not controlled, but confirm based on end-use.

Regulatory & Safety Standards

Ensure products meet relevant regional and international standards:

- RoHS (EU): Restriction of Hazardous Substances – Ensure no lead, cadmium, mercury, or other restricted substances exceed limits.

- REACH (EU): Registration, Evaluation, Authorization, and Restriction of Chemicals – Declare SVHCs if applicable.

- Conflict Minerals (U.S. Dodd-Frank Act): Disclose if tin, tantalum, tungsten, or gold (3TG) used in production originate from conflict-affected regions.

- Material Certifications: Provide mill test reports (e.g., EN 10204 3.1) upon request for traceability.

Inventory & Traceability Management

Maintain visibility and control throughout the supply chain:

- Lot/Batch Tracking: Assign unique identifiers to production batches for traceability in case of recalls or quality issues.

- Storage Conditions: Store in dry, temperature-controlled environments. Follow FIFO (First In, First Out) inventory rotation.

- Audit Readiness: Keep records of compliance documents, test reports, and shipment logs for at least 5 years.

Sustainability & Environmental Compliance

Support environmental initiatives and corporate responsibility goals:

- Recyclable Packaging: Use recyclable or biodegradable materials where possible.

- Waste Reduction: Optimize packaging size to reduce material usage and shipping volume.

- End-of-Life Disposal: Provide guidance on metal recovery and recycling of scrap screw components.

Supplier & Vendor Compliance

Ensure all partners meet required standards:

- Qualification: Audit suppliers for ISO 9001, IATF 16949, or equivalent quality management systems.

- Compliance Agreements: Include clauses on RoHS, REACH, and conflict minerals in procurement contracts.

- Performance Monitoring: Track on-time delivery, defect rates, and compliance adherence.

Following this guide ensures that Star Screw Head logistics operations remain efficient, compliant, and aligned with global trade and environmental regulations. Regular reviews and updates are recommended to adapt to evolving standards.

Conclusion for Sourcing Star Screw Heads:

Sourcing star screw heads (commonly referred to as Torx screws) requires careful consideration of specifications, material quality, supplier reliability, and cost-efficiency. These fasteners offer superior torque transmission and reduced cam-out compared to traditional screw drive types, making them ideal for applications in automotive, electronics, and industrial manufacturing. A successful sourcing strategy involves identifying suppliers capable of meeting technical requirements—such as exact sizes (e.g., T8 to T50), coatings (e.g., zinc, black oxide), and material grades (e.g., stainless steel, alloy steel)—while also ensuring consistency in quality and adherence to industry standards (such as ISO 10664).

Engaging with reputable suppliers, conducting supplier audits, and obtaining samples for testing can mitigate risks related to counterfeit or substandard products. Additionally, evaluating lead times, minimum order quantities (MOQs), and logistical capabilities supports supply chain stability. In conclusion, effective sourcing of star screw heads combines technical diligence with strategic supplier management to ensure performance, reliability, and cost-effectiveness across applications.